Dinel CLM-36-10 User manual

Read the instructions published in this manual carefully before the rst use of the sensor.

Keep the manual in a safe place. The manufacturer reserves the right to make changes without prior notice.

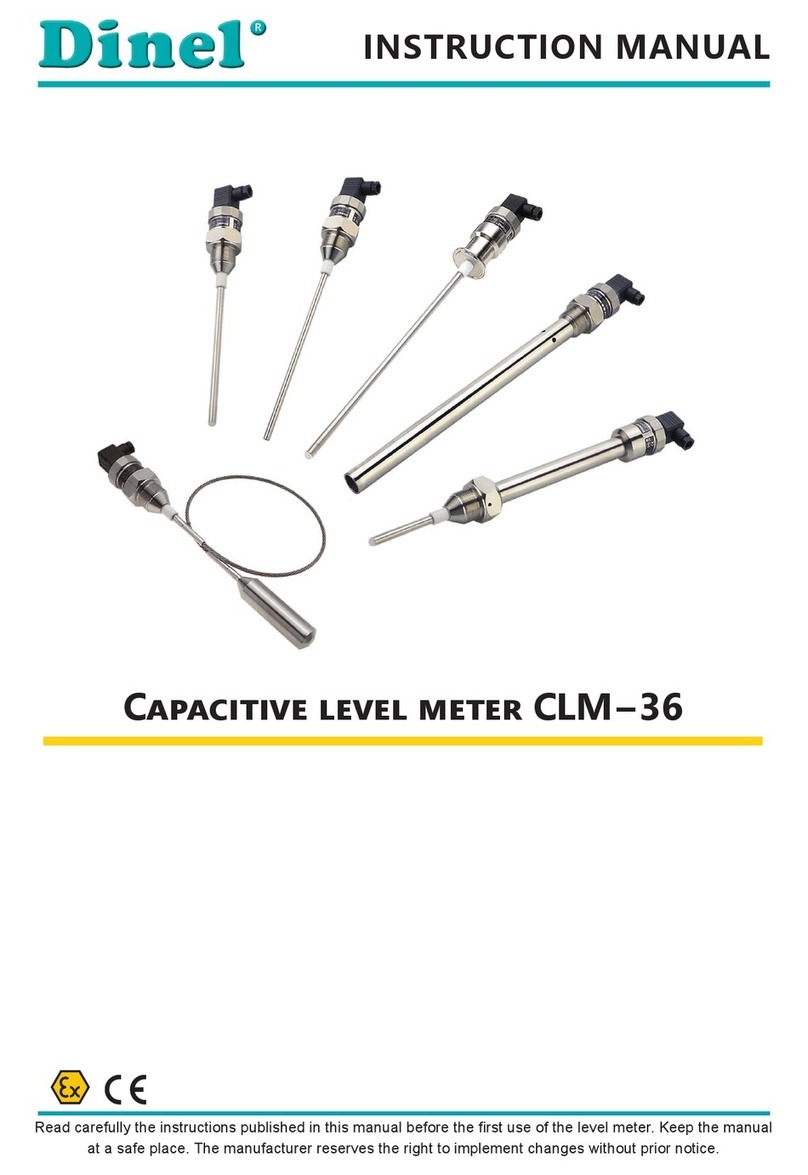

Capacitive level meters CLM – 36Capacitive level meters CLM – 36

INSTRUCTIONS MANUAL

2 . Basic description .................................................................................................................... 4

1 . Range of application ............................................................................................................... 4

3 . Variants of sensors ................................................................................................................. 5

4 . Dimensional drawing ............................................................................................................... 6

5 . Inuence of the tank shape on a linearity of measurement ..................................................... 8

6 . Installation and putting into operation ..................................................................................... 9

7 . Mechanical mounting .............................................................................................................. 9

8 . Electrical connection ............................................................................................................... 12

9 . Preparing of level meter for measuring ................................................................................... 14

10 . Settings ................................................................................................................................. 15

11 . Order code ............................................................................................................................ 17

12 . Correct specication examples ............................................................................................. 17

13 . Accessories ........................................................................................................................... 17

14 . Safety, protections, compatibility and explosion proof .......................................................... 18

15 . Use, manipulation and maintenance ..................................................................................... 19

16 . General, conditions and warranty ......................................................................................... 20

17 . Marking of labels ................................................................................................................... 21

18. Technical specications......................................................................................................... 23

19 . Table of relative permittivity .................................................................................................. 27

20 . Packaging, shipping and storage .......................................................................................... 28

CLM–36 © Dinel, s.r.o.

4

Capacitive level meters CLM® are designed for continuous level measurement of liquids,

powders and bulk-solid materials in vessels, tanks, sumps, containers, silos, etc. CLM consists

of the stainless steel housing with electronic module and the measuring electrode. The

electronic part converts the capacity into the current signal (4 ... 20 mA) or voltage signal (0 ...

10 V). Sensitivity (SPAN) and initial capacity compensation (ZERO) can be uently set.

Level meters are produced in the following performances: N – for non-explosive areas, NT –

high temperature for non-explosive areas, Xi – Explosion proof – intrinsically safe for hazardous

(explosive) areas and XiT - high-temperature conf. for explosive environments. CLM are oered

in variants with various types of process connection (thread, Tri-clamp).

Capacitive level meters are suitable for continuous level measurement of liquid and bulk-solid

materials. CLMs are resistant to any changes in the atmosphere above the surface (vacuum,

pressure, vapours, dust).

To ensure maximum safety of control processes, we have dened the following safety instructions

and information. Each instruction is labelled with the appropriate pictogram.

This symbol informs you about particularly important instructions for installation and operation of

equipment or dangerous situations that may occur during the installation and operation. Not observing

these instructions may cause disturbance, damage or destruction of equipment or may cause injury.

This symbol indicates particularly important characteristics of the device.

This symbol indicates helpful additional information.

All operations described in this instruction manual have to be carried out by trained personnel

or by an accredited person only. Warranty and post warranty service must be exclusively

carried out by the manufacturer.

Improper use, installation or set-up of the sensor can lead to crashes in the application.

The manufacturer is not responsible for improper use, loss of work caused by either direct

or indirect damage, and for expenses incurred at the time of installation or during the period

of use of the level sensors.

5

© Dinel, s.r.o. CLM–36

• CLM–36_–10 With uncoated rod electrode for level measurement of non-conductive

liquids (oils, diesel, petrol) and powder or bulk-solid materials (our, sand,

cement, plastic granulates, etc.).

Electrode length from 0.2 m to 5 m (for materials with a low permittivity

εr <10, the minimum electrode length is 0.5m).

• CLM–36_–11 With fully (PFA) coated rod electrode suitable for surface level measurement

of water and other electrically conductive liquids. Also suitable for polluted

liquids in metallic storage tanks, concrete sumps, etc.

Electrode length from 0.2 m to 3 m.

• CLM–36_–12 With fully (FEP) coated rod electrode suitable for surface level measurement

of water and other electrically conductive liquids. Also suitable for polluted

liquids in metallic storage tanks, concrete sumps, etc.

Electrode length from 0.2 m to 3 m.

• CLM–36_–20 With uncoated rod electrode and reference tube for accurate level meas-

urement of clean non-conductive liquids (oils, diesel, petrol).

Electrode length from 0.2 m to 3 m.

• CLM–36_–22 With fully FEP coated rod electrode and reference tube for surface level

measurement of electrically conductive liquids, (e.g. in plastic or glass storage

tanks) and where greater measurement accuracy is required. Electrode

insulation from FEP material.

Electrode length from 0.2 m to 3 m.

• CLM–36_–30 With uncoated stainless steel rope electrode and uncoated weight for

level measurement of bulk-solid materials (grains, sand, our, cement, etc.)

Shortened cable option.

Electrode length from 1 m to 20 m.

