Dinel ULM - 54 User manual

Read carefully the instructions published in this manual before the rst use of the level meter. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice.

INSTRUCTION MANUAL

ULTRASONIC LEVEL METER ULM – 54

Firmware: v.3.0

1. Basic description .......................................................................................................................4

2. Range of application ................................................................................................................4

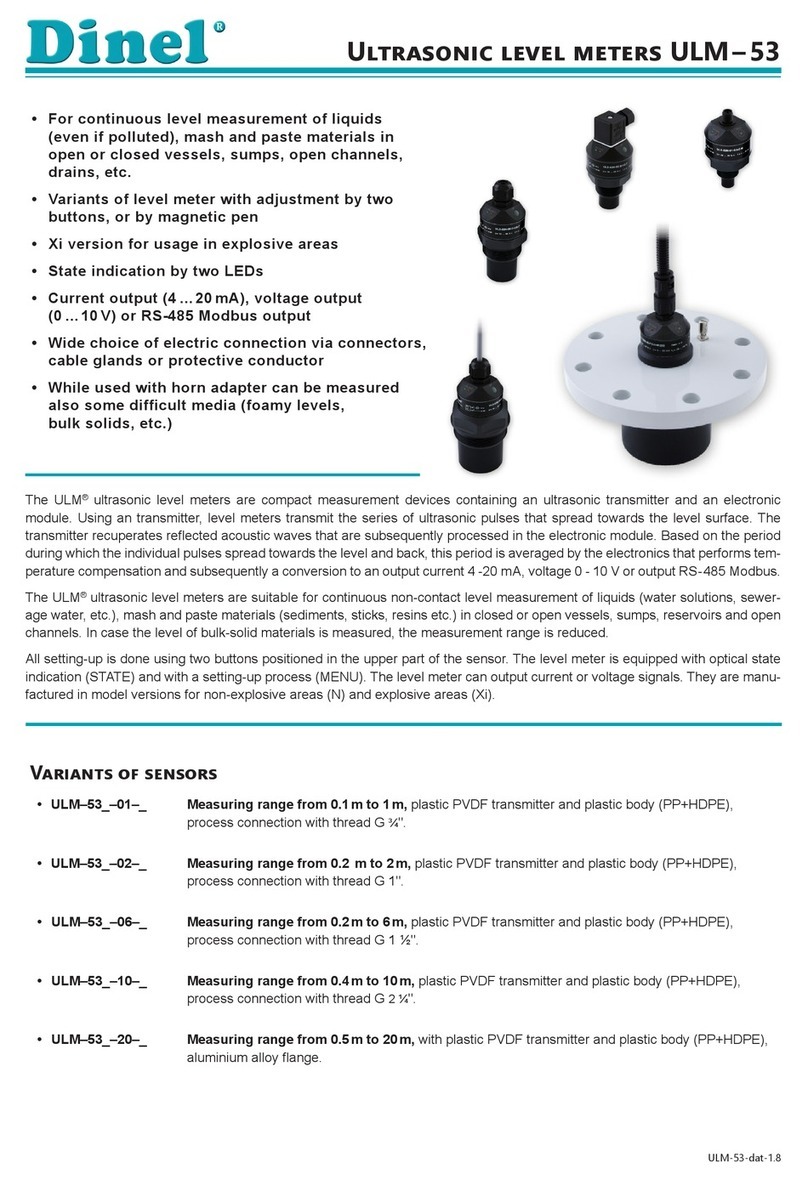

3. Variants of sensors ...................................................................................................................5

4. Dimensional drawings .............................................................................................................5

5. Installation and putting into operation ............................................................................... 6

6. Mechanical mounting...............................................................................................................6

7. Electrical connection .............................................................................................................. 11

8. Connection examples ULM-54 ..............................................................................................12

8.1. Connection diagram of ULM-54 with UHC-01 converter............................................12

8.2. Connection diagram of ULM-54 with the PCU ...........................................................15

8.3. Connection diagram of ULM-54 to the PDU......................................................................... 16

8.4. Connection diagram of ULM-54 to the MGU..............................................................16

9. Setting ........................................................................................................................................15

