Dinel ULM-53 series User manual

Ultrasonic level meters ULM – 53

ULM-53-dat-1.8

průmyslová elektronika

• For continuous level measurement of liquids

(even if polluted), mash and paste materials in

open or closed vessels, sumps, open channels,

drains, etc.

• Variants of level meter with adjustment by two

buttons, or by magnetic pen

• Xi version for usage in explosive areas

• State indication by two LEDs

•Current output (4 ... 20 mA), voltage output

(0 ... 10 V) or RS-485 Modbus output

•Wide choice of electric connection via connectors,

cable glands or protective conductor

•While used with horn adapter can be measured

also some difficult media (foamy levels,

bulk solids, etc.)

• ULM–53_–01–_ Measuring range from 0.1m to 1 m, plastic PVDF transmitter and plastic body (PP+HDPE),

process connection with thread G ¾".

• ULM–53_–02–_ Measuring range from 0.2 m to 2 m, plastic PVDF transmitter and plastic body (PP+HDPE),

process connection with thread G 1".

• ULM–53_–06–_ Measuring range from 0.2 m to 6 m, plastic PVDF transmitter and plastic body (PP+HDPE),

process connection with thread G 1 ½".

• ULM–53_–10–_ Measuring range from 0.4 m to 10 m, plastic PVDF transmitter and plastic body (PP+HDPE),

process connection with thread G 2 ¼".

• ULM–53_–20–_ Measuring range from 0.5 m to 20 m, with plastic PVDF transmitter and plastic body (PP+HDPE),

aluminium alloy ange.

The ULM® ultrasonic level meters are compact measurement devices containing an ultrasonic transmitter and an electronic

module. Using an transmitter, level meters transmit the series of ultrasonic pulses that spread towards the level surface. The

transmitter recuperates reected acoustic waves that are subsequently processed in the electronic module. Based on the period

during which the individual pulses spread towards the level and back, this period is averaged by the electronics that performs tem-

perature compensation and subsequently a conversion to an output current 4 -20 mA, voltage 0 - 10 V or output RS-485 Modbus.

The ULM®ultrasonic level meters are suitable for continuous non-contact level measurement of liquids (water solutions, sewer-

age water, etc.), mash and paste materials (sediments, sticks, resins etc.) in closed or open vessels, sumps, reservoirs and open

channels. In case the level of bulk-solid materials is measured, the measurement range is reduced.

All setting-up is done using two buttons positioned in the upper part of the sensor. The level meter is equipped with optical state

indication (STATE) and with a setting-up process (MENU). The level meter can output current or voltage signals. They are manu-

factured in model versions for non-explosive areas (N) and explosive areas (Xi).

ULM-53-dat-2.8

ULM – 53_– 01 ULM – 53_– 02 ULM – 53_– 06

ULM – 53_– 20

ground

terminal

Al alloy

ULM – 53_– 10

Variant "G" with connector ISO

Variant "H" with outlet

for protective conductor

Variant "C" with connector M12

Variant "B" with cable outlet PG11

ULM-53-dat-3.8

Measuring range 1)

ULM–53_–01–_

ULM–53_–02–_

ULM–53_–06–_

ULM–53_–10–_

ULM–53_–20–_

0.1 ... 1 m

0.2 ... 2 m

0.2 ... 6 m

0.4 ... 10 m

0.5 ... 20 m

Supply voltage ULM–53N–_ _–_

ULM–53Xi–_ _ –I

18 ... 36 V DC

18 ... 30 V DC

Current supply

ULM–53N(Xi)–_ _ –I

ULM–53N–_ _ –U

ULM–53N–_ _ –M

4 ... 20 mA / max. 22 mA

Max. 12 mA

Max. 20 mA

Current output ULM–53_–_ _ –I

Voltage output ULM–53N–_ _ –U

Modbus output ULM–53N–_ _ –M

4 ... 20 mA (limit values 3.9 ... 20.5 mA)

0 ... 10 V (limit values 0 ... 10.2 V)

Modbus RTU protocol

Resolution < 1 mm

Accuracy

(within the total range)

ULM–53_–01 in area 0,1–0,2 m / 0,2–1,0 m

ULM–53_–02; –06

ULM–53_–10; –20

0,3 % / 0,2 %

0,15 %

0,2 %

Temperature error Max. 0,04% / K

Beamwidth (-3 dB)

ULM–53_–01–_ ; 02–_ ; 10–_

ULM–53_–06–_

ULM–53_–20–_

10°

14°

12°

Ambient temperature range ULM–53_–01–_ ; 02–_ ; 06–_

ULM–53_–10–_ ; 20–_

-30 ... +70°C

-30 ... +60°C

Measuring period

ULM–53_–01–_; 02–_

ULM–53_–06–_; 10–_

ULM–53_–20–_

ULM–53_–_ _–M

0,5 s

1,2 s

5,0 s

adjustable via Modbus RTU

Averaging (can be modied according to agreement) ULM–53_ – _ _–_

ULM–53_–__–M

4 measurement

adjustable via Modbus RTU

Short time temperature stress resistance +90°C / 1 hod.

