Delta OHM DO2003 User manual

The quality level of our instruments is the result of a continuous improve of product. This

situation can cause possible differences comparing this manual with the instrument you

bought. We regret in advance for any possible mistake in this manual.

Data, drawings and descriptions included in this manual cannot be juridically in force. We

reserve us the right to modify and correct the manual without prior notice.

DO2003

ENGLISH

ENGLISH

- -

2

HVACR Datalogger

DO2003

- -

3

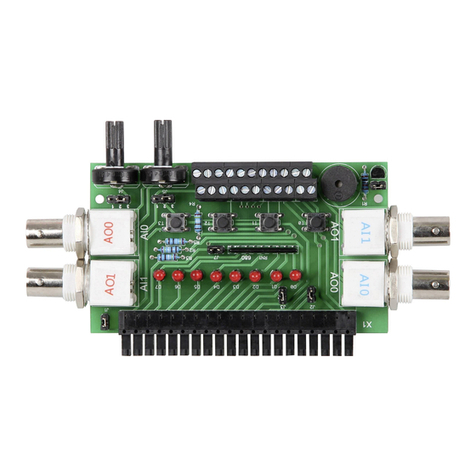

1. Input Afor air speed, pressure and Pt100 temperature probes - DIN45326 8-pole connectors.

2. HOLD symbol: appears when you press HOLD.

3. Battery symbol: indicates a low battery level (fixed symbol) or the auto shut-off mode disabled

(flashing symbol).

4. Display lower line relating to the module connected to input B.

5. RS232 symbol: flashes while transferring data to the instrument serial line.

6. REL symbol: appears if you press REL to indicate the instrument is collecting relative

measurements.

7. AVG symbol: the display shows the average values detected through the RCD function.

8. Unit of measurement related to the variable viewed on the display upper line (probe connected

to input A).

9. <REL/Esc> key: displays the difference between the current value and the one logged when the

key was pressed. Within the programs, it cancels the operation in progress without changing the

instrument parameters.

10. <MEM/Enter> key: stores the current value to be used for flow calculation. In the programs, it

confirms the current value.

11. <UNIT A/Pitot Tcomp> key: selects the unit of measurement for input A. In the programs, it

sets manual temperature to compensate the measurement provided by the Pitot tube.

12. <PRINT/Baud Rate> key: activates a data transmission through the RS232 serial output. In the

programs, it sets the serial line baud rate.

13. <LOG Start-Stop/Dump Log> key: in measurement mode, it starts and stops storage. In the

programs, it starts the download of stored data and increases the displayed parameter.

14. <Probe ZERO/Delete Log> key: allows to set to zero hot-wire speed probes and differential

pressure gauges. From the programs, it allows to clear memory data.

15. RS232 9-pole connector.

16. <RCD Start-Stop/RCD Clear> key: starts and stops the Record function; in the programs, it

resets the previous Record measurements and decreases the displayed parameter.

17. <PROG> key: activates the instrument programs.

18. <Max-Min-Avg CALL> key: recalls the maximum (MAX), minimum (MIN) and average

(AVG) values, measured through the Record function.

19. <UNIT B/DuctCalc> key: selects the unit of measurement for input B. Within the programs, it

makes the calculation of pipe flow.

20. <HOLD/SampleTime> key: freezes current measurements. Inside the programs, it sets the

number of measurements to calculate the current average.

21. <ON/OFF> key: switches on and off the instrument.

22. Temperature unit of measurement related to the two inputs.

23. Unit of measurement related to the variable displayed on the display lower line (probe

connected to input B).

24. MAX symbol: the display indicates the maximum values measured through the RCD function.

25. MIN symbol: the display indicates the minimum values measured through the RCD function.

26. RCD symbol: indicates that the record function is active.

27. LOG symbol: indicates that the logging function is active.

28. Display upper line related to the probe connected to input A.

29. 103symbol: indicates the multiplicative factor (x1000) for channel A.

30. Input Bfor relative humidity probes and Pt100 temperature probes – DIN45326 8 - pole

connector.

