English

15

• For transporting by vehicle or by any kind

of hoist, 3 lashing or hoisting points are

provided :

■Two at shaft height.

■One on protection ring.

• During transport, rest the front of the

machine on a block of wood.

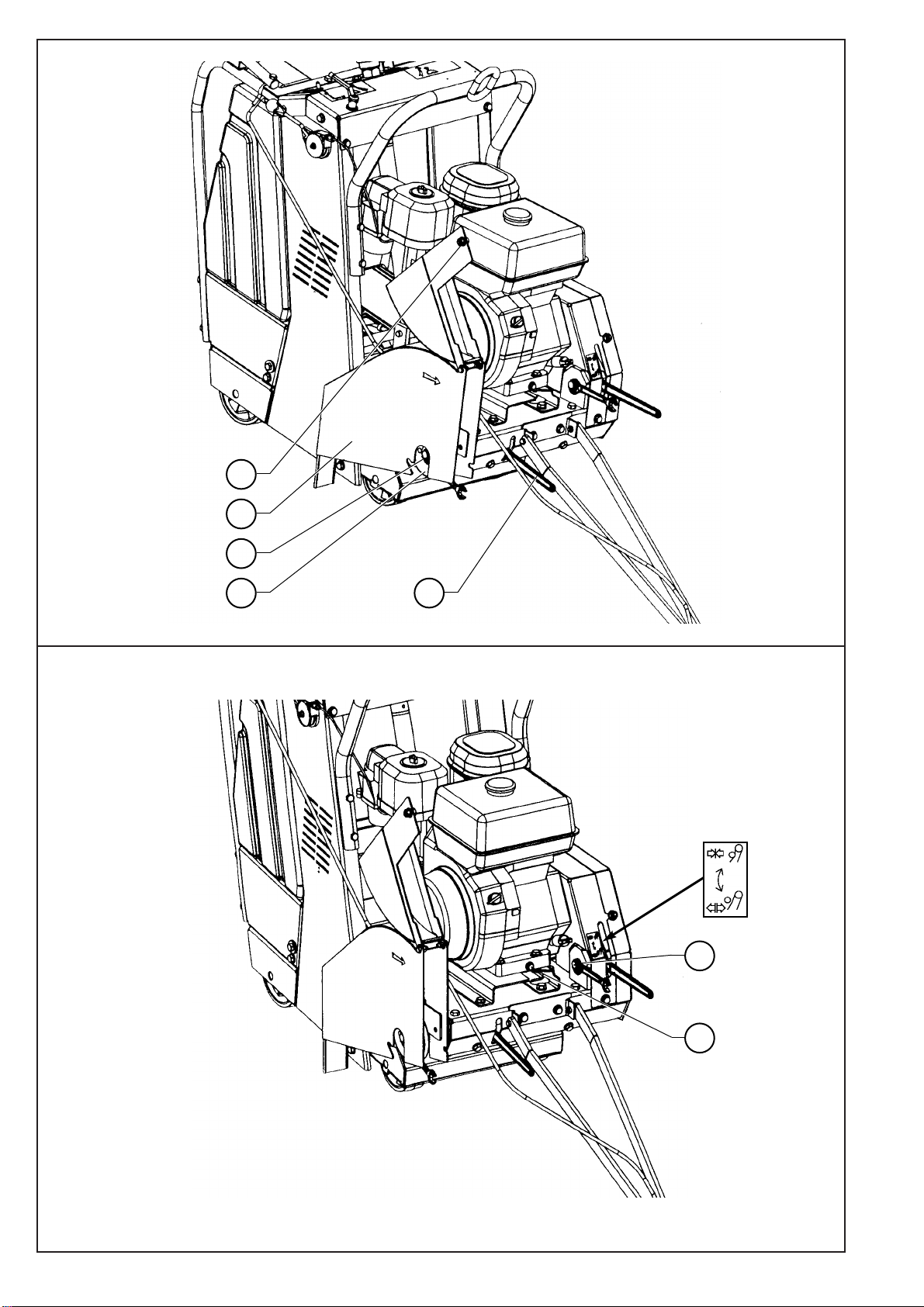

• Turn off the tap (4) [SEE FIG. 1].

• Refill the water tank from the mains (F)

[SEE FIG. 1] (optional isolating valv ).

