Dinel ULM-53 series User manual

Read carefully the instructions published in this manual before the first use of the level meters. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice.

INSTRUCTION MANUAL

ULTRASONIC LEVEL METERS ULM–53

CONTENT

Safety ...............................................................................................................................................3

Measuring principle..........................................................................................................................3

Range of application ........................................................................................................................3

Features of variants .........................................................................................................................3

Dimensional drawings ....................................................................................................................4

Installation instructions ....................................................................................................................5

Electrical connection ......................................................................................................................8

Set-up elements...............................................................................................................................8

Status and failure signalization........................................................................................................9

Operational modes ..........................................................................................................................9

Setting up .........................................................................................................................................9

Order code ..................................................................................................................................... 11

Accessories ....................................................................................................................................11

Safety, protection, compatibility and explosion proof.................................................................... 11

Use, manipulation and maintenance .............................................................................................11

Marking of labels............................................................................................................................12

Technical specifications.................................................................................................................16

Area classification..........................................................................................................................17

ULM–53 © Dinel, s.r.o.

3

SAFETY

All operations described in this instruction manual have to be carried out by trained personnel or by

an accredited person only. Installation, commissioning, operation and maintenance of the ultrasonic

level meters has to be carried out in accordance with this instruction manual; the provisions of

regulations in force regarding the installation of electrical equipment have to be adhered to.

Improper use, installation or set-up of the sensor can lead to crashes in the application, (overfilling

of the tank or damage of system components).

The manufacturer is not responsible for improper use, loss of work caused by either direct or

indirect damage, and for expenses incurred at the time of installation or during the period of use

of the sensor.

Customer service must be carried out by the manufacturer exclusively.