Max. operation overpressure (on transmission surface) 0,1 MPa

Max. internal values

2) (for the Xi version only) Ui=30V DC; Ii=132mA; Pi=0,99W; Ci=370nF; Li=0,9mH

Failure indication

echo failure – basic mode

echo failure – inverse mode

level in dead zone – basic mode

level in dead zone – inverse mode

3,75 mA (0 V)

22 mA (10,5 V)

22 mA (10,5 V)

3,75 mA (0 V)

Protection class

- UL

M

-53_-__-_-_-_- T

- UL

M

-53_-__-_-_- G-M, L

IP67

- UL

M

-53_-__-_-_- C-M, L

IP67 3)

- UL

M

-53_-__-_-_- B-M, L

- UL

M

-53_-__-_-_- H-M, L

IP68

Recommended cable PVC 2 x 0,75 mm2 (3 x 0,5 mm2)

Maximal current output load resistance at U = 24 V DC

at U = 22 V DC

at U = 20 V DC

Rmax = 270 Ω

Rmax =180 Ω

Rmax = 90 Ω

Minimal voltage output load resistance Rmin > 1 kΩ

Delay between supply

power rise time and rst

measurement

ULM–53_–01–_ ; 02–_ ; 06–_

ULM–53_–10–_; 20–_

5 s

9 s

Process connection

ULM–53_–01–_

ULM–53_–02–_

ULM–53_–06–_

ULM–53_–10–_

ULM–53_–20–_

thread G ¾‘‘

thread G 1‘‘

thread G 1½‘‘

thread G 2¼‘‘

aluminium alloy ange

Weight

ULM–53_–01–_

ULM–53_–02–_

ULM–53_–06–_

ULM–53_–10–_

ULM–53_–20–_

0,20 kg

0,20 kg

0,25 kg

0,65 kg

2,80 kg

1) In case the level of bulk-solid materials is measured, the measurement range is reduced.

2) Allowed pressure range in the zone 0: 80 ... 110 kPa.

ULM-53-dat-4.8

Recommended installation Possible installation through the neck

Level meter installation outside the inuence of lling circulation

Installation distance from the tank wall

c - Maximum reach

of the level meter

d - Minimum distance

from tank wall

a - neck height

b - neck width

m - dead zone

Level meter is installed into the upper lid of the tank (vessel), using a xing nut or a ange.

If installed in an open channel (sumps, reservoirs, etc.), install the level meter as closest as you can to the maximum level expected.

The front of the level meter must run in parallel to the measured level.

Emitted acoustic signal must not be aected by near objects (stieners, ladders, mixers, unevenness, etc.), stream of lling, air

ow, etc.

Foam on the level absorbs the acoustic wave reection which might cause malfunction of the level meter. If possible select the

location where the foaming is as low as possible. Protect the level meter against direct sunlight.

In the case of uncertainty we recommend to consult the application with the producer.

ULM–53–01; 02; 06 a < 3 b

b > 100 mm

ULM–53–10 a < 1,5 b

b > 100 mm

ULM–53–20 a < 1,5 b

b > 150 mm

(according to EN 60079-10 and EN 60079-14)

ULM–53N–_ _–_ Performance for non-explosive areas

ULM–53Xi–01–I

ULM–53Xi–02–I

ULM–53Xi–06–I

Explosive proof – suitable for explosive areas (combustible gases or vapours)

II 1/2G Ex ia IIB T5 Ga/Gb with isolating repeater (IRU–420)

the whole level meter – zone 1, front head part – zone 0

ULM–53Xi–10–I

Explosive proof – suitable for explosive areas (combustible gases or vapours)

II 1/2G Ex ia IIA T5 Ga/Gb with isolating repeater (IRU–420)

the whole level meter – zone 1, front head part – zone 0

ULM–53Xi–20–I

Explosive proof – suitable for explosive areas (combustible gases or vapours)

II 2G Ex ia IIA T5 Gb with isolating repeater (IRU–420)

the whole level meter – zone 1

ULM–53– 01; 02; 10 d > 1/12 c

(min. 200 mm)