- -

4

INTRODUCTION

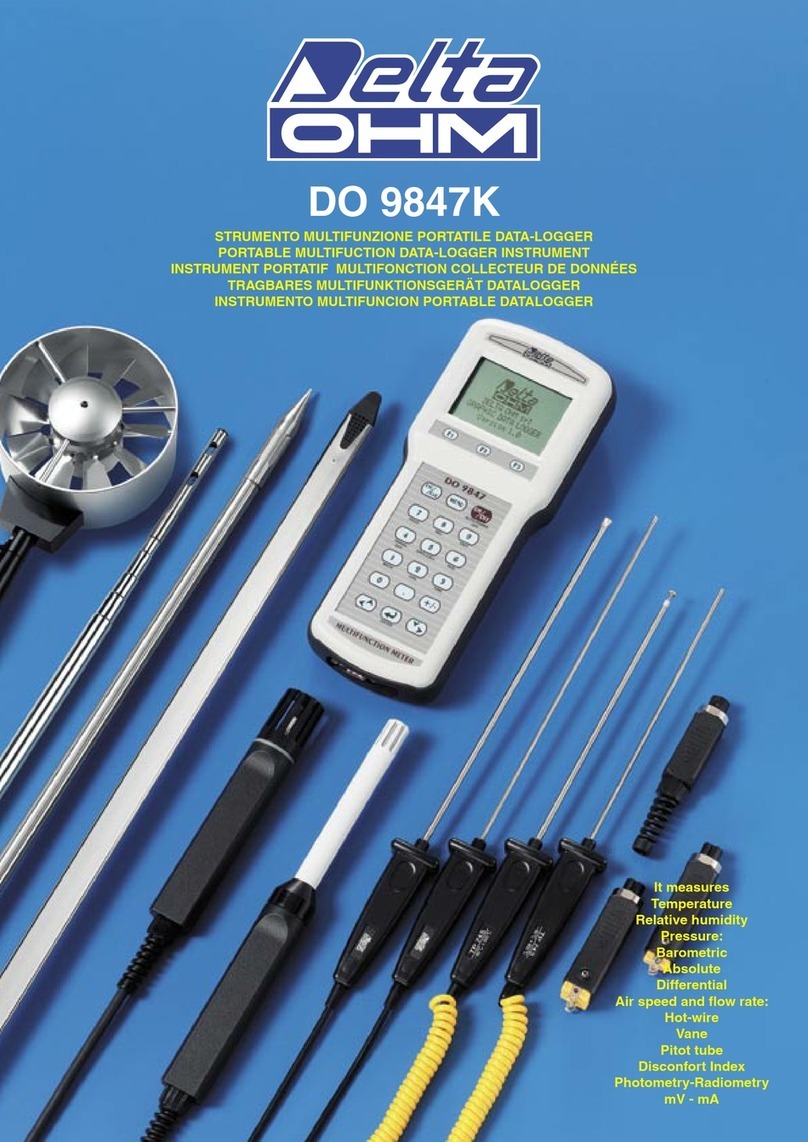

The DO2003 is a datalogger portable unit, especially designed to make measurements

in the field of air-conditioning, heating, ventilation, environmental comfort, energy

saving, both in private and industrial sectors, thanks to a complete series of dedicated

probes. It measures air speed and flow in ducts, pipe or vents with hot-wire, vane or

Pitot tube probes; relative humidity and temperature with combined probes;

differential pressure up to 2000 mbar, as well as barometric pressure; temperature

with immersion, penetration and surface probes.

As a datalogger, it stores up to 12,000 readings that can be transferred to a PC

connected to the instrument by means of the RS232C serial port. From the menu, you

can configure logging interval, print and baud rate.

The "Record" (RCD) function calculates the maximum, average and minimum

values.

The instrument comes out with other additional functions: relative measurement,

Hold function, zero correction for differential pressure gauges and hot-wire probes.

- -

5

KEYBOARD DESCRIPTION

Introduction

The DO2003 keyboard has 22 indication LEDs and 12 keys. The keys provide a main function

indicated on the key itself, as well as one or two secondary functions indicated just over or under

the key. The main function is active when the instrument is in measurement mode, while the

secondary functions are activated when the DO2003 is in the programs. For example, the

key activates the function of start and stop logging when in measurement mode, while,

in the programs, it starts the Dump Log function or increases the value of the current parameter.