MEASURING PRINCIPLE

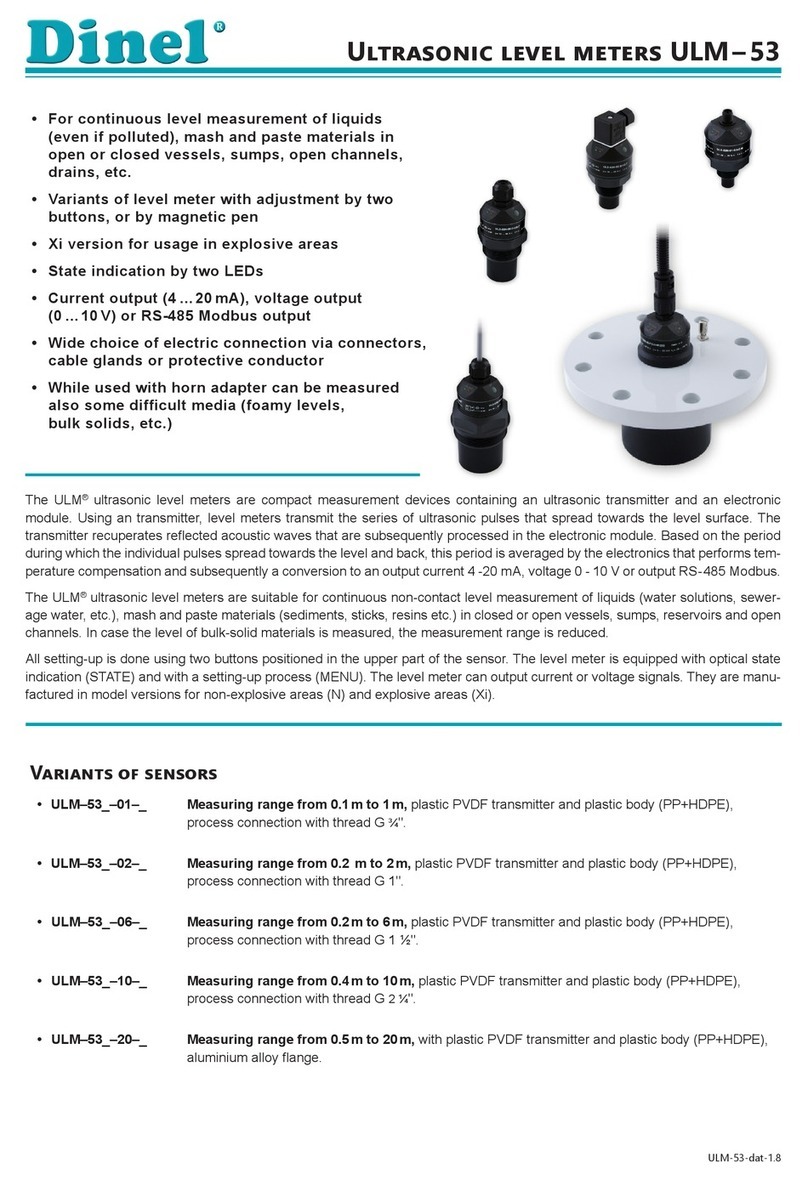

The ULM®ultrasonic level meters are compact measurement devices containing an ultrasonic

transmitter and an electronic module. Using an transmitter, level meters transmit the series of

ultrasonic pulses that spread towards the level surface. The transmitter recuperates reflected

acoustic waves that are subsequently processed in the electronic module. Based on the period

during which the individual pulses spread towards the level and back, this period is averaged by

the electronics that performs temperature compensation and subsequently a conversion to an

output current (voltage).

RANGE OF APPLICATION

For continuous non-contact level measurement of liquids (water solutions, sewerage water, etc.),

mash and paste materials (sediments, sticks, resins etc.) in closed or open vessels, sumps, reser-

voirs and open channels. In case the level of bulk-solid materials is measured, the measurement

range is reduced.

All setting-up is done using two buttons positioned in the upper part of the sensor. The level meter

is equipped with optical state indication (STATE) and with a setting-up process (MENU). The level

meter can output current or voltage signals. They are manufactured in model versions for non-

explosive areas (N) and explosive areas (Xi).

ULM–53_–02–_ measuring range from 0.25m to 2m, plastic PVDF transmitter and plastic

body (PP+HDPE), process connection with thread G 1".

ULM–53_–06–_ measuring range from 0.25m to 6m, plastic PVDF transmitter and plastic

body (PP+HDPE), process connection with thread G 1 ½".

ULM–53_–10–_ measuring range from 0.5m to 10m,plastic PVDF transmitter and plastic

body (PP+HDPE), aluminium alloy ("Xi" version) or HDPE ("N" version)

flange.

ULM–53_–20–_ measuring range from 0.5m to 20m, with plastic PVDF transmitter and

plastic body (PP+HDPE), aluminium alloy flange.

FEATURES OF VARIANTS

4

© Dinel, s.r.o. ULM–53

DIMENSIONAL DRAWINGS

ground

terminal

ULM–53_–02–_ ULM–53_–06–_

ULM–53N–10–_

ULM–53_–20–_

ULM–53Xi–10–I

Al alloy

ground

terminal

Al alloy

HDPE

ULM–53 © Dinel, s.r.o.

5

Fig. 2: Level meter dead zone

m – Dead zone

INSTALLATION INSTRUCTIONS

Install the level meter in a• vertical position into the upper lid of the tank (vessel) or reservoir

using a lug, a fastening nut or a flange in such a way that the ULM axis is perpendicular to the

level of the measured liquid (Fig. 1).

M i n i m u m• dimension parameters when installing into

a lid or a ceiling of a tank are listed in Fig. 3.

When installing in an• open channel (reservoir, drain

and the like), install the level meter onto a console to

the expected maximum level as close as possible.

In compliance with the measurement principle, no sig-•

nals reflected in the area directly below the level me-

ter (the so-called dead zone) can be evaluated. The

dead zone (Fig. 2) determines the minimum distance

possible between the level meter and the highest sur-

face level. Medium minimum distance parameters are

listed in chapter on "Technical specifications".

It is necessary to install the level meter in such a way•

that the bin level does not interfere with the dead

zone when filled up to the maximum. If measured level

interferes with the dead zone, the level meter will not

work properly.