ULM–53–06 d > 1/8 c

(min. 200 mm)

ULM–53–20 d > 1/10 c

(min. 200 mm)

ULM-53-dat-5.8

Connection diagram of the ULM level meter (variant –U)

and inside view of the connector

BK – black WH – white

BU – blue YE – yellow

BN – brown GN – green

legend:

0V (bu)

+U (bn)

0V (bu)

+U (bn)

Uout (bk)

The ULM level meter with a G type cable gland are con-

nected to processing (display) units by means of a cable

with an outer diameter of 6 to 8 mm (recommended wire

cross-section 0.5 to 0.75 mm2), via a detachable ISO

connector with inner screw terminals, which is part of the

delivery. The connection diagram and the inner view of the

connector are shown in Figures on the right. Non-detach-

able connector IP67 with PVC cable 5 m long can be sup-

plied as an extra option.

Connection diagram of the ULM level meter (variant –I)

and inside view of the connector

The ULM level meter with a C type cable gland are con-

nected to processing (display) units by means of a cable

with an outer diameter of 4 to 6 mm (recommended wire

cross-section 0.5 to 0.75 mm2), via a connector socket

with a moulded cable (2 or 5 m long) or via a detachable

connector socket without a cable (see accessories). In this

case connect the cable to the inner socket pins under g-

ures on the right.

1

3

4

0 V

+U

BN ()1

BU ()2

mA +U

0V

V

+U

0V

U

Uout

V

+U

0V

U

Uout

mA +U

0V

+U

0V

BN (1)

BU (2)

BK (3)

+U

0V

BN (1)

BU (3)

BK (4)

BN ()1

BU (3)

BN ()1

BU ()2

BK (3)

BN ()1

BU (3)

BK (4)

BN ()1

BU ()2

mA +U

0V

mA +U

0V

BN ()1

BU (3)

1

3

4

0 V

+U

Uout

BN ()1

BU ()2

mA +U

0V

V

+U

0V

U

Uout

V

+U

0V

U

Uout

mA +U

0V

+U

0V

BN (1)

BU (2)

BK (3)

+U

0V

BN (1)

BU (3)

BK (4)

BN ()1

BU (3)

BN ()1

BU ()2

BK (3)

BN ()1

BU (3)

BK (4)

BN ()1

BU ()2

mA +U

0V

mA +U

0V

BN ()1

BU (3)

Connection diagram of the ULM level meter (variant –I)

and inside view of the connector

Connection diagram of the ULM level meter (variant –U)

and inside view of the connector

View of the connector ISO

View of the connector M12

The ULM level meter or ULS sensor with a B or H type cable

gland are connected to processing (display) units by means

of a xed PVC cable 5 m long. PG 11 (B) or plastic bushings

with a thread for protective hoses (H) can be used as a cable

gland. Connection diagrams are shown in Figures on the

right.

Connection diagram of the ULM level meter (variant –I)

and inside view of the connector

Connection diagram of the ULM level meter (variant –U)

and inside view of the connector

Connection diagram of the level meter with an

RS–485 output (variant –M)

View of the cable

gland PG11

View of the cable gland for

protective hose

ULM-53-dat-6.8

The measuring range is setup by means of two buttons "DOWN" and

"UP".The "DOWN" button is used to enter to the setting mode (setting

the 4 mA or 0 V limit) and to decrease the output current or voltage.

The "UP" button as an opposite function (setting the 20 mA or 10 V limit

and increasing the output current or voltage). Values are conrmed

by simultaneous pressing of both buttons for about 1 sec. The setting

process is indicated by yellow "STATE" LED indicator.

For detailed information please read at the instructions manual.

Key parts of the measuring device (version with buttons)

Wiring operations shall only be carried out without voltage!

Taking into account the potential occurrence of electrostatic discharge on non-conducting parts of the level meter, it is necessary to ground

the ange of level meters ULM–53Xi–20–F, located in an explosive atmosphere, using a ground terminal!

The supply source should be preferably designed as a stabilized source of safe voltage 18 V

to 36 V DC (max. 30 V DC for version Xi), which is part of the downstream processing or display system.

In case of strong ambient electromagnetic disturbance, parallel run of the input cable with the power line or its length exceeding 30m, we recommend

using a shielded cable.

It is also necessary to design and take measures to reduce the effects of static electricity to a safe level in the wiring.

Installation in explosive atmospheres needs to be carried out in compliance with ČSN EN 60079-14 (Electrical installations for explosive

gaseous atmospheres – Part 14: Electrical installations in dangerous areas other than mining) and possibly also in compliance with other

standards relating to the area concerned.