9.1. Parametrization of connected level meter ULM-54

using PCU-100-H with the HART®protocol.............................................................................17

9.2. Parameterization of ULM-54 using HART®protocol with UHC-01 communicator 24

10. Function and status indication ............................................................................................25

11. Order code.................................................................................................................................26

12. Accessories ...............................................................................................................................27

13. Safety, protection and compatibility .................................................................................27

14. Use, operation and maintenance ........................................................................................28

15. Marking of labels .....................................................................................................................28

16. Technicalspecications ........................................................................................................29

17. Packing, shipping and storage..............................................................................................30

ULM–54 © Dinel, s.r.o.

4

The ULM-54 ultrasonic level meters are compact measurement devices including an elec-

troacoustics converter, central processor unit and display module. Using the electro acoustics

converter, the level meters transmit the sequence of ultrasonic pulses that propagate towards

the level. The converter receives reected acoustic waves that are subsequently processed in

the electronic module. The intelligent evaluation block lters out interfering signals, compares

the cleaned received signal with the false reection map (e.g. from mixers, ladders, reinforce-

ment etc.) and selects a suitable reection (echo). Based on the period during which the indi-

vidual pulses propagate towards the level and back and based on the measured temperature

in the tank, the instant distance to the level is calculated. According to the level height, the

level meter output is set: current 4 -20 mA with HART® protocol.

The level meters are suited to level measurement of various liquid materials, sewerage wa-

ters, mash and paste materials, suspensions in closed or open vessels, sumps, reservoirs and

open channels. In case the level of bulk solids is measured, the measurement range is re-

duced. We recommend to consult the use with the manufacturer.

Impossible use for strongly evaporating media, organic solventy or powders.

To ensure maximum safety of control processes, we have dened the following safety instructions

and information. Each instruction is labelled with the appropriate pictogram.

Alert, warning, danger

This symbol informs you about particularly important instructions for installation and operation of

equipment or dangerous situations that may occur during the installation and operation. Not observing

these instructions may cause disturbance, damage or destruction of equipment or may cause injury.

Information

This symbol indicates particularly important characteristics of the device.

Note

This symbol indicates helpful additional information.

Alloperations describedin thisinstruction manualhave tobe carriedout bytrained personnel

or by an accredited person only. Warranty and post warranty service must be exclusively

carried out by the manufacturer.

Improper use, installation or set-up of the sensor can lead to crashes in the application.

The manufacturer is not responsible for improper use, loss of work caused by either direct

or indirect damage, and for expenses incurred at the time of installation or during the period

of use of the level sensors.

5

© Dinel, s.r.o. ULM–54

Variant "H" with outlet

for protective conductor

Variant "B"with short

cable terminal PG11

ULM-54N_-02 ULM-54N_-06 ULM-54N_-10

18

39

97 20 26

143

25

G1

55

46

G1

o-ring

38

G1 1/2

30

53

108 20 26

154

55

G1

o-ring

56

G2 1/4

42

65

129 20 26

175

65

G1

o-ring

VARIANTS

code measuring range description

ULM–54N–02 od 0,15 m do 2 m all-plastic performance, PVDF emitter, process connection via

G 1” screwing (upper or lower threads)

ULM–54N–06 od 0,25 m do 6 m all-plastic performance, PVDF emitter, process connection via

lower G 1½” or upper G 1” screwing

ULM–54N–10 od 0,4 m do 10 m

all-plastic performance, PVDF emitter, process connection via

lower G 2¼” or upper G 1” screwing. Plastic ange connection

can also be selected from the accessories menu.

ULM–54 © Dinel, s.r.o.

6

• The level meter is installed in a vertical posi-

tion on the console or into the upper lid of the

tank or reservoir using a lug, a fastening nut or

a ange in such a way that the axis of the device

is perpendicular to the level of the measured

liquid (Fig. 1b). The level meter shall be installed

in places with no risk of mechanical damage to

the front of the sensor.