Fig. 1: Recommended installation

in the tank

Fig. 4: Possible installation of the installation neck

Fig. 3: Installation distance from the tank wall

d – Distance from tank

wall

c – Measuring range

In case the maximum surface level in the tank interferes with the dead zone, the level meter•

has to be mounted into a higher installation neck. Subsequently, the tank can be filled nearly

up to the maximum volume. The neck's inner surface has to be even and smooth (without

edges and welded joints), the inner edge should be rounded in the position point where the

ultrasonic waves leave the pipe. Choose the largest possible neck's diameter, but keep the

neck's height as low as possible. Recommended dimensions of the neck are listed in Fig. 4.

a– Neck height

b– Neck width

m– Dead zone

ULM–53–02;06 a< 3b

b>100mm

ULM–53–10 a<1,5b

b>100mm

ULM–53–20 a<1,5b

b>150mm

ULM–53–02 ;10 d>1/12c

(min. 200 mm)

ULM–53–06 d>1/8c

(min. 200 mm)

ULM–53–20 d>1/10c

(min. 200 mm)

6

© Dinel, s.r.o. ULM–53

Foam• on the level absorbs the acoustic wave re-

flection which might cause malfunction of the level

meter. For mounting find the location where the

foaming is as low as possible (Fig. 5).

Emitted acoustic signal must not be affected by• near objects (ladders, mixers, propellers, etc.),

stream of filling, air flow, etc. (Fig. 6).

Fig. 6: Minimum distance of the level meter to nearby objects in

the tank

Do not install the level meter in or above the• filling point. (Fig. 7).

Fig. 7: Level meter installation outside the influence of filling circulation

x – distance to the edge

of the longest object

c – measurement range

of the level gauge

Fig. 5: Thick foam on the surface

!

In case the level of• bulk-solid materials is measured, the measurement range is reduced.

We recommend to consult the use with the manufacturer.

ULM–53–02;10 x> 1/12c

(min. 200 mm)

ULM–53–06 x>1/8c

(min. 200 mm)

ULM–53–20 x>1/10c

(min. 200 mm)

ULM–53 © Dinel, s.r.o.

7

Fig. 10: Reflection board

H + L = dead zone

Fig. 12: Intensely stirred

surface

!

Fig. 9: Prevention to avoid

intrusion of humidity

Fig. 8: Direct solar radiation shielding

cover

The level meter must not be installed in places with•

direct solar radiation and must be protected against

weather conditions.

In case the installation at places with direct solar ra-•

diation is inevitable, it is necessary to mount a shield-

ing cover above the level meter (Fig. 8).

If possible, insert the cable from above and let a drain-•

ing loop in order to avoid intrusion of humidity (Fig. 9).

The cable bushing as well as the connector have to•

be tightened sufficiently to prevent penetration of

moisture.

To lower the minimum distance to the medium meas-•

ured , a reflection board made from solid, even and

smooth material can be installed together with the

level gauge (Fig. 10). Subsequently, the tank can be

filled nearly up to the maximum volume. The solution

is suitable for open tanks and reservoirs.

Scattering or attenuation of the ultrasonic signal•

can result if the surface level has been moderately

stirred or rippled as a consequence a stirrer's op-

eration, inflow of liquid and the like. Consequently,

measuring range or unreliable level meter's function-

ing might follow (Fig. 11).

False surface reflections of the ultrasonic signal might•

result as a consequence of rotating mixer's blades

that ripple the surface level and thus cause unreliable

level meter's functioning (Fig. 12).

The level meter should not be installed at places•

where ultrasonic signal false reflections caused by

stirrer blades might occur (Fig. 13).

!

