Dinel GRLM-70 User manual

Read carefully the instructions published in this manual before the rst use of the level meter. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice.

GRLM–70

1 . Basic description ..................................................................................................................... 4

2 . Range of application ................................................................................................................ 4

3 . Variants of sensors .................................................................................................................. 5

4 . Dimensional drawings ............................................................................................................. 6

5 . Installation and putting into operation ...................................................................................... 8

6 . Mechanical mounting ................................................................................................................ 9

7 . The installation of the custom measuring electrode,exchange or shortening of the electrode ...19

8 . Electrical connection ............................................................................................................... 23

9. GRLM-70 connection examples ............................................................................................. 25

9.1. Connection diagram of the level meter with current output to the UHC-01 converter . 25

9.2. Connection diagram of the level meter with the Modbus output to the URC-485 unit . 27

9.3. Connection diagram of the level meter with the current output to the PCU unit .......... 28

9.4. Connection diagram of the level meter with the current output to the PDU unit .......... 29

9.5. Connection diagram of the level meter with the current output to the MGU unit ......... 29

9.6. Connection diagram of the level meter with the MODBUS output

to the MGU unit using RS485 / MODBUS ........................................................................... 29

10 . Setting elements ..................................................................................................................... 31

11 . Settings .................................................................................................................................. 32

11.1. Initial setting procedure during commissioning .......................................................... 32

11.2. Basic settings ............................................................................................................ 33

11.3. Service settings ......................................................................................................... 36

11.4. Additional functions ................................................................................................... 39

12 . HART®protocol ...................................................................................................................... 42

12.1. Parametrization of GRLM-70 using the Hart® protocol with PCU-100-H ................... 43

12.2. Parametrization of GRLM-70 using the Hart®protocol

with the UHC-01 communicator........................................................................................... 43

13 . Protocol Modbus® ................................................................................................................... 44

14 . Function and status indication ............................................................................................... 44

15 . Order code ............................................................................................................................. 45

16 . Accessories ............................................................................................................................ 46

17 . Safety, protection, compatibility and explosion proof ............................................................. 46

18 . Use, manipulation and maintenance ...................................................................................... 47

19 . General conditions and warranty ........................................................................................... 47

20 . Marking of labels .................................................................................................................... 48

21 . Technical specications .......................................................................................................... 50

22. Packing, shipping and storage ............................................................................................... 58

23 . Menu structure ........................................................................................................................ 59

GRLM–70 © Dinel, s.r.o.

4

The GRLM®radar level meters are compact measuring devices consisting of three main parts

- measuring electrodes, housing with the computing electronics (head) and a display module

(screen). The electronic transmits very short electrical pulses (0.5 ns), which is connected with a

one-wire transmission line (measuring electrode). Measuring electrode can be formed from rod or

rope. The pulse propagates along the electrode in the form of electromagnetic wave toward the

level part of electromagnetic wave, where it is partly reected and the reected returned to the

receiving module of the electronic. The electronic measures the time of ight of electromagnetic

wave and the current (actual) distance to the level is calculated. Then based on the height of the

level, the level meter current output 4 ... 20 mA is set with the HART communications or an industrial

RS-485 line with Modbus RTU communications and the measured value is shown on the display.

Radar level meters with guided wave are suited to continuous level measurement of various

liquid, mush and bulk-solid materials. Level meters are resistant against changes in the atmos-

phere (pressure, temperature, dust, steam) and to changes in medium parameters (change in

dielectric constant, conductivity).

To ensure maximum safety of control processes, we have dened the following safety instructions

and information. Each instruction is labelled with the appropriate pictogram.

This symbol informs you about particularly important instructions for installation and operation of

equipment or dangerous situations that may occur during the installation and operation. Not observing

these instructions may cause disturbance, damage or destruction of equipment or may cause injury.

This symbol indicates particularly important characteristics of the device.

This symbol indicates helpful additional information.

Alloperationsdescribedinthis instruction manual have to be carried out by trained personnel

or by an accredited person only. Warranty and post warranty service must be exclusively

carried out by the manufacturer.

Improper use, installation or set-up of the sensor can lead to crashes in the application.

The manufacturer is not responsible for improper use, loss of work caused by either direct

or indirect damage, and for expenses incurred at the time of installation or during the period

of use of the level sensors.

5

© Dinel, s.r.o. GRLM–70

• GRLM–70_–00 Without electrode, the electrode is made by customer (only variant 10

or 30) and connected to the electrode junction by M8 thread.

• GRLM–70_–10 Uncoated stainless steel rod electrode, for level measurement liquids

and bulk solid materials (water solutions, emulsion, oils, diesel, our, sand,

granulates, etc.). Electrode length 0,5 ... 8 m.

• GRLM–70_–11 Fully coated stainless steel rod electrode (PFA), for level measurement

of aggressive liquids and very pure liquids. Electrode length 0,5 ... 2 m.

• GRLM–70_–12 Fully coated stainless steel rod electrode (FEP), for level measurement

of aggressive liquids and drinks. Electrode length 0,5 ... 2 m.

• GRLM–70_–13 Semi-coated stainless steel rod electrode (FEP), for level measure-

ment of liquids in area,where it could condense steam on the electrode.

Electrode length 0,5 ... 8 m.

• GRLM–70_–20 Uncoated stainless steel rod electrode with reference tube (coaxial),

for accurate level measurement of liquids in cramped spaces. Electrode

length 0,5 ... 3 m.

• GRLM–70_–30 Uncoated stainless steel rope electrode and weight, for level

measurement of liquids and bulk solid materials (water, grains, sand, our,

cement, etc.) in higher silos, vessels, reservoirs. Electrode length 1 ... 40 m.

• GRLM–70_–32 Fully coated stainless steel rope electrode (FEP) and coated weight

(PTFE), for level measurement of aggressive liquids and very pure liquids.

Electrode length 1 ... 12 m.

• GRLM–70_–33 Uncoated stainless steel rope electrode with anchorage, for level

measurement of bulk solid materials (grains, our, cement, etc.) It is

recommended to anchor in storage tanks and silos for bulk solid materials

up to a depth of 10 meters. . Electrode length 1 ... 40 m.

• GRLM–70_–34 Coated stainless steel rope electrode (Polyamide) and uncoated

weight, for level measurement of liquids and adhesive bulk solids (our,

cement, etc.). Electrode length 1 ... 40 m.

• GRLM–70_–35 Coated stainless steel rope electrode (Polyamide) with uncoated

anchorage, for level measurement of adhesive bulk solids (our, cement,

etc.). It is recommended to anchor in storage tanks and silos for bulk solid

materials up to a depth of 10 meters. Electrode length 1 ... 40 m.

• GRLM–70_–36 Uncoated rope electrode without weight, for level measurement of

unsticky bulk solids (grains, sand, etc.) Anchoring with rope clamps and

eye ring. Recommended anchoring in storage tanks and silos deeper than

10 meters. Electrode length 1 ... 40 m.

