Dinel CLM-70 User manual

Before the rst use of the level meter , read the instructions in this manual and keep it

carefully. The manufacturer reserves the right to make alterations without a prior notice.

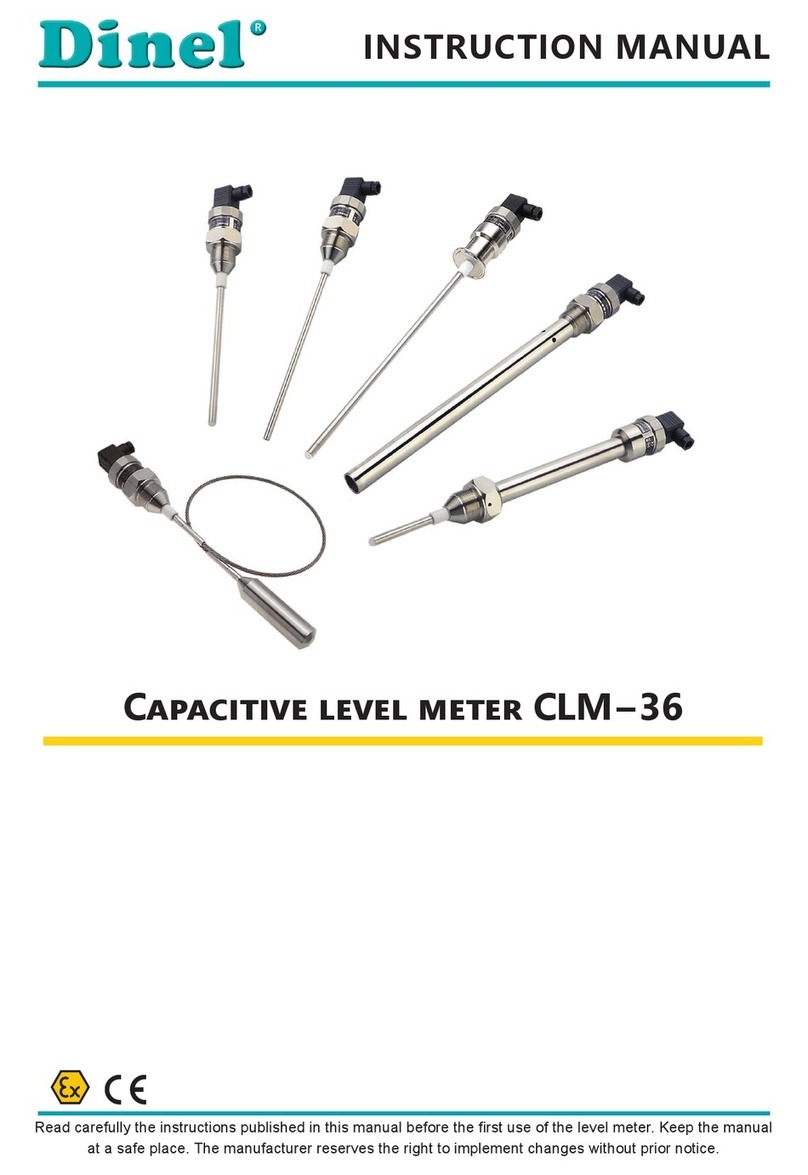

Capacitive level meter

CLM–70

INSTRUCTION MANUAL

Applies to rmware version 1.0

Contents

1. Safety.............................................................................................................................................4

2. Basic description.........................................................................................................................4

3. Range of application ..................................................................................................................5

4. Variants of sensors ....................................................................................................................5

