20

www.debem.it

Nachdem Sie die Positionierung durchgeführt haben, ist es

möglich, den Anschluss der Pumpe an den Produktkreislauf

anzuschließen. Der Vorgang wird im Folgenden beschrieben:

ACHTUNG: für die Verbindungen des Produktkreis-

laufs an die Pumpe dürfen nur Anschlüsse mit zy-

lindrischem Rohrgewinde aus mit dem zu pumpen-

den Fluid und dem Baumaterial des Dämpfers kompatiblen

Material verwendet werden.

BSP: Pumpe aus PP = Anschluss PP

1. Installieren Sie auf dem Anschluss des Ablass- und Einlass-

kollektors ein manuelles Kugelventil (mit vollem Durchgang) mit

dem gleichen Durchmesser des Anschlusses der Pumpe (nie

kleiner), um so das Auffangen des Fluids bei Leckagen und/

oder zukünftigen Wartungsarbeiten zu gewährleisten.

2. Sorgen Sie für die Installation der Muffen für die Befestigung

der Schläuche auf beiden manuellen Ventilen.

ACHTUNG: die Verbindungsleitungen an die Kol-

lektoren der Pumpe müssen FLEXIBEL UND MIT

EINER STEIFEN SPIRALE VERSTÄRKT SEIN und

mit einem Durchmesser, der niemals kleiner als die Verbin-

dungsstelle ist. Verwenden Sie für viskose Flüssigkeiten

Leitungen mit einem vergrößerten Durchmesser, beson-

ders auf der Absaugung.

Der DIREKTE Anschluss an die Pumpe mit starren Me-

tallrohren (an Pumpen aus Kunststoff und/oder mit koni-

schem Gewinde) ist verboten, da dadurch starke Belastun-

gen und/oder Vibrationen und ein Bruch der Kollektoren

und anderer Teile der Pumpe verursacht werden können.

Benutzen Sie immer exible Schläuche mit Anschlussstü-

cken aus dem gleichen Material wie das der Pumpe (PP mit

PP, PVDF mit PVDF).

Ebenso ist die Verwendung von Gewindesicherungsstof-

fen und/oder Teonpaste verboten. Der Installateur muss

bei der Montage auf die Zentrierung der Anschlüsse ach-

ten, um Risse bzw. ein Nachgeben der Gewinde zu vermei-

den.

Außerdem ist zu kontrollieren, ob nicht eventuell über-

schüssiges PTFE-Band und ein übermäßiger Anzugsdruck

den Kollektor oder andere Teile der Pumpen zu stark be-

lastet.

Besondere Beachtung ist Phänomenen von Spannungs-

korrosion zu schenken. Das Material der Pumpe kann

durch die kombinierte Wirkung von Korrosion und der An-

wendung einer Last verschleißen und dadurch der plötzli-

che und unerwartete Bruch der belasteten Teile verursacht

werden, insbesondere bei Temperaturgrenzwerten.

3. Sorgen Sie für den Anschluss der Einlass- und Ablassleitung.

Stellen Sie sicher, dass die Anschlussleitungen der Pumpe in-

nen sauber sind und auf keinen Fall Verarbeitungsrückstände

enthalten.

4. Sorgen Sie für die Befestigung der Leitungen mit entspre-

chenden Schellen.

ACHTUNG: stützen Sie ausreichend die Leitungen.

DIE LEITUNGEN MÜSSEN AUSREICHEND WIDER-

STANDSFÄHIG SEIN, UM SICH NICHT UNTER DER

SAUGWIRKUNG ZU VERFORMEN UND DÜRFEN NIEMALS

IN IRGENDEINER WEISE AUF DER PUMPE LASTEN UND

UMGEKEHRT.

ACHTUNG: kontrollieren Sie, dass im behandelte

Fluid keine festen Partikel großer Form oder von

schädlicher Form vorhanden sind oder sein kön-

nen und dass keine Einschränkungen am Einlass und/oder

Ablass der Pumpe vorhanden sind, um Kavitationserschei-

nungen oder Kraftanstrengung des Elektromotors oder

Trockenlauf zu vermeiden.

Der Anschluss an den Produktkreislauf ist somit beendet.