The display provides alphanumeric indications: the values of the measurements detected by the

inputs and the description of a current function. As each display line has got three characters

available, some words are divided between the two lines: for example, the caption PRESSU is

divided into PRE on the upper line and SSU on the lower one, the word SPEED is displayed as SPE

on the first line and ED on the second one, TEMP appears as TE on the upper line and MP on the

lower one,…

The following table shows the characters as they appear on display:

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

A CEFhI- - LoP-SU - - - -

LED Description

The LEDs (red luminous points: Light Emitting Diodes), at the upper side of the keyboard, provide

indications about the units of measurement and the displayed type of measurement. They are

divided into three groups: the one on a pink background relates to input A and to the display upper

line, the one on a light blue background refers to input B and to the display lower line. The two °C

and °F LEDs indicate the unit of measurement of temperature, valid for both channels.

Channel A LEDs (they refer to the indication of the display upper line)

m/s

Air speed measurement through a hot wire probe, a vane probe or a Pitot tube.

Ft/min

km/h

mph

l/sec

Flow measurement through a hot wire probe, a vane probe or a Pitot tube.

cfm

m3/h

Temp Temperature provided by the RH/temperature probe connected to input A. The unit of

measurement is provided either by the °C or by the °F LED.

mbar

Pressure measurement through a barometric probe, a differential gauge or a Pitot tube.

Pa

mmH2O

InchW

- -

6

Channel B LEDs (they refer to the indication of the display lower line)

RH% Relative humidity measurement.

g/m3Absolute humidity measurement.

Temp

Temperature provided by the RH/temperature probe connected to input B. The unit of

measurement is provided either by the °C (Celsius) LED or by the °F (Fahrenheit)

LED.

Td Dew point expressed in °C (Celsius) or in °F (Fahrenheit).

DI Discomfort Index provided by the relative humidity probe connected to input B.

ET Net Index provided by the relative humidity probe connected to input B.

Mem In the "Duct calc" program for flow calculation, it indicates that the number on the of

display lower line is the number of logged samples.

m2The value on the display lower line is the area of the section for flow calculation.

°C and °F LEDs (they refer to the indications of both the display lines)

°C Temperature measurement is expressed in Celsius degrees.

°F Temperature measurement is expressed in Fahrenheit degrees.

ON

OFF

A

uto-Power-Off

ON/OFF Key

Press the ON/OFF key to switch on and off the instrument. The check of the probes connected to

the inputs is made upon the power on and not when the instrument is already operating.

Therefore, after replacing a probe it is necessary to switch the instrument off and on again. It

is suggested to replace probes when the instrument is off.

The instrument is provided with the AutoPowerOff function that automatically switches off the

instrument after 8 minutes that no key is pressed. The AutoPowerOff function can be disabled in

this way, by using the HOLD key: with the instrument off, press and hold down the HOLD key and,

at the same time, press <ON/OFF> to switch the instrument on. Release HOLD only when the

switching on routine is over. In this case the battery symbol flashes to remind the user that the

instrument will not automatically shut-off, but, to do it, you need to press <ON/OFF>.

HOLD / SampleTime Key

If you press this key, in the standard operating mode, the measurement will be frozen; HOLD will

appear on display: press this key to go back to standard measurement.

The key secondary function (Sample Time) indicates the number of samples used for the mobile

average (or current average) calculation in stream measurements. Because a reading per second is

collected, it also represents the interval of time in which the current average is calculated. The value

goes from 1 (no average) to 99.

- -

7

REL / ESC-Discard Key

In measurement mode, it displays (for each channel) the difference between the current value and

the value measured when the key was pressed. The REL symbol appears at the bottom of the

display; to go back to standard measurement, press the key again.

In the programs, it deletes or cancels the active function.

UNIT B / Duct calc Key

In measurement mode, it selects, among the variables available in the light blue LED area, the

variable to be viewed on the display lower line.

The available variables change accordingly to the instrument mode (i.e.: measurement mode or in

the programs) and to the probe connected to input B.

The DuctCalc subfunction (PROG key >> UNIT B key) starts flow calculation when the air speed

probe is connected to input A. See the introduction of the chapter concerning air speed on page 13.

MEM / ENTER Key

The MEM key main function is used for flow calculation inside the DuctCalc function to store a

single point (for more details, see the chapter concerning the DuctCalc function on page 14).

The secondary function – ENTER – confirms the displayed current parameter.

UNIT A / Pitot Tcomp Key

In measurement mode, it selects the variable to be viewed on the display upper line among the

variables included in the pink area.

