ULM-nav-3.4

Setting the level meter up inside the measured vessel (cesspit) is also possible and we recommend it especially:

- if accurate data of individual distances are not available

- if it is necessary to measure hot media (the meter must be tempered for about 1 hour before adjusting it;

the meter is equipped with temperature compensation)

- if it is necessary to measure a rippled surface (e.g. due to a nearby inflow)

Note:

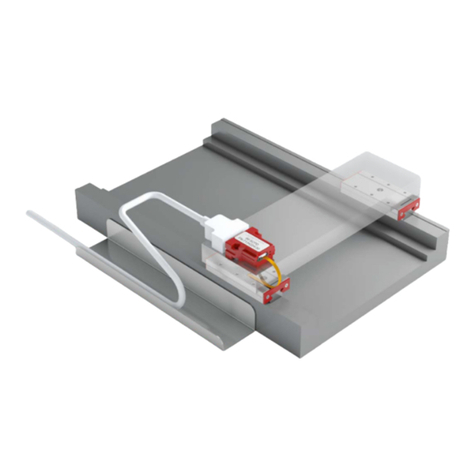

1) Set up the level meter is possible to proceed by simpler way outside of the measured tank. For example op-

posite a wall or opposite a flat surface (sized aprox. 1 x 1m). Level meter must be perpendiculary targeted to

the measured surface (wall). While moving the level meter please avoid jumping distance changes (control

logic in ULM presuppose smooth level movement, jumping distance can be incorrectly evaluated).

2) If you don´t succeed in the level meter´s setting, or you don´t know at which distance the level meter is sett

then first set the level meter to the basic stage by turning the trimer "20 mA" fully to the left (approximately 15

turn anti-clockwise).

3) If the level (reflected surface) comes to the dead zone (see the catalogue’s data) during the setting, then the

current increases to the alarm value >21mA.

This value is kept, untill the level meter doesn´t register the continuous motion of the level away from the dead

zone to the nominal measuring range (jumping distance is evaluated as a permanent fault).

If the alarm signaling continues and it is impossible to put the current back by any motion of the level, then it

is necessary to make “Reset” of the level meter (disconnection and connection of the power supply).

The level meter makes level detection again.

4) Depending on the type, the level meter is set up by default for the following ranges:

ULM-55_-02 - 0,5 m (20 mA) to 2 m (4 mA)

ULM-55_-06 - 1 m (20 mA) to 4 m (4 mA)

ULM-55_-10 - 1 m (20 mA) to 8 m (4 mA)

VI. Usage, operation and maintenance

The level meter requires no operating personnel. In the case of operation, the optional local connected display

informs operating personnel about the measured level.

The maintenance of the unit includes a check-up on the good condition of the level meter and the supply cable.

Depending on the nature of the measured substance, we recommend to inspect the cleanliness of the emitting

surface at least once per year, and clean it if necessary, if detecting any visible damage. Contact the producer or

dealer immediately.

It is forbidden to modify or tamper in any way the ULM-55 unit without the approval of the producer. Repairs may

only be carried out by the producer or a service organisation authorised by the producer.

The ULM-55 unit must be assembled, installed, put into operation, operated and maintained in accordance

with these instructions, and the provisions of valid standards concerning electrical equipment installation must

complied with the ULM-55 features.

VII. Protection, safety, compatibility and non-explosiveness

The level meter is equipped with a protection against a reversal of polarity of supply voltage and against current

overload. Safety low voltage according to the Czech State Norm CSN 33 2000-4-41 protects against dangerous

touch.ElectromagneticcompatibilityisensuredinaccordancewiththeNormsEN55022/B,EN61326-1,EN61000-

4-2, EN 61000-4-3, EN 61000-4-4, EN 61000-4-5, EN 61000-4-6. The non-explosiveness of the ULM-55Xi type is

certified by FTZÚ-AO210 Ostrava-Radvanice, certificate number FTZÚ 02 ATEX 0263.

VIII. Labelling

The cap nut of the ULM-55N type contains the following information:

- Producer’s/ label and contact information

- Type of the level meter ULM-55N-_ _ (old version) or ULM-55N-_ _A (new version)

- Year of production (first two digits) and serial number (remaining three digits) xx-xxx

- Supply voltage: U = 12÷30 VDC

- Range of output current I = 4÷20 mA

- Range of head working temperatures ta = - 30 … +70 °C (or ta= - 30 ... +60 °C for ULM-55N-10)

- Protection: IP65 / IP67

- CE labelling

- mark of electronic device waste (bin)