Fig. 1b: Recommended

installation of the ULM-54

level meter in the tank using

the bottom thread

Fig. 1a: Recommended installation

level meter ULM-54 on the console

Fig. 1c: Recommended installation

of the ULM-54 level meter in the tank

via the upper thread

Please follow next 4 steps:

• Mechanical mounting - see chapter 6

• Electrical connection - see chapter 7

• Settings - see chapter 9

7

© Dinel, s.r.o. ULM–54

m – dead zone

c – maximum reach

of the device

d – distance from

tank wall

ULM–54–02; 10 d > 1/12 c (min. 200 mm)

ULM–54–06 d > 1/8 c (min. 200 mm)

• The minimum distance when you are install-

ing level meter into the lid or the ceiling of the

tank are listed in Fig. 2.

Fig. 3: Dead zone of the device

Fig. 4: Installation in the channel

Fig. 2: Distance of the device from the tank wall

starting point for

the measurement

the installation must be in

the middle of the channel

• When mounting in drains, the perpendicular-

ity of the level meter axis to the measured level

must be strictly observed and it is also recom-

mended to install the level meter in the center

of the drain so that the level meter is as far away

from both edges of the drain as possible. Fur-

thermore, it is necessary to choose the instal-

lation location so that at the maximum possible

level, this level does not interfere with the dead

zone of the level meter. If the situation allows,

it is recommended to install the level meter in

a quiet part of the drain, where the level does

not clear.

a – neck height from source edge

b – neck width

m – dead zone

• Only if the maximum level in the tank gets into the dead zone, the device shall be mounted

into a higher installation neck. The tank can be then lled nearly up to the maximum vol-

ume. The neck’s inner level shall be even and smooth (without edges and welded joints),

the inner edge should be rounded in the spot where the ultrasonic wave leaves the pipe.

Choose the largest possible neck diameter, but keep the neck height as low as possible.

The recommended dimensions of the inlet neck are listed in Fig. 5.

ULM–70–02; 06 a < 3 b

b > 100 mm

ULM–70–10 a < 1,5 b

b > 100 mm

Fig. 5: Installation of the level meter

in the installation neck

ULM–54 © Dinel, s.r.o.

8

• If the emitted acoustic signal of the level meter is aected by nearby objects (edges of

drains and channels, unevenness on the tank walls, various partitions, stirrers, etc.), it is

necessary to create a map of false reections by activating the "LEARNING" mode. In the

case of installed stirrers, it is necessar y to move the stirrers to the position below the level

meter (direct the stirrer blade to the place of the ultrasonic signal), see Fig. 6 and 7.

Fig. 6: False reection

from barrier

Fig. 7: False reection

from mixer blades

• Do not install the device in or above the lling point (Fig. 8). The measurement could be

aected by the inowing medium.

Obr. 8: Installation of the device out of reach of lling circulation

9

© Dinel, s.r.o. ULM–54

• In case the level of bulk solids is measured, the measurement range is reduced due

to absorption of acoustic waves by a bulk medium, shortening of the measuring range

occurs by up to 50% depending on the grain size. We therefore recommend selecting a

level meter with greater range than the maximum range of measuring the medium. It is

also appropriate to use a directional horn (see image 8), which reduces the shortening of

the measuring range, because it better concentrates acoustic energy while preserving

the same beam angle, and improves the sensitivity when receiving the reected echo.

We recommend to consult the use with the manufacturer.

• The ultrasonic signal can be scattered or at-

tenuated if the level is moderately stirred or

rippled (due to a mixer, inow of liquid, etc.).

This may result in reduction of the measure-

ment range or unreliable operation of the device

(Fig. 10).

• False level reections of the ultrasonic sig-

nal and unreliable operation of the de-

vice might result from the mixer’s rotat-

ing blades that ripple the level (Fig. 10).

For a rippled or swirling level, you can use

the directional horn to eliminate scattering

of the ultrasonic signal.