Fig. 11: Moderately stirred

surface Fig. 13: False reflection caused by

mixer blade

8

© Dinel, s.r.o. ULM–53

ELECTRICAL CONNECTION

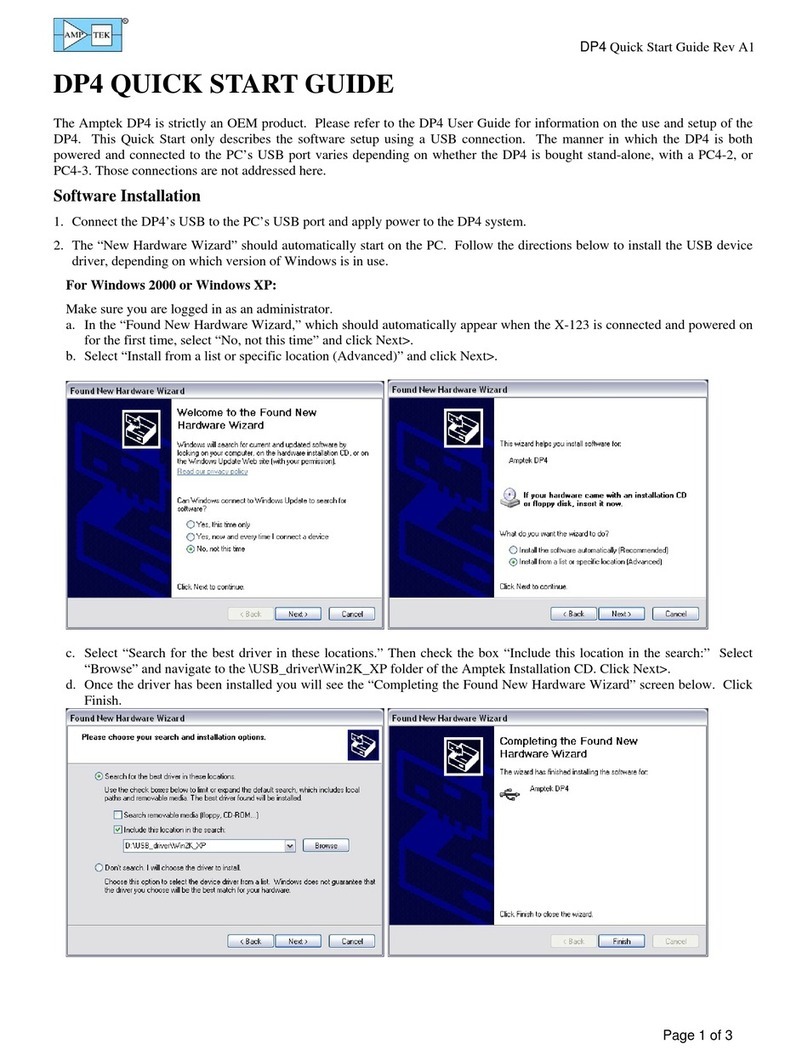

The ultrasonic level meter is designed to be connected to supply unit or to controller through two

or three-wire cable with outer diameter 6 ÷ 8 mm (recommended cross section of cores 0.5 mm2

to 0.75 mm2) by means of connector which is included in delivery. Connection diagram and inner

view of the connector as shown in

Fig. 14 and 15.

Make the electric connection in

voltage-free state.

Note: In case of strong electromag-

netic interferences (EMI), parallel

cable ducting with power lines, or

when cable length exceeds 30m

we recommended to use shielded

cable.

WARNING:

With regard to possible occurrence

of electrostatic charge on non-

conductive parts of the level meter,

metallic flangesof the ULM–53Xi–10

and20 (forexplosive areas) level me-

ters must be grounded with ground

terminal!

SET-UP ELEMENTS

button "DOWN"

– set-up mode access

– direct set-up to value 4 mA (0 V)

– decreasing of values by predefined pitch

button "UP"

– set-up mode access

– direct set-up to value 20mA (10V)

– increasing of values by predefined pitch

LED indicator "STATE"

– signalling of measuring mode

LED indicator "MENU"

– signalling of set-up mode access Fig. 16: Full view of ultrasonic level meter

Button "DOWN"

Button "UP"

LED indicator "MENU"

LED indicator "STATE"

Connector

Ultrasonic transmitter

Safety screw

Fig. 14: Level meter connection diagram ("I" version) and the

inside of the connector socket

Fig. 15: Level meter connection diagram ("U" version) and the

inside of the connector socket

bk – black bn – brown

bu – blue NC – not connected

comments:

+U (bn)

0V (bu)

Uout (bk)

+U (bn)

0V (bu)

ULM–53 © Dinel, s.r.o.

9

SETTING UP

After the level meter has been installed, set it up using the "DOWN" and "UP" buttons (see fig. 16).

The LED indicator "MENU" indicates the on-going set-up procedure of the level meter. You can

set up the "basic mode", which measures the level height (Fig. 17) and set up the "inverse mode"

to measure distances (Fig. 18).

