CLM–36 © Dinel, s.r.o.

19

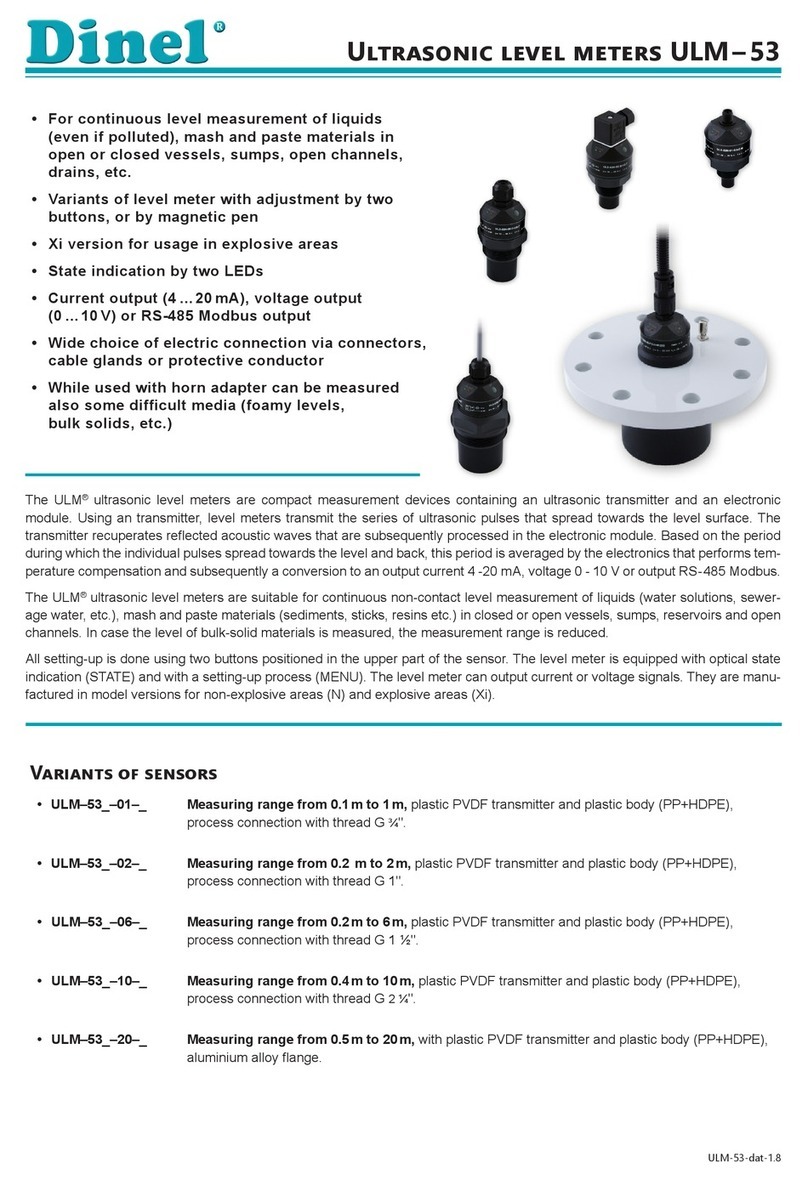

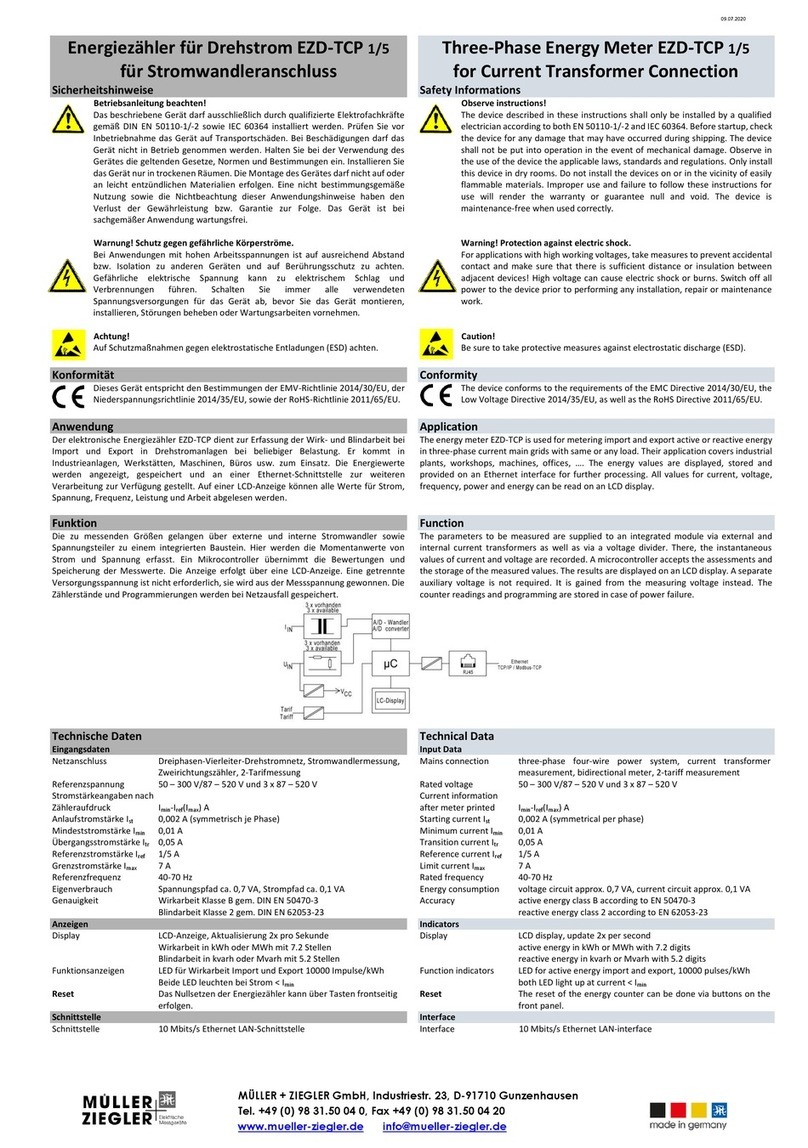

Level meters label data

CLM–36Xi:

Level meters label data

GRLM–70XiT:

IP65

IP67

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

dinel@dinel.cz

U =0÷10V

out

U=16÷36V

i

Dinel

U

3

2Uout

Ui

0V

Vt = -40 ... +85 °C

a

IP65

IP67

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

dinel@dinel.cz

U =0÷5V

out

U=11÷36V

i

Dinel

U

3

2Uout

Ui

0V

Vt = -40 ... +85 °C

a

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

dinel@dinel.cz

I = 4 ... 20 mAU=9...36V

Dinel U

t = -40 ... +85 °C

a

IP65

IP67

0V

1

2

II1D ICT83°CDaExiaII

Dinel

FTZÚ 02 ATEX 0235X

U = 30V I = 132mA P = 0,99W

C = 370nF L = 0,9mH

t = -20 ... +60 °C (zone 0)

t = -40 ... +75 °C

a

a

i

i

i

ii

Ui

Dinel, s.r.o.

Zlín

www.dinel.cz

Czech Republic

CLM-36Xi-__-__-I E_____ No.: ______

IP65

IP67

1026

II1G BT5GaExiaII

II1/2D ICT83°CDa/DbExiaII

Dinel

FTZÚ 02 ATEX 0235X

U = 30V I = 132mA P = 0,99W

C = 370nF L = 0,9mH

t = -20 ... +60 °C (zone 0)

t = -40 ... +75 °C

a

a

i

i

i

ii

Ui

Dinel, s.r.o.