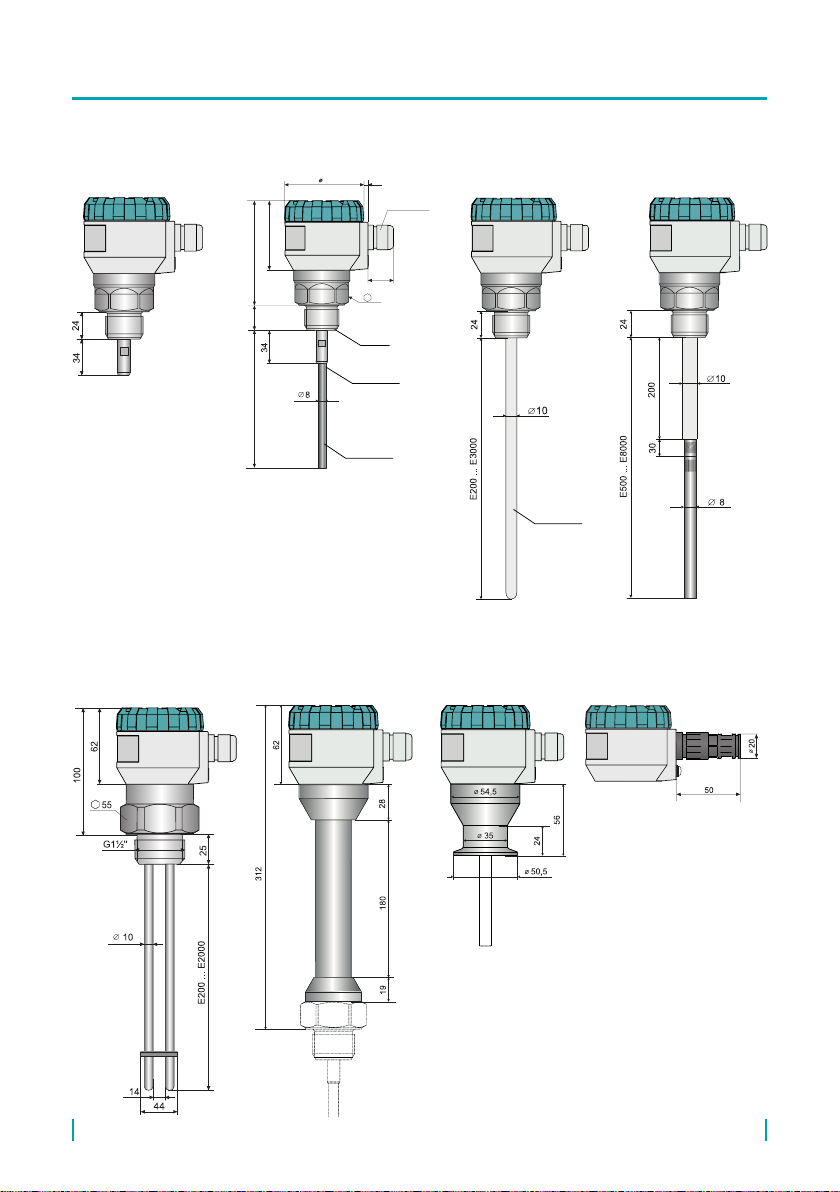

5. Dimensional drawings ..............................................................................................................6

6. Installation and putting into operation ...............................................................................8

7. Installation instructions ...........................................................................................................8

8. Electrical connection ............................................................................................................. 13

9. Setting elements...................................................................................................................... 14

10. Setting the level meter .......................................................................................................... 15

10.1. Basic settings.................................................................................................................. 15

10.2. Service settings............................................................................................................... 18

10.3. Additional functions ...................................................................................................... 19

11. HART®protocol......................................................................................................................... 21

12. How to install a custom measuring electrode, replace or shorten the electrode..........22

13. Order code................................................................................................................................. 24

14. Failure status indication........................................................................................................ 24

15. Accessories................................................................................................................................ 25

16. Safety, protection, compatibility and explosion proof................................................... 25

17. Use, manipulation, and maintenance ................................................................................ 25

18. Marking of labels ..................................................................................................................... 26

19. Menu structure ........................................................................................................................ 27

20. Technicalspecications ......................................................................................................... 28

21. Error codes ................................................................................................................................ 31

22. Packing, shipping and storage.............................................................................................. 31

CLM–70 © Dinel, s.r.o.

4

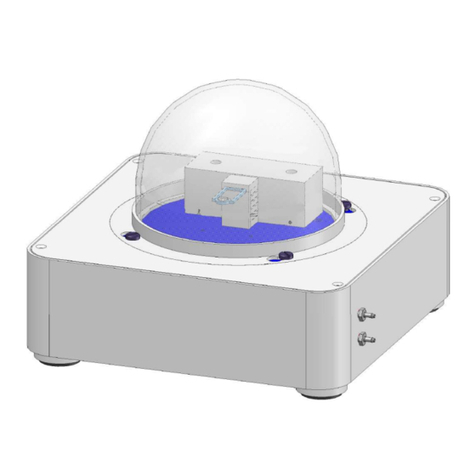

Capacitive level meters CLM-70 are compact measuring devices consisting of the level meter

body and a measuring electrode. The level meter body contains measurement electronics

and a display module. The electronics measure the electrical capacity of the electrode system,

which is dependent on the level height. The level meter’s electrical output corresponds to the

capacity (level height) and the measured data are shown on the meter’s display.

The level meter can be adjusted by the display module positioned under the transparent lid.

The level meter has 4–20mA current output with HART®communication. The level meter is

power supplied using a cable connected to the terminal block located under the display and

adjustment module.

Level meters are available in several measuring electrode modications (rod and rope-type

electrodes). Electrodes may be coated with insulation, which is important for their functioning

in the case of adherent, electrically conductive and aggressive media. Rod electrodes are

also available in a version provided with a reference tube or a pair of parallel electrodes for

measuring liquids in non-conductive tanks.

All operations described in this instruction manual have to be carried out by trained

personnel or by an accredited person only. Warranty and post warranty service must

be exclusively carried out by the manufacturer.

Improper use, installation or set-up of the sensor can lead to crashes in the ap-

plication.

The manufacturer is not responsible for improper use, loss of work caused by either

direct or indirect damage, and for expenses incurred at the time of installation or

during the period of use of the level sensors.

To ensure maximum safety of control processes, we have dened the following safety instruc-

tions and information. Each instruction is labelled with the appropriate pictogram.

Alert, warning, danger

This symbol informs you about particularly important instructions for installation and

operation of equipment or dangerous situations that may occur during the installation

and operation. Not observing these instructions may cause disturbance, damage or de-

struction of equipment or may cause injury.

Information

This symbol indicates particularly important characteristics of the device.

Note

This symbol indicates helpful additional information.

