Delta OHM HD32.7 User manual

Our instruments’ quality level is the results of the product continuous development. This

can bring about differences between the information written in this manual and the

instrument that you have purchased. We cannot entirely exclude errors in the manual, for

which we apologize.

The data, figures and descriptions contained in this manual cannot be legally asserted. We

reserve the right to make changes and corrections without prior notice.

REV. 1.2

12/12/2016

HD32.7

RTD DATALOGGER

ENGLISH

- 2 -

RTD Datalogger

HD32.7

- 3 -

HD32.7

1. ON/OFF key: It turns the instrument on and off.

2. TIME key: It allows the display of date and time, in the first line for about 8 seconds.

3. SHIFT FNC key: It activates the Shortcut window.

4. Graphic display.

5. Function keys F1, F2, F3: Activate the function in the bottom line of the display.

6. ENTER key: In the menu, it confirms the data entered.

7. ESC key: It allows to exit from the menu or, in case of a submenu, to exit from the current level

display.

8. Navigation keys ▲▼◄►: Allow navigation through the menus. During measurement, the

◄► arrows change the display contrast.

9. PRINT key: It starts and ends the data transfer to the serial/USB communication port.

10. MEM key: It starts and ends the recording of the data.

11. SETUP key: It allows to enter and exit the instrument’s functioning parameter setting menu.

12. Inputs for the temperature probes: Pt100 with SICRAM module, direct 4-wire Pt100 or direct 2-

wire Pt1000. The connected probes must be of the same type: you cannot simultaneously

connect probes of different types.

13. Battery compartment.

14. Sub D 9-pole male connector for the RS232C serial port.

15. USB type B port.

16. Power supply input 12Vdc/1A – external ∅5.5mm, internal ∅2.1mm. The power supply

positive must be connected to the central pin.

- 4 -

TABLE OF CONTENTS

1. GENERAL CHARACTERISTICS....................................................................................................................... 6

2. KEYBOARD AND DISPLAY DESCRIPTION ................................................................................................... 7

2.1 THE DISPLAY .................................................................................................................................................... 7

2.2THE KEYBOARD ............................................................................................................................................... 7

3. OPERATION .......................................................................................................................................................10

3.1 THE UNIT OF MEASUREMENT “UNIT”.................................................................................................................10

3.2 THE MAXIMUM,MINIMUM AND AVERAGE VALUES OF THE CAPTURED QUANTITIES ..............................................10

3.3 INSTRUMENT SETUP .........................................................................................................................................11

3.4 START OF A NEW LOGGING SESSION ..................................................................................................................11

4. MAIN MENU .......................................................................................................................................................12

4.1 INFO.................................................................................................................................................................12

4.2 LOGGING..........................................................................................................................................................13

4.2.1 Log Interval.............................................................................................................................................13

4.2.2 Self Shut-off mode...................................................................................................................................13

4.2.3 Start/stop time .........................................................................................................................................14

4.2.4 Cancel auto start ......................................................................................................................................17

4.2.5 Log File Manager ....................................................................................................................................17

4.3 SERIAL (SERIAL COMMUNICATION) ...................................................................................................................20

4.3.1 The Baud Rate.........................................................................................................................................21

4.3.2 Print Interval ...........................................................................................................................................21

4.4 INPUT ..............................................................................................................................................................22

4.5 CONTRAST .......................................................................................................................................................22

4.6 FIRMWARE.......................................................................................................................................................23

4.7 TIME/DATE ......................................................................................................................................................23

4.8 CALIBRATE......................................................................................................................................................24

4.9 KEY LOCK........................................................................................................................................................24

4.10 PASSWORD ....................................................................................................................................................25