Zlín

www.dinel.cz

dinel@dinel.cz

Czech Republic

CLM-36XiT-__-__-I E_____ No.: ______

IP65

IP67

1026

II1/2G BT5Ga/GbExiaII

CLM-36N_-__-__-U E_____ No.: ______

CLM-36N_-__-__-U E_____ No.: ______

CLM-36N_-__-__-I E_____ No.: ______

Symbol of producer

:

logo Dinel®

Connection scheme and labelling of wires: U, 0V, GND

Type of level meter: CLM-36-Xi-__-_, P/N include length of electrode: E in mm

Serial number: Ser. No.:

______

-

(

from the left: production year, serial production number

)

Label of non-explosive device:

Performance: II 1 G Ex ia IIB T5 Ga, II 1 D Ex ia IIIC T83°C Da

No. of authorized person examining control of system quality

:

1026

Number of certicate of intrinsically safety

:

FTZÚ 02 ATEX 0235X

Limit operating parameters:

Ui= 30 V DC, Ii= 132 mA, Pi= 0,99 W, Ci= 370 nF,

Li= 0,9 mH

Ambient temperature range: ta= -40 ... +75 °C, ta = -20 ... +60 °C (zone 0)

Protection class: IP 65 / IP 67

Compliance mark:

Electro-waste take-back system mark:

IP65

IP67

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

dinel@dinel.cz

U =0÷10V

out

U=16÷36V

i

Dinel

U

3

2Uout

Ui

0V

Vt = -40 ... +85 °C

a

IP65

IP67

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

dinel@dinel.cz

U =0÷5V

out

U=11÷36V

i

Dinel

U

3

2Uout

Ui

0V

Vt = -40 ... +85 °C

a

Dinel, s.r.o.

Zlín, Czech Republic

www.dinel.cz

dinel@dinel.cz

I = 4 ... 20 mAU=9...36V

Dinel U

t = -40 ... +85 °C

a

IP65

IP67

0V

1

2

II1D ICT83°CDaExiaII

Dinel

FTZÚ 02 ATEX 0235X

U = 30V I = 132mA P = 0,99W

C = 370nF L = 0,9mH

t = -20 ... +60 °C (zone 0)

t = -40 ... +75 °C

a

a

i

i

i

ii

Ui

Dinel, s.r.o.

Zlín

www.dinel.cz

dinel@dinel.cz

Czech Republic

CLM-36Xi-__-__-I E_____ No.: ______

IP65

IP67

1026

II1G BT5GaExiaII

II1/2D ICT83°CDa/DbExiaII

Dinel

FTZÚ 02 ATEX 0235X

U = 30V I = 132mA P = 0,99W

C = 370nF L = 0,9mH

t = -20 ... +60 °C (zone 0)

t = -40 ... +75 °C

a

a

i

i

i

ii

Ui

Dinel, s.r.o.

Zlín

www.dinel.cz

Czech Republic

CLM-36XiT-__-__-I E_____ No.: ______

IP65

IP67

1026

II1/2G BT5Ga/GbExiaII

CLM-36N_-__-__-U E_____ No.: ______

CLM-36N_-__-__-U E_____ No.: ______

CLM-36N_-__-__-I E_____ No.: ______

Symbol of producer

:

logo Dinel®

Connection scheme and labelling of wires: U, 0V, GND

Type of level meter: CLM-36-XiT-__-_, P/N include length of electrode: E in mm

Serial number: Ser. No.:

______

-

(

from the left: production year, serial production number

)

Label of non-explosive device:

Performance: II 1/2 G Ex ia IIB T5 Ga/Gb, II1/2D Ex ia IIIC T83°C Da/Db

No. of authorized person examining control of system quality

:

1026

Number of certicate of intrinsically safety

:

FTZÚ 02 ATEX 0235X

Limit operating parameters:

Ui= 30 V DC, Ii= 132 mA, Pi= 0,99 W, Ci= 370 nF,

Li= 0,9 mH

Ambient temperature range: ta= -40 ... +75 °C, ta = -20 ... +60 °C (zone 0)

Protection class: IP 65 / IP 67

Compliance mark:

Electro-waste take-back system mark: