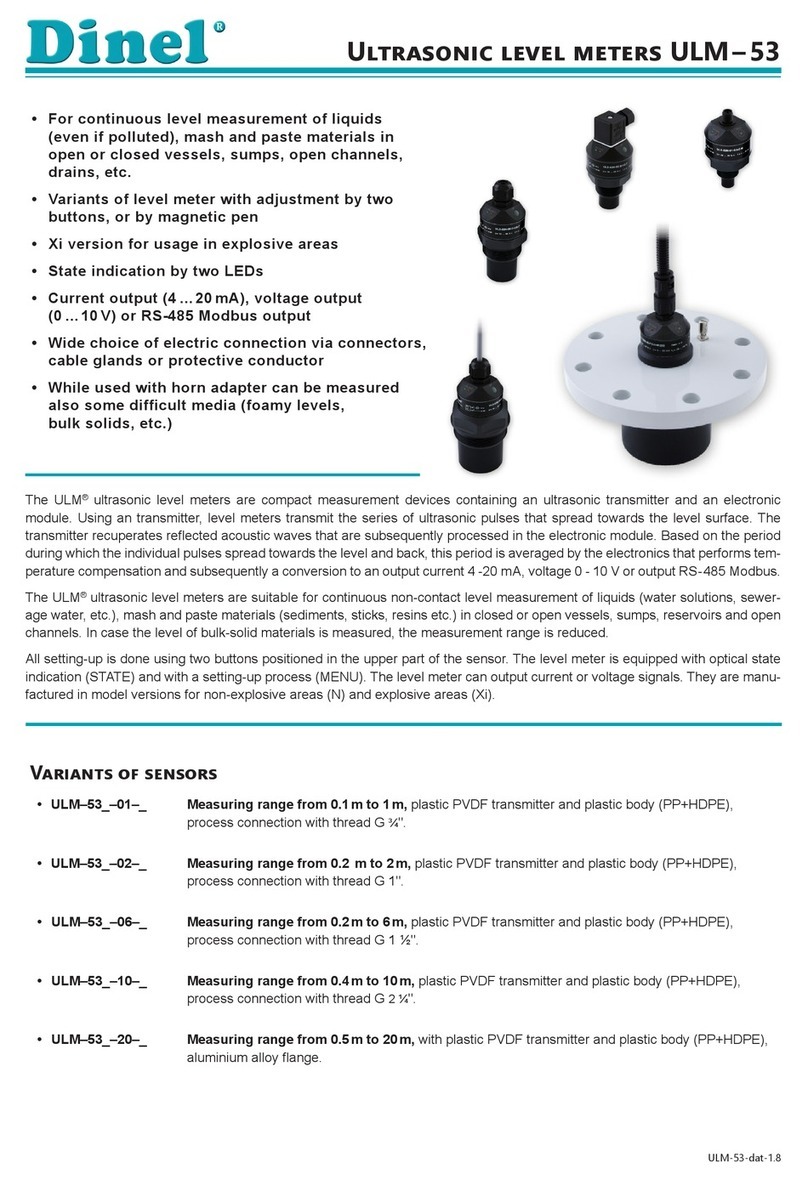

Dinel ULM-53 series User manual

Other manuals for ULM-53 series

5

Table of contents

Other Dinel Measuring Instrument manuals

Dinel

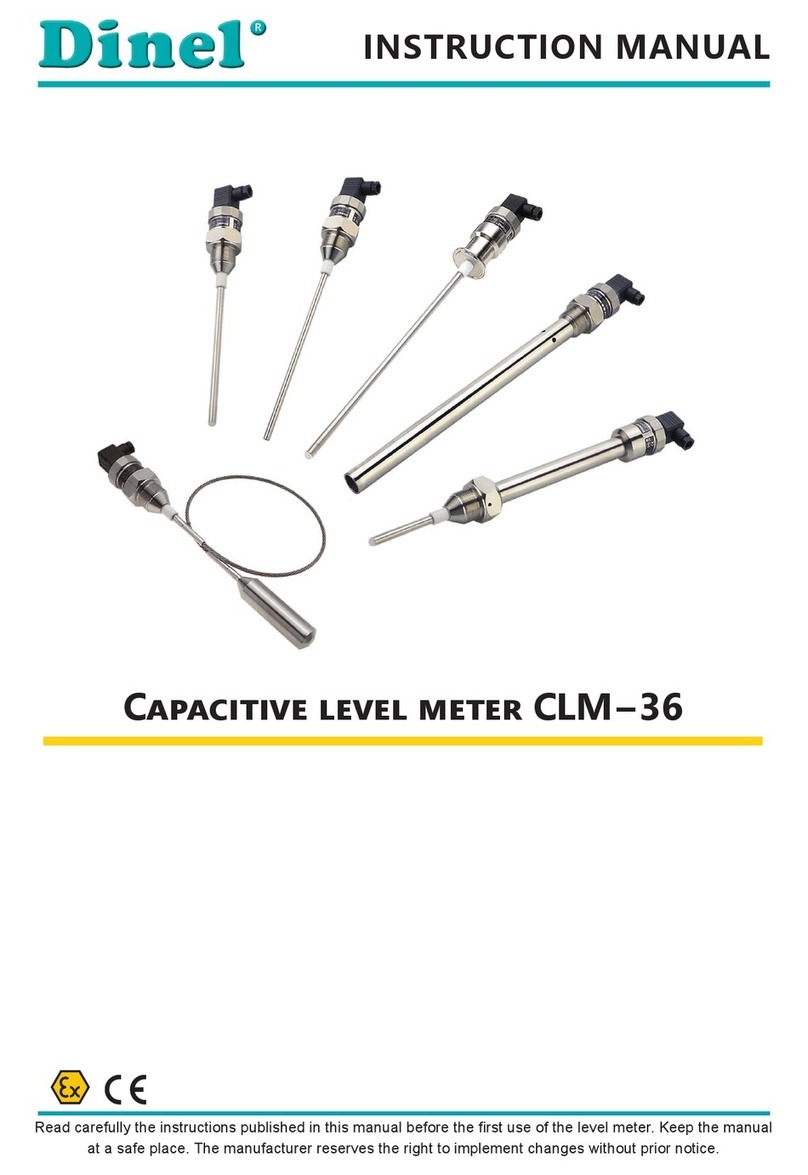

Dinel CLM-36 User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel GRLM-70 User manual

Dinel

Dinel ULM-55N User manual

Dinel

Dinel DLM-35 User manual

Dinel

Dinel ULM - 54 User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel CLM-36-10 User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel PDU-40-W Series User manual

Dinel

Dinel ULM-53L User manual

Dinel