DOWN button

UP button

LED indicator “STATE”

LED indicator “RUN”

connector

Ultrasonic transmitter

locking screw

The measuring range is setup by touching of the magnetic pen to

sensitive spots "EMPTY" and "FULL" . The "EMPTY" spot is used to

enter to the setting mode (setting the 4 mA or 0 V limit) and to decrease

the output current or voltage. The "FULL" spot as an opposite func-

tion (setting the 20 mA or 10 V limit and increasing the output current

or voltage). Values are conrmed by touching of the magnetic pen to

the sensitive spot for about 3 sec. The setting process is indicated by

yellow "STATE" LED indicator.

For detailed information please read at the instructions manual.

EMPTY sensitive area

FULL sensitive area

LED indicator “STATE”

LED indicator “RUN”

connector

Ultrasonic transmitter

locking screw

Key parts of the measuring device

(version with Hall probes)

LED indicator Colour Function

"RUN" green

short ashing (repeated depending on the measurement interval approx. 1 ... 2 s) - correct function, receipt of signal (echo)

reected from the measured surface

fast ashing – the measured surface is in the dead zone of the level meter or the ultrasound transducer is dirty

off – the level meter is not capable of receiving the echo. Incorrect installation or malfunction

"STATE" orange

ULM-53

slow ashing – 4 mA (0 V) threshold setting indication

fast ashing – 20 mA (10 V) threshold setting indication

3 short ashes – setting conrmation

ULM-53 variant "M" with Modbus communication

fast ashing – communication under way on line RS-485

ULM-53-dat-7.8

standard

(included in device price)

optional

(for a extra charge)

• 1x seal (for UL_–53_– 01; 02; 06, 10)

• 1x connector with IP67 coverage (for versions with

an ISO connector)

• 1x magnetic pen MP–8 (for device type adjusted

with a magnetic pen)

• free-to-download programme Basic Scada Level

(for the Modbus version)

• stainless steel or plastic fastening nuts G ¾”, G1", G1 ½" and

G2 ¼

• stainless steel or plastic lugs G ¾”, G1“, G1 ½” and G2 ¼

• horn adapter ST–G1 (thread G1"), ST–G1,5 and ST–G2,25

• socket ELWIKA 4012 K PG7

• connector with IP67 coverage (type GAN-DADE 7A) with 5m

cable

(for current output and ISO type connector)

• connector with IP67 coverage (type GAN-DAEE 7A) with 5m

cable

(for voltage output and ISO type connector)

• converter URC-485 (for the Modbus version)

ULM–53N–02–G–I–G–T ULM–53N–20–F–U–H–M

ULM–53Xi–06–G–I–B–M ULM–53N–10–G–M–C–L

Thanks to the proximity principle employed, the devices are suitable for continuous or limit measurement of the level of liquids,

waste water, sludge, suspensions, adhesives, resins in various open and closed vessels, sumps, open channels and drains.

Applicability for measuring the surface level of loose materials is limited, the range of measurement is shorter there.

Performance:

Maximum range:01 – 0,10 ... 1 m

02 – 0,20 ... 2 m

06 – 0,20 ... 6 m

10 – 0,4 ... 10 m

20 – 0,5 ... 20 m

N– non-explosive atmosphere

Xi – explosive atmosphere

ULM –

Output type: I – current output (4 ... 20 mA)

U – voltage output (0 ... 10 V)

M – RS-485 line with Modbus RTU communication

–––

Process connection:G– pipe thread

F– ange

Connection method: G – ISO connector

C – M12 connector

B – short cable gland PG11

H – cable gland for protective hose

–

Control units: T – setting using buttons

M – setting using a magnetic pen (MP8)

L – no setting controls and LED

53

–– cable (cable length in m) – only for variants with connection type "B" and "H"

adjustable range (in dm) – only variants without setting controls " L"

with output type "I" and "U":

0005 ... 0020 – 0,5 ... 2 m (variant „02“)

0008 ... 0050 – 0,8 ... 5 m (variant „06“)

0010 ... 0090 – 1,0 ... 9 m (variant „10“)

0020 ... 0200 – 2,0 ... 20 m (variant „20“)

verze 05/2015

ULM-53-dat-8.6

Dinel, s.r.o.

UTescomy 249

76001 Zlín, Czech Republic

Phone:

Fax:

+420 577002003

+420 577002007

www.dinel.cz

ULM a Dinel jsou registrované ochranné známky společnosti Dinel, s.r.o.