The active variables depend on the probe connected to input A..

“Pitot Tcomp” secondary function, selectable from program through the keys: PROG >> UNIT A,

allows to enter the air temperature value manually when you are using a Pitot tube probe without

thermocouple and no Pt100 probe is connected to input B: in this case the instrument uses this

temperature to compensate the measurement (see details in the Pitot tube chapter on page 25).

- -

8

CALL Max-Min-Avg Key

If you press this key repeatedly, you will recall the MAX, MIN and AVG (average) values of data

detected by means of the Record function (RCD key). If you press the key again, the instrument

switches to standard measurement. The function is active only if some data have been previously

recorded and if the Record function is active at that time.

PROG Key

The PROG key let you go through the instrument programs. Press PROG to jump to the next

program. Press ENTER to select a single program. To increase or decrease the current value of a

parameter, use the arrow keys (sub-function of LOG and RCD keys). Press MEM/ENTER to

confirm a parameter; on the contrary, press REL/ESC-Discard to quit without confirming.

Here is a short description of the programs as they appear (same order) when you press PROG:

PRG STD (Program Standard): this program activates the key secondary functions. For example,

the PRINT/BaudRate key will have the function to set the baud rate and not its PRINT

primary function.

LOG INT (Logging interval): it represents the interval between two consecutive loggings (LOG)

and the data dump frequency to the RS232C serial port (PRINT). To set a new interval, use

the arrow keys and press ENTER to confirm. The available values are: 1, 2, 5, 10, 15, 30, 60

seconds and 2, 5, 10, 15, 30, 60 minutes.

LOG OPT (Logging options): when the instrument is in logging mode, it controls the auto power

off between two consecutive loggings. If you press ENTER (LOG OPT >> ENTER), the

word OFF will appear on the display upper line, while the parameter current status will appear

on the lower one: YES or NO.

If the set logging interval is smaller than 1 minute, the instrument will remain always on,

whatever is the value of the LOG OPT parameter. If the interval is bigger than 1 minute, or

equals it, LOG OPT = YES will switch the instrument off during the interval between two

measurements, while LOG OPT = NO will let the instrument always on. Press ENTER to

confirm the parameter selected by means of the arrow keys.

SCT m2 (Section m2): it represents the area of the section used to calculate duct or pipe flow; it is

expressed in m2 and it goes from .001m2 (10cm2) to 1.999m2.

SCT INC2(Section inch2): it represents the area of the section used to calculate duct or pipe flow,

it is expressed in inch2and it goes from 1 inch2 to 1999 inch2. This value is automatically

converted into m2by the instrument, thus, if you recall the “area” parameter during flow

calculation, the corresponding value in m2 will be displayed.

DATE: this is a program to set date and time. From the DATE screen-page, press ENTER: the last

two digits of the year will appear. Use the arrows to select the correct value and press ENTER

to confirm. The month appears (MonTH): use the arrows to select the correct value and press

ENTER to confirm. Day (DAY), hour (HOU) and minute (MIN) ranges will then appear:

when confirming the minute value, the instrument quits the program and returns to the

measurement mode.

SET MEA (Set measures): it provides the list of the variables to be printed (PRINT command), to

be logged (LOG command) and to be displayed (UNIT A and UNIT B keys). The

- -

9

corresponding unit of measurement is required for air speed, pressure, flow and humidity

physical quantities. The selection is made through the arrow keys and confirmed by ENTER.

This function also allows to set currently displayed variables as print and logging ones.

Procedure:

1. press PROG and hold it until SET MEA is displayed.

2. press ENTER to access the desired function. The indication YES or NO will appear: if

you select NO, print and logging will use the current units of measurement; press ENTER

to confirm, and the instrument will return to the measurement mode. If you select YES

and press ENTER to confirm, you can start setting.

3. PRESSU will be displayed: use the arrows to select pressure unit of measurement (mbar,

Pa, mmH2O or inchW) and press ENTER to confirm.

4. FLOU will be displayed: use the arrows to select flow unit of measurement (l/sec, m3/h or

cfm) and press ENTER to confirm.

5. SPEED will be displayed: use the arrows to select air speed unit of measurement (m/sec,

km/h or cfm) and press ENTER to confirm.

6. RH will be displayed: use the arrows to select the kind of measurement connected to

humidity (%RH, g/m3, TD dew point, DI discomfort index or ET net index). Press

ENTER to confirm and the instrument will switch again to the measurement mode.

TEMPER (temperature): it chooses the unit of measurement between Celsius (°C) and Fahrenheit

(°F) degrees.

PRINT / Baud Rate Key

The PRINT key sends data being logged to the RS232C serial port of the instrument. The print

interval is set through the LOG INT program. Before pressing PRINT to start data print, set the

baud rate value with which data have to be downloaded from the instrument to the PC. To do it,

press PROG just once to enable the key sub-functions (from measurement mode the instrument

turns into PRG STD), press PRINT/BaudRate and use the arrows to select the maximum value

equal to 38.4 (38400 bauds). Press ENTER to confirm. While connecting, the software of the PC

linked to the DO2003 (DeltaLog3) will automatically set the same value, that is 38400 bauds. If

you are using a program others than DeltaLog3, be sure that the baud rate value is the same

both for the instrument and for the PC: the communication will work only in this way.

RCD Start-Stop / RCD Clear / Key

The Record function stores the maximum, average and minimum value of measurements,

updating them every second, as new samples are recorded.

To start the function, press RCD once, to stop it, press RCD again. The indication RCD on display

means that the function is active.

Recorded data will be added to those already stored, thus, if you wish to start with a new measuring

session, you have to delete the previous values by using the RCD Clear sub-function (PROG key >>

RCD key >> ENTER key to confirm).

- -

10

If you press "Max-Min-Avg CALL" repeatedly, the MAX (higher), MIN (lower) and AVG

(average) values relating to all data available on memory will be sequentially displayed: this can be

made after closing the measurement session or, in real time, by pressing RCD first, to start

recording, and then "Max-Min-Avg CALL" to view the MAX, MIN and AVG values.

Note: the UNIT B/DuctCalc key uses a “Record on command”. Unlike the record started

through the RCD key, where the sampling interval equals one second, in flow calculation, the

MEM key has to be pressed every time a new sample has to be added. When a new sample is

measured, the counter on the display lower line, will increase by one unit.

The max, min and average values of processing measurements can be also viewed here (see details

on page 14).

In the programs, the key has its secondary function, that is, it decreases the current parameter.

Warning: data detected through the Record function cannot be downloaded to a PC.

LOG / Dump Log / Key

The LOG key is used either to start or to stop logging of a new data block to be stored in the

instrument built-in memory. The frequency with which data are stored is set through the LOG INT

program (press PROG twice >> ENTER >> use the arrows to select the interval >> press ENTER to

confirm). The data stored between a consecutive start and stop form a block. Each block ends with

the indication of the maximum, minimum and average value of the samples. The LOG indication

will remain lit for the whole logging period.

The DO2003 provides a function that allows to switch off the instrument in the time between a

logging and the other: this function is controlled by the LOG OPT parameter (press PROG 3 times).

When the logging interval is lower than a minute, the instrument will always remain on while

logging; when the interval equals one minute or is higher, if the parameter LOG OPT= YES has

been configured, the instrument will switch off in the time between a logging and the next one,

while, on the contrary, if LOG OPT=NO has been set, it will remain always on.

In the programs, the secondary function of this key is to decrease the current parameter.

As secondary function (keys: PROG >> LOG >> ENTER), the LOG key commands the download

of stored data: when you press ENTER, the data stored in the instrument memory are transferred to

the PC connected to the serial port. Either DeltaLog3 (version 4.0 or higher) or Windows

HyperTerminal have to be installed on the computer (see the description of the connection to a PC

on page 38).

- -

11

ProbeZERO/ Delete Log Key

Before being used, differential pressure gauges and Pitot tube or hot-wire air speed probes need to

be set to zero. The key Probe ZERO has this function: for details on how it works, see the chapters

concerning the different probes.

The secondary function of this key is to clear the whole memory content (press PROG >> Probe

ZERO – DEL LOG is viewed >> press ENTER to confirm).

In order to know which is the available memory space, press PROG and then CALL: the number of

available pages will appear – from 1 to 1999 -; ALL means that the whole memory space is

available (2000 pages). .