• Foam may be produced on the level of the meas-

ured liquid during lling, mixing and other pro-

cesses. The thick foam signicantly absorbs the

ultrasound signal and may cause malfunction of

the device (Fig. 9). In those cases it is necessary

to set "SENSITIVITY" to the value "HIGH" and test

the level meter in advance, or contact the manu-

facturer. In case of a thin layer of foam, it is also

possible to use directional horn for improving re-

ceipt of the reected echo.

Fig. 9: Thick foam on the level

Fig. 10: wavy level

ULM–54 © Dinel, s.r.o.

10

• If the level sensor is mounted to

bottlenecks and places with bar-

riers, or near uneven walls or the

lling area, where the transmis-

sion signal could be distorted, we

recommend using a guide tube

(acoustic horn). The tube must be

made from a single material with

a smooth inner surface (see im-

age 12a, 12b ). The minimum tube

diameter must have the dimen-

sion "b" according to image 4 on

page 5. After installing, you must

perform the procedure "LEARN-

ING". We recommend consult-

ing with the manufacture on

the construction of the guide

tube.

Fig. 11b: Total guide tube

installation

ventilation

holes

Fig. 11a: Short guide tube

installation

sleeves for

mounting

• The measuring device shall not be installed in places with direct sunlight and shall be

protected against weather conditions. If installation in places with direct sunlight is inevi-

table, it is necessary to mount a shielding cover above the device (Fig. 12).

• It is advisable to keep cable under the cable gland (sagging down) as shown in Fig. 13 to

prevent penetration of moisture. Rain and condensing water can be therefore drained

away freely.

• The cable gland as well as the connector shall be tightenedsuciently to prevent pen-

etration of moisture.

Fig. 12: Shielding cover against

direct sunlight

Fig. 13: Protection against

penetration of moisture

ULM–54–02 h ≥ 70 mm

ULM–54–06 h ≥ 100 mm

ULM–54–10 h ≥ 150 mm

11

© Dinel, s.r.o. ULM–54

Wiring operations shall only be carried out without voltage!

The supply source should be preferably designed as a stabilized source of safe

voltage with galvanic separation. If a switching power supply is used, its design must

eectively suppress common mode interference. If the switching power supply is

equipped with a PE protective terminal, it must be earthed!

If the sensor is located outdoors at a distance of more than 20 m from an outdoor

switchboard or from an enclosed building, the electrical supply to the sensor must

be supplemented with suitable over voltage protection.

In case of strong ambient electromagnetic interference, concurrence of the supply

cable with the power line, or its length greater than 30 m, we recommend grounding

the level meter (see above) and using a shielded cable. Ground the cable shield on

the side of the power supply.

Connection diagram

Performance „B“ with

short cable gland

Performance „H“ with cable gland

for protective hose

ULM-54 level meters with cable gland type B or H are equiped by 5m PVC cable (standard) for

connection to evaluation (display) units by PVC cable 5 m long. Standard glands M16 x 1.5 (B) or

protection glands (H). The connection diagram is shown in the gure.

The positive supply pole +U is con-

nected to the brown wire, the nega-

tive pole is connected to the blue

wire.

ULM–54 © Dinel, s.r.o.

12

The following sections show all possible connection variants. All gures show the output side of

the converter towards the level meter, including communication LEDs and a switch for switching

the communication HART resistor on or o.

8 .1 . CONNECTION DIAGRAM OF ULM-54 WITH UHC-01 CONVERTER

Connection of ULM-54 powered by an internal source when using an internal communica-

tion HART resistor 250 Ω

This connection is used in case of connection of one level meter where no power supply is avail-

able or is not required and at the same time there is no communication HART resistor in the cur-

rent loop. The switch is set to the ON position (highlighted in green).

Obr. 14: Connection of a level meter which is powered by an internal source

when using an internal communication HART resistor 250 Ω

A) Examples of connection to devices with current input 4 - 20 mA with the pos-

sibility of parameterization of ultrasonic level meter ULM-54 via HART commu-

nication protocol

Parameterization is performed using UniScada Dinel software, which must be installed on the

PC. The connection of the UHC-01 converter to a PC is typically made with a standard USB-A

<-> USB-B cable.