Used symbols

1 . safety

2 . basiC desCription

5

© Dinel, s.r.o. CLM–70

• CLM–70_–00 Without electrode; customer makes an electrode himself (types 10

or 30 only) and attaches it to the electrode holder using M8 threaded

connection.

• CLM–70_–10 Uncoated stainless steel rod electrode for level measurement of

electrically non-conductive liquids (oils, diesel fuel) and bulk solids (our,

sand, cement, granulated plastic materials, etc.). Length 0.2 ... 8 m.

• CLM–70_–11 Coated stainless steel rod electrode (PFA) with enhanced resistance

to penetration (diusion) of vapours and gases. For level measurement

of water and other electrically conductive liquids in food processing,

pharmaceutical, and chemical industries. It can be used temporarily for

high-temperature applications (e.g. sanitization with hot steam) or for

volatile aggressive liquids, etc. Length 0.2 ... 3 m.

• CLM–70_–12 Coated stainless steel rod electrode (FEP), suitable for level measure-

ment of water and other electrically conductive liquids. Also suitable for

impure liquids in metallic tanks, concrete sumps, etc. Length 0.2 ... 3 m.

• CLM–70_–13 Semi-coated stainless steel rod electrode (FEP) for level measurement

of electrically non-conductive liquids in environments where partial

condensation of vapours on the electrode may occur. Length 0.5 ... 8 m.

• CLM–70_–20 Uncoated stainless steel rod electrode with reference tube for level

measurement of unpolluted and electrically non-conductive liquids (oil,

diesel fuel, petrol). Length 0.2–3 m.

• CLM–70_–22 Coated stainless steel rod electrode (FEP) with reference tube for level

measurement of clean electrically conductive liquids (e.g. in plastic and

glass tanks) and for higher measuring accuracy. Length 0.2 ... 3 m.

• CLM–70_–30 Uncoated stainless steel rope electrode and weight for level

measurement of bulk solids and powders (sand, our, cement, etc.). The

rope can also be shortened. Length 1 ... 20 m.

• CLM–70_–31 Uncoated stainless steel rope electrode and coated dynamic anchor

for measurement of bulk solids in taller silos. Length 1 ... 20 m.

• CLM–70_–32 Fully coated stainless steel rope electrode and weight (FEP rope

insulation, PTFE weight insulation), designed for level measurement of

water and other electrically conductive liquids. Length 1 ... 12 m.

• CLM–70_–61 Two coated stainless steel rod electrodes (FEP electrode insulation,

PTFE head) for level measurement of aggressive liquids. Length 0.2 ... 2 m.

4 . Variants of sensors

3 . range of appliCation

The capacitive level meters are suitable for continuous level measurement of various liquids

and solid materials. The level meters are resistant to any changes in the atmosphere above the

level (vacuum, overpressure, steam, or dust).

CLM–70 © Dinel, s.r.o.

6

5 . dimensional drawings

CLM–70_–10CLM–70_–00 CLM–70_–13CLM–70_–11, 12

E200 ... E8000

24 97

62

70 4

M16x1,5

27

46

electrode

holder

electrode

thread*

coated

electrode

CLM–70_–61 Variant CLM-70

with a cable gland

for protective hose

High temperature

performance

CLM–70_T**

Process connection

Tri-clamp***

* types of thread: G1" (except type 61),

1″ NPT (except type 61)