• GRLM–70_–37 Coated rope electrode without weight (rope coated with polyamide),

for level measurement of sticky bulk solids (our, cement, etc.). Anchoring

with cable clamps and eye ring. Recommended anchoring in storage tanks

and silos deeper than 10 meters. Electrode length 1 ... 40 m.

GRLM–70 © Dinel, s.r.o.

6

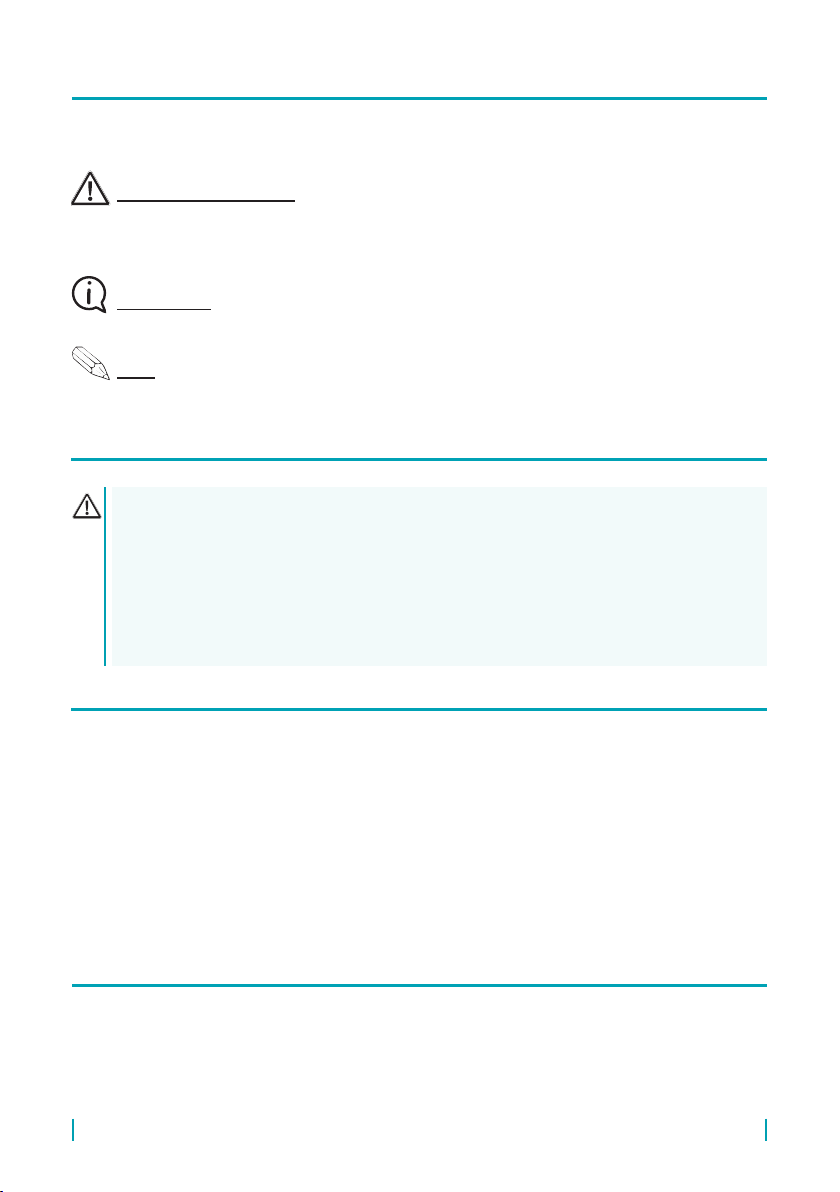

GRLM–70_–20

GRLM–70_–00

GRLM–70_–13

Procesní připojení

Tri-clamp

GRLM–70_–10 GRLM–70_–11(12)

holder of

electrode

electrode

7

© Dinel, s.r.o. GRLM–70

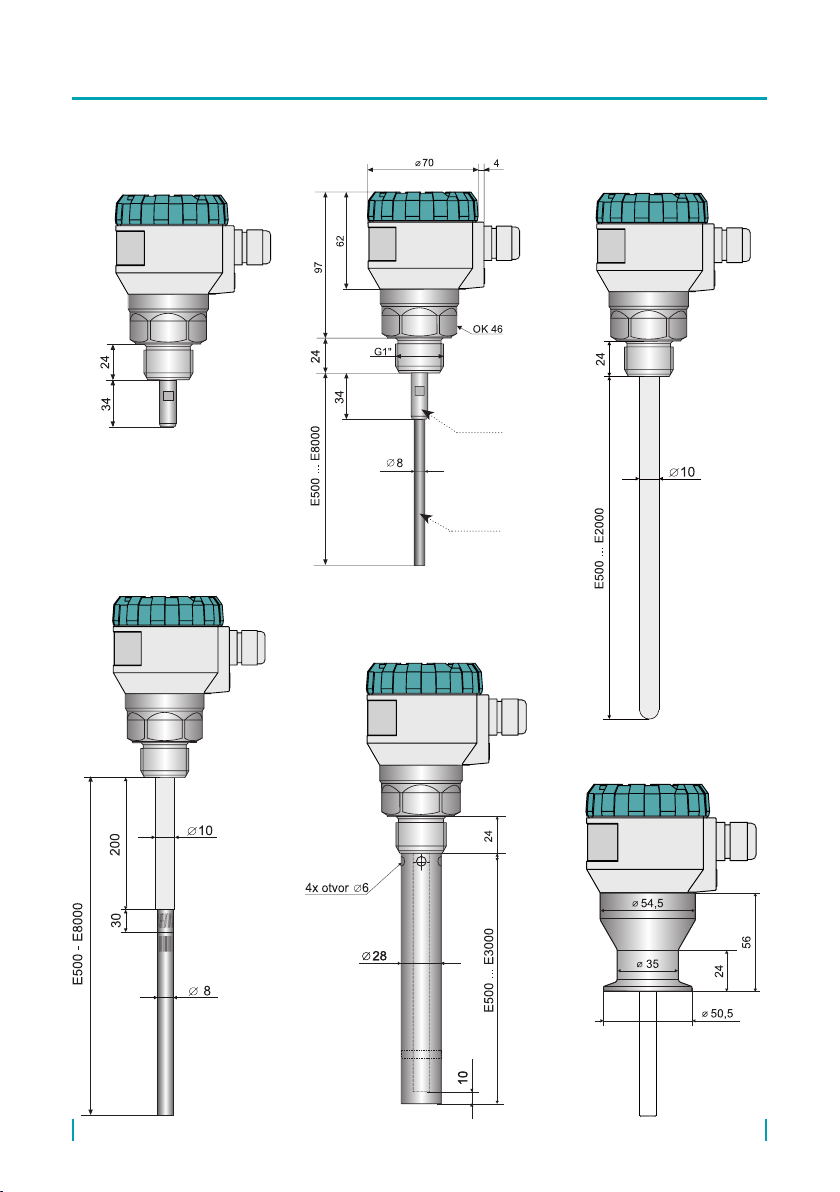

* Details on rope length, attachment or shortening for version GRLM-70_-36 (37) on pages 22 and 37.

