14

© Dinel, s.r.o. DLM–35

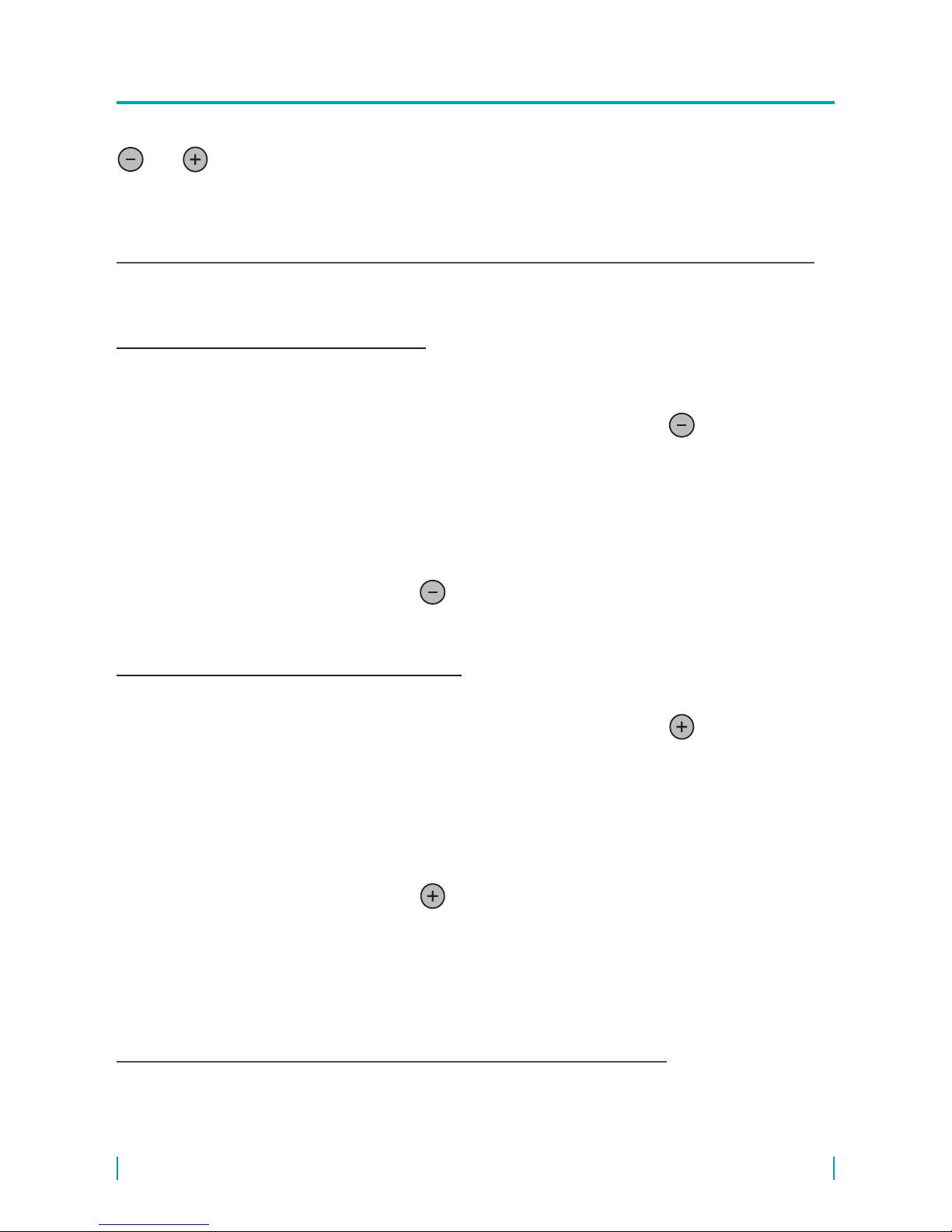

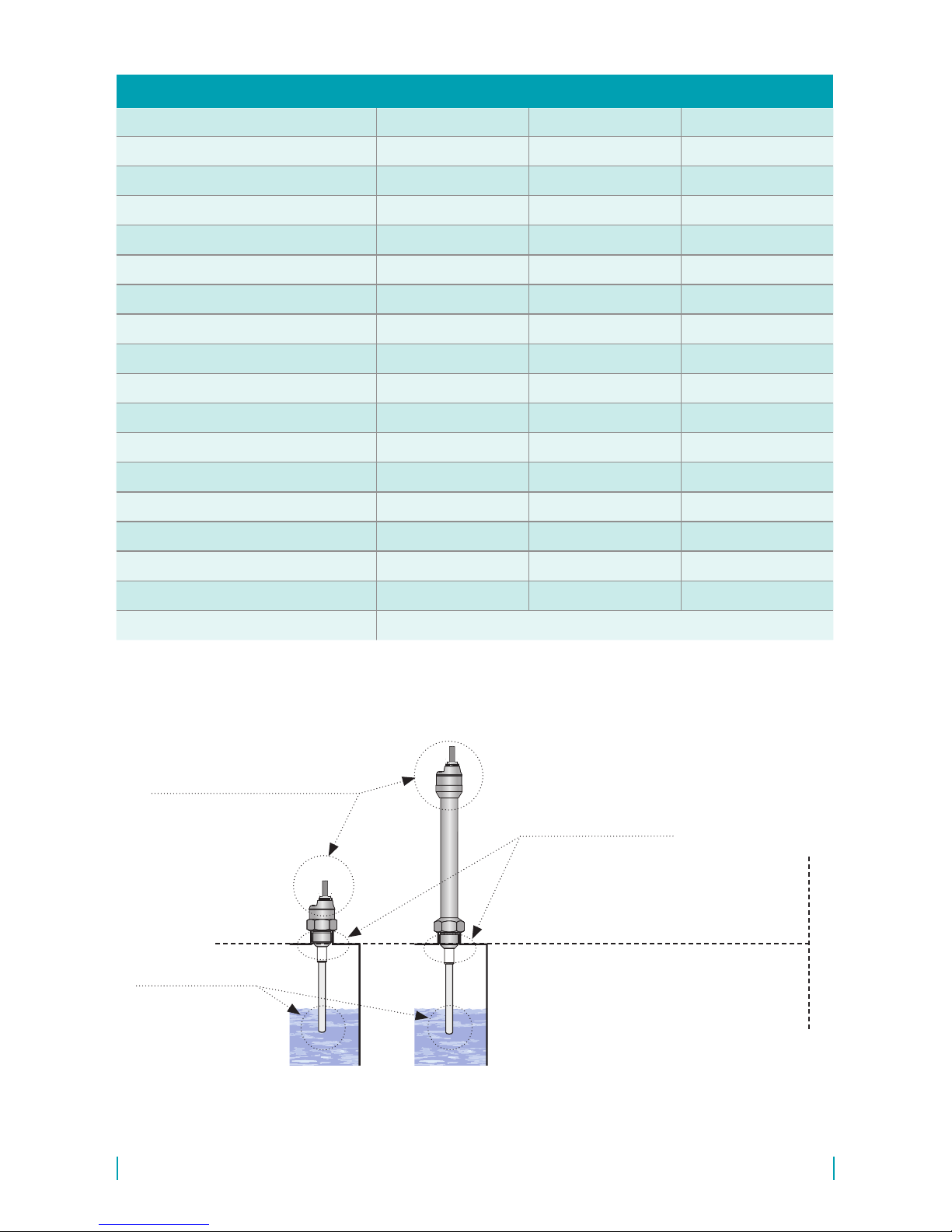

optional – for a surcharge

(see catalogue sheet of accessories)

• cable (over the standard length 2m)

• connector socket (type ELWIKA or ELKA)

• normal steel welding ange or stainless steel

welding ange

• protective hose (for type of cable outlet H)

• stainless steel xing nut

• various types of seals (PTFE, Al, etc.)

standard – included in the level sensor price

• 1 pcs. magnetic pen MP-8

• 1 pcs. seal (asbestos free) *

The level sensor is equipped with protection against electric shock on the electrode, reverse polarity,

output current overload, short circuit and against current overload on output.

Protection against dangerous contact is provided by low safety voltage according to EN

33 2000- 4- 41. Electromagnetic compatibility is provided by conformity with standards EN 55022 / B,

EN 61326-1, EN 61000-4-2 to -8.