• Mark the floor by drawing a line in the

place to be cut.

• Position the machine so that the folded-

down front guide (6) and the blade are

lined up with the mark.

• Start up the motor :

Petrol and Diesel : refer to the

instructions in the manufacturer's service

manual.

Allow the motor to warm up.

• Turn on the water tap (4).

• The locking lever (8) should be down to

move the wheel (7).

• Increase the motor speed to full power.

•

Adjust the travel of the disk by means of the

hand-wheel (7) : a slow descent is

advisable to prevent the motor from stalling.

(1 turn of the handwheel = 1.25 cm).

• Raise the lever (8) when the required

depth has been set.

• Advance the machine gently whilst

ensuring that the front guide and the

blade always follow the mark.

- Automatic v rsion

- Set the potentiometer (23) [Fig. 1] to a

minimum.

- Control the release of the lever to engage

forward motion.

- Push the controller (21) [Fig. 1] forward

(on-position)

- Turn the potentiometer to obtain the

required advance speed

(speed adjustable from 0 to 2 m/min ma .)

- A rational advance speed cannot be set

as this depends on the cutting depth, the

type of cutting wheel and the material to

be cut.We recommend that you do not

make the motor labour uselessly

(characterised by black e haust fumes).

Travel at a regular speed.

Automatic Advanc

For short distances or loading assistance, it

is possible to use the "rapid" automatic

advance without starting up the motor. To

do this:

- raise the machine as far as possible

- Control the release of the lever to engage

forward motion.

- push the controller forward or backward

(if reverse required) and hold it in

position. By releasing the pressure, the

machine stops automatically.

7Starting up

Always pay extreme care and

attention to the preparation of

the machine before starting up

Remove all adjustment tools and

wrenches from floor and

machine

Always keep blade guard in

place

Abundant water cooling =

guaranteed long blade life

•PETROL OR DIESEL MOTOR (refer to

the engine maintenance manual)

•MACHINE WITH ELECTRIC MOTOR

(direction on the sides of the guard).

Check the following :

• Motor power supply : reinforced electric

cable with 4 (3P+E) or 5 (3P+N+E)

conductors 2.5 mm2for lengths less than

100 m.

• Earthing of the machine (mandatory).

• The motor’s direction of rotation must

match the arrow on the disc casing(if the

motor does not rotate in the requisite

direction, invert the 2 feed wires).

■Ensure the fuel is topped up.

Diesel : do not wait until the tank is

empty before filling up. A lack of fuel

risks draining the pump.

■Check the oil level : as the motor

frequently works on an incline, check,

in the horizontal position, that its oil

level never falls below the second line

one the gauge.

■To start up, refer to the engine

instructions.

- Stop switch set to stop.

- Battery: Battery isolation switch

turned on.

Take into account the working

conditions from health and safety

point of wiew.

Use only blades marked with a

maximum operating speed

greater than blade shaft speed

The working area must be

completely cleared, well lit and

all safety hazards removed (no

water or dangerous objects in

the vicinity)

The operator must wear

protective clothing appropriate

to the work he is doing. We

recommend that this includes

both eye and ear protection

Any persons not involved in the

work should leave the working

area

The use of ear protection is

mandatory.

5Ch ck b for starting

Please read the instructions for

use prior to operating the

machine for the first time.

otor off.

Take care about the direction of

rotation which is shown by an

arrow on one of the faces

(direction of rotation on the right

side of the casing)

ake sure the contact faces of

flanges, of blade and the axle are

clean

The disk clamping screw (D) has

a left-hand thread.

For your own safety and for the

protection of other people,

replace all the protective

devices.