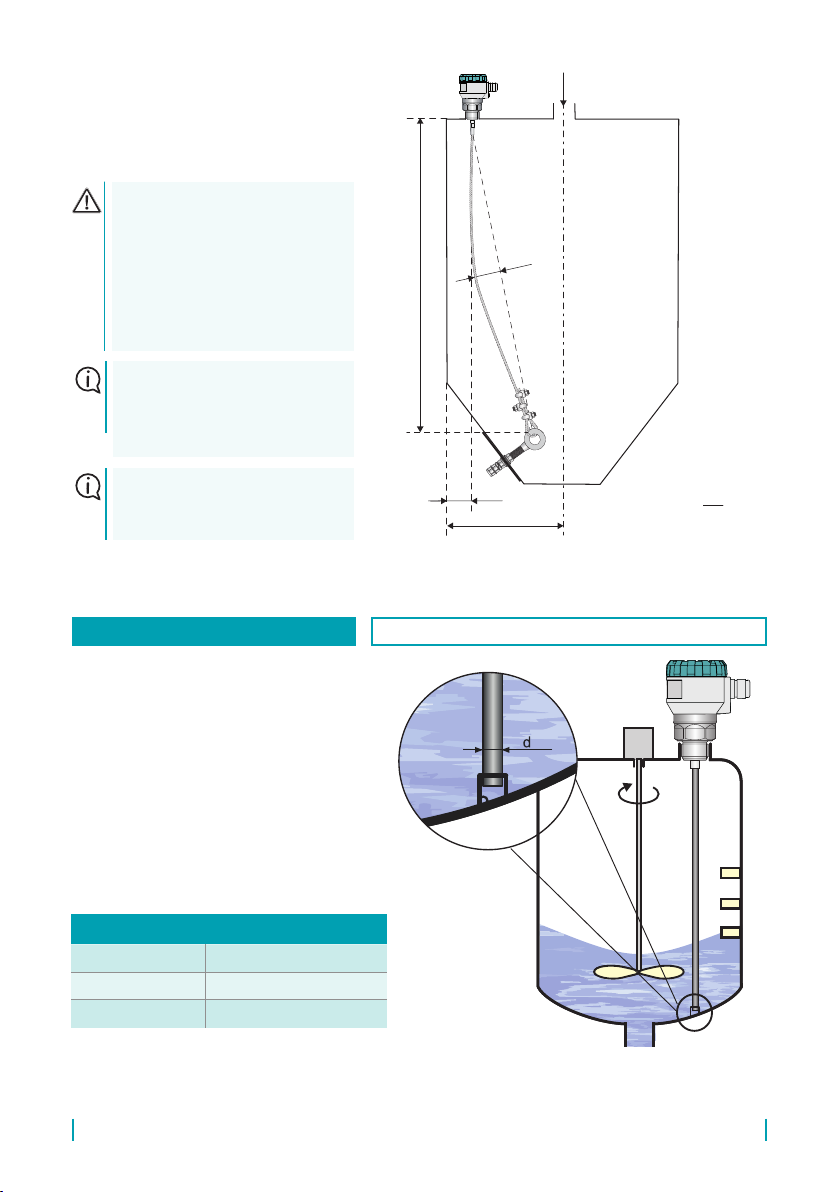

GRLM–70_–30(33,34,35) GRLM–70_–36(37)

*

GRLM–70_–32

Anchoring eye for variant

GRLM-70_-33 (35)

GRLM–70 © Dinel, s.r.o.

8

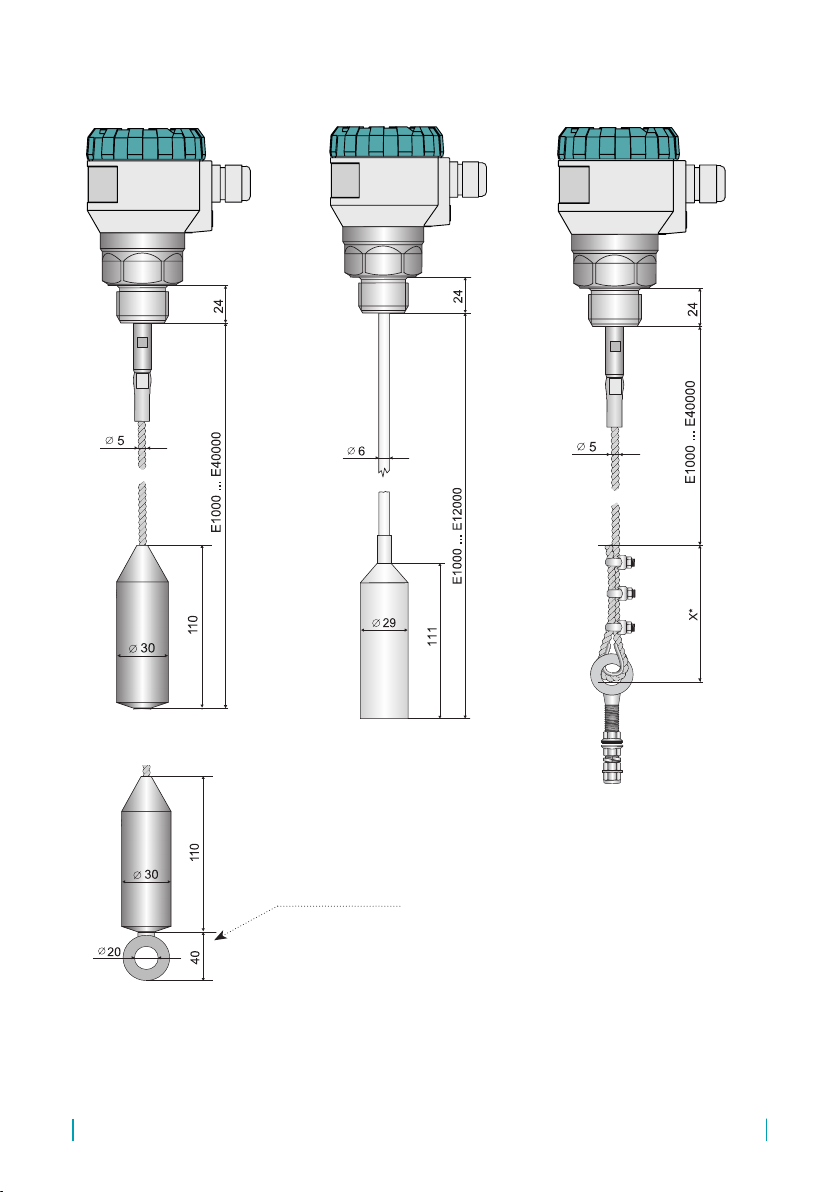

Please follow next 4 steps:

High temperature performance

GRLM–70_T

performance "H1"

cable gland for protective hose M16

performance "B1"

plastic cable gland M16

performance "B2"

plastic cable gland M20

26

28

26

28

9

© Dinel, s.r.o. GRLM–70

• Install the level meter into the upper lid of the tank or reservoir using a welding ange or

fastening nut.