** Except type CLM–70_–61

*** Only for type CLM–70_–11(12, 13, 32)

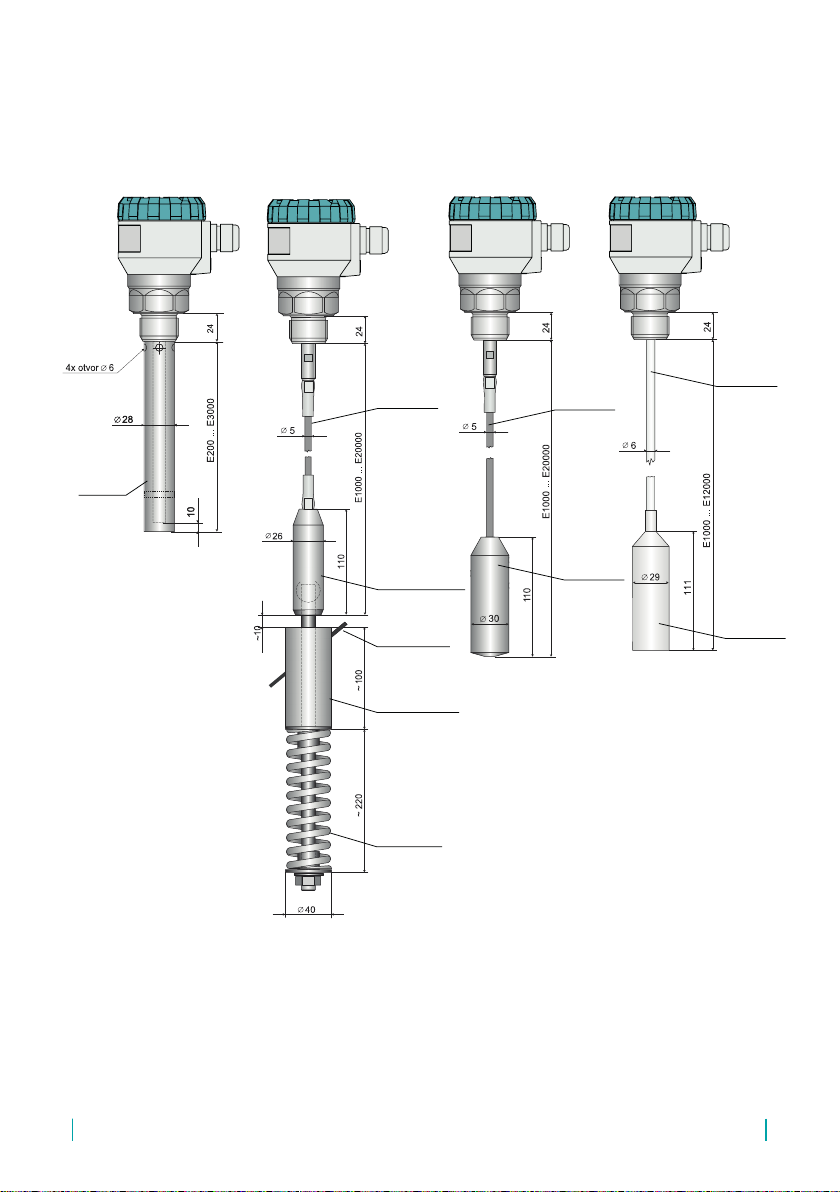

7

© Dinel, s.r.o. CLM–70

CLM–70_–20, 22

reference

pipe

CLM–70_–30CLM–70_–31 CLM–70_-32

compression

spring

hopper wall

(KV–31, PR–31)*

anchor

with ball joint

rope

electrode

coated rope

electrode

coated

weight

rope

electrode

weight

* anchor roll KV–31 or dust proof bushing

PR–31 (see accessories)

CLM–70 © Dinel, s.r.o.

8

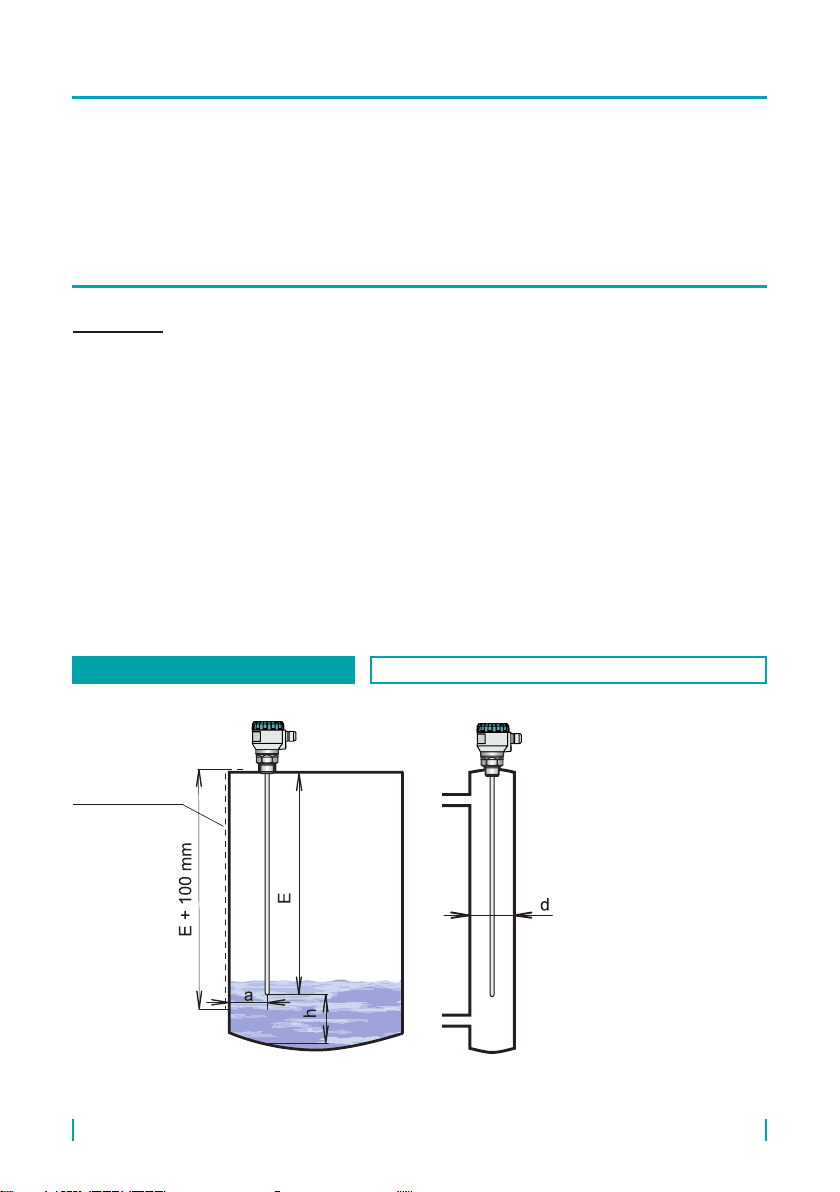

BASIC INFO

• The level meters with an insulated electrode are equipped with a protective cap at the

electrode end, which must be removed before installation.