- -

12

THE PROBES

The datalogger probes are equipped with an "intelligent" module (SICRAM) that works as an

interface between the sensor in the probe and the DO2003 unit. Inside the module there is a

microprocessor circuit with a permanent memory which allows the datalogger to recognise the type

of connected probe: temperature, humidity, pressure, air speed, … the probe calibration data are

stored in the memory. In this way the probes are interchangeable and they can be used on any

DO2003 indifferently.

PROBE CONNECTION

The recognition of the probes takes place upon the instrument power on, and not when the

instrument is already on, thus if a probe is connected when the instrument is already

operating, it has to be switched off and on again.

The two DO2003 inputs are identified by an “A” (left input) and by a “B” (right input). Air speed,

flow, pressure and temperature probes have to be connected (and are thus recognised) to input A.

On the contrary, RH/temperature probes and Pt100 temperature probes have to be connected (and

are thus recognised) to input B.

For more details concerning the probes, see the paragraphs related to the single measurements.

HOW TO MEASURE

1. USE THE ON/OFF KEY TO SWITCH ON AND OFF THE INSTRUMENT

•To turn on the instrument, press and release the ON/OFF key.

•This operation activates the self shut-off timer: after approximately 8 minutes the keyboard is

inactive, the instrument will shut-off. If you want to disable the self shut-off function, hold down

the HOLD key throughout the whole switching-on routine, the battery symbol will flash once a

second to show that the self shut-off function has been disabled.

•Upon power on, all the display digits and symbols, as well as all the keyboard LEDs will be lit

up: in this way you can check if they work properly. The change to standard operation is

automatic.

2. DISPLAY CONTROL

•After all segments have lit up, the instrument is ready to measure and uses the unit set before the

instrument had been switched off.

•If a probe is either broken, not properly connected, or if it is measuring a value beyond the

provided range, the Err indication will be displayed: check the sensor and/or the connector.

•If no probe is connected to the inputs, a dotted line (- - -) will be displayed.

3. SELECTING THE UNIT OF MEASUREMENT

•Press the Unit A key repeatedly to select the unit of measurement related to input A (visible on

the display top side); press Unit B to select the unit of measurement related to input B (visible at

the bottom of the display).

- -

13

4. SWITCHING OFF THE INSTRUMENT

•Press ON/OFF to switch the instrument on or off. If the AutoPowerOff function is active, the

instrument can switch off while measuring: press ON/OFF to switch it on again.

•The instrument switches automatically off after 8 minutes the keyboard is inactive, except if:

a) The instrument is in RCD mode.

b) The AutoPowerOff function is disabled.

In these two cases the instrument will switch off only if you press ON/OFF.

c) The instrument is downloading logged data (DUMP LOG).

d) The instrument is processing the immediate transfer of data to the serial port (PRINT).

e) The instrument is in logging mode (LOG).

If the battery is completely flat, the instrument will switch off, and any logging or data dump

operation is interrupted.

When switching on the instrument again, you have two choices:

1. If batteries are low, but not completely flat, upon power on the indication LOU BAT will be

displayed, together with the battery symbol fixed.

The PROG key activates (PROG >> LOG >> ENTER) data dump even if battery is low.

In these conditions, no new logging session can be started.

2. If batteries are completely flat, when you press ON/OFF the LEDs will be lit up for a few

seconds, the instrument will make a short sound (beep) and will switch off. The display will

remain off.

5. VARIED OPERATIONS

•For the following operations, see the function description of each key: HOLD, relative

measurements, record RCD, DATA CALL, PRINT, storage on LOG internal memory, download

of logged data, memory clear, set of working parameters.

AIR SPEED MEASUREMENT

The probes of AP471, AP472 and AP473 series measure speed and flow of an incident airstream

and some of them can also measure air temperature. The applied principles of measurements are:

hot-wire for the AP471 series, vane for the AP472 series and Pitot tube for the AP473 series. On

request the probes of AP471 and AP472 series can be equipped with a telescopic shaft to make

measurements in hard-to-access areas easier (such as in duct inlets/outlets).

Their typical applications include: the control of air speed and flow on conditioning, heating and

cooling plants, the definition of environmental comfort, etc.

Hot-wire probes are generally used for accurate measurements in environments with a medium-low

air speed (up to 10 m/s), vane probes in environments with an air speed from 5 to 40m/s, Pitot tube

probes in environments with an air speed higher than 40m/s.