• The min. distance to install the level meter into a lid or a ceiling of a tank from the tank wall or

bottom is given in table below.

• Otherwise, the level meter install as far as possible from the walls, to the middle between the

wall and the vertical inlet, see Fig. 1., 2, 3 and 4.

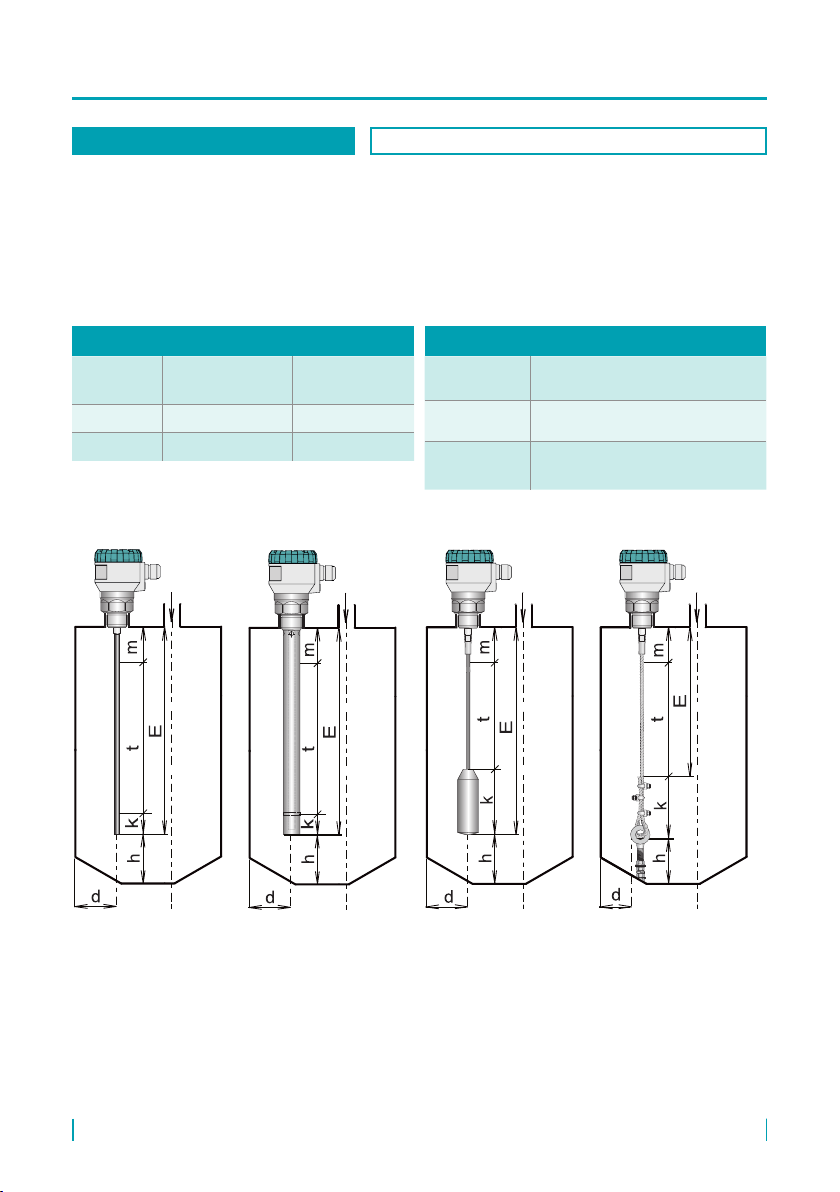

BASIC INFORMATIONS VALID FOR: all types

E – The length electrode

t – Maximum measuring range

m – Dead zone on the beginning of electrode

k – Dead zone on the end of electrode or the length of

weight (110 mm) at the rope

d – The distance from the tank wall (see. Tab. above)

h – The distance from the bottom (see. Tab. above)

type of

wall

d

(without ref. tube)

d

(with ref. tube)

metal ≥ 300 mm*any distance

non-metal ≥ 500 mm* any distance

* it is recommended that a smaller distance from a wall is consulted

with the manufacturer.

type of

electrode h

rod

(no anchoring)

≥ 100 mm2) (length of electrode to 2 m)

≥ 150 mm2) (length of electrode over 2 m)

rope

(no anchoring)

≥ 100 mm (length of electrode to 10 000 mm)

≥ 150 mm (length of electrode over 10 000 mm)

2) In case of a sloping bottom the distance "h" should be twice as long.

Fig. 1: Level meter

installation with the

rod electrode

Fig. 3: Level meter

installation with the rope

electrode

Fig. 4: Level meter

installation with the rope

electrode without weight

Fig. 2: Level meter

installation with the

reference tube

GRLM–70 © Dinel, s.r.o.

10

• It is an area in which continuous level measurement takes place. The maximum measur-

ing range is determined by the length of the measuring electrode with the subtraction of

dead zones at the beginning and at the end of the electrode, see Figs. 1, 2, 3, and 4. This

range is also the default setting of the level meter. The maximum measuring range can be

reduced by the user by changing the minimum and maximum levels in case of obstacles

near the end or in particular at the beginning of the measuring electrode.

• If the measured level falls out of the measuring range limits, the level meter will enter the failure

mode and the output current will resume the value that was set by the user, see service settings

– Failure Mode, p. 38 (the default value for the failure mode is provided in the Default Settings

Table, p. 57). For the M Modbus version, the corresponding bits of the measurement status

register 104 are activated, see the Variables Table for GRLM-70 Modbus.

MEASURING RANGE VALID FOR: all types

• In connection with the measurement principle, electromagnetic waves reected in the area im-

mediately below the level meter and also at the end of the electrode cannot be evaluated (see

Figs. 1, 2, 3, and 4). These zones determine either the minimum possible distance between

the level meter and the highest level (“m” parameter) or the minimum distance at the end of the

electrode (“k” parameter). The level meter must be installed in such a way that the level

does not interfere with the dead zones at the maximum and minimum possible lling of

the storage tank.

• The size of the dead zone is shown in Figs. 49–52 on pages 51, 52.