• CLM–36_–31 With uncoated stainless steel rope electrode and coated dynamic

anchorage for level measurement of bulk-solid materials in higher silos.

Electrode length from 1 m to 20 m.

• CLM–36_–32 With fully coated rope electrode and coated weight (rope insulation FEP,

weight insulation PTFE), for level measurement of electrically conductive and

non-conductive liquids.

Electrode length from 1 m to 20 m.

CLM–36 © Dinel, s.r.o.

6

CLM–36_–30CLM–36_–10, 11, 12 CLM–36_–20, 22

* type threads: M36x2; G1"

** for materials with a low permittivity (εr <10) the

minimum electrode length is E500.

thread *

High temperature variants

CLM–36_T

18056

7

© Dinel, s.r.o. CLM–36

CLM–36_–32 CLM–36_–31

Rope

electrode

Wall of container

(KV–31, PR–31)*

Spring

Anchor with

spherical joint

thread **

Housing with Tri-clamp

coupling

* Anchor welding cylinder KV–31 or Dust-tight

bushing PR–31 (see accessories)

** type of threads: Tri-Clamp CI50 (ø 50,5 mm)

CLM–36 © Dinel, s.r.o.

8

• In a curved tanks (most frequently horizontal cylinder)

capacity change during measuring of electrically non-

conductive material is non-linear.

• Linearity is done by reference tube (CLM – 36_–20, 22).

• In the tank with straight wall (for example vertical

cylinder) and with the sensor placed parallely

with the wall capacity change is linear.

FOR TYPE: CLM-36_-10, 11, 12

CLM-36_-30, 31, 32

FOR TYPE: CLM-36_-20, 22

FOR TYPE: All variants

9

© Dinel, s.r.o. CLM–36

• Level meters with coated electrode have protection cover at the end of electrode, which is

necessary take down before mounting.

• Level meters mount in vertical position to upper lid of tank or reservoir by steel welding ange

ON-36x2 (steel 11375), stainless steel welding ange NN-36x2 (stainless steel 1.4301), xing

nut UM-36x2 (stainless steel 1.4301) or Clamp ange.

• For mounting level meter to the metal tank or reservoir is not necessary to ground housing again.

• In case of installation in concrete sumps or silos it is properly to install level meter at metallic

auxiliary construction (console, lid, etc.) and then connect with metal all the time submerged

object, eventually with steel armouring.

• For measuring of material in plastic and glass vessels by level meter without reference

tube is necessary to connect grounding screw at housing with auxiliary electrode which is

xed by the appropriate method to the outer casing of vessels (or at inner wall). Material of

auxiliary electrode is necessary to choose with consideration to the working environment and

properties of measured material.

E- the length of electrode [mm] - the end of

the electrode has to be dipped min. 20 mm

below the lowest measured level

h- the distance from the bottom - min. 50 mm

a- the distance from the wall - min. approx. E/20

d- the diameter of auxiliary tube vessel - min.

40 + E/20 (smaller dimension has to be

discussed with producer)

auxiliary electrode

width = min. 30 mm

(necessary only for

non-metal vessels)

Fig. 1: Installation of level meter with rod electrode

Please follow next 3 steps:

METAL AND NON-METAL VESSESLS FOR TYPE: CLM-36_-10, 11, 12

CLM–36 © Dinel, s.r.o.

10

h - the distance from the bottom

- min. 50 mm with respect on

possibility of presence of heavy

fraction (water) in oil products

k - the distance from the wall -

optional

connection to the

armouring

E - The length of electrode - the lower end of the electrode has to be dipped - min. 20 mm below the lowest measured level

h - The distance from the bottom - min. 100 mm

a - The distance from the wall - at least E/20, as far as possible from the walls, to the middle between the wall and the vertical