6Fitting th blad

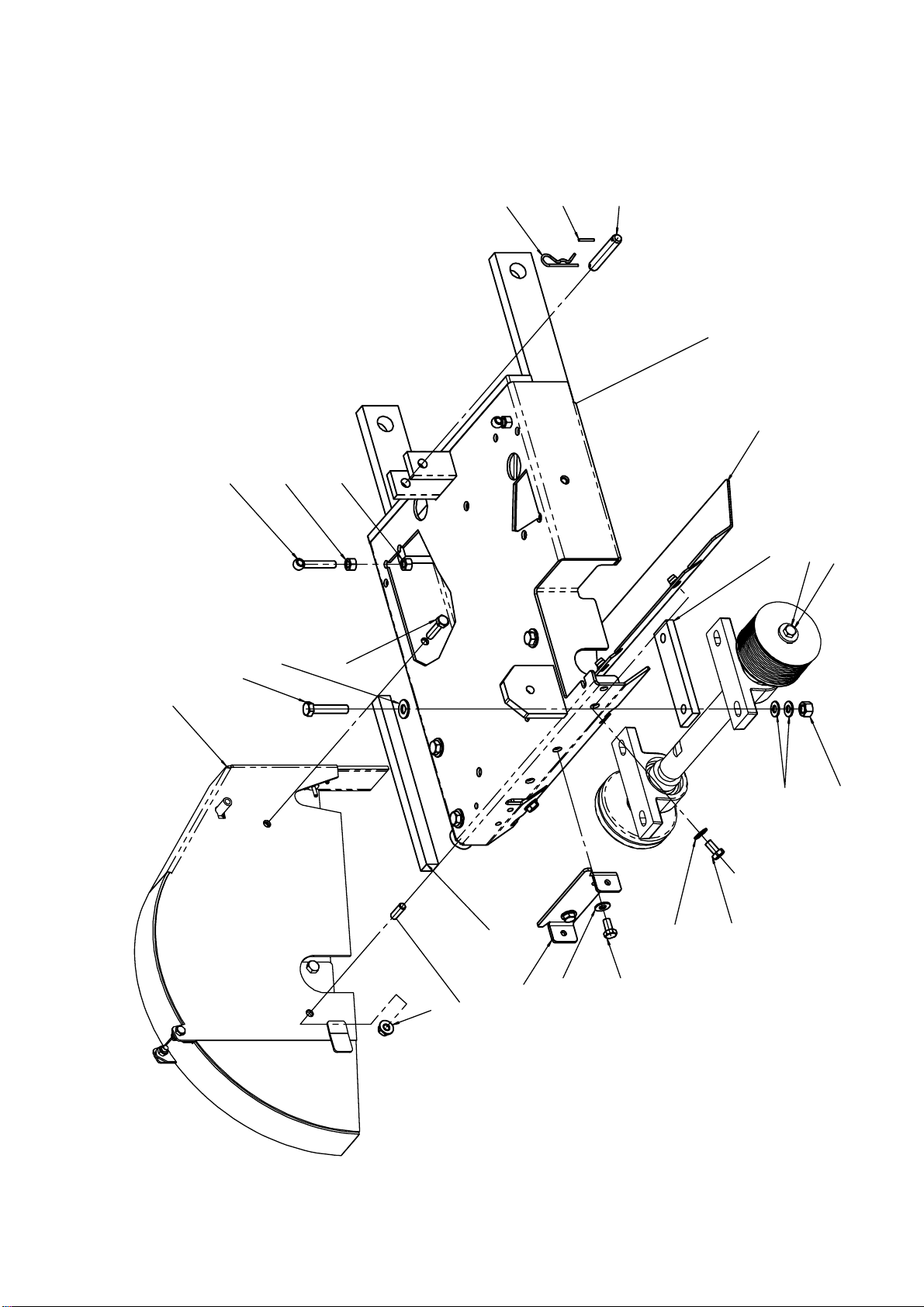

• Lift the front mobile part of the disc

protection housing (A) [see Fig. 2]

(loosen the housing nut (B)).

• Slacken the screw (D) and remove the

smooth plate (C).

• Fit the disk by slotting it into the fi ed

casing.

• Lock the screw (D) firmly using the 18

mm spanner while holding the pin shaft in

position using the 30mm spanner (E)

• Replace the guard (lock nut (B)).

Motor off

Disconn ct th pow r plug

- ELECTRICAL SAFETY :

Operate this machine only on a

supply equipped with a 30 mA

earthed current-limiting circuit-

breaker. Otherwise, consult our

catalogue for appropriate

models.

- Th RCCB must b us d

corr ctly, including t sting it

r gularly. For tools suppli d

with an int gral RCCB in th

cabl or in th mains plug, if

th cabl or plug has b n

damag d, r pairs must b

carri d out by th

manufactur r, on of his

ag nts or by a qualifi d

r pair workshop to avoid any

risks r sulting from rrors.

Danger: risk of injury