DEAD ZONE VALID FOR: all types

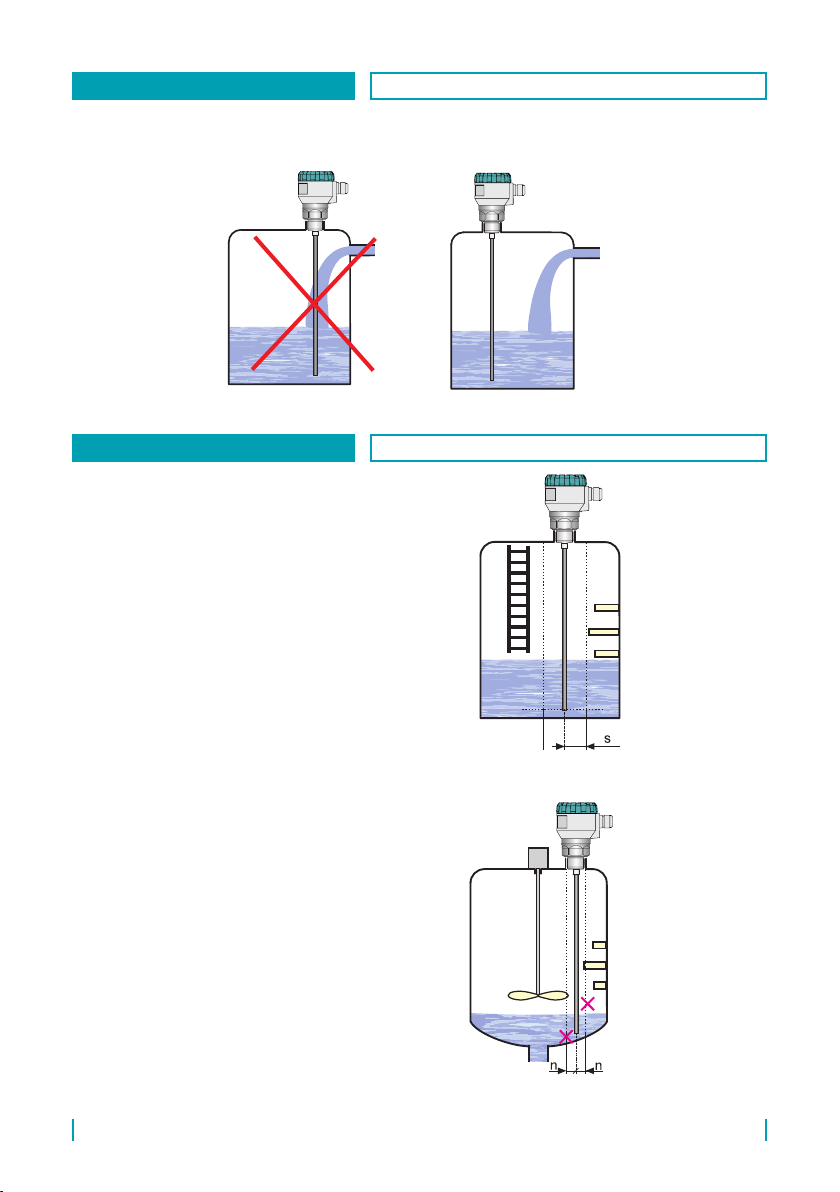

• For correct measurement, it is im-

portant to avoid installing the level

meter in a high input neck or high

welding ange. If this is not possible,

the level meter may be installed in

a short input neck, the parameters

of which are provided in g. 5. Here

it applies that the neck diameter se-

lected should be as large as possi-

ble but the neck height should be as

small as possible.

Fig. 5: Level meter installation

in the input neck

a ≤ b

b ≥ 50 mm

a – neck height

b – neck width

INPUT NECK VALID FOR: all types except GRLM-70_-20

When installing the level meter

into an input neck, use the

TEACHING procedure (see

chapter11.2. Basic settings). This

will put the sensor into a mode

that suppresses false reections.

• The end of the socket or the welding

ange must not have an extension

into the tank in Fig. 6.

• Dimension restrictions of the input

nozzle does not apply to the use of

GRLM-70_-20 with reference tube.

Fig. 6: Incorrect welding ange

mounting to the tank

11

© Dinel, s.r.o. GRLM–70

• When installing the level meter into the roof of a concrete silo, the level meter installation hole

b must be larger than the thickness of the concrete a, see g. 8.

• In the event that the thickness of the concrete is greater than the diameter of the hole, it is

necessary to install the level meter into a countersink, see g. 9.

a < b

• To install the level meter in a non-

metallic water tank, it is necessary

to insert a metal plate with a diame-

ter greater than 200 mm in the area

of the process connection, see g.

7. The metal plate must be in con-

tact with the thread stop of the level

meter.

Fig. 7: Level meter installation

in the non-metal tank

Fig. 8: Level meter installation

on the roof of the concrete silo

Fig. 9: Level meter installation

on the roof of the concrete silo

NON-METAL TANK VALID FOR: all types except GRLM-70_-20

CONCRETE SILO VALID FOR: GRLM-70_-30, 32, 33, 34, 35, 36, 37

• The level meter must not be installed

in locations exposed to direct solar

radiation and must be protected

against the eects of weather.

In the event that installation in a

location with direct solar radiation

is unavoidable, it is necessary to

install a shielding cover above the

level meter (g. 10).

Fig. 10: Solar radiation shielding cover

LEVEL METER PROTECTION VALID FOR: all types

GRLM–70 © Dinel, s.r.o.

12

• It is not recommend to install the level meter in or above the lling location. Measurement may

be aected by the medium owing in rather than measuring the level of the material.