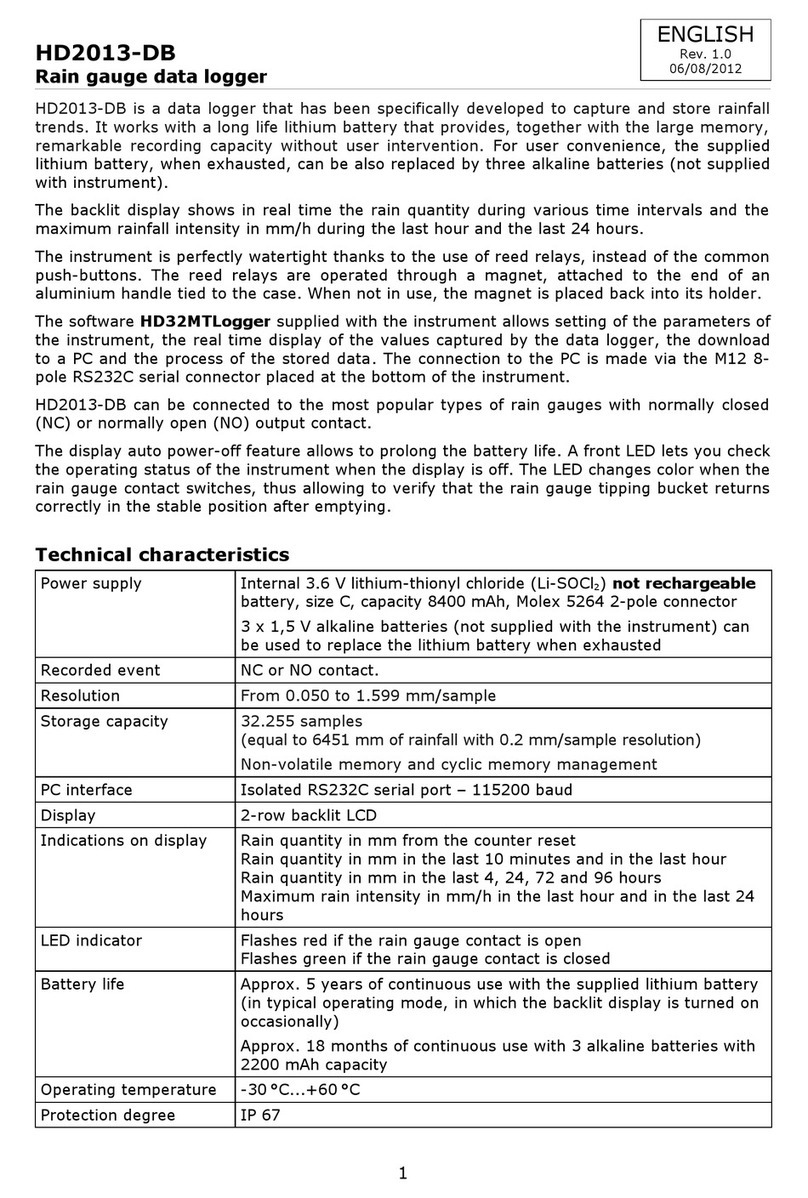

5. PROBES AND MEASUREMENTS.....................................................................................................................27

5.1 TEMPERATURE MEASUREMENT .........................................................................................................................28

5.2 CALIBRATION OF THE PROBE .............................................................................................................................28

5.3 INSTRUCTIONS TO CONNECT THE TP47 CONNECTOR FOR 4-WIRE PT100 AND 2-WIRE PT1000 PROBES ...................28

5.3.1 Direct connection of 4-wire Pt100 and 2-wire Pt1000 sensors to the DIN45326 8-pole female connectors..30

5.4 WARNINGS,CARE AND MAINTENANCE OF THE PROBES.......................................................................................30

6. INSTRUMENT SIGNALS AND FAULTS..........................................................................................................31

7. BATTERY SYMBOL AND BATTERY REPLACEMENT, MAINS POWER SUPPLY ..................................32

7.1 WARNINGS ABOUT BATTERY USE.......................................................................................................................33

8. INSTRUMENT STORAGE .................................................................................................................................33

9. SERIAL INTERFACE AND USB .......................................................................................................................34

10. STORING AND TRANSFERRING DATA TO A PC.......................................................................................36

10.1 THE LOGGING FUNCTION................................................................................................................................36

10.1.1 Storage capacity .....................................................................................................................................36

10.1.2 The Erase function: clearing the memory................................................................................................37

10.2 THE PRINT FUNCTION ......................................................................................................................................37

- 5 -

11. CONNECTION TO A PC ..................................................................................................................................38

11.1 CONNECTION TO THE RS232C SERIAL PORT ....................................................................................................38

11.2 CONNECTION TO THE USB 2.0 PORT................................................................................................................38

12. FUNCTIONING NOTES AND OPERATING SAFETY ..................................................................................39

13. TECHNICAL CHARACTERISTICS................................................................................................................40

14. ORDERING CODES..........................................................................................................................................44

- 6 -

1. GENERAL CHARACTERISTICS

The HD32.7 RTD datalogger is an instrument that can capture, log and then send to a PC or serial

printer the data coming from 8 temperature probes with Pt100 or Pt1000 sensor connected to the

inputs.