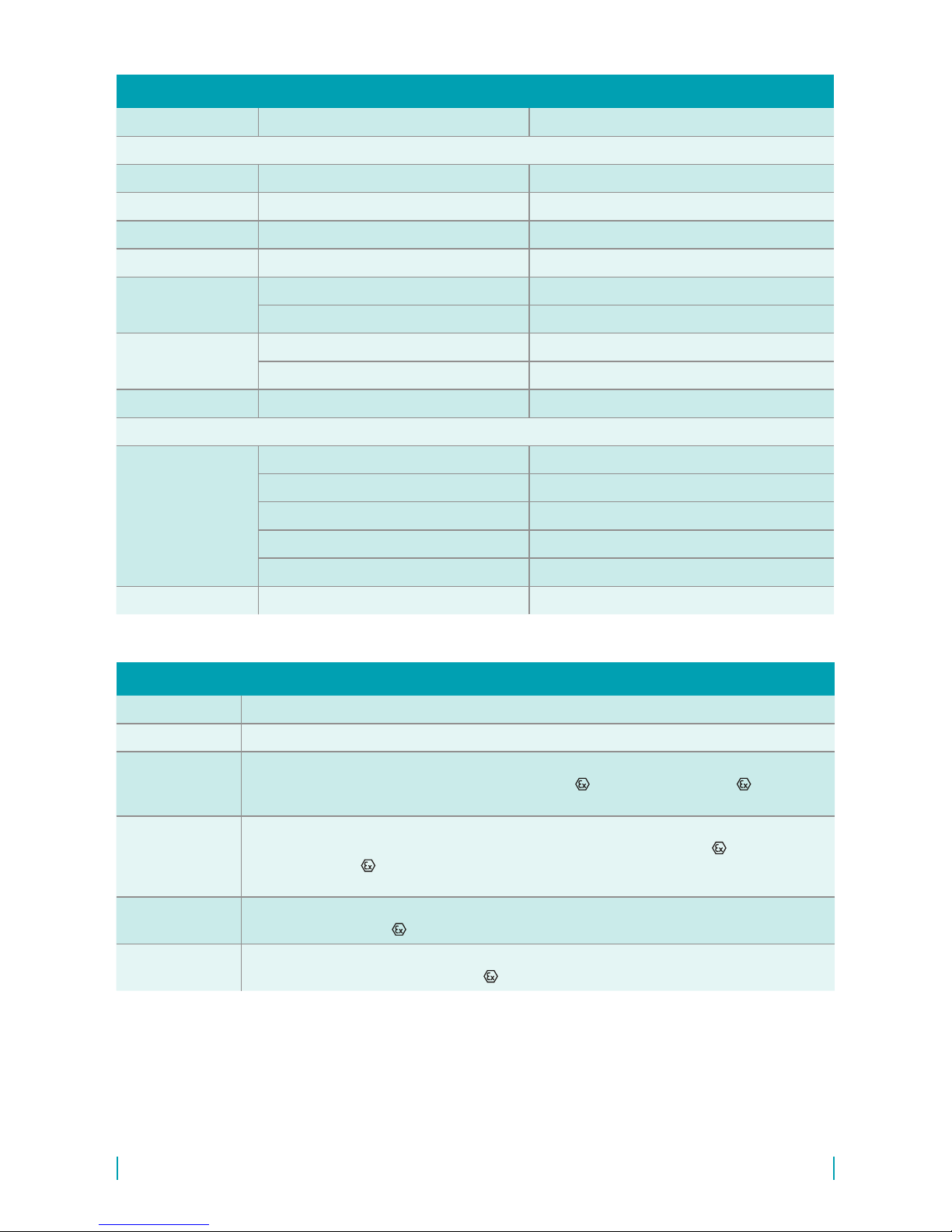

Explosion proof DLM–35Xi (XiT, XiM, XiMT) is provided by conformity with standards EN 60079-0,

EN 60079-11, EN 60079-26.

Explosion proof DLM–35Xi (XiT, XiM, XiMT) is veried FTZÚ – AO 210 Ostrava – Radvanice:

FTZÚ 16 ATEX 0140X.

A declaration of conformity was issued for this device in the wording of Act No. 90/2016 Coll., as

amended. Supplied electrical equipment matches the requirements of valid European directives for

safety and electromagnetic compatibility.

Level meters DLM-35Xi(XiT, XiM, XiMT) are intended for connection to approved spark-safe power

supply unit circuits (of insulating transducers) with galvanic separation. In the event that devices

without galvanic separation are used (Zener barriers), it is necessary to balance the potential

between the sensor, resp. level meter and the barrier grounding location.

The limit output parameters of spark-safe units (insulating transducers) must correspond to the limit

input parameters of the level meter. When assessing spark-free safety of circuits, it is necessary

to also take into consideration the parameters of the connected cable (namely its induction and

capacity).

The DLM-35Xi conguration may be located in zone 0 or zone 20. With the DLM-35XiT conguration

it is only possible to located the electrode part in zone 0 and in zone 20, and then the head with the

electronics in zone 1 or zone 21.

Ambient temperature: Tamb = -40°C to +75°C.

The temperature of the measured material according to the variant conguration, see chapter

"Technical parameters". The maximum temperature of the electrodes equals the temperature of the

measured material.

Variant DLM–35XiMT it is necessary to observe that temperature of any surface of apparatus,

when coal dust can from a layer, do not exceed 150°C.

* Pressure resistance - see the table in

the accessories datasheet in the "seals

and gaskets".