s - Radius of protective

zone along the electrode

level meter

s = 300 mm

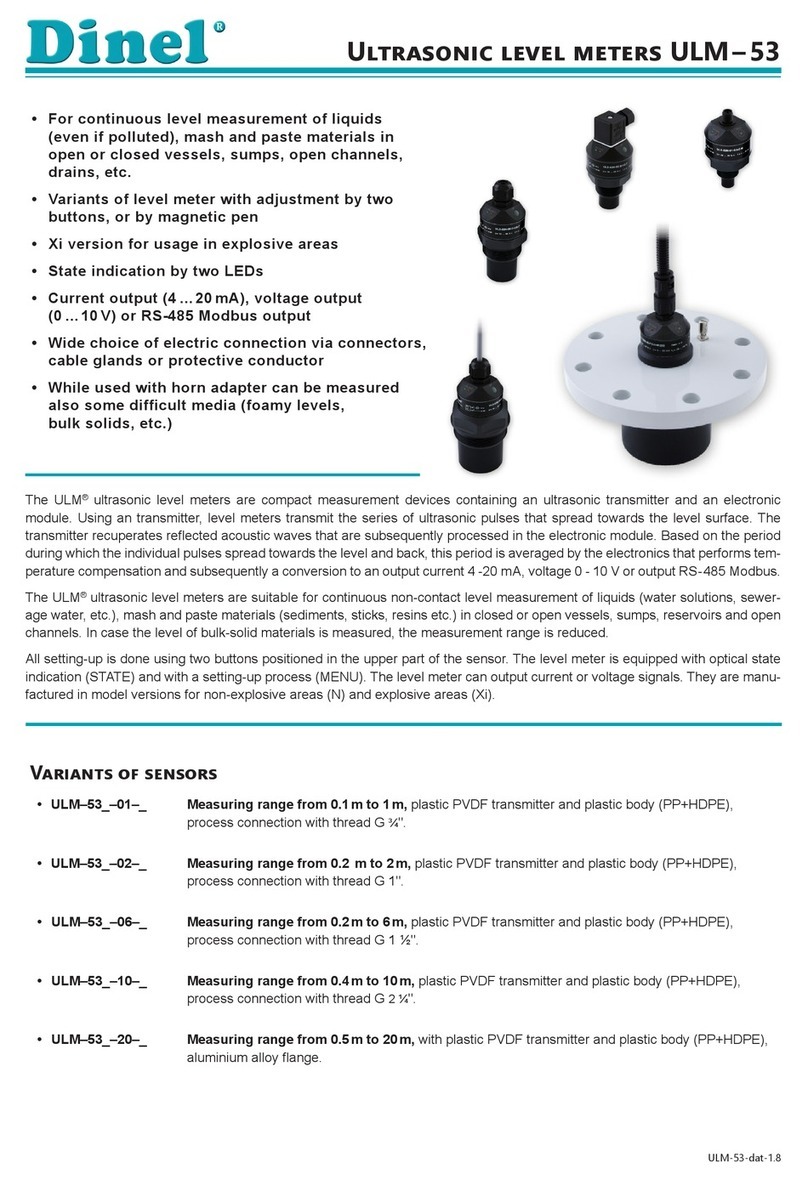

• The level meter generates electro-

magnetic guided wave, which cre-

ates an electromagnetic eld along

the electrode. Objects placed close

to the electrode disturb the elec-

tromagnetic eld and thus aect

the measurement. Therefore, it is

determined protective zone along

the electrode of radius 300 mm.

The level meter is recommended

to install the tank so that the items

placed inside the tank (ladders,

various partitions, mixers, etc.)

does not intervene into the protec-

tive zone, see Fig. 12.

Fig. 11: Level meter installation outside the inuence of lling

Fig. 12: Level meter installation

outside obstacles in the tank

OUTSIDE THE INFLUENCE OF FILLING VALID FOR: all types

OBSTACLES IN THE TANK VALID FOR: all types except GRLM-70_-20

• If still these objects intervene into

the protective zone of the level me-

ter, it is necessary to create a map

of false reections by activating the

"TEACHING" mode (p. 35). In case

of installed mixers, it is necessary

to position the mixers near the level

meter (turning the mixer blade to the

proximity of the electrode). Items

inside the tank must not be from

the electrode distance of less than

100 mm, because a interference of

electromagnetic eld is very strong

in this zone and "TEACHING" mode

can not be used.

n = 100 mm

Fig. 13: Incorrect level meter

installation close to obstacles

n - minimal distance of

objects from the elec-

trode from level meter

13

© Dinel, s.r.o. GRLM–70

• For the type of level meter with

reference tube (coaxial) electro-

magnetic guided wave propagates

inside the reference tube. This

wave is not aected by the ambient

environment. So for this type of ra-

dar is not intended protective zone

around the electrodes and the level

meter can be used for measure-

ments in cramped spaces.

Fig. 15: Level meter installation with

reference tube (coaxial) in cramped spaces

CRAMPED SPACES VALID FOR: GRLM-70_-20

• When measuring the level of ag-

gressive media (strong acids, lyes,

chlorides, hydrogen chloride, etc.) in

non-conductive vessels.

• The level meter with a rod electrode

is inserted into a non-conductive

tube with a diameter of 16 ... 30 mm.

The tube must have an encapsu-

lated bottom and the upper part is

welded to the non-conductive ceil-

ing of the vessel.

• The level of the medium is meas-

ured through the wall of the non-

conductive tube by a radar. The

value of relative permittivity must

not exceed 3.

• The instructions for mounting the

level meter into a non-metallic ves-

sel apply here, i.e. a metal plate with

the diameter greater than 200 mm

must be inserted at the process con-

nection point.

Fig. 14: Level meter installation with

reference tube (coaxial) into the auxiliary tube

AGGRESSIVE MEDIA VALID FOR: GRLM-70_-10

material: metal

min. Ø 200 mm

material: PE, PP

(εr max=3)

Ø 16 - 30 mm

Ø 12 - 15 mm

GRLM–70 © Dinel, s.r.o.

14

• Type of level meter without electrode

is supplied without an electrode. It is

therefore necessary to a customer

to mount his own made measuring

electrode. The diameter of the elec-

trode must be between 8-10 mm.

For a connection it is necessary that

on the electrode is made M8 thread.

The connection procedure is given

in Sec. 12 page. 30.

Fig. 17: Level meter without electrode

• Deposits, layers and sediments on the electrode may distort measurement and reduce the

permeability of the electromagnetic wave propagated along the electrode.

For the type of level GRLM-

70_-00 manufacturer is not

responsible for failures related

to the mounted measuring

electrode.

DEPOSITS ON THE ELECTRODE VALID FOR: all types

VARIANT WITHOUT ELECTRODE VALID FOR: GRLM-70_-00

• It is appropriate to lead the ca-

ble underneath the cable terminal

(through the dip diagonally down-

wards) This will prevent potential

"ingression of moisture through the

cable grommet. Thereby, rain and

condensing water can ow away

freely, g. 16.

• The cable bushing and connector

have to be suciently tightened to

prevent penetration of humidity.

