UL_–53 © Dinel, s.r.o.

13

It is also necessary to design and take measures to reduce the effects of static electricity to

a safe level in the wiring.

Installation in explosive atmospheres needs to be carried out in compliance with EN 60079-14

(Electrical installations for explosive gaseous atmospheres – Part 14: Electrical installations

in dangerous areas other than mining) and possibly also in compliance with other standards

relating to the area concerned.

Type ULM–53_–_ _–_–U–B(H)–_

The positive supply pole +U is connected to the

brown wire of the connected cable, the negative

pole is connected to the blue wire of the connect-

ed cable. Output voltage is connected to the black

wire of the cable.

Type ULM–53_–_ _–_–M–B(H)–_

Level meters are designed for connection to the

PLC input (RS–485). The positive supply pole +U

is connected to the brown wire of the connected

cable, the negative pole is connected to the blue

wire of the connected cable. Terminals A and B

of line RS-485 are connected to the yellow and

green communication wires. The ground terminal

of line RS-485 is connected to cable shielding.

Type ULS–53_–_ _–_–S–B(H)–_

The positive supply pole +U is connected to the

brown wire of the connected cable, the negative

pole is connected to the blue wire of the connect-

ed cable.

Type ULS–53_–_ _–_–P–B(H)–_

The positive supply pole +U is connected to the

brown wire of the connected cable, the negative

pole is connected to the blue wire of the connect-

ed cable. Load is connected to the black wire of

the cable.

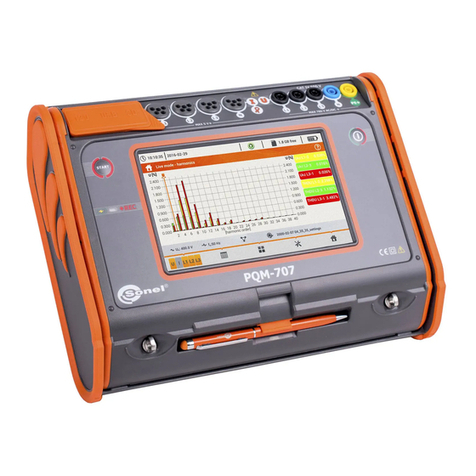

Fig. 26: Connection diagram of the ULM level

meter with a voltage output (variant –U)

Fig. 27: Connection diagram of the level meter

with an RS–485 output (variant –M)

Fig. 28: Connection diagram of the ULS sensor

with S type output (two-state current switch 4

mA / 20 mA)

BN ()1

BU ()2

mA +U

0V

V

+U

0V

U

Uout

V

+U

0V

U

Uout

mA +U

0V

+U

0V

BN (1)

BU (2)

BK (3)

+U

0V

BN (1)

BU (3)

BK (4)

BN ()1

BU (3)

BN ()1

BU ()2

BK (3)

BN ()1

BU (3)

BK (4)

BN ()1

BU ()2

mA +U

0V

mA +U

0V

BN ()1

BU (3)

Fig. 29: Connection diagram of the ULS sensor

with P type output (PNP) with an open collector

+U

0V

BN (1)

BU (2)

BK (3)

legend:

BK – black WH – white

BU – blue YE – yellow

BN – brown GN – green

Wiring operations shall only be carried out without voltage!

Taking into account the potential occurrence of electrostatic discharge on non-conducting

parts of the level meter, it is necessary to ground the ange of level meters ULM–53Xi–20–F

and sensors ULS–53Xi–20–F, located in an explosive atmosphere, using a ground terminal!

The supply source should be preferably designed as a stabilized source of safe voltage 18 V

to 36 VDC (max. 30 V DCfor version Xi),which is part ofthe downstream processing or displaysystem.

In case of strong ambient electromagnetic disturbance, parallel run of the input cable with the power

line or its length exceeding 30 m, we recommend using a shielded cable.