The probes can be Pt100 with SICRAM module, direct 4-wire Pt100 or direct 2-wire Pt1000. All

the connected probes must be of the same type.

The Pt100 SICRAM probes are fitted with an electronic circuit that communicates with the

instrument. The sensor calibration information, the probe’s type and the serial number are

memorized inside. Thanks to the SICRAM module, the probes’ interchangeability on the instrument

is guaranteed. While the probes with SICRAM module are calibrated in the factory and can be

recalibrated, the 4-wire Pt100 and 2-wire Pt1000 probe uncertainty depends on the sensor quality.

All probes are detected during turn on: After connecting or disconnecting a probe, turn the

instrument off and on.

The communication with the PC occurs through a multi-standard serial port RS232 or an automatic

detection USB 2.0. The memorization and printing interval, the logging start and end date, and the

communication parameters can be configured using the menu.

The captured data can be displayed on the PC using the DeltaLog9 software (vers. 3.0 and later).

Through the RS232 serial port, you can transfer the data in real time to an 80 column serial printer.

NOTE: The set capture and print intervals are valid for all the connected probes.

Other user selectable/settable parameters are:

•The type of probes connected to the instrument inputs.

•The units of measurement for the displayed temperature quantities: °C, °F, °K.

•The system date and time

•The display of the maximum, minimum, and average statistic parameters.

•The data transfer speed via the serial RS232 port.

•The setting, enabling and disabling of the password that locks the keyboard.

The instrument can store up to 64 LOG sessions (data capture) in two modes:

•Automatic: Setting the automatic start and stop dates;

•Manual: Pressing MEM to start and end the data capture session.

The flash memory has a total capacity of 96,000 recordings from 8 inputs each.

The memory space can be handled in two modes:

•When the available memory is full, the collected data are overwritten starting from the

oldest ones (circular memory),

•The recording is stopped when the available memory is full.

- 7 -

2. KEYBOARD AND DISPLAY DESCRIPTION

The user interface consist of a backlit LCD display and the power-on, function, and setting keys.

Turn the instrument on and off with the ON/OFF key: When you turn the instrument on, the logo

and model will be displayed for a few seconds, and then the main display.

The turning on starts a self test including the detection of the probes connected to the inputs. As the

SICRAM probes’ identification and calibration data are captured upon turning the

instrument on, it is necessary to connect the probes when the instrument is off. If a SICRAM

probe is connected and the instrument is on, the “New” indication appears on the display and

an intermittent beep is issued: It is necessary to turn the instrument off and on.

Once turned off, wait few seconds before turning it on to allow completion of the shut down

routine.

The type of probe connected to the inputs (Pt100 with SICRAM, direct 4-wire Pt100 or direct 2-

wire Pt1000) is selected from the menu. (Please see the “Input” paragraph on page 22.)

2.1 The Display

The HD32.7 standard display is divided in two areas:

The first area displays the battery’s charge status and the current time (above); then, the

temperatures measured by the probes connected to the inputs (below) arranged on two columns.

The unused inputs are indicated by dashes.

The bottom line displays the options that can be activated using the F1, F2 and F3 keys. Please see

the SHIFT FNC key in the following paragraph.

In the example, the function keys are associated to the temperature measurement units:

°C: Celsius degrees

°F: Fahrenheit degrees

°K: Kelvin degrees

2.2 The Keyboard

The keys on the instrument perform the following functions:

ON/OFF key

It turns the instrument on and off.

When turning on the instrument using this key, the first screen will be displayed with the logo and

model. After few seconds the temperatures measured by the probes connected will be displayed.

- 8 -

NOTE: The non-connected inputs will be indicated by dashes. If a probe is disconnected when the

instrument is on, the “LOST” message will be displayed in case of a SICRAM probe, or dashes in

the other cases: Reconnect the probe to read the measured temperature. Do not connect the probes

when the instrument is on: In order to correctly detect them, you need to turn the instrument off and

then back on again.

TIME key

It allows the display of year/month/day and hour/minutes/seconds, in the first line for about 8

seconds. Normally the display shows, on the left, the icon for the battery’s charge status, on

the right, the hour/minutes/seconds. The battery symbol becomes [~] when the external power

supply is connected.

SHIFT FUNCTION key

It activates the Shortcut window.

A drop-down menu opens as in the figure: The black background item is the active item. To select

another item, use the ▲▼ arrows and confirm with ENTER.

F1, F2, F3 keys

These are “function keys”: They activate the function in the last line of the display (indicated by the

arrow in the figure); the function, enabled by SHIFT FNC, is selected and displayed in “reverse”

(e.g. in the figure the “°C” function is enabled).

SETUP key

It allows to enter and exit the instrument’s functioning parameter setting menu.

- 9 -

ENTER key

In the menu, it confirms the entered data.

ESC key

It allows to exit from the menu or, in case of a submenu, to move up one level.

MEM key

It allows to start and end a “logging” session (data recording); the data logging interval must be set

in the menu.

PRINT key

It allows direct printing of the data via the serial port; the data printing interval must be set in the

menu.

Arrow keys

Allow navigation through the menus. During measurement, the ◄► arrows change the display

contrast.

- 10 -

3. OPERATION

Before turning on the instrument, connect the probes to the 8-pole male DIN45326 inputs, located

in the lower part of the instrument (see figure on page 2).

All probes must be of the same type: The selection of the type of probe should be performed in the

Input menu item (please see page 22).

NOTE: Connect the probes when the instrument is off. If a new probe is connected when the

instrument is on, the “New” indication appears on the display for a SICRAM probe, or dashes

for another probe. Turn the instrument off and then back on again to enable the new probe.

If a SICRAM probe is disconnected when the instrument is on, you will get an acoustic signal (a

beep) and an indication on the display near the physical quantity being disconnected. The “LOST”

message will be displayed.

The Pt100 probe with SICRAM module is fitted with an electronic circuit that communicates with

the instrument. The sensor calibration information are memorized inside. This guarantees its

interchangeability.

Connect the probes. Turn on the instrument: After few seconds, the display will appear as follows:

The battery charge symbol and current time are in the upper part (for further details, see the chapter

8).

Then the temperatures detected by each input are displayed. Use the F1, F2 and F3 keys to select

the unit of measurement (°C, °F or °K).

3.1 The unit of measurement “Unit”

By using the “Functions” menu, enabled by the SHIFT FNC key, select the unit of measurement

for the temperature in °C (Celsius), °F (Fahrenheit) or °K (Kelvin) degrees, as follows:

1. Use SHIFT FNC to open the drop-down menu;

2. Use the arrows ▲▼ to select unit;

3. Press ENTER to confirm: The selected quantity is displayed in the central line of the display;

4. The three different temperature units of measurement are shown in the bottom line of the

display using F1, F2 or F3: The selected unit is displayed near the measured value;

5. Press ESC to exit the drop-down menu without making any change.

3.2 The maximum, minimum and average values of the captured quantities

In order to display the maximum, minimum and average values of the measured quantities, proceed

as follows:

1. Use SHIFT FNC to open the drop-down menu;

2. Use the arrows ▲▼ to select “data”;

3. Confirm by pressing ENTER: The selected quantity is displayed in the central line of the

display;

- 11 -

4. The three items max (maximum), min (minimum) and avg (average) are shown in the bottom

line of the display using F1 or F2.

NOTE: Once selected, for example max, all displayed quantities represent the maximum value.

The average is calculated on the first five minutes of samples, and then on the current

average.