• The level meters are mounted vertically into the upper lid of the tank or hopper or on xing

brackets using a welding ange for a xing nut or a Clamp-type ange.

• When installing the level meter in a metal tank or hopper, the housing is not necessary to

be grounded separately.

• In the case of installation in concrete sumps or silos, the level meter is advisable to

be installed on an auxiliary metal structure (bracket, lid, etc.) and then connected to

a permanently submerged metal object or steel reinforcements in concrete (armouring).

E - electrode length [mm] –

select so that the electrode

end is submerged at least

20 mm below the lowest

measured level

h - distance from the bottom

– at least 50 mm

a - distance from the wall – at

least approx. E/20

d - diameter of the auxiliary

tubular vessel – at least 40

+ E/20 (smaller dimensions

must be discussed)

Auxiliary electrode

width = minimum

30 mm

(required for non-

metal vessels only)

Fig. 1: Installation of level meters with rod electrodes

6 . installation and pUtting into operation

This procedure has the following three steps:

• installation instrUCtions

• eleCtriCal ConneCtion

• settings

7 . installation instrUCtions

METAL AND NON-METAL VESSELS APPLIES TO: CLM-70_-10, 11, 12, 13

9

© Dinel, s.r.o. CLM–70

h- distance from the

bottom – at least 50

mm due to the possible

presence of heavier

fractions (water) in

petroleum products

k - distance from the wall –

arbitrary

Fig. 2: Installation of the level meter with a reference tube

VARIANTS WITH A REFERENCE TUBE APPLIES TO: CLM-70_-20, 22

DEEP METAL AND CONCRETE SILOS APPLIES TO: CLM-70_-30, 32

To be connected to

the armouring

Concrete silo

Metal tank

E- electrode length [mm] – to be selected so that the electrode end is placed at least 20 mm

below the lowest measured level

h- distance from the bottom – at least 100 mm

a- distance from the wall – at least E/20; otherwise, choose as large as possible (as far from

the wall as possible) in the middle between the wall and the vertical drain

Fig. 3: Installation of level meters with rope electrodes

CLM–70 © Dinel, s.r.o.

10

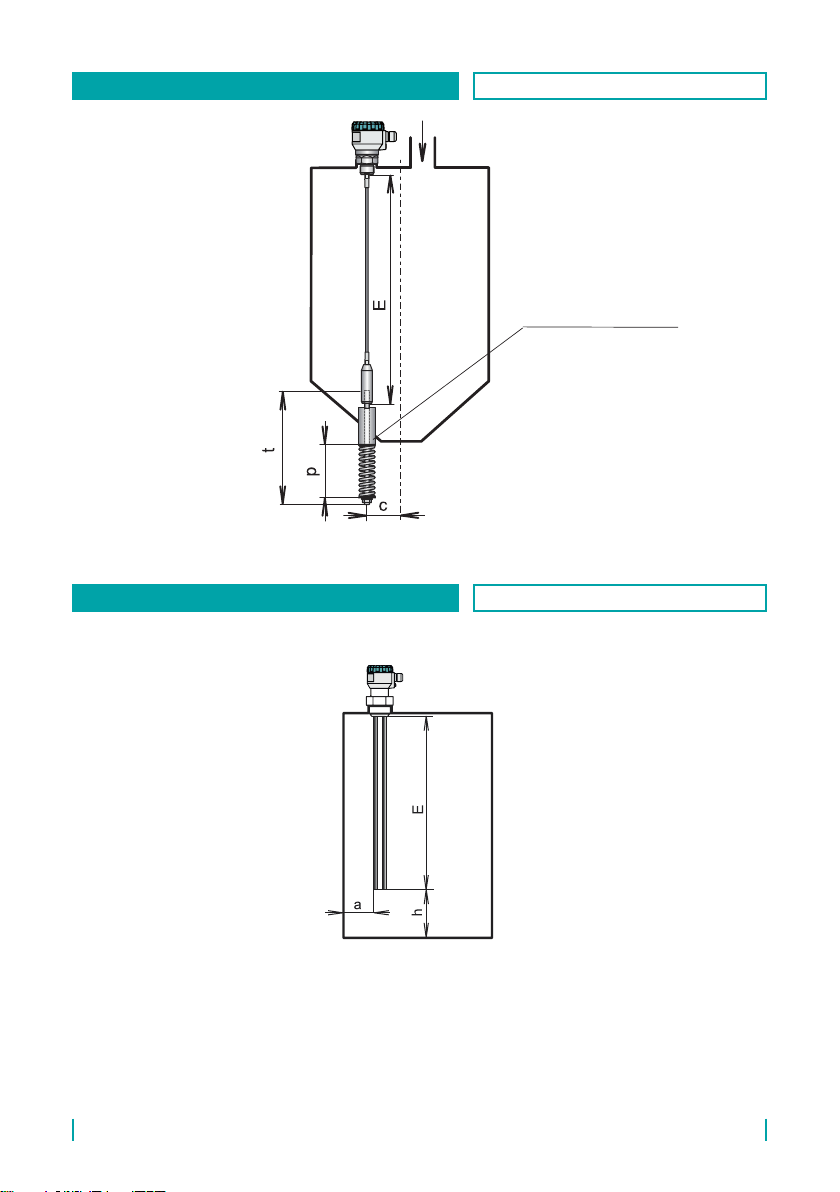

E- electrode length [mm]

t- guide rod length – approx.