Dinel CLM-70 User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel ULM-70 Series User manual

Dinel

Dinel MLM-35 User manual

Dinel

Dinel ULM-53 series User manual

Popular Measuring Instrument manuals by other brands

janitza

janitza UMG 804 User manual and technical data

Trio

Trio CASA VT-150 instruction manual

David White

David White DWT-10 instruction manual

Siemens

Siemens Sitrans F Series Function manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 66322ANZ1 Installation and operating manual

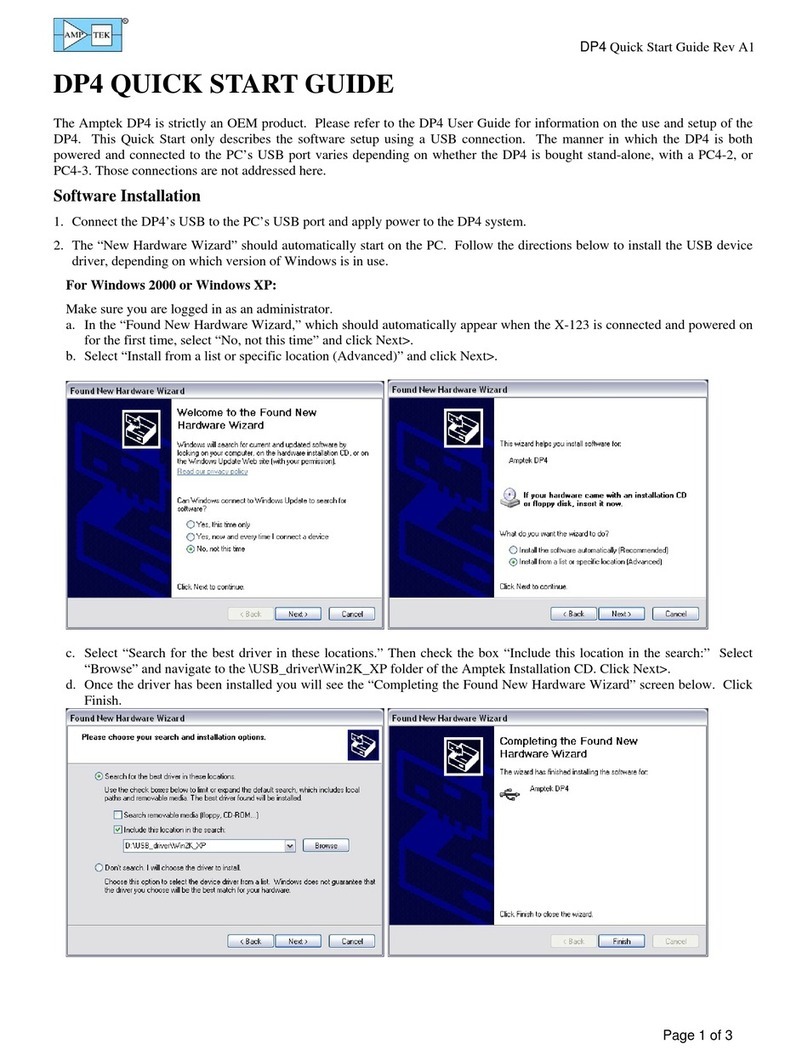

Amptek

Amptek DP4 quick start guide