The F3 key allows choosing to clear (Clr) the maximum, minimum and average data of the

captured measurements:

1. Select Clr using F3 to clear the max, min and avg calculations;

2. Another drop-down menu will open;

3. Use the arrows ▲▼ to select yes;

4. Press ENTER to confirm.

5. Press ESC or select no, to exit without clearing the data.

3.3 Instrument Setup

In order to set the instrument, open the main menu by pressing SETUP. See the next chapter for

further details.

3.4 Start of a new logging session

Press MEM to start and end a logging session: This key starts and stops the logging of a data block

to be saved in the instrument’s internal memory. The data logging frequency is set in the “Log

interval” menu parameter. The data logged between a start and subsequent stop represent a

measurement block.

During logging, the LOG indication is displayed, the battery symbol blinks and a beep is issued

each time a logging occurs.

To end the logging, press MEM again.

The instrument can turn off during logging between one capture and the next: The function is

controlled by the Self_shut_off_Mode menu parameter. When the logging interval is less than one

minute, the logging instrument remains on; with an interval of at least one minute, it turns off

between one capture and the next, if the Self_shut_off_Mode parameter is enabled.

For the details see par. “4.2 MENU LOGGING”.

- 12 -

4. MAIN MENU

To access the programming menu press SETUP: The setting menu will be displayed with the

following items:

0) Info

1) Logging

2) Serial

3) Input

4) Contr.

5) Firmware

6) Time/date

7) Calibrate

8) Key lock

9) Password

If you do not press any key within 2 minutes, the instrument goes back to the main display.

Use the arrows ▲▼ ◄► and press ENTER to select an item.

To exit the selected item and return to the previous menu, press ESC.

To exit the menu and return directly to measurement, press SETUP.

4.1 Info

To access the Info menu, open the main menu using the SETUP key. Using the ▲▼ ◄► arrows,

select Info and confirm with ENTER.

The following information on the instrument will be displayed: Instrument code, firmware date and

version, serial number, instrument calibration date, user identification code.

This screen cannot be modified: The user identification code (User ID) can be set using the

DeltaLog9 software (vers. 3.0 and later).

Press ESC to return to the main menu. Press SETUP to exit the menu.

- 13 -

4.2 Logging

To access the Logging menu, open the main menu using the SETUP key. Using the ▲▼ ◄►

arrows, select Logging and confirm with ENTER.

The parameter setting submenu for the logging sessions will be displayed.

You can set the data capture frequency (Log interval) and the automatic logging start (Start/stop

time). The capture interval is the same for all probes.

With the “Log File Manager” you can handle the stored data sessions: printing, erasure.

4.2.1 Log Interval

Use this item to set the LOG interval (interval between two subsequent sample records). To enter

this setting, proceed as follows:

Once you have accessed the LOGGING submenu (previous par.) use the arrows ▲▼to select Log

Interval:

1. Use the arrows ▲▼to select the interval duration from a minimum of 2 seconds to a

maximum of one hour;

2. Press ENTER to confirm and return to the Logging menu;

3. Press ESC to return to the Logging menu without making any change;

4. Press ESC again to return to the main menu;

5. Press SETUP to exit immediately from the menu.

These are the available values:

2, 5, 10, 15, 30 seconds, 1, 2, 5, 10, 15, 20, 30 minutes and 1 hour.

4.2.2 Self Shut-off mode

The Self shut-off mode item controls the instrument’s automatic turning off during logging,

between the capture of a sample and the next one. When the interval is lower than 60 seconds, the

instrument will always remain on. With intervals greater than or equal to 60 seconds, it is possible

- 14 -

to turn off the instrument between loggings: it will turn on 15 seconds before the sampling and will

turn off immediately afterwards, thus increasing the battery life.

Once you have accessed the LOGGING submenu (previous par.) use the arrows ▲▼to select Self

shut-off mode:

•If the set Log Interval (see previous par.) is lower than 60 seconds, the following will be

displayed

•If the set Log Interval (see previous par.) is greater or equal to 60 seconds, the following will

be displayed

1. By using the arrows ▲▼you can select:

...STAY ON... (the instrument stays on)

...SHUT OFF... (the instrument shuts off between one logging and the next)

2. Press ESC to return to the Logging menu;

3. Press ESC again to return to the main menu;

4. Press SETUP to exit immediately from the menu.

4.2.3 Start/stop time

The logging start and end date and time can be programmed. When called, the function suggests

the current time plus 5 minutes as the start time: Press <ENTER> to confirm or set the date and

time using the ▲▼ arrows. Then you are asked to set the data to end the recording: By default

(factory setting) the instrument suggests the start time plus 10 minutes. The default suggested

values are such to allow the user to setup an instrument ready for acquisition.