The ULM-53 level meter is equipped with protection against reverse polarity of the supply voltage and against short voltage

surges and with protection against current overload at the output.

Protection against dangerous contact is provided by low safe voltage under EN 33 2000-4-41.

Electromagnetic compatibility complies with EN 55011/B, EN 61326-1

and EN 61000-4-2 to 6.

The explosion-proof design of types ULM–53Xi is provided in conformity to the standards: EN 60079-0 : 2007; EN 60079-11 :

2007 and EN 60079-26 : 2007.

Explosion-proof design is certied by FTZÚ–AO 210 Ostrava–Radvanice, Report No.: FTZÚ 09 ATEX 0119X.

A declaration of conformity has been issued for this device in accordance with Act No. 22/1997 Coll., as amended. The sup-

plied electrical device conforms to the applicable government regulations concerning safety and electromagnetic compatibility.

sensor part type variant standard material

Case all plastic PP

Electro-acoustic transducer all plastic PVDF

Flange ULM-53_-20 aluminium with surface nish (powder coating)

Cable gland all plastic PA

Other manuals for ULM-53 series

5

This manual suits for next models

5

Table of contents

Other Dinel Measuring Instrument manuals

Dinel

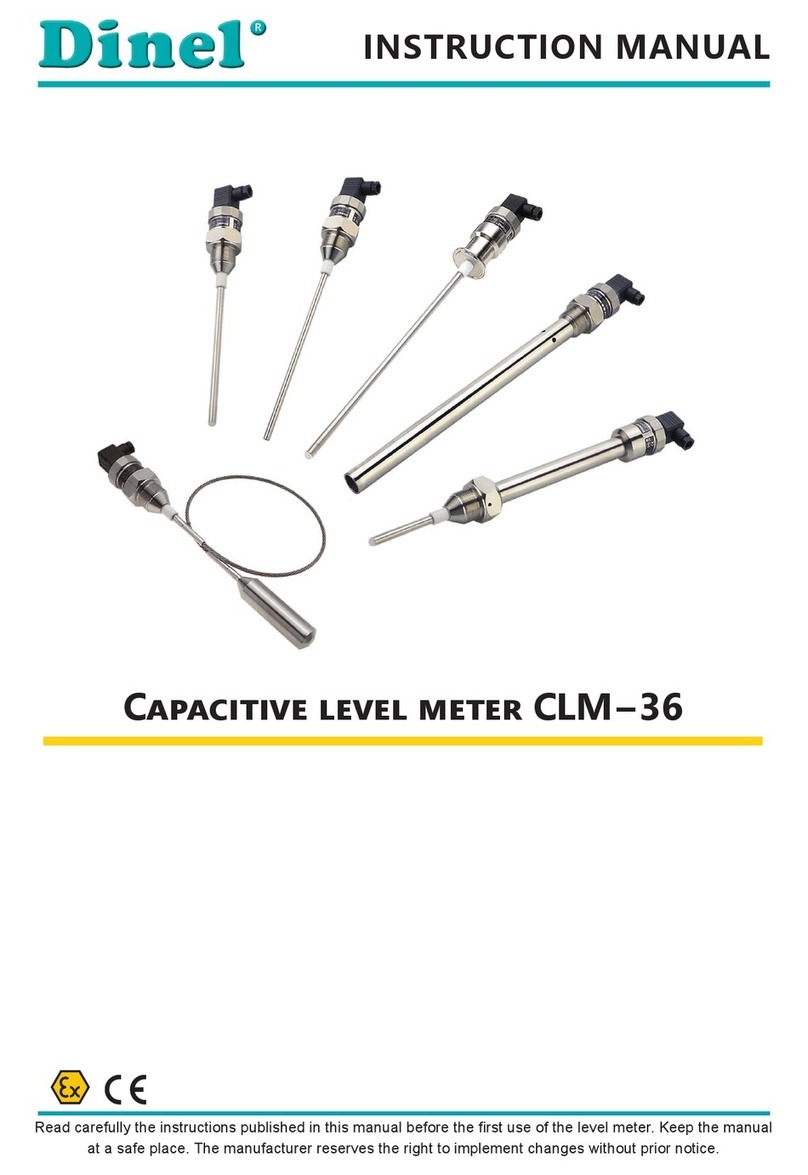

Dinel CLM-36 User manual

Dinel

Dinel CLM-70 User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel GRLM-70 User manual

Dinel

Dinel CLM-36-10 User manual

Dinel

Dinel MLM-35 User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel ULM-70 Series User manual

Dinel

Dinel DLM-35 User manual