PRESCRIZIONI DI SICUREZZA

!

!

!

!

ANSCHLUSS DES PRODUKTKREISLAUFS

I

GB

TRASPORTO E

POSIZIONAMENTO

Al ricevimento verificare che l’imballo e

la pompa siano integri e non abbiano

subito danni dopodichè bisogna:

1La fornitura viene spedita in imballo di

cartone, su pallet o in cassa: al

ricevimento aprire e rimuovere l’imbal-

lo.

2Prelevare il manuale d’uso e manu-

tenzione ed operare come descritto.

3Provvedere al montaggio del motore

sul corpo della pompa e serrare la

ghiera di fissaggio.

TRANSPORT AND

POSITIONING

Check at time of delivery that the pump

and packaging are fully intact and have

suffered no damage, following which:

1The product is supplied in cardboard

packaging, on a pallet or in a crate.

Upon receipt, undo and remove the

packaging.

2Consult the use and maintenance

manual and follow its instructions to

the letter.

3Fit the motor to the pump body and

tighten the fixing nut.

17

1

2

3

4

ISTRUZIONI PER

L’USO E LA

MANUTENZIONE

INSTRUCTIONS

FOR USE A N D

MAINTENANCE

TR

4Effettuare una verifica del serraggio di

tutte le viti di fissaggio.

NOTA

Le pompe TR vengono fornite con il

motore. Nel caso di future

movimentazioni, se la pompa è in

assenza del motore, prima di procedere

al posizionamento bisogna provvedere

al suo montaggio operando come

descritto qui di seguito.

4Ensure that all fixing screws are

properly tightened.

NOTE:

TR pumps are supplied with a motor.

Should you decide to re-site the pump at

some future time, if the pump has no

motor, before positioning this needs to

be fitted by proceeding in the following

manner.