Also the temperature of the fluid to be measured has to be taken into consideration: hot-wire probes

and vanes measure streams having an 80°C max. temperature; Pitot tube probes measure the speed

of air streams having temperatures up to 460°C, according to the model.

- -

14

The measurements provided by the probes are: air speed, air temperature and flow.

Connect the probe to input A and switch on the instrument.

Use the UNIT A key to select the unit of measurement of the value viewed on the top of the display.

The following units are available:

•For air speed: m/s, km/h, ft/min, mph;

•For air temperature: °C and °F;

•For flow: l/s, m3/h, cfm.

FLOW MEASUREMENT

The measurement of air flow requires to know the area of the pipe or of the vent perpendicular to

the flow: in the DO2003 programs there are two specific items, “SCT m2“ (SECTION m2) and the

corresponding "SCT INC2" (SECTION inch2), through which you can configure this parameter

either in m2or in inch2.

To enter the area, press PROG several times to display either SCT m2 (area in m2) or SCT INC2

(area in inch2), then press ENTER. Use the arrows to set the area value and press ENTER to

confirm.

GENERAL REMARKS ON OPERATION

By moving the probe inside a stream, speed and flow can change both their position in the space

(from a point to another) and their performance over the time (in the same position, but in

subsequent moments): this is particularly true when the involved area is quite big and when some

turbulences are generated in front of a ventilating grill or a diffuser. The DO2003 provides some

solutions to get a correct measurement even before these elements of disturbance.

1) Space Average (Duct calc Function)

It is always suggested to record more measurements in different positions and to consider as

valid data only average values. Through the Duct Calc function (subfunction of UNIT B key),

the DO2003 can record several measurements and provide the relating minimum, maximum and

average value. In particular, the average value is the most important one in this kind of

measurements.

Procedure:

Press UNIT A to select the variable of which you want to get the maximum, minimum and

average value.

Then press PROG >> UNIT B to activate the DUCT CALC function: the display upper line will

show the instant value of the selected variable (speed, flow or temperature), while the lower line

will indicate the number of measured points (at the beginning the value will be 0 because, every

time DUCT CALC is started, the values of previous measurements will be deleted). Place the

probe in the first point to be measured and press MEM to record the first value/point. Repeat

this operation for all the other points to be measured and press MEM every time you want to get

a measurement: the indicator will provide the number of recorded samples. While recording, or

after recording, press Max-Min-Avg Call: the max, min and average values of the selected

quantity will be viewed.

To quit this function, press ESC (REL key).

In general, the bigger the number of recorded measurements is, the higher the accuracy of the

results will be.

- -

15

2) Moving Average

The Duct Calc function provides a space average of acquired values in order to compensate

speed differences between a point and another in the pipe section. There is also another cause of

error due to stream variations over the time: actually, a stream is not steady but, on the contrary,

it can decrease or increase even in the same point. In order to compensate this second source of

instability, a time moving average of the last n acquired measurements can be provided: thus

n>1 (the displayed valued) will not correspond to a single acquired value, but to the current

average of the last recorded and continuously updated n measurements.

To set the “n” value, use the SAMPLE TIME sub-function of the HOLD key: press PROG >>

HOLD, use the arrows to select the desired “n” value and press ENTER to confirm it. “n” can be

set between 1 (no average) and 99.

Note: grills and diffusers with reclining fins cause stream measurement errors because of

turbulences. These turbulences develop because part of the stream meets an obstacle (the fin)

and, consequently, slows down, while the rest of the stream speeds ahead. In this case, to get

correct measurements, it is suggested to temporarily insert, in front of the ventilating grill, a pipe,

having a length twice the length of the grill diagonal. Measurements have to be taken at the ends

of this pipe. The area to be considered for flow calculations will be that of the temporary pipe

positioned between the ventilating grill and the probe.