Fig. 16: Prevention to avoid intrusion of humidity

through cable gland

HUMIDITY VALID FOR: all types

15

© Dinel, s.r.o. GRLM–70

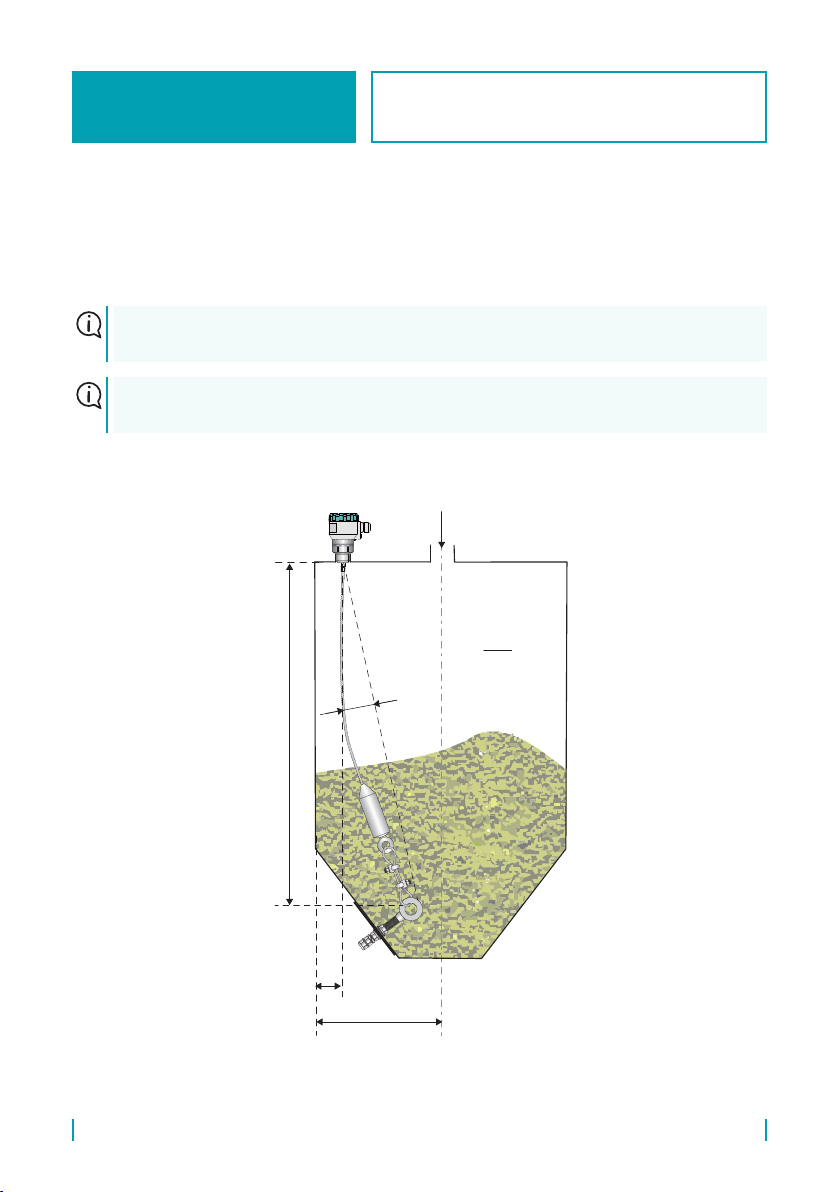

• When calculating the length of the

rope electrode, it is necessary to

take into account that the meas-

urement takes place only up to the

upper edge of the weight, i.e. it is

advisable to choose the electrode

length so that the whole weight is

below the minimum measured level,

see Fig. 18. For variants 30 and

34, it is possible to shorten the

rope electrode.

• The distance the electrode from

the tank wall must be at least 300

mm. Otherwise, the level meter

install as far as possible from the

walls, to the middle between the

wall and the vertical inlet, see Fig.

18. It must be ensured that the rope

electrode could not touch the ves-

sel wall caused by the motion of

the medium. In the case of an unan-

chored rope electrode, its end must

not extend into the conical part of

the storage tank.

• Ensure that the maximum tensile

load on the rope of the electrode is

not exceeded. Its value is specied

in chapter "Technical parameters".

A large load could result in the rope

tearing. The tensile load depends

on the height and shape of the tank,

the thickness and adhesion of the

measured medium and the tank

emptying speed.

E – The length of rope electrode

t – Measuring range

m – Dead zone at the beginning of the electrode

k – The lengt of weight (110 mm)

d – The distance from the tank wall min. 300 mm

h – The distance from the bottom (see. Tab. page 8)

E = m + t + z

Fig. 18: Level meter installation

with the rope electrode

For the electrode shortening procedure, see chapter 7. How to install a custom measuring

electrode, replace or shorten the electrode.

In the case of shortening the electrode, after installation it is necessary to carry out settings in

the MENU of the ELECTRODE option (see p. 36).

ROPE ELECTRODE

WITHOUT ANCHORING

VALID FOR: GRLM-70_-30, 32, 34

GRLM–70 © Dinel, s.r.o.

16

ANCHORING OF THE ROPE

ELECTRODE WITH WEIGHT AND

ANCHORING RING

VALID FOR: GRLM-70_-33, 35

• At the bottom of the tank (silo), it is necessary to install an anchoring point (by welding or drill-

ing an anchoring ring), to connect to the ring at the end of the electrode.

• This anchoring is recommended for applications with liquids, where turbulences occur or

media is stirred, or for applications with bulk solids in small and medium sized silos (up to 10

m height).

For the electrode shortening procedure, see chapter 7. How to install a custom measuring

electrode, replace or shorten the electrode.

In the case of shortening the electrode, after installation it is necessary to carry out settings in

the MENU of the ELECTRODE option (see p. 36).