500mm

p- compression spring length

– approx. 200 mm

c- distance from the hopper

axis (choose the minimum

one, if possible)

Anchor welding cylinder

(mat. 11375) or the

dust-tight bushing to the

hopper casing

Fig. 4: Installation of the level meter with arope electrode and anchor

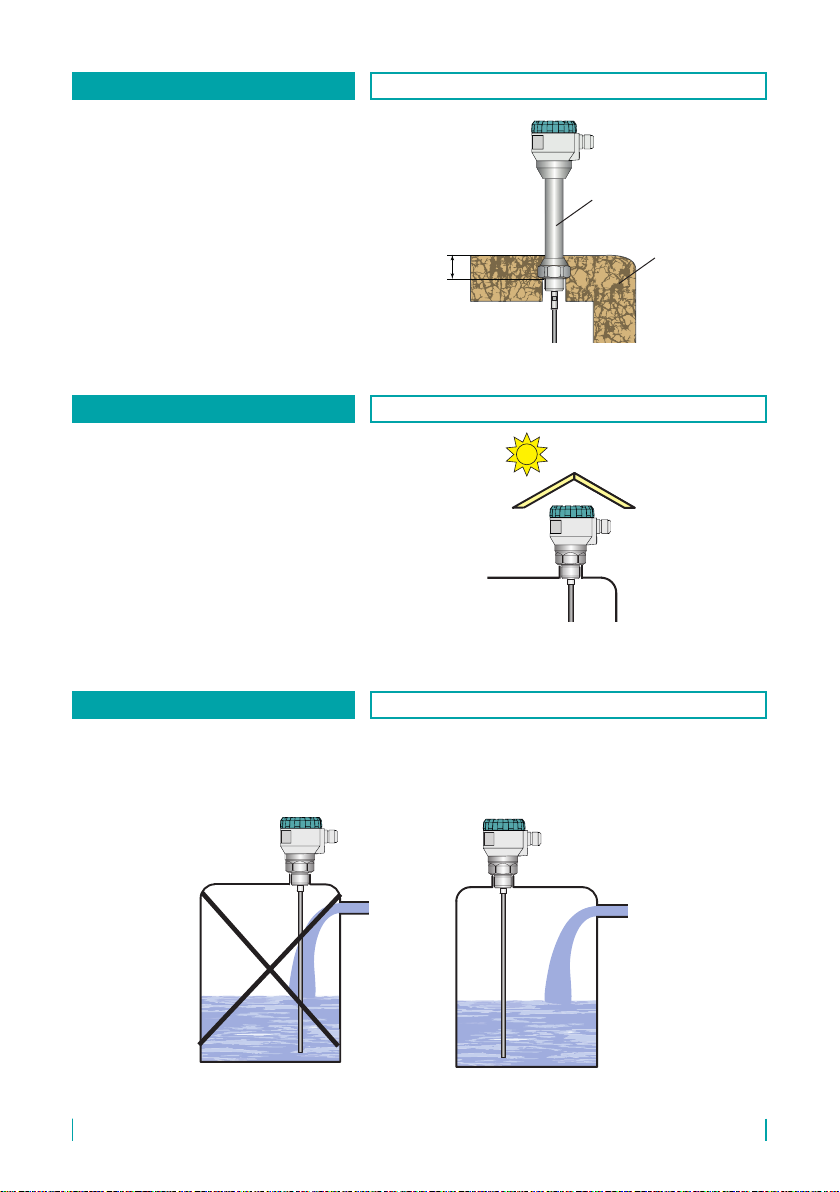

E – electrode length [mm] –

submerge the electrode

end at least 20 mm below

the lowest measured level.

h – distance from the bottom

(at least 30 mm)

a – distance from the wall (at

least E/20)

Fig. 5: Installation of the level meter with a reference electrode

ROPE ELECTRODE WITH AN ANCHOR APPLIES TO: CLM-70_-31

AGGRESSIVE LIQUIDS, NON-METAL VESSELS APPLIES TO: CLM-70N-61

11

© Dinel, s.r.o. CLM–70

Heat insulation

50

high-temperature

extension

• The level meter must not be in-

stalled in places exposed to direct

sunlight and must be protected

from the weather inuences. Even

so installation is in exposed places

to direct sunlight a shielding cov-

er is necessary to be tted over

the level meter (see Fig. 7).

• The level meters for high operat-

ing temperatures are equipped

with an extension. This is used to

thermally insulate the electronics

part of the meter from the high

operating temperature. The ex-

tension must not be embedded in

the insulation more than 50 mm.

Fig. 7: A shielding cover protecting against direct sunlight

Fig. 6: Installation of the level meter in an insulated tank

COVERING THE LEVEL METER APPLIES TO: All types

TANK WITH INSULATION APPLIES TO: CLM-70NT-_

• The level meter is not recommended to be installed at or above the lling point. Measure-

ment may be inuenced by the inow medium.