BASIC MODE :

Low margin (4mA or 0V) setting up

The tank fills up to the level required1.

Press the "DOWN" button for at least 2 seconds to activate the set-up mode (the LED indicator2.

"MENU" blinks slowly). Keep the "DOWN" button pressed for another 3 seconds to directly set the

value to 4mA (0V). In this case, item 3 can be omitted.

LED

indicators color function

"STATE" green

Slow flashing (1–2 sec., depends on the measuring interval) – reception of

reflected signal (echo) from the measured level. Correct function.

Fast blinks – the measured value is in "dead zone" of the level meter, or the

ultrasonic transmitter is polluted.

Dark –the measured value is in "dead zone" of the level meter, or the

ultrasonic transmitter is polluted. Incorrect installation or malfunction.

"MENU" yellow Slow blinks – signalization setting limit 4mA (0 V).

Fast blinks – signalization setting limit 20 mA (10V).

STATUS AND FAILURE SIGNALIZATION

OPERATIONAL MODES

The level meters can either work in the "basic" mode that measures the level height (Fig. 17), or in

the "inverse mode" that measures distances (Fig. 18).

Fig. 17: Basic mode

(measurement of level height) Fig. 18: Inverse mode

(distance measurement)

10

© Dinel, s.r.o. ULM–53

3. P

ress the "DOWN" and "UP" buttons to accurately set-up an arbitrary value stepwise

(hold the

relevant button to increase the adjustment step gradually)

.

4. Press both buttons simultaneously for at least 1 second to confirm the values set.

5. Further adjustment cannot be performed sooner than 2 seconds after both of the buttons have

been released.

High margin (20mA or 10V) setting up

1. The tank fills up to the level required

2. Press the "UP" button for at least 2 seconds to activate the setting-up mode (the LED indicator

"MENU" blinks fast). Keep the "UP" button pressed for another 3 seconds to directly set the value

to 20 mA (10V). In this case, item 3 can be omitted.

3. Press the "DOWN" and "UP" buttons to accurately set-up an arbitrary value stepwise

(hold the

relevant button to increase the adjustment step gradually)

.

4. Press both buttons simultaneously for at least 1 second to confirm the values set.

5. Further adjustment cannot be performed sooner than 2 seconds after both of the buttons have

been released.

INVERSE MODE:

Low margin (20mA or 10V) setting up

1. The tank fills up to the level required

2. Press the "UP" button for at least 2 seconds to activate the setting-up mode (the LED indicator

"MENU" blinks fast). Keep the "UP" button pressed for another 3 seconds to directly set the value

to 20 mA (10V).

3. Press the "DOWN" and "UP" buttons to accurately set-up an arbitrary value stepwise

(hold the

relevant button to increase the adjustment step gradually)

.

4. Press both buttons simultaneously for at least 1 second to confirm the values set.

5. Further adjustment cannot be performed sooner than 2 seconds after both of the buttons have

been released.

High margin (4mA or 0V) setting up

1. The tank fills up to the level required

2. Press the "DOWN" button for at least 2 seconds to activate the setting-up mode (the LED indicator

"MENU" blinks slowly). Keep the "DOWN" button pressed for another 3 seconds to directly set the

value to 4mA (0V).

3. Press the "DOWN" and "UP" buttons to accurately set-up an arbitrary value stepwise

(hold the

relevant button to increase the adjustment step gradually)

.

4. Press both buttons simultaneously for at least 1 second to confirm the values set.

5. Further adjustment cannot be performed sooner than 2 seconds after both of the buttons have

been released.

Note 1: In case the level appears in the dead zone (the LED indicator "STATE" blinks fast), the setting-up mode

terminates instantly and is inaccessible as long as the level stays within the dead zone.

Note 2: In case no button is pressed during the "setting-up mode" for as long as 20 seconds, the level meter

returns to the measuring mode. Newly adjusted values will not be saved.

ULM–53 © Dinel, s.r.o.

11

USE, MANIPULATION AND MAINTENANCE

The level meter does not require any personnel for its operation. Follow-up displaying device is

used to inform the technological entity operating personnel on the measured substance level

height during the operation.