Obr. 19: Recommended Level meter

installation with anchorage

d

r

p

H

mm 200 50h

E

3

2

m

E

4

3

p

E

3

4

s

E

3

1

E

10

1

a

20

E

40 b

20

H

000 1 r

50

H

000 1 d

100

H

p

mm

mm

mm

d=1000+H/50

17

© Dinel, s.r.o. GRLM–70

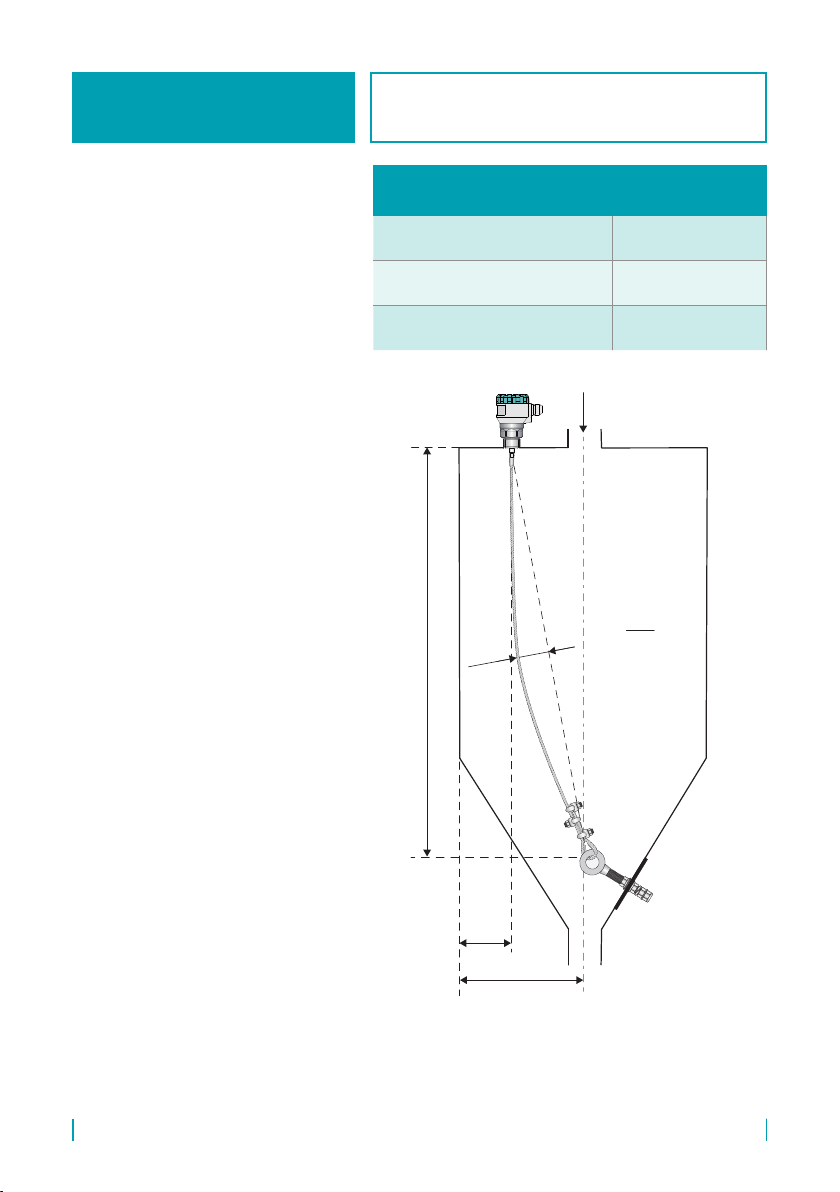

• For the variants 36 and 37, an ad-

ditional 1 m of stainless steel rope

length is supplied with a corre-

sponding number of clamps and eye

rings.

• This additional 1 m of stainless steel

rope is intended as a reserve for

pulling through the anchoring eye.

Not intended for level measure-

ment! It comes with three clamps

and one eye ring.

• At the bottom of the tank (silo), it

is necessary to install an anchor-

ing point (by welding or drilling an

anchoring ring), to pull the rope

through and then attached with at

least 2 clamps (3 clamps are rec-

ommended for deep silos over 20

m). When designing the length of

the rope “E”, it is necessary to take

into account the bending of the rope,

or anchoring on the opposite side of

the silo.

• Suitable for bulk media in silos

deeper than 10 meters.

• For applications with bulk solids

it is appropriate to anchor the rope

electrodes at the opposite sides of

the tank (silo) so that the rope is

sagging, see Fig.20. Minimum rec-

ommended sag is p = H/100 [mm].

This installation increases the re-

sistance of the rope to tension load.

d

r

p

H

mm 200 50h

E

3

2

m

E

4

3

p

E

3

4

s

E

3

1

E

10

1

a

20

E

40 b

20

H

000 1 r

50

H

000 1 d

100

H

p

mm

mm

mm

Fig. 20: Recommended installation of the level meter

with anchoring on the opposite side of the silo

Anchoring method r

[mm]

opposite side of the silo (Fig. 20) any

same side of silo (Fig. 21) ≥ 1000 + H/20

H – depth of the silo (from rope start to anchor)

p – rope sag (see formula above)

r – radius of the silo

d – distance to wall (see formula above)

ANCHORING OF THE ROPE

ELECTRODE WITHOUT WEIGHT,

ANCHORED WITH CLAMPS

VALID FOR: GRLM-70_-36, 37

GRLM–70 © Dinel, s.r.o.

18

d

r

p

H

mm 200 50h

E

3

2

m

E

4

3

p

E

3

4

s

E

3

1

E

10

1

a

20

E

40 b

20

H

000 1 r

50

H

000 1 d

100

H

p

mm

mm

mm

Fig. 21: Recommended installation of the level meter

with anchoring on the same side of the silo

After installing the rope using

clampss, a check of the min.

distance of the rope from the

wall (d) and also the bend of

the rope (p) is performed. Then

the rest of the rope must be cut

in close proximity to the last

clamp, see chapter 7.

After installation, it is neces-

sary to carry out settings in the

MENU of the ELECTRODE

option (see p. 36).

A mounting kit for rope anchor-

ing and a rope tensioner are

available as accessories.

• If the ratio of silo width to depth is

determined by formula: r ≥ 1000 +

H/20 [mm], the rope can be anchored

also on the same side of the silo, see

Fig.21.

• Recommended for rod electrodes long-

er than 3 m.

• The end of the measuring electrode

may be installed in a short tube welded

to the bottom of the tank. At the bottom

part of the anchoring tube, it is recom-

mended to have a media overow hole.

The diameter of the tube should ensure

permanent contact of the tube walls

with the electrode.

electrode type d

uncoated 8 mm

fully coated 10 mm

ANCHORING OF THE ROD ELECTRODE VALID FOR: GRLM-70_-10, 11, 12, 13

Fig. 22: Recommended installation

of the level meter with anchoring

of the rod electrode

19

© Dinel, s.r.o. GRLM–70

1. Create your own electrode as shown on Fig. 23 or 24 The length of the electrode must be about

7 mm shorter than the dimension "E" in gure 23. The material of the electrode is recommended

to be used stainless steel type 1.4404 (AISI 316 L) or similar depending on the application.

2. Apply glue intended for securing threaded junctions (the amount of adhesive is determined by

its manufacturer) on to the thread of the prepared electrode produced according to drawing

(see pic. 23 or 24). The glue used must meet certain criteria depending on the application, e.g.

resistance against high temperatures, corrosion, chemicals or must have a permit, e.g. for use

in food processing.

3. Screw the electrode using suitable pliers or a spanner (on the side of the electrode) and a at

spanner 10 mm (on the side of the electrode holder) rmly into the electrode holder.

4. Let the glued junction to harden, as recommended by the glue manufacturer, then the level

meter is ready for installation.

5. After an installation into an empty tank, set a new level meter electrode type and the length -

see Chap. ELECTRODE on the page 36

6. If necessary, enter a new range of level measurement - see Chap. MIN / MAX LEVEL on the

page 33.

Fig. 23: Detail of a drawing of a rod electrode

Fig. 24: Detail of a drawing of a rope electrode

"E" - 55 mm

30

5

Ø

M8

grooves

GRLM–70 © Dinel, s.r.o.

20

24E

Fig. 25: Drawing of a level

meter with a rod electrode

electrode

holder

rod

electrode

60

110

E24

Fig. 26: Drawing of a level

meter with a rope electrode

electrode

holder

rope

electrode

Table of contents

Other Dinel Measuring Instrument manuals

Dinel

Dinel ULM - 54 User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel MLM-35 User manual

Dinel

Dinel DLM-35 User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel ULM-53L User manual

Dinel

Dinel ULM-55N User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel ULM-53 series User manual

Popular Measuring Instrument manuals by other brands

RKI Instruments

RKI Instruments GX-6000 Operator's manual

Waycon

Waycon LLD-150-PROF2 manual

Endress+Hauser

Endress+Hauser Deltabar FMD71 technical information

Teledyne Lecroy

Teledyne Lecroy WaveMaster 8000HD Getting started guide

BioLAB

BioLAB BSFL-103 Operation manual

Zoom

Zoom H1essential Firmware update guide