13

© Dinel, s.r.o. ULM–54

Connection of ULM-54 powered by an internal source when using an external

communication HART resistor 250 Ω

This connection is used in the case of connecting one level meter where no power supply is

available or is not required and at the same time there is a communication HART resistor in

the current loop. The switch is set to OFF (highlighted in green).

Obr. 15: Connection of a level meter which is powered by an internal source

when using an external communication HART resistor 250 Ω

Connection of ULM-54 powered by an external source when using an internal communica-

tion HART resistor 250 Ω

This connection is used in the case of connecting one level meter where the use of an exter-

nal power supply is required and at the same time there is no communication HART resistor

in the current loop. The switch is set to the ON position (highlighted in green). The external

power supply is marked as U in the connection.

Obr. 16: Connection of a level meter which is powered by an external source

when using an internal communication HART resistor 250 Ω

ULM–54 © Dinel, s.r.o.

14

Obr. 18: UHC-01 converter connection options

UniScada Dinel

software

Universal data convertor

UHC-01

4 ... 20 mA

HART®

4 ... 20 mA

HART®

4 ... 20 mA

HART®

USB

Ultrasonic

level meter

ULM-54

Capacitive

level meter

CLM-70

Ultrasonic

level meter

ULM-70

Radar

level meter

GRLM-70

Connection of ULM-54 by the internal source when using the internal communication

HART resistor 250Ω

This connection is used in the case of connecting one level meter where a power supply is not

available or is not required and at the same time there is no communication HART resistor in the

current loop. The switch is set to the ON position (highlighted in green).

Obr. 17: Connecting a level meter powered by an internal source when using

an internal communication HART resistor 250Ω

15

© Dinel, s.r.o. ULM–54

8 .2 . CONNECTION DIAGRAM OF ULM-54 WITH THE PCU

I input

Parameterization is performed directly from the PCU menu (see chapter 9 Level meter settings)

or using the UniScada Dinel software, which must be installed on the PC. The PCU is connected

to the PC with a standard USB-A <-> USB-B cable.

Obr. 19: Connecting multiple level meters to the PCU-100

ULM–54 © Dinel, s.r.o.

16

PDU-420-W

(input 4 ... 20 mA )

(0V) –

ULM-54N-_ _-_-I

User manual - METER PDU-4xx-P

Figure 4.7. Terminals description (relay outputs, device with current output)

Figure 4.8. Terminals description (OC-type outputs)

Figure 4.9. Connection of 2-wire current converters

11

1 2 5 6 7 8 9

GND DATA+

DATA-

RS - 485

+ Uo -

+24V +5%, -10%

Imax = 100mA

10 11 12 13 14 15

R1

3 4

optional ACTIVE

current output

- +

R2

n.c. n.c. n.c.

n.c.

GND

0/1 - 5V, 0/2 - 10V

0/4-20mA

++

(optional) (optional)

Power

supply

(depending on version)

16

31

17

32

18

33

19

34

20

35

1 2 5 6 7 8 9

GND DATA+

DATA-

RS - 485

+ Uo -

+24V +5%, -10%

Imax = 100mA

10 11 12 13 14 15

3 4

OC1 OC2

- + + -

OC1 ÷ OC4: Umax = 30V DC,

Imax = 30mA, Pmax = 100mW

+ -

- +

OC3

OC4

(optional)

(optional)

n.c.

n.c.

GND

0/1 - 5V, 0/2 - 10V

0/4-20mA

++

(optional)

(optional)

Power

supply

(depending on version)

16

31

17

32

18

33

19

34

20

35

5 6 24V DC

- +

+ -

+

-

+

-

internally connected

16

31

17

32

18

33

19

34

20

35

16

31

17

32

18

33

19

34

20

35

ULM-54N-_ _-_-I

internally connected

PDU-4xx-P

(input 4 ... 20 mA )

(+U) +(+U) +(0V) –

User manual - METER SRP-N118

a) b)

Figure 4.2. Recommended dimensions of cable stripping

a) for big connectors (1 to 6), b) for small connectors (7 to 13, 15 to 17)

Figure 4.3. Method of connecting cables to the clamping connectors

All connections must be made while power supply is disconnected !