D

L = 2 x D

TEMPORARY PIPE

PROBE

A

IR VENT

PIPE SECTION

PIPE

Unit Conversion Table

m/s ft/min km/h mph

1 m/s 1 196.87 3.60 2.24

1 ft/min (1 foot/minute) 0.00508 1 0.01829 0.01138

1 km/h 0.2778 54.69 1 0.6222

1 mph (1 statute mile/hour) 0.4464 87.89 1.6071 1

- -

16

AP471 S1 -AP471 S2 -AP471 S3 -AP471 S4

HOT WIRE PROBES FOR THE MEASUREMENT OF AIR SPEED EQUIPPED WITH SICRAM MODULE

AP471S… probes have to be connected to the DO2003 A input. The probes AP471 S1 and AP471

S3 measure air flows up to 40m/s; the AP471 S2 and AP471 S4 probes are fitted with an

omnidirectional sensor allowing measurement of speeds up to 5m/s in any direction of the air flow

incident on the probe. The AP471 S4 probe is fitted with a support base and sensor protection. The

wind speed measurement is compensated for according to temperature within the range of

0…+80°C. The probes AP471S1, AP471 S2, and AP471S3 measure the environment temperature

in the range of -25°C…+80°C; AP471 S4 in the range 0°C…+80°C.

A

P471 S1

A

P471 S3

ZERO COMMAND

AP471 S… modules are factory calibrated and do not require

any calibration by the user.

Before carrying out a measurement, you have to adjust the

“zero” point of the probe. This means that, failing the wind,

speed and flow values provided by the probe, at a temperature

next to that of the airstream to be measured, shall correspond to

zero.

The AP471 S1, S2 and S3 probes are equipped with a

cylindrical shield which is able to lengthwise slide on a rail.

The shield has two positions of limit stroke which stop in the

measurement condition (all downwards) or rest condition (all

upwards). In order to reduce the volume when unused, the

AP471 S4 is equipped with a protection cylinder to screw on

the probe head.

This is the procedure: let the cylindric shield slide upwards till

the complete closing of the speed sensor window placed on the

probe top. For AP471 S4 probe, close the probe head by the

protection cylinder.

- -

17

SPEED SENSOR

LINE OF STREAM DIRECTION

COMPENSATION SENSOR

AMBIENT

SENSOR

TEMPERATURE

CYLINDRICAL SLEEVE

Place the head of the probe in the airstream to be measured and press PROBE ZERO. Any fault

(drifts) related to speed and flow instant values will be cleared.

OPERATION

Extend the telescopic shaft as much as necessary, taking care that the cable passes through the

handle without any problem.

Cover the speed sensor and reset the measurement value, as detailed in the previous paragraph.

Uncover the sensor and position the probe in the airstream to be measured holding the arrow on the

top of the probe parallel to flow, as indicated in the following pictures.

The probe has to stand in orthogonal position with respect to the flow and it shall not to be inclined:

OK NO

Now you can carry out your measurement, pursuant to the indications provided in the first

paragraphs of this chapter.

Probe Top

Indicator of airstream direction

- -

18

PROBE CARE AND MAINTENANCE

The speed sensor of AP471 S… probes is heated up and, in presence of vapours or

gases, it might cause a fire or an explosion. Avoid using these probes if inflammable

gases are available. Check that no gas leak or explosive product vapour be present

in the environment where measurements have to be carried out.

The probe is very delicate then handle it with great care. Also a simple push, most of all with the

omni-directional probes which have the uncovered sensor, can definitively damage the probe. After

the measurement, the sensor placed on the probe head has to be protected by the metal shield or by

the threaded cylinder which is equipped with. During the use, the AP471 S4 omni-directional probe

has to be protected by the metal cage. For transport, the sensor has to be closed inside the relevant

protection cylinder by screwing it on the top of the probe.

Do not touch sensors with your fingers.

Use pure alcohol to clean sensors.

- -

19

DIMENSIONS

85 87200 min - 880 max

Ø13

Ø8

A

P471 S1

110

Ø13

Ø8

A

P471 S2

85 87

102

200 min

880 max

Ø13

Ø8

A

P471 S3

- -

20

MIN=350 - MAX=1020

∅

=120

AP471 S4

Table of contents

Other Delta OHM Data Logger manuals

Delta OHM

Delta OHM HD50CR-AS User manual

Delta OHM

Delta OHM HD37B17D User manual

Delta OHM

Delta OHM HD30.1 User manual

Delta OHM

Delta OHM HD32.7 User manual

Delta OHM

Delta OHM DO 9721 User manual

Delta OHM

Delta OHM HD32MT.1 User manual

Delta OHM

Delta OHM HD 2013 Series User manual

Delta OHM

Delta OHM HD32.8.8 User manual

Delta OHM

Delta OHM HD35 Series User manual

Delta OHM

Delta OHM DO 9847K User manual