Maintenance of this equipment consists in verification of integrity of the level meter and of the

supply cable. Depending on the character of the substance measured, we recommend to verify at

least once per year the clarity of the ultrasound transducer emitting field and to clean it, respec-

tively. In case any visible defects are discovered, the manufacturer or reseller of this equipment

must be contacted immediately.

It is forbidden to perform any modifications or interventions into the ULM–53 level meter without

manufacturer's approval. Potential repairs must be carried out by the manufacturer or by a manu-

facturer authorized service organization only.

Installation, commissioning, operation and maintenance of the ULM–53 level meter has to be car-

ried out in accordance with this instruction manual; the provisions of regulations in force regarding

the installation of electrical equipment have to be adhered to.

SAFETY, PROTECTION, COMPATIBILITY AND EXPLOSION PROOF

The level meter ULM–53 is equipped with protection against reverse polarity and output current

overload.

Protection against dangerous contact is secured by low safety voltage that complies with

EN 33 2000-4-41.

Electromagnetic compatibility according to EN 55022/B, EN 61326/Z1 and EN 61000-4-2 to 6.

Explosion proof of ULM–53Xi type complies with the following standards: EN 60079-0 : 2007;

EN 60079-11 : 2007 ; EN 60079-26 : 2007 and examined by FTZÚ-AO 210 Ostrava - Radvanice

certificate No.: FTZÚ 09 ATEX 0119X.

ORDER CODE

ACCESSORIES

standard – included in the price optional – for extra charge

• 1x Seal (only for ULM–53_–02, 06)

• 1x Connector socket with the IP67

protection class

•

Stainless fixing nut UM–G1'' (for ULM–53_–02–_)

•

Stainless fixing nut UM–G1 ½'' (for ULM–53_–06–_)

Performance:

Maximum range: 02 - 0.2 ... 2m

06 -0.25 ... 6m

10 -0.5 ... 10m

20 -0.5 ... 20m

N- Normal - usable in non-explosive areas only

Xi - Explosive proof - suitable for explosive areas

Output type: I- Current ; U- Voltage (only for performance "N")

ULM–53 ––

12

© Dinel, s.r.o. ULM–53

MARKING OF LABELS

Level meters label data ULM–53N–02–I and ULM–53N–06–I:

Symbol of producer: Dinel logo• ®

Internet address: www.dinel.cz•

Connection scheme and labelling of wires: U• i; 0V

Level meter type:•

ULM–53N–02–I, ULM–53N–06–I

Serial number: Ser. No.: xxxxx - (from the left: production year, serial production number)•

Supply voltage: U• i

=18... 36 V =

Output current range: I• o

=4... 20 mA

Ambient temperature range: t• a= -30 ... +70°C

Protection class: IP67•

Compliance mark:•

Electro-waste take-back system mark:•

Level meters label data ULM–53N–10–I and ULM–53N–20–I:

Symbol of producer: Dinel logo• ®

Internet address: www.dinel.cz•

Connection scheme and labelling of wires: U• i; 0V

Level meter type:•

ULM–53N–10–I, ULM–53N–20–I

Serial number: Ser. No.: xxxxx - (from the left: production year, serial production number)•

Supply voltage: U• i

=18... 36 V =

Output current range: I• o

=4... 20 mA

Ambient temperature range: t• a= -30 ... +60°C

Protection class: IP67•

Compliance mark:•

Electro-waste take-back system mark:•

ULM–53 © Dinel, s.r.o.

13

Level meters label data ULM–53N–02–U and ULM–53N–06–U:

Symbol of producer: Dinel logo• ®

Internet address: www.dinel.cz•

Connection scheme and labelling of wires: U• i ; Uo ; 0 V

Level meter type:•

ULM–53N–02–U, ULM–53N–06–U

Serial number: Ser. No.: xxxxx - (from the left: production year, serial production number)•

Supply voltage: U• i

=18... 36 V =

Output current range: U• o

=0... 10 V

Ambient temperature range• : ta= -30 ... +70°C

Protection class: IP67•

Compliance mark:•

Electro-waste take-back system mark:•

Level meters label data ULM–53N–10–U and ULM–53N–20–U:

Symbol of producer: Dinel logo• ®

Internet address: www.dinel.cz•

Connection scheme and labelling of wires: U• i ; Uo ; 0 V

Level meter type:•

ULM–53N–10–U, ULM–53N–20–U

Serial number: Ser. No.: xxxxx - (from the left: production year, serial production number)•

Supply voltage: U• i

=18... 36 V =

Output current range: U• o

=0... 10 V

Ambient temperature range: t• a= -30 ... +60°C

Protection class: IP67•

Compliance mark:•

Electro-waste take-back system mark:•

14

© Dinel, s.r.o. ULM–53

Level meters label data ULM–53Xi–02–I a ULM–53Xi–06–I:

Symbol of producer: Dinel logo• ®

Internet address: www.dinel.cz•

Connection scheme and labelling of wires: U• i; 0V

Level meter type:•

ULM–53Xi–02–I, ULM–53Xi–06–I

Serial number: Ser. No.: xxxxx - (from the left: production year, serial production number)•

Output current range: I• o

=4... 20 mA

Limit operating parameters:• Ui

=30 V=, Ii=132mA; Pi

=0,99W; Ci=370nF; Li=0,9 mH

Ambient temperature range for the zone 0: t• a= -20 ... +60°C

Ambient temperature range: t• a= -30 ... +70°C

Label of non-explosive device:•

Performance: II 1/2G Ex ia IIB T5•

Number of certificate of intrinsically safety: FTZÚ 09 ATEX 0119X•

Protection class: IP67•

Compliance mark:•

Number of authorized person examining control of system quality: 1026•

Electro-waste take-back system mark• :

Level meters label data ULM–53Xi–10–I

Symbol of producer: Dinel logo• ®

Internet address: www.dinel.cz•

Connection scheme and labelling of wire: U• i; 0V

Level meter type:•

ULM–53Xi–10–I

Serial number: Ser. No.: xxxxx - (from the left: production year, serial production number)•

Output current range: I• o

=4... 20 mA

Limit operating parameters:• Ui

=30 V=, Ii=132mA; Pi

=0,99W; Ci=370nF; Li=0,9 mH

Ambient temperature range for the zone 0: t• a= -20 ... +60°C

Ambient temperature range: t• a= -30 ... +60°C

Label of non-explosive device:•

Performance: II 1/2G Ex ia IIA T5•

Number of certificate of intrinsically safety• : FTZÚ 09 ATEX 0119X

Protection class: IP67•

Compliance mark:•

Number of authorized person examining control of system quality: 1026•

Electro-waste take-back system mark:•

Note: Real label size is 175x11mm.

ULM–53 © Dinel, s.r.o.

15

Level meters label data ULM–53Xi–20–I

Symbol of producer: Dinel logo• ®

Internet address: www.dinel.cz•

Connection scheme and labelling of wire: U• i; 0V

Level meter type:•

ULM–53Xi–20–I

Serial number: Ser. No.: xxxxx - (from the left: production year, serial production number)•

Output current range: I• o

=4... 20 mA

Limit operating parameters:• Ui

=30 V=, Ii=132mA; Pi

=0,99W; Ci=370nF; Li=0,9 mH

Ambient temperature range for the zone 0: t• a= -20 ... +60°C

Ambient temperature range: t• a= -30 ... +60°C

Label of non-explosive device:•

Performance: II 2G Ex ia IIA T5•

Number of certificate of intrinsically safety• : FTZÚ 09 ATEX 0119X

Protection class: IP67•

Compliance mark:•

Number of authorized person examining control of system quality: 1026•

Electro-waste take-back system mark:•

16

© Dinel, s.r.o. ULM–53

TECHNICAL SPECIFICATIONS

Measuring range

1)

ULM–53_–02–_

ULM–53_–06–_

ULM–53_–10–_

ULM–53_–20–_

0.25 ... 2 m

0.25 ... 6 m

0.5 ... 10 m

0.5 ... 20 m

Supply voltage ULM–53N–__–_

ULM–53Xi–__–I

18 ... 36 V DC

18 ... 30 V DC

Current output ULM–53_–__–I

Voltage output ULM–53N–__–U

4 ... 20 mA (limit values 3.9 ... 20.5 mA)