Fig. 8: Installation of the level meter out of the reach of lling ow

OUT OF REACH OF FILLING APPLIES TO: All types

CLM–70 © Dinel, s.r.o.

12

• The level meter of the CLM-70_-

00 type is provided without a

measuring electrode. Therefore,

the measuring electrode is nec-

essary to be made and mounted

to the level meter body. The elec-

trode diameter must be between

8–10 mm. For connection, the

electrode must have an M8 male

thread. For the connection proce-

dure, see chapter 12, p. 22. Fig. 10: The level meter without an electrode

For the level meter of the CLM-70_-00 type, the manufacturer is not responsible for

defects related to the connected measuring electrode!

It is intended for non-conductive media only, as only a non-insulated rod or rope

can be connected.

VARIANT WITHOUT AN ELECTRODE APPLIES TO: CLM-70_-00

• It is advisable to run the cable un-

der a cable gland (sagging down-

wards). This prevents possible

ingress of moisture through the

cable gland. Rain and condensing

water can ow freely downwards,

see Fig.9.

• The cable gland and the top lid

must be suciently tightened

to prevent moisture ingress. Fig. 9: Preventing moisture from ingress

through the cable gland

MOISTURE APPLIES TO: All types

13

© Dinel, s.r.o. CLM–70

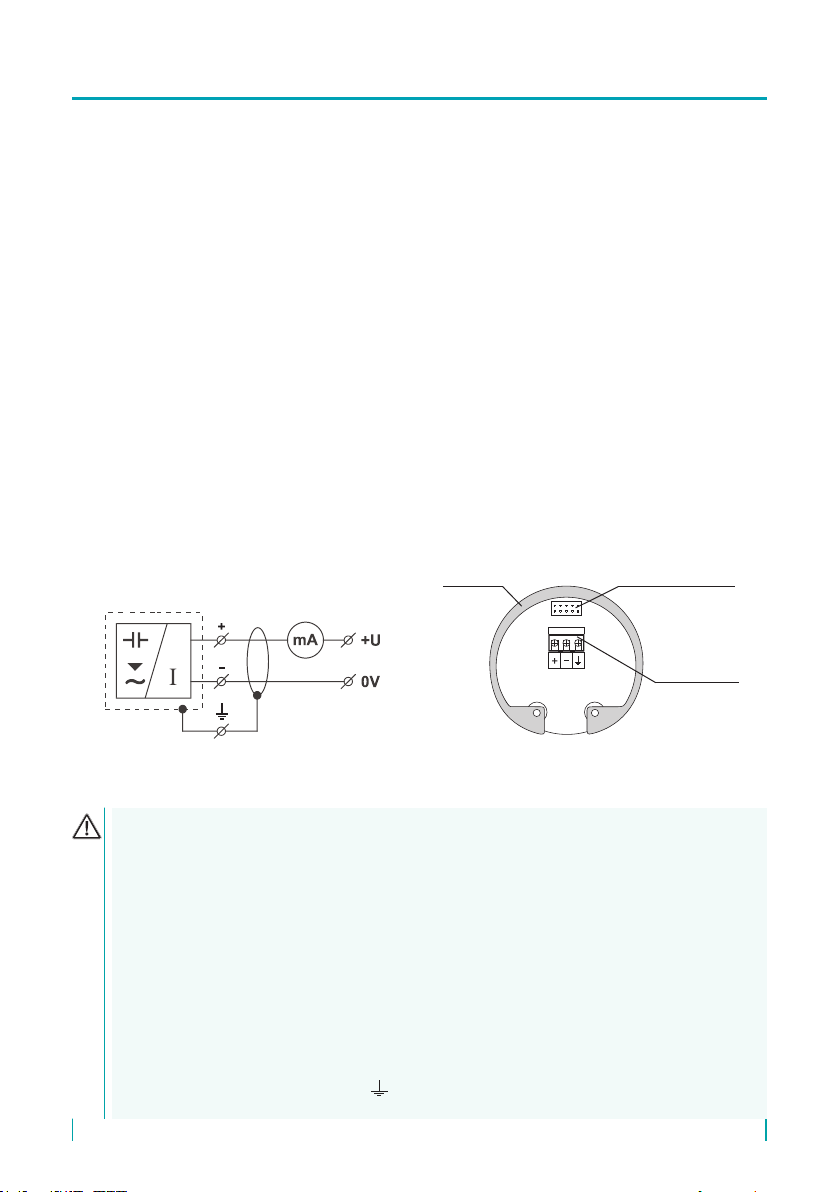

8 . eleCtriCal ConneCtion

The level meter is connected to the follow-up (evaluation) device using a suitable cable with

an outer diameter of 6–8 mm by means of screw terminals located under the display module.

The recommended wire cross-section is 2× 0.5–0.75 mm2 (shielded) for the current version.

The positive pole (+U) is connected to the (+) terminal, the negative pole (0 V) to the (-) terminal,

and the shield (only for shielded cables) is connected to the ( ) terminal.

To connect a cable to the level meter:

1. Unscrew the upper lid nut.

2. Grasp the top edge of the display module and carefully slide it upwards carefully by slightly

swinging it.