Figure 4.4. Terminals description (relay outputs)

9

!

+ Uo -

n.c.

R1 R2

GND

0/1 - 5V

0/2 - 10V

0/4 - 20mA

+

+

GND

GND

DATA+

151617 12 11 10 9 8 71314 1

2

3

4

5

6

DATA-

RS - 485

(option) (option)

Power supply

(depending

on version)

24V (+5%, -10%)

Imax = 100 mA

PE

n.c.

5 mm

max. 1.6 mm

6 mm

max. 2 mm

internally connected

User manual - METER SRP-N118

a) b)

Figure 4.2. Recommended dimensions of cable stripping

a) for big connectors (1 to 6), b) for small connectors (7 to 13, 15 to 17)

Figure 4.3. Method of connecting cables to the clamping connectors

All connections must be made while power supply is disconnected !

Figure 4.4. Terminals description (relay outputs)

9

!

+ Uo -

n.c.

R1 R2

GND

0/1 - 5V

0/2 - 10V

0/4 - 20mA

+

+

GND

GND

DATA+

151617

12 11 10 9 8 713

14 1

2

3

4

5

6

DATA-

RS - 485

(option) (option)

Power supply

(depending

on version)

24V (+5%, -10%)

Imax = 100 mA

PE

n.c.

5 mm

max. 1.6 mm

6 mm

max. 2 mm

18

39

97 20 26

143

25

G1

55

46

G1

o-kroužek

18

39

97 20 26

143

25

G1

55

46

G1

o-kroužek

8 .3 . CONNECTION DIAGRAM OF ULM-54 TO THE PDU

The PDU-420-W connection is valid for rmware version 6.00 or higher. For older

versions (up to version 5.99), the level meter output + U is connected to terminal

7 and the 0 V output to terminal 10.

(+U) +

(0 V) –

ULM-54N-_ _-_-I

MGU-800

(with module IUI4)

8 .4 . CONNECTION DIAGRAM OF ULM-54 TO THE MGU

18

39

97 20 26

143

25

G1

55

46

G1

o-kroužek

B) Examples of connection to devices with current input 4 - 20 mA without the

possibility of parameterization of ultrasonic level meter ULM-54

17

© Dinel, s.r.o. ULM–54

9. SETTING

9.1. Parametrization of connected level meter ULM-54 using

PCU-100-H with the HART®protocol

The unit in PCU-100-H version makes it possible to communicate with measuring devices / level

meters using the HART® protocol. HART® (Highway Addressable Remote Transducer) is a com-

munication protocol used for setting up, reading measured data, and measuring device diagnos-

tics. Communication proceeds via a 4–20 mA current loop and no additional wires are required.

The unit allows communication via the HART® protocol with ULM-54, ULM-70, GRLM-70, and

CLM-70 level meters from Dinel s.r.o. It also allows you to communicate with third-party meas-

uring devices that comply with the HART® Protocol Revision 5 to 7 as dened in the protocol

standard.

The menu for communication with the measuring probe using the HART®protocol is accessible

only after successful connection to this device.

If the display shows 'DEVICE SEARCH', periodic attempts are made to establish communication

with the measuring device.

Fig. 16: PCU-100 connection diagram

UniScada Dinel

software

Programmable

control unit

PCU-100

USB

GSM

Internet

4 ... 20 mA

HART®

Ultrasonic

level meter

ULM-54

DinelCloud

web interface

ULM–54 © Dinel, s.r.o.

18

The value of the measured magnitude at which the level meter output will be at the minimum

(4 mA) is entered here.

For level meter ULM-54 using the reex method se the data is entered in millimeters and repre-

sents the distance of the level from the front of the ultrasonic transducer. The value is always a

oating-point decimal number.