0 ... 10 V (limit values 0 ... 10.2 V)

Resolution < 1 mm

Accuracy

(within the total range)

ULM–53_–06–_;10–_;20–_

ULM–53_–02–_

0.2%

0.3%

Temperature error max. 0.04% / K

Beamwidth (-3 dB)

ULM–53_–02–_;10–_

ULM–53_–06–_

ULM–53_–20–_

10°

14°

12°

Ambient temperature range ULM–53_–02–_;06–_

ULM–53_–10–_;20–_

-30 ... +70°C

-30 ... +60°C

Measuring period

ULM–53_–02–_

ULM–53_–06–_

ULM–53_–10–_

ULM–53_–20–_

0.6 sec.

1.4 sec.

1.8 sec.

5.0 sec.

Averaging (can be modified according to agreement) 8 measuring

Short time temperature stress resistance +90°C / 1 hour

Max. operation overpressure (on transmission surface) 0.1 MPa

Limit operating parameters

2)

(for the Xi version only)

U

i

=30V DC; I

i

=132mA; P

i

=0.99W; C

i

=370nF; L

i

=0.9mH

Failure indication

echo failure – basic mode

echo failure – inverse mode

level in dead zone – basic mode

level in dead zone – inverse mode

3.75 mA (0 V)

22 mA (10.5 V)

22 mA (10.5 V)

3.75 mA (0 V)

Protection class IP67

Recommended cable PVC 2 x 0.75 mm2 (3 x 0.5 mm2)

Current output load resistance (at U = 24 V DC) Rmax = 270 Ω

Voltage output load resistance R > 1 kΩ

Delay between supply power rise

time and first measurement

ULM–53_–02–_;06–_;10–_

ULM–53_–20–_

3 sec.

5 sec.

Delay between power supply rise

time and full emission output

ULM–53_–02–_;06–_;10–_

ULM–53_–20–_

30 sec.

45 sec.

Weight

ULM–53_–02–_

ULM–53_–06–_

ULM–53_–10–_

ULM–53_–20–_

0.20 kg

0.25 kg

0.65 kg

2.80 kg

1) In case the level of bulk-solid materials is measured, the measurement range is reduced.

2) Allowed temperature range in the zone 0: -20°C ... +60°C; allowed pressure range in the zone 0: 80 ... 110kPa.

ULM–53 © Dinel, s.r.o.

17

AREA CLASSIFICATION (according to EN 60079-10 and EN 60079-14)

ULM–53N–_ _–_ Performance for non-explosive areas

ULM–53Xi–02–I

ULM–53Xi–06–I

Explosive proof – suitable for explosive areas (combustible gases or vapours)

II 1/2G Ex ia IIB T5 with isolating repeater (IRU–420),

the whole level meter – zone 1, front head part – zone 0

ULM–53Xi–10–I

Explosive proof – suitable for explosive areas (combustible gases or vapours)

II 1/2G Ex ia IIA T5 with isolating repeater (IRU–420),

the whole level meter – zone 1, front head part – zone 0

ULM–53Xi–20–I

Explosive proof – suitable for explosive areas (combustible gases or vapours)

II 2G Ex ia IIA T5 with isolating repeater (IRU–420),

the whole level meter – zone 1

The lastest version of this instruction manual can be found at www.dinel.cz

(version 02/2010)

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

Phone: +420 577 002 003

Fax: +420 577 002 007

E-mail: [email protected]

www.dinel.cz

industrial electronics

Other manuals for ULM-53 series

5

Table of contents

Other Dinel Measuring Instrument manuals

Dinel

Dinel CLM-36 User manual

Dinel

Dinel ULM-70 Series User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel ULM-55N User manual

Dinel

Dinel DLM-35 User manual

Dinel

Dinel PDU-40-W Series User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel CLM-70 User manual

Popular Measuring Instrument manuals by other brands

janitza

janitza UMG 804 User manual and technical data

Trio

Trio CASA VT-150 instruction manual

David White

David White DWT-10 instruction manual

Siemens

Siemens Sitrans F Series Function manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 66322ANZ1 Installation and operating manual

Amptek

Amptek DP4 quick start guide