inlet

concrete silo

metal tank

Fig. 2: Installation of level meter with reference tube

Fig. 3: Installation of level meter with rope electrode

VARIANTS WITH REFERENCE TUBE FOR TYPE: CLM-36_-20, 22

DEEP VESSELS, CONTAINERS AND SILOS FOR TYPE: CLM-36_-30, 32

11

© Dinel, s.r.o. CLM–36

E - the length of electrode [mm]

t - the length of the conduction

rod - approx. 500 mm

p - the length of the press

spring - approx. 200 mm

c - the distance from the centre

line of the silo - has to be as

minimal as possible

steel anchor welding

cylinder (mat. 11375) or

dust-tight bushing

to be welded into the

conical bottom wall

Fig. 4: Installation of rope electrode with anchor

ROPE ELECTRODE WITH ANCHOR FOR TYPE: CLM-36_-31

CLM–36 © Dinel, s.r.o.

12

The level meter is designed to be connected to supply unit or to controller through a cable with

the outer diameter of 6 ÷ 8 mm (recommended cross-section of cores 0.5 ÷ 0.75 mm2) by means

of connector which is standard part of CLM level meter. The diagram and the inside view of the

connector are shown in the gures. Disassemblable connector IP67 with a 5m long PVC cable

can be supplied as an above-standard accessory.

Procedure to connect the cable to the level meter:

1. Unscrew connector from the body of the level meter using a suitable screwdriver.

2. Use a at screwdriver to remove the inner part of the connector (screwdriver into the gap

marked by arrow).

3. Unscrew the cable gland and put the cable inside.

4. Connect the cable wires to the screw terminals as shown in Fig. 7 (current output 4-20 mA) or

Fig. 9 (voltage output 0-10 V). Tighten the terminals rmly.

5. Push the terminals back into the connector so that the terminal no. 3 is oriented toward the

cable entry. Tighten the cable gland.

6. Check the seal on the connector and connect the connector back to the body of the sensor.

Fig. 6: Connection scheme with current

output

Shielding

(GNYE)

+U (BN)

0V (BU)

Fig. 7: Connection scheme with

current output

Fig. 8: Connection scheme with voltage

output

Uout (BK) +U (BN)

Shielding

(GNYE)

0V (BU)

Fig. 9: Connection scheme with

voltage output

13

© Dinel, s.r.o. CLM–36

Electrical connection can only be made when de-energized!

The source of the power voltage must comprise of a stabilised safe low power source with

galvanic separation. In the event that a switch-mode power supply is used, it is essential

that its construction effectively suppresses common mode interference on the secondary

side. In the event that the switch-mode power supply is equipped with a PE safety terminal, it

mustbe unconditionally grounded! Spark-safe devices type CLM–36Xi(XiT) must be powered

from a spark-safe power source meeting the above-mentioned requirements.

Due to the possible occurrence of an electrostatic charge on the non-conductive parts of

the sensor, it is necessary to ground all sensors intended for use in environments with an

explosion hazard type CLM–36Xi(XiT). This can be performed by grounding el. conductive

tanks or el. conductive tank lids, and in the case of el. non-conductive tanks using and

grounding an auxiliary plate electrode PDE-27.

In the event that sensor is installed in an outdoor environment at a distance greater than 20

m from the outdoor switchboard, or from an enclosed building, it is necessary to supplement

the electrical cable leading to sensor with suitable over voltage protection.

In the event of strong ambient electromagnetic interference, paralleling of conductors with

power distribution, or for distribution to distances over 30 m, we recommend using a shielded

cable and grounding the shielding on the side of the power source.

CLM–36 © Dinel, s.r.o.

14

1. For access to the adjustment elements disconnect a connector and unscrew a nut (attention for

inside connecting wires). Connect the connector again.

2. Connect the level meter to the supply unit through milliammeter (controller, etc.).

3. Set the trimmer*1) 20 mA into the basic position (this position is set by producer):

a) Turn the trimmer totally right (clockwise).

b) Turn the trimmer back about 3 turns left (anti clockwise).