To enter this setting, proceed as follows.

Once you have accessed the LOGGING submenu use the arrows ▲▼to select Start/Stop time:

The following message “Enter start time” will be displayed:

- 15 -

1. Press ENTER to confirm the data prompted by the instrument;

2. To change the prompted data, use the arrows ◄►to select the data to be changed

(year/month/day and hour:minutes:seconds);

3. The selected data will flash;

4. Use the arrows ▼▲ to change its value;

5. Confirm by pressing ENTER;

6. Press ESC to return to the Logging menu without making any change;

7. Press ESC again to return to the main menu;

8. Press SETUP to exit immediately from the menu.

After setting the logging start time, the logging end time (enter stop time) window will be

displayed:

1. Press ENTER to confirm the data prompted by the instrument;

2. To change the prompted data, use the arrows ◄►to select the data to be changed

(year/month/day and hour:minutes:seconds);

3. The selected data will flash;

4. Use the arrows ▼▲ to change its value;

5. Confirm by pressing ENTER;

6. Press ESC to return to the Logging menu without making any change;

7. Press ESC again to return to the main menu;

8. Press SETUP to exit immediately from the menu.

NOTE: The logging end time prompted by the instrument is 10 minutes after the logging

session start time.

9. Once both values have been set, a summary will be displayed showing the start and end time of

the LOG session.

- 16 -

10. Press ENTER to confirm or ESC to exit without enabling the automatic start: In both cases,

you will return to the LOGGING menu.

11. Press SETUP to exit immediately from the main menu.

When the instrument starts automatically a LOG session, a beep is issued on each capture and the

blinking LOG message is shown at the top of the display.

Press MEM to stop the session before the set time.

To cancel the automatic start setting, use the Cancel auto start function as illustrated in the

following paragraph.

NOTE 1: The automatic logging session is started even when the instrument is off. If it is off when

the automatic logging session is started, the instrument is turned on few seconds earlier and remains

on at the end of logging. If it is powered by the battery, it is turned off when idle for some minutes

at the end of the logging session.

NOTE 2: Use of the MEM key after setting the automatic start and stop.

•If the automatic start and stop have been set and, before the automatic start, you press the MEM

key, the instrument starts recording at once. The next automatic start command is ignored, the

recording ends at the automatic stop command.

•If the automatic start and stop have been set and, after the automatic start, you press the MEM

key, the instrument stops recording. The next preset automatic stop command is cleared.

Automatic Start Automatic StopMEM key

Logging Interval

I

g

nore

d

Automatic Start Automatic StopMEM key

Logging Interval

- 17 -

4.2.4 Cancel auto start

Once the LOG session start and end times are set, you can inhibit the session automatic start by

using Cancel auto start.

Once you have accessed the LOGGING submenu:

1. Use the arrows ▲▼to select Cancel auto start

2. The LOG session start and end times will be displayed:

3. By pressing ▲the following message will be displayed: “Self timer not active”;

4. Press ENTER to confirm the automatic start cancellation;

5. Press ESC to exit without cancelling the automatic start;

6. Press ESC again to exit from the submenus;

7. Or press SETUP to exit immediately from the main menu.

See the previous paragraph to set a new automatic start time after cancelling the previous one.

4.2.5 Log File Manager

This item allows managing the captured logging sessions: The instrument allows printing the files

of the captured sessions (Print selected log), cancelling the entire memory (Erase ALL logs) and

selecting the memory management mode (Select memory Type).

The instrument can store up to 64 LOG sessions, progressively numbered from 00 to 63: The

session list is arranged on 4 lines and 4 columns. If you have over 16 sessions, using the F1 function

key (Page-) you shift to the previous screen, and with the F3 key (Page+) to the next one. The

current page (0, 1, 2 or 3) and the total data pages are displayed in the upper right corner: In the

example, “0/3” means page 0 of three pages of logged data.