This part of the menu is intended only for setting the ULM-54, ULM-70, GRLM-70, and CLM-70

level meters from Dinel, s.r.o. It is not displayed when a dierent device is connected. The basic

settings for these probes can also be carried out in the BASIC PARAMETRIZATION. In the men-

tioned menu, however, it is possible to set, in addition to the basic parameters, also some other

parameters that are specic for the mentioned devices.

• Menu: (ID 072)

• [↔] - Movement between characters, [↕] - Increase in the value of the marked digit

(at marked decimal point, a shift by one order occurs)

008

CONFIGURATION

069

BASIC SETUP

057

HART

072

MIN LEVEL

059

DINEL DEVICE MENU

The value of the measured magnitude at which the level meter output will be at the maximum

(20 mA) is entered here.

For level meter ULM-54 the value is entered in millimetres and it represents a distance of the level

from the transducer face or from the beginning of the electrode. The value is always a oating

comma number.

• Menu: (ID 073)

• [↔] - Movement between characters, [↕] - Increase in the value of the marked digit

(at marked decimal point, a shift by one order occurs)

008

CONFIGURATION

069

BASIC SETUP

057

HART

073

MAX LEVEL

059

DINEL DEVICE MENU

19

© Dinel, s.r.o. ULM–54

• mm – distance in millimetres

• cm – distance in centimetres

• m – distance in meters

• in – distance in inches

• ft – distance in feet

• pf - distance in picofarad

• Menu: UNITS (I D 074)

• [↕] - Changing the unit

008

CONFIGURATION

069

BASIC SETUP

057

HART

074

UNITS

059

DINEL DEVICE MENU

Setting of measurement response rate. It is useful to use the function for the suppression of

uctuations on the display at fast and jump changes in the level (whirling level). The subsequent

reaction time will depend on the exponential curve. Damping with dened delay in seconds indi-

cates the time that the exponential curve reaches 2/3 of its maximum value. The value is always

a oating comma number.

• Menu: DAMPING (ID 075)

• [↔] - Movement between characters, [↕] - Increase in the value of the marked digit

(at marked decimal point, a shift by one order occurs)

008

CONFIGURATION

069

BASIC SETUP

057

HART

075

DAMPING

059

DINEL DEVICE MENU

This function restarts the measuring device. The option must be conrmed with “YES”.

• Menu: RESET (ID 083)

• [↔] - Change of the YES / NO option

008

CONFIGURATION

070

SERVIS

057

HART

083

RESET

059

DINEL DEVICE MENU

ULM–54 © Dinel, s.r.o.

20

The setting denes the sensitivity of the ULM-54 level meters in three steps:

• "LOW" - reduced sensitivity in case of ambient interference aecting the measurement.

• "MEDIUM" - medium sensitivity (suitable for most applications)

• "HIGH" - increased sensitivity for media partially absorbing the ultrasonic signal (bulk ma-

terials, foam).

The type and contents of supported messages depend on the connected device.

Preset sensor sensitivity levels are LOW (1), MEDIUM (3), and HIGH (5). To change the sensor

sensitivity, select the appropriate item and conrm it.

• Menu: MESSAGE (ID 068)

• [↔] - Movement between characters, [↕] - Character change

008

CONFIGURATION

057

HART

069

BASIC SETUP

068

MESSAGE

• Menu: SENSITIVITY (ID 076)

• [↕] - Sensitivity change

008

CONFIGURATION

069

BASIC SETUP

057

HART

076

SENSITIVITY

059

DINEL DEVICE MENU

Table of contents

Other Dinel Measuring Instrument manuals

Dinel

Dinel PDU-40-W Series User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel DLM-35 User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel CLM-70 User manual

Dinel

Dinel CLM-36-10 User manual

Dinel

Dinel ULM-53 series User manual

Popular Measuring Instrument manuals by other brands

Keysight Technologies

Keysight Technologies U3810A Getting started guide

Olympus

Olympus 27MG Getting started guide

Keysight

Keysight 11644A R manual

InclusiveEnergy

InclusiveEnergy Smart Biogas installation manual

GREER Company

GREER Company Microguard 414 Operator's manual

CONDTROL

CONDTROL Beton user manual