*1) The trimmers are without backstops - approx. 15 turns

Fig. 10: The top view on the internal electronic module

with current output (variant –I)

DIP switches

(for range select)

trimmer 4 mA

(for compensation

of initial capacity)

trimmer 20 mA

(for sensitive span

adjustment)

BU (-) BN (+)

GNYE

(Shielding)

brass tie

(for pull out of

electronic module)

DIP switches (for

range select)

trimmer 0 V

(for compensation of

initial capacity) trimmer 10 V

(for sensitive span

adjustment)

BU (-) BN (+)

GNYE

(Shielding)

BK

(Uout)

brass tie

(for pull out of

electronic module)

0V 10V

Fig. 11: The top view on the internal electronic module

with voltage output (variant –U)

Legend:

GNYE – green-yellow

BU – blue

BK – black

BN – brown

15

© Dinel, s.r.o. CLM–36

1. Empty the tank to the minimum level.

2. Set the DIP switches on the CLM to range*3) No. 2 (250 pF).

3. By a screwdriver turn the trimmer 4 mA and set the quiescent current of the level meter to

4 mA. Turning rightwards (clockwise) increases the current, turning leftwards decreases the

current. When it is impossible to set required current to 4 mA, then switch DIP switches to the

nearest higher range and set up the current 4 mA at that range.

4. Fill the tank to the maximum level. When it is impossible ll the tank to the maximum known

(or checkable) level. For the next settings calculate the output current using the next formula:

I out = 4 + (0,16 x level in %) [mA]

5. If the output current is less than 20 mA (or the calculated value of I out), set the DIP switch to the

lowest range No. 1. and continue to step 7. When the output current exceeds 20 mA, continue

on step 6.

6. Set the DIP switches step by step to higher ranges till the current is greater then 20 mA (or

calculated value of I out), then the current e.g. 21 mA*4) ows through the level meter. Trimmer

20 mA is still in basic position.

7. Then set the current of CLM by trimmer 20 mA onto 20 mA (or to the calculated value of I out

- see above).

8. To reach a maximum accuracy is useful to check the setting of 4 mA again (compensation of

initial capacity - quiescent current).

1. Empty tank to the minimum level.

2. By DIP switches on level meter set range*3) No. 2 (250 pF).

3. Use a screwdriver to turn the trimmer to 0 V and set the voltage at the output from the level

meter to 0 V. Turning rightwards (clockwise) increases the voltage, turning leftwards decreases

the voltage. When it is impossible to set required voltage to 0 V, then switch DIP switches to the

nearest higher range and set up the voltage 0 V at that range.

4. Fill the tank to the maximum level. When it is impossible ll the tank to the maximum known

(or checkable) level. For the next settings calculate the output voltage using the next formula:

U out = 0,1 x level in % [V]

5. If the output voltage is less than 10 V (or the calculated value of U out), set the DIP switchto the

lowest range No. 1. and continue to step 7. When the output voltage exceeds 10 V, continue

on step 6.

6. Set the DIP switches step by step to higher ranges till the voltage is greater then 10 V (or

calculated value of U out), then the voltage e.g. 10,5 V ows through the level meter. Trimmer

10 V is still in basic position.

CLM–36 © Dinel, s.r.o.

16

7. Then set the voltage of CLM by trimmer 10 V onto 10 V (or to the calculated value of U out -

see above).

8. To reach a maximum accuracy is useful to check the setting of 0 V again.

Table of ranges

No. Sensitivity 2) (C) Range 3) (R) Position of DIP switch

11) 20 pF 70 pF

230 pF 250 pF

350 pF 600 pF

4100 pF 1 200 pF

5150 pF 3 000 pF

6300 pF 7 000 pF

7500 pF 18 000 pF

81 000 pF 36 000 pF

Tables of recommended ranges depending on the medium and the type of level meter

Medium Plastic granulates (εrapproximately 2)

Type / electrode length 1 m 2 m 5 m 10 m 20 m

10, 30, 31 12234

Medium Flour, sand, grains (εrapproximately3)