- 18 -

Once you have accessed the LOGGING submenu:

1. Use the arrows ▲▼to select Log File manager: You will see the following submenu

0) Print selected log

1) Erase ALL logs

2) Select memory type

2. Use the arrows ▲▼ to select a menu item;

3. Press ENTER to confirm;

4. Press ESC to return to the menu;

5. Press SETUP to exit immediately from the main menu.

NOTE: You can connect a PC or serial port printer to the instrument RS232C serial port. A parallel

port printer requires a serial/parallel converter between the instrument and the printer (non

supplied).

Before starting the printing via the RS232C port, you have to set the baud rate.

To do so, select the Baud Rate in the menu Serial (see par. 4.3.1 The Baud Rate) and select the

maximum value equal to 38400 baud. To connect a printer, use the maximum allowed value for the

printer.

The communication between instrument and PC or between instrument and printer, only

works if the instrument and connected device (PC or printer) baud rates are the same.

- 19 -

0) Print selected log:

By selecting this item, the page of the log to be printed will be displayed:

1. Use the arrows ▲▼◄►to select the log to be printed, and the F1 and F3 function keys to shift

page.

2. Once a file is selected, the acquisition start date and time and the number of samples contained in

the file (Rec) are displayed at the bottom of the display.

Warning: The files are stored in ascending order. However, if the memory is arranged in

circular mode (please see later at point 3), it could be that a lower number corresponds to a

more recent file. Each file is only identified by the date and time, shown on the display. In the

example above, the file 00 is selected: The recording started at 18:50 on 27 January 2006. The

file contains 6 samples.

3. Press ENTER to print the selected log (or press ESC to return to the previous menu, without

printing);

4. The data transfer message will be displayed a few seconds, then the instrument will go back to

the Print selected log page to select another log to be printed;

5. Repeat the procedure to print the required sessions or press ESC to exit this menu;

6. Press SETUP to exit immediately from the main menu.

1) Erase ALL logs

By selecting this item, the “Erase ALL files” message will be displayed:

1. Press ENTER to erase all the files;

2. Press ESC to cancel the operation and return to the previous menu level;

3. Press SETUP to exit immediately from the main menu.

2) Select memory type

By selecting this item, the memory type selection page will be displayed:

- 20 -

The memory can be handled in two modes that can be selected using the ▲▼ arrows:

•Circular memory. When the memory is full, the new files will overwrite the oldest ones.

•Until memory full. When the memory space is full, the recording will stop and the message

“WARNING: MEMORY FULL!!” will be displayed. In order to continue recording, the files in

the memory should be erased.

1. Press ENTER to confirm the selected mode;

2. Press ESC to cancel the operation and return to the previous menu level;

3. Press SETUP to exit immediately from the main menu.

4.3 Serial (Serial Communication)

The Serial submenu allows setting the data transfer speed via the serial port (Baud rate), and the

record printing interval (Print Interval).

The LOG sessions can be downloaded on a PC, through the serial RS232 or USB connection.

In case of serial connection, the transfer speed can be set by the user (see next par.) up to a

maximum of 38400 baud.

In case of USB connection, the transfer speed is fixed at 460800 baud.

The data downloaded to the PC using the DeltaLog9 software (vers. 3.0 and later) can be displayed

as a table or graphically.

The instrument can be connected directly to a printer with serial input.

To access the Serial submenu, proceed as follows:

1. Press SETUP;

2. Use the arrows ▲▼◄► to select Serial;

3. Press ENTER;

4. You will get the Serial submenu.

Table of contents

Other Delta OHM Data Logger manuals

Delta OHM

Delta OHM DO 9847K User manual

Delta OHM

Delta OHM HD35 Series User manual

Delta OHM

Delta OHM HD32.1 User manual

Delta OHM

Delta OHM DO 9721 User manual

Delta OHM

Delta OHM HD32MT.3 User manual

Delta OHM

Delta OHM HD50R-MB User manual

Delta OHM

Delta OHM HD37B17D User manual

Delta OHM

Delta OHM HD30.1 User manual

Delta OHM

Delta OHM DO2003 User manual

Delta OHM

Delta OHM HD2013-DB User manual