Controls MVP-G142 User manual

Other Controls Control Panel manuals

Controls

Controls C3-G8386 User manual

Controls

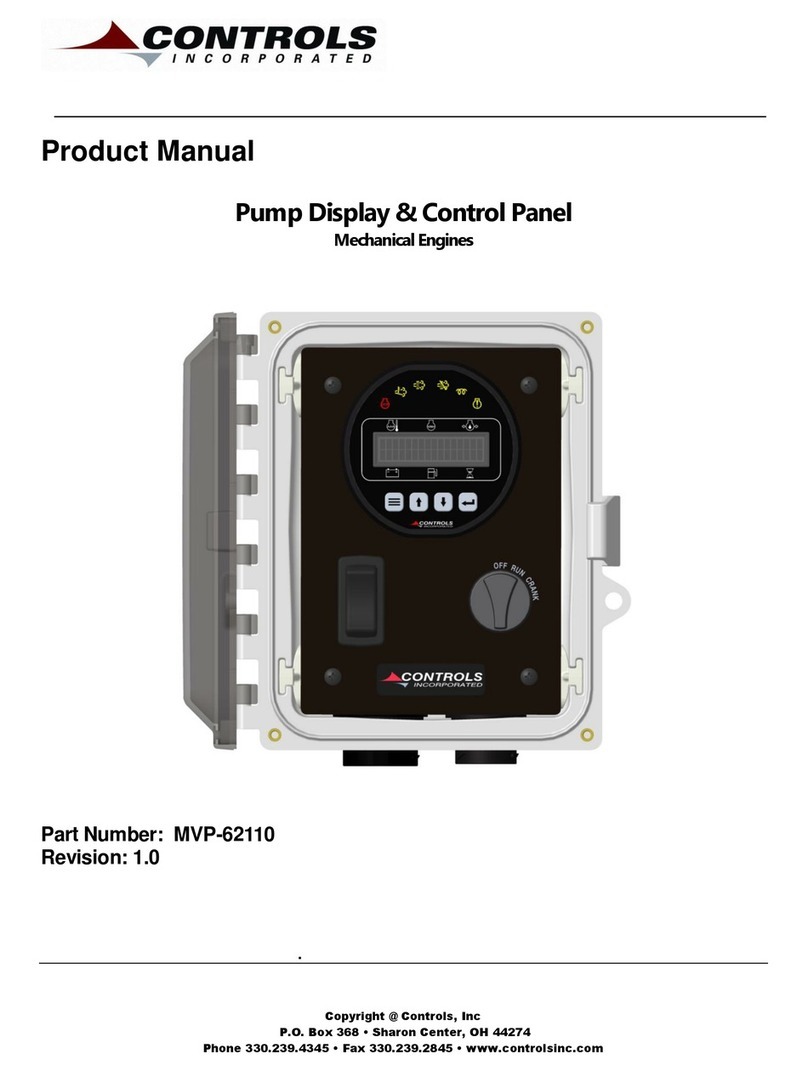

Controls MVP-62110 User manual

Controls

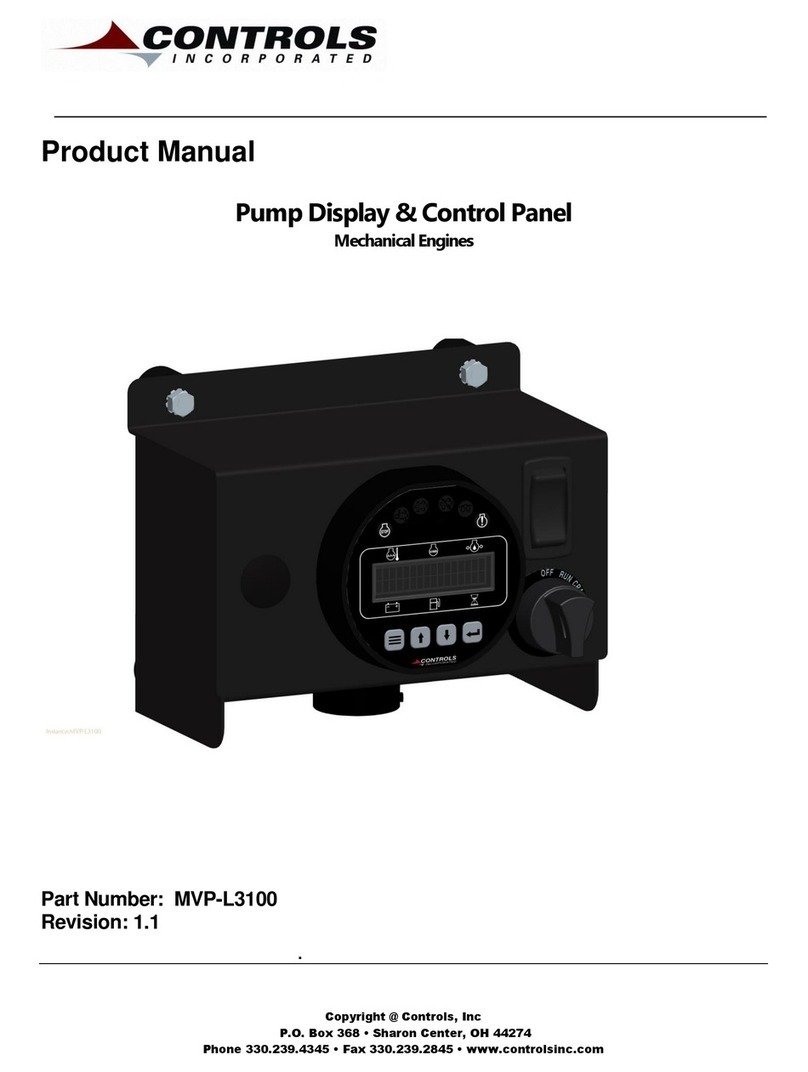

Controls MVP-L3100 User manual

Controls

Controls XE-9501-AS User manual

Controls

Controls C4F-F10198 User manual

Controls

