4 - English

Operator’s Manual WS 463

Safety Instructions

During the design and production of Dimas products,

great importance is placed on safety, as well as

effectiveness and ease of use. To ensure that the

machine remains safe you must pay attention to the

following points:

WARNING!

This machine is only intended for use

together with a DIMAS PP 355, DIMAS PP

455 and DIMAS RC 455. All other use is

forbidden.

CAUTION

Under no circumstances may the machine be

started without observing the safety

instructions. Should the user fail to comply

with these, Electrolux Construction Products

Sweden AB or its representatives are free

from all liability both directly and indirectly.

Read through these operating instructions and

make sure that you understand the contents

before starting to use the machine. Should

you, after reading these safety instructions,

still feel uncertain about the safety risks

involved you must not use the machine Please

contact your dealer for more information.

• Check that all couplings, connections and hydraulic

hoses are in full working order.

• Make sure that all hoses and electrical cables are

connected to themachine correctly before you start the

machine.

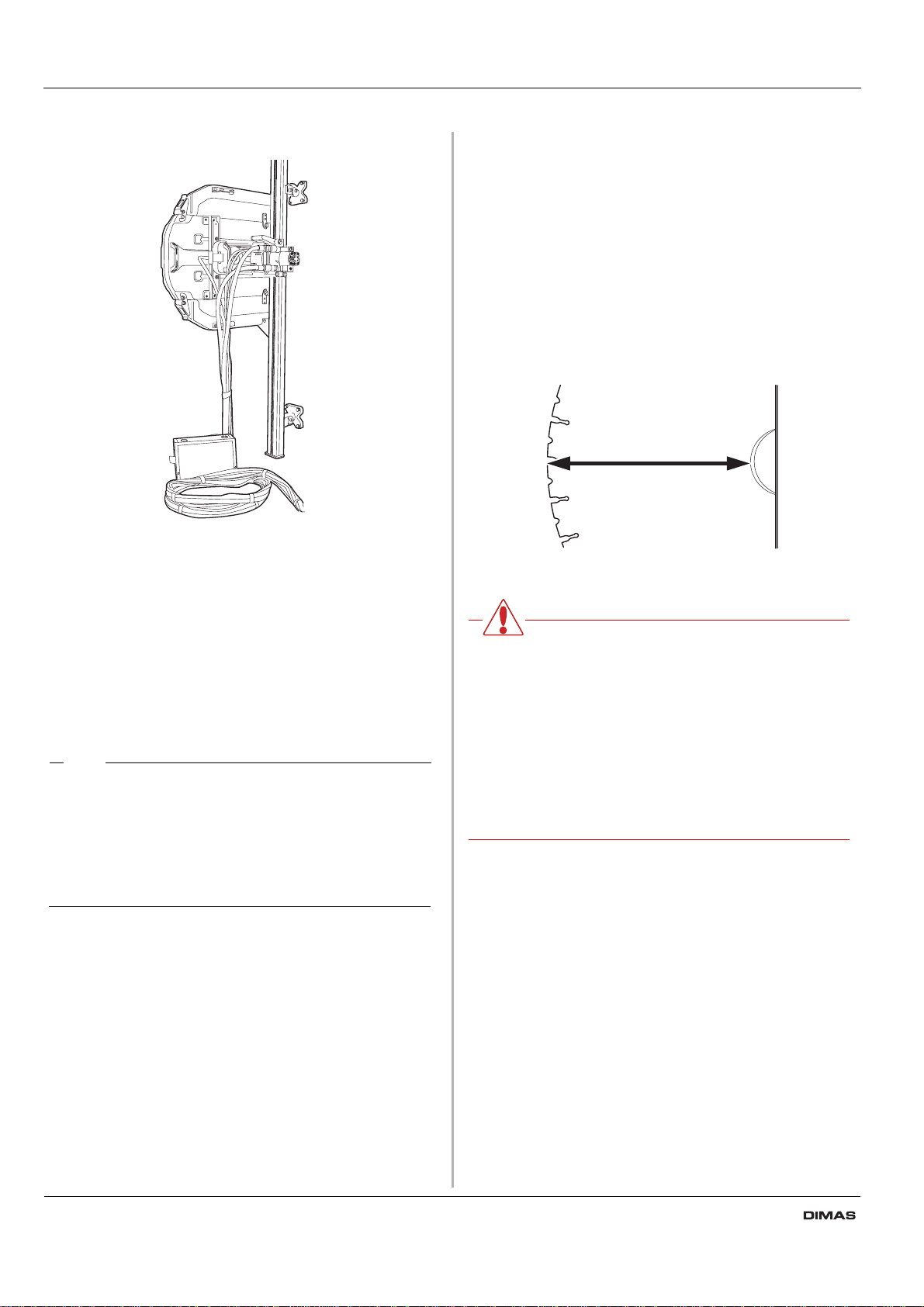

• The safety distance is 4 metres in front of and to the

side of the saw.

• Make sure that there are no persons or animals in the

working area.

• Check that the blade guard is not damaged and that it

has been fitted correctly.

• Never cut without using the blade guard. The

maximum size of saw blade when starting is 1000 mm.

As accessories there are also blade guards for 800,

1240, and 1600 mm blades.

Never remove the blade guard without first shutting off

the hydraulic unit and ensuring that the blade has

finished rotating completely.

• Never disconnect the hydraulic hoses without first

shutting off the hydraulic unit and ensuring the motors

have stopped completely.

• Check the machine, couplings and hydraulic hoses

daily for leakage. A rupture or leak can cause a

”hydraulic fluid injection” in the body or result in other

serious physical injury.

• Do not exceed the specified hydraulic fluid flow or

pressure for the tool being used. Too high pressure or

flow can resulting rupturing

• Never use the hydraulic hoses to lift the saw.

• Do not misuse hoses.

• Do not use hoses that are distorted, worn, or damaged.

• Check that the hoses are connected correctly to the

machine and that the hydraulic couplings lock as

intended before pressurising the hydraulic system. The

couplings are locked by turning the outer sleeve on the

female coupling so that the slot moves away from the

ball.

• Keep the hydraulic hoses and couplings free from dirt.

• Always switch off the power to the hydraulic unit before

moving the equipment.

• Always saw in a manner that permits easy access to

the emergency stop.

• Never leave the machine unsupervised with the engine

running.

• Clearly mark out all cuts to be made before you start

sawing, plan these so they can be carried out without

danger to persons or the machine.

• Check with the construction drawings whether there

are electrical cables, water mains, gas pipes or

drainage pipes within the working area.

• Always check and mark out where gas pipes are

routed. Cutting close to gas pipes always entails

danger. Make sure that sparks are not caused when

cutting in view of the risk of explosion. Remain

concentrated and focused on the task. Carelessness

can result in serious personal injury or death.

• Check that electrical cables within the working area are

not live.

• Hoses that are marked and approved as electrically

non conductive must be used when using hydraulic

tools on or in the vicinity of electrical cables. The use of

other types of hoses can result in serious physical

injury or even death.

• Observe care when lifting. You are handling heavy

parts, which implies the risk of pinch injuries or other

injuries.