Type / electrode length 1 m 2 m 5 m 10 m 20 m

10, 30, 31 22345

Medium Cement (εrapproximately 4)

Type / electrode length 1 m 2 m 5 m 10 m 20 m

10, 30, 31 22345

Medium Water (water solutions)

Type / electrode length 1 m 2 m 5 m 10 m 20 m

11, 12 345x x

22 3 4 xxx

32 34566

Medium Benzine, petroleum, diesel, oil (εrapproximately 2)

Type / electrode length 1 m 2 m 5 m 10 m 20 m

10, 30 12234

20 3 4 xxx

17

© Dinel, s.r.o. CLM–36

CLM-36

Nnon-explosive areas

NT high temperature performance

Xi for explosive environments

XiT high-temperature conf. for explosive environments

10 uncoated St. steel rod electrode, length 0,2 / 0,5 ... 5 m

11 fully coated St. steel rod electrode (PFA), length 0,2 ... 3 m

12 fully coated St. steel rod electrode (FEP), length 0,2 ... 3 m

20 uncoated St. steel rod electrode with reference tube, length 0,2 ... 3 m

22 coated St. steel rod electrode with reference tube (FEP), length 0,2 ... 3 m

30 uncoated St. steel rope electrode, length 1 ... 20 m

31 uncoated St. steel rope electrode with anchor, length 1 ... 20 m

32 suspension electrode with insulated cable (FEP) and insulated ballast (PTFE), length

1 ... 20 m

Mthread M36x2

Gthread G1"

Cl50 Tri-clamp (ø 50,5 mm)

Icurrent (4 ... 20 mA)

Uvoltage (0 ... 10 V)

Eelectrode length in mm

Kcable length in m

C N I

*1) Range No. 1 (70 pF) is very sensitive and we recommend to use it only at level meters with short electrode (approx. to 500

mm) and measured media with low permittivity

*2) Sensitivity - minimal capacity change of electrode to reach output range 4 ÷ 20 mA or 0 ÷10 V.

*3) Range = capacity of housing + activated electrode to reach output range 4 ÷ 20 mA or 0 ÷10 V. (For example.: uncoated

electrode 1000 mm immersion in fuel: 20 pF + 30 pF, coated electrode 1000 mm immersion in water: 20 pF + 500 pF)

*4) In case of short of electrode on housing or setting of a very sensitive range can caused to current restriction of level meter

on value max. 30 mA.

Note.: Types 10, 12, 30, 31, 32 in distance 250 mm from conducting wall.

Showned ranges are orientation. Exact range for existing conguration electrode / tank must be

set directly in application on mearured medium.

CLM–36 © Dinel, s.r.o.

18

CLM–36N–10–G–I E1000

(N) normal (for non-explosive areas); (10) uncoated St. steel rod electrode; (G) process connection thread G1"; (I)

current (4 ... 20 mA); (E1000) length electrode 1000 mm

CLM–36XiT–30–G–I E9750

(XiT) high-temperature conf. for explosive environments; (30) uncoated St. steel rope electrode; (G) process connec-

tion thread G1"; (I) current (4 ... 20 mA);(E9750) length electrode 9750 mm.

optional – for a surcharge (see catalogue

sheet of accessories)

• Connector with protection class IP67 (GAN–

DADE 7A) with 5 m cable (current output)

• Connector with protection class IP67 (GAN–

DAAE 7A) with 5 m cable (voltage output)

• Steel welding ange ON–36x2

• St. steel welding ange NN–36x2

• St. steel xing nut UM–36x2

• Anchor welding cylinder KV–31 (only

CLM–36–31)

• Dust-tight bushing PR–31(only CLM–

36–31)

standard (included in the level meter price)

• 1x of seal, other seals are on request

(PTFE, Al, etc.) *

• 1x connector socket

• 1x scr ewdr iver for adjustme nt (eac h 5 pcs)

* Pressure resistance - see the table in the

accessories datasheet in the "seals and

gaskets".