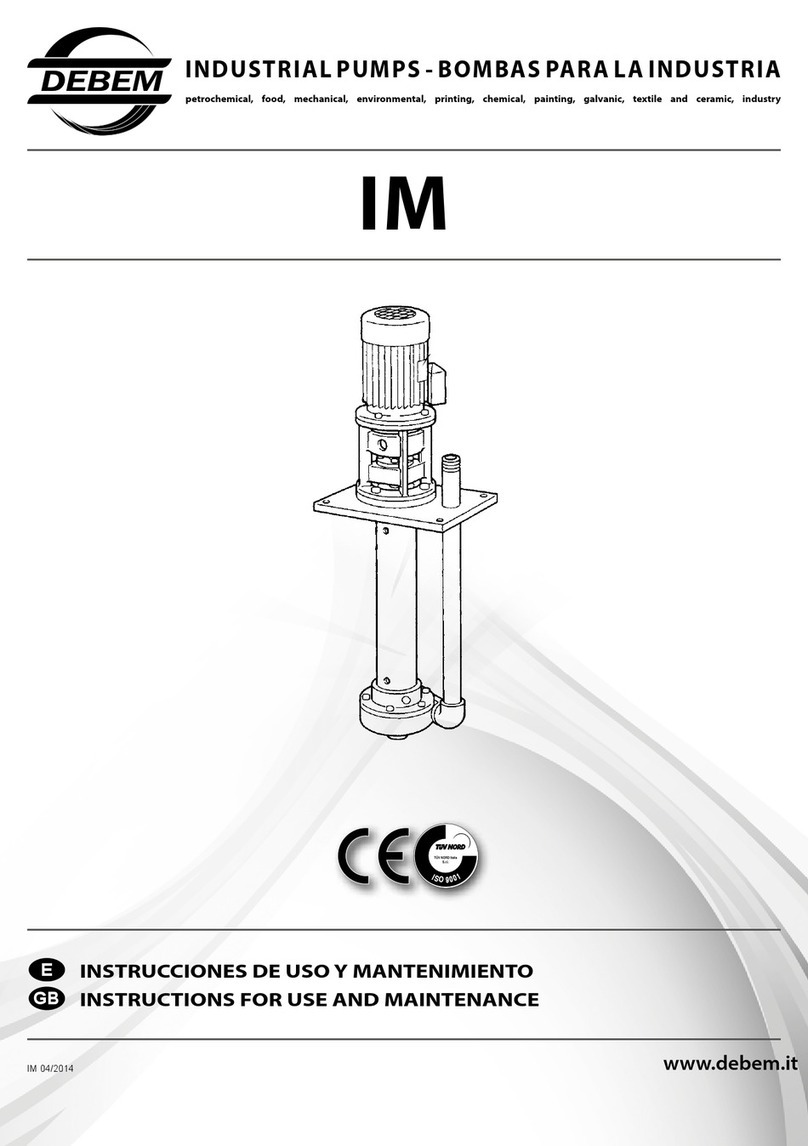

POMPE VERTICALI DA TRAVASO FUSTI

VERTICAL DRUM TRANSFER PUMPS

I

GB

TRASPORTO E

POSIZIONAMENTO

Al ricevimento verificare che l’imballo e

la pompa siano integri e non abbiano

subito danni dopodichè bisogna:

1La fornitura viene spedita in imballo di

cartone, su pallet o in cassa: al

ricevimento aprire e rimuovere l’imbal-

lo.

2Prelevare il manuale d’uso e manu-

tenzione ed operare come descritto.

3Provvedere al montaggio del motore

sul corpo della pompa e serrare la

ghiera di fissaggio.

TRANSPORT AND

POSITIONING

Check at time of delivery that the pump

and packaging are fully intact and have

suffered no damage, following which:

1The product is supplied in cardboard

packaging, on a pallet or in a crate.

Upon receipt, undo and remove the

packaging.

2Consult the use and maintenance

manual and follow its instructions to

the letter.

3Fit the motor to the pump body and

tighten the fixing nut.

17

1

2

3

4

ISTRUZIONI PER

L’USO E LA

MANUTENZIONE

INSTRUCTIONS

FOR USE A N D

MAINTENANCE

TR

4Effettuare una verifica del serraggio di

tutte le viti di fissaggio.

NOTA

Le pompe TR vengono fornite con il

motore. Nel caso di future

movimentazioni, se la pompa è in

assenza del motore, prima di procedere

al posizionamento bisogna provvedere

al suo montaggio operando come

descritto qui di seguito.

4Ensure that all fixing screws are

properly tightened.

NOTE:

TR pumps are supplied with a motor.

Should you decide to re-site the pump at

some future time, if the pump has no

motor, before positioning this needs to

be fitted by proceeding in the following

manner.

POMPE VERTICALI DA TRAVASO FUSTI

VERTICAL DRUM TRANSFER PUMPS

D

After having correctly positioned the plant, proceed with connect-

ing the pump to the product circuit, as follows:

WARNING: To connect the pump only use connec-

tions with cylindrical gas threads made with materials

compatible with the uid to be pumped and with the

pump materials. E.g: pump in PP = connections in PP

1. On the suction and delivery install a manual ball valve (full-

bore) with a diameter equal to the connection to the pump (never

smaller), to ensure uid shut-off in case of leaks and/or future

maintenance.

2. Proceed with installation of pipe couplings for fastening the

exible pipes on to both of the manual valves.

WARNING: The connection pipes to the pump must

be FLEXIBLE, RIGID SPIRAL REINFORCED pipes

never with a smaller diameter than the connection of

the pump. For viscous uids, use pipes with an OVERSIZED

DIAMETER, particularly in suction.

Do not attach the pump DIRECTLY with rigid metal pipes (on

plastic pumps) and/or pipes with tapered thread, as they can

cause severe stress and/or vibrations and breakage of the

manifolds and other parts of the pump.

Always use exible joints with ttings made of the same

material of the pump (PP with PP, PVDF with PVDF)

Do not use threadlockers and/or Teon paste. The installer

must ensure that the ttings are centred during assembly to

prevent cracks and/or to prevent the threads from yielding.

Also check that any excess PTFE tape and excessive clamp-

ing pressure does not place stress on the manifold or other

parts of the pump.

Pay particular attention to stress corrosion cracking. The

pump material may deteriorate due to the combined action of

corrosion and application of a load, which may cause parts

subjected to stress to break suddenly and unexpectedly,

especially at low temperatures

3. Proceed to connect the product suction and delivery pipes to

their respective joints.

Check if the connection tubes to the pump are clean inside and

do no contain any working residue.