Controls MVP-A3413-FT4 User manual

Controls

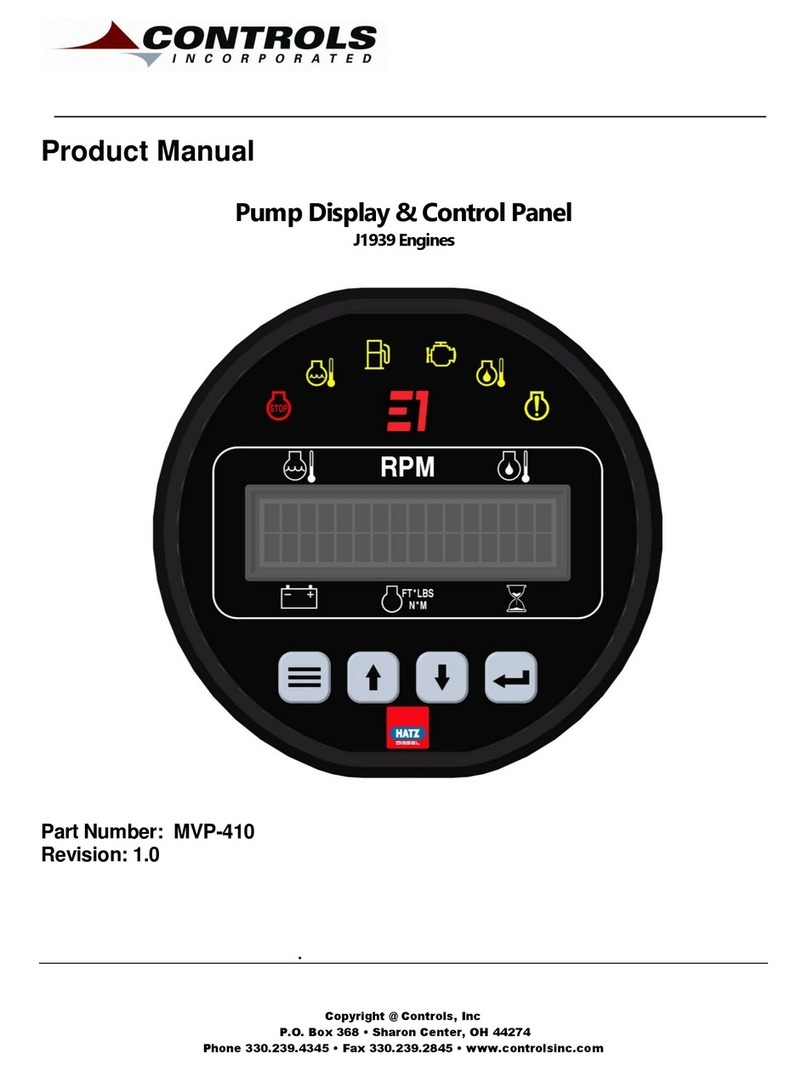

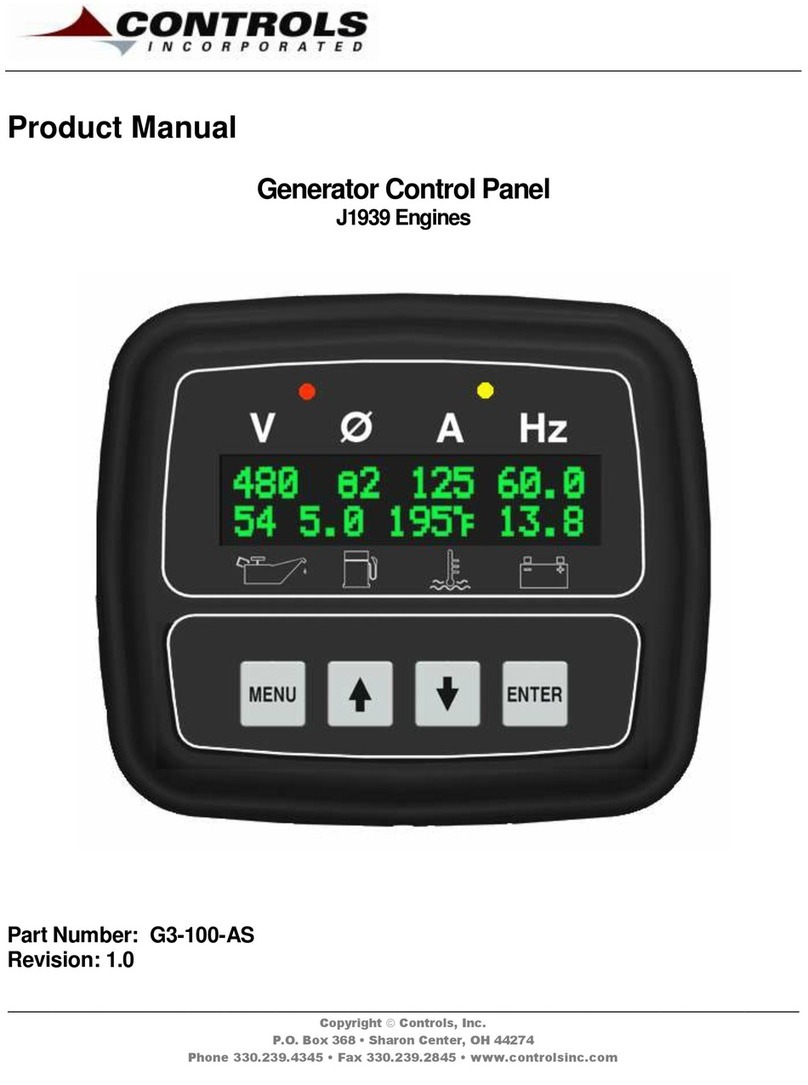

Controls J1939 User manual

Controls

Controls HARLO MVP-902 User manual

Controls

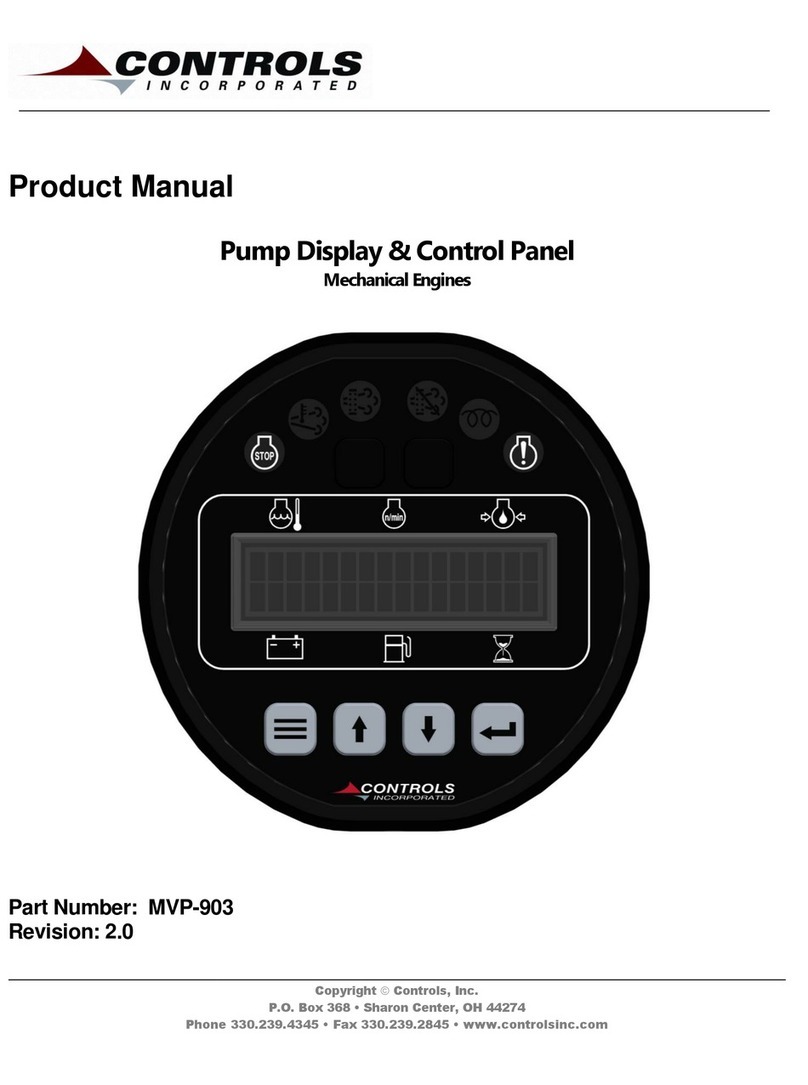

Controls MVP-903 User manual

Controls

Controls J1939 User manual

Controls

Controls MVP-A6307 User manual

Controls

Controls C3-C10186 User manual

Controls

Controls C3M-G7230-AS User manual

Controls

Controls MVP-L6100 User manual

Controls

Controls C3-G7230-AS User manual

Controls

Controls MVP-702 User manual

Controls

Controls J1939 User manual

Controls

Controls J1939 User manual

Controls

Controls MVP-A3702 User manual

Controls

Controls MVP-62350 User manual