19

© Dinel, s.r.o. CLM–36

Level meter is equipped with protection against electric shock on the electrode, reverse polarity,

output current overload, short circuit and against current overload on output.

Protection against dangerous contact is provided by low safety voltage according to 33 2000-4-41.

Electromagnetic compatibility is provided by conformity with standards EN 55022 / B, EN 61326-1,

EN 61000-4-2 to -6.

Explosion proof CLM–36Xi(XiT) is provided by conformity with standards EN 60079-

0:2013+A11:2014, EN 60079-11:2012.

Explosion proof CLM–36Xi(XiT) is veried FTZÚ – AO 210 Ostrava – Radvanice: FTZÚ 02 ATEX

0235X.

A declaration of conformity was issued for this device in the wording of Act No. 90/2016 Coll., as

amended. Supplied electrical equipment matches the requirements of valid European directives for

safety and electromagnetic compatibility.

If the apparatus is used as device of Group II and with using of an approved power supply device,

which output parameters comply with required input parameters, it is necessary to have an galvanic

separation.

When used in zone 0 the present explosive atmosphere of air mixture and gases, vapours of mists

must comply with: -40°C ≤ Tamb ≤ 60°C; 0,08 Mpa ≤ p ≤ 0,11 Mpa.

Design CLM–36Xi can be used in zone 0 or zone 20. With design CLM–36XiT can be used in zone

0 and zone 20 only electrode part an head with electronics can be used only in zone 1 or zone 21.

Ambient temperature: Tamb = -40°C to +75°C

Temperature of measured medium according to design variant:

bar non-insulated electrode -40°C to +200°C

bar insulated electrode -40°C to +120°C

cable with insulated cable -40°C to +105°C

Maximum temperature of electrodes is equal to temperature of measured medium.

Maximum input parameters: Ui = 30 V; Ii = 132 mA; Pi = 0,99 W; Ci = 370 nF; Li = 0,9 mH

CLM–36 © Dinel, s.r.o.

20

The level meter does not require any personnel for its operation. Follow-up displaying device is

used to inform the technological entity operating personnel on the measured substance level height

during the operation.

MAINTAINCE OF LEVEL METER

Maintenance of this equipment consists in verication of integrity of the level meter and of the sup-

ply cable. Depending on the character of the substance measured, we recommend to verify at least

once per year the clarity of the ultrasound transducer emitting eld and to clean it, respectively. In

case any visible defects are discovered, the manufacturer or reseller of this equipment must be

contacted immediately.

It is forbidden to perform any modications or interventions into the CLM–36 level meter

without manufacturer's approval. Potential repairs must be carried out by the manufacturer

or by a manufacturer authorized service organization only.

Installation, commissioning, operation and maintenance of the CLM–36 level meter has to

be carried out in accordance with this instruction manual; the provisions of regulations in

force regarding the installation of electrical equipment have to be adhered to.

The level meter must be installed to prevent tensile overload of the rope electrode, see.

Specications.

REPLACEMENT OF DEFECTIVE ELECTRONIC MODULE

In case of detected electronic failure it is possible to replace the electronic module directly in pro-

cess place of level meter by following procedure:

1. Disconnect connector and unscrew a nut (attention for inside connecting wires).

2. Defective electronic module pick up by pliers onto brass tie and remove by tensile from housing

of level meter.

3. Check placing of white seal O-ring in housing and on pressure ring.

4. Repaired or new electronic module return back into housing of level meter and press down by

clamping ring (attention that contact pin will be a little open before insertion and contact springs

were not pressed under level of electronic casing).

5. Check placing of black seal O-ring on connector.

6. Screw a nut back (attention for inside connecting wires) and connect the connector.

contact pin

contact springs

brass tie

electronic module

cover

trimmers

Fig. 12: Side view of the electronic module

This manual suits for next models

8

Table of contents

Other Dinel Measuring Instrument manuals

Dinel

Dinel ULM-55N User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel CLM-70 User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel DLM-35 User manual