4. Proceed with fastening the pipes with appropriate metal rings.

WARNING: the pipes must be adequately suppor-

ted; PIPES MUST BE STRONG ENOUGH NOT TO

DEFORM IN SUCTION AND MUST NEVER WEIGHT

THE PUMP DOWN OR VICEVERSA

WARNING: Check that the treated uid does not or

could not contain solid matters of a large size or with

a potentially damaging shape and that the intake

and/or delivery ports are not obstructed in order to avoid

cavitation or electric motor strain or dry operation.

The circuit connection is now completed.

GB

!

! !

!

PRODUCT CIRCUIT CONNECTION

I

GB

TRASPORTO E

POSIZIONAMENTO

Al ricevimento verificare che l’imballo e

la pompa siano integri e non abbiano

subito danni dopodichè bisogna:

1La fornitura viene spedita in imballo di

cartone, su pallet o in cassa: al

ricevimento aprire e rimuovere l’imbal-

lo.

2Prelevare il manuale d’uso e manu-

tenzione ed operare come descritto.

3Provvedere al montaggio del motore

sul corpo della pompa e serrare la

ghiera di fissaggio.

TRANSPORT AND

POSITIONING

Check at time of delivery that the pump

and packaging are fully intact and have

suffered no damage, following which:

1The product is supplied in cardboard

packaging, on a pallet or in a crate.

Upon receipt, undo and remove the

packaging.

2Consult the use and maintenance

manual and follow its instructions to

the letter.

3Fit the motor to the pump body and

tighten the fixing nut.

17

1

2

3

4

ISTRUZIONI PER

L’USO E LA

MANUTENZIONE

INSTRUCTIONS

FOR USE A N D

MAINTENANCE

TR

4Effettuare una verifica del serraggio di

tutte le viti di fissaggio.

NOTA

Le pompe TR vengono fornite con il

motore. Nel caso di future

movimentazioni, se la pompa è in

assenza del motore, prima di procedere

al posizionamento bisogna provvedere

al suo montaggio operando come

descritto qui di seguito.

4Ensure that all fixing screws are

properly tightened.

NOTE:

TR pumps are supplied with a motor.

Should you decide to re-site the pump at

some future time, if the pump has no

motor, before positioning this needs to

be fitted by proceeding in the following

manner.

POMPE VERTICALI DA TRAVASO FUSTI

VERTICAL DRUM TRANSFER PUMPS

I

GB

TRASPORTO E

POSIZIONAMENTO

Al ricevimento verificare che l’imballo e

la pompa siano integri e non abbiano

subito danni dopodichè bisogna:

1La fornitura viene spedita in imballo di

cartone, su pallet o in cassa: al

ricevimento aprire e rimuovere l’imbal-

lo.

2Prelevare il manuale d’uso e manu-

tenzione ed operare come descritto.

3Provvedere al montaggio del motore

sul corpo della pompa e serrare la

ghiera di fissaggio.

TRANSPORT AND

POSITIONING

Check at time of delivery that the pump

and packaging are fully intact and have

suffered no damage, following which:

1The product is supplied in cardboard

packaging, on a pallet or in a crate.

Upon receipt, undo and remove the

packaging.

2Consult the use and maintenance

manual and follow its instructions to

the letter.

3Fit the motor to the pump body and

tighten the fixing nut.

17

1

2

3

4

ISTRUZIONI PER

L’USO E LA

MANUTENZIONE

INSTRUCTIONS

FOR USE A N D

MAINTENANCE

TR

4Effettuare una verifica del serraggio di

tutte le viti di fissaggio.

NOTA

Le pompe TR vengono fornite con il

motore. Nel caso di future

movimentazioni, se la pompa è in

assenza del motore, prima di procedere

al posizionamento bisogna provvedere

al suo montaggio operando come

descritto qui di seguito.

4Ensure that all fixing screws are

properly tightened.

NOTE:

TR pumps are supplied with a motor.

Should you decide to re-site the pump at

some future time, if the pump has no

motor, before positioning this needs to

be fitted by proceeding in the following

manner.

POMPE VERTICALI DA TRAVASO FUSTI

VERTICAL DRUM TRANSFER PUMPS