3. If you are unable to grasp the display module, a small screwdriver can be used – insert it under

the edge and slightly lift the module from several sides.

4. Loosen the cable gland to pass a stripped power cable inside.

5. Connect the cable to threaded terminals, as shown in the diagram in Fig.11. Tighten the termi-

nals and cable gland rmly. For the tightening torque, see the Technical Specications.

6. Return the display module into the head until the connector is connected correctly.

7. Slide the silicone seal onto the level meter body thread and tighten the upper lid nut rmly.

Connect the cable to the downstream device.

display connector

threaded ter-

minals

metal

clip

Fig. 12: Internal view of threaded terminals of level meter

with current output CLM-70_-_-_-I

Fig. 11: Connection diagram of level meter

with current output CLM-70_-_-_-I

Electrical connection can only be made in a voltage-free state!

The power supply must be designed as a stabilized source of low safe voltage with

galvanic isolation. If a switched power supply is used, its design must eectively sup-

press common mode interference. If the switched power supply is equipped with a

PE protective terminal, it must be earthed without fail!

If the sensor is to be installed in an outdoor environment more than 20 m from an

outdoor switchboard or an enclosed building, the electrical supply to the sensor must

be supplemented with suitable overvoltage protection.

In case of a strong environmental electromagnetic interference, common routing of

the signal cable with the power cable or in case of more than 30 m in length, we

recommend grounding the level meter and using a shielded cable. Ground the cable

shielding on the side of power supply or connect it to the internal connection termi-

nal of the level meter marked as , see Figs. 22 and 23 (the cable shielding should

always be connected in one point).

CLM–70 © Dinel, s.r.o.

14

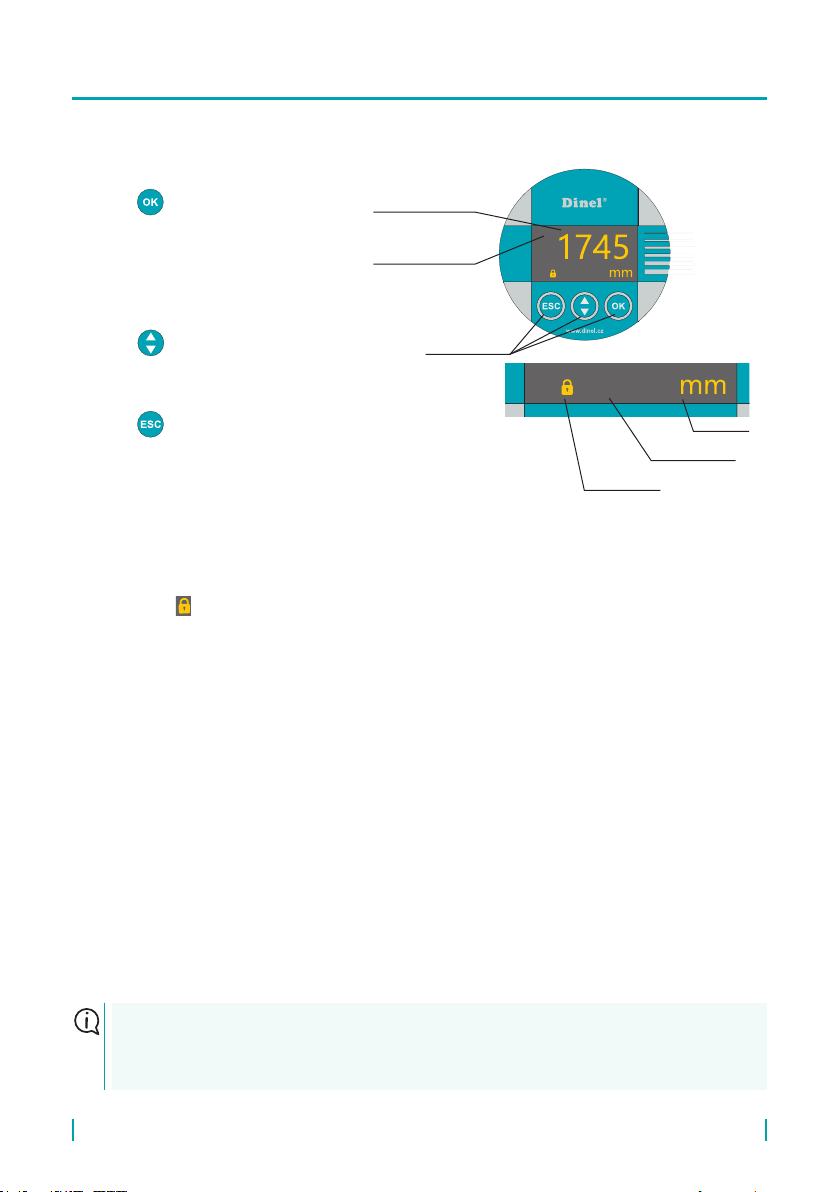

9 . setting elements

Button

• access to the setting menu

• acknowledgement of the

selected menu item

• cursor movement in line

• saving settings

Button

• navigation in menu

• changing values

Button

• cancelling changes

• moving up a level

units

display

of measured values

display

error codes

setting

elements

level meter

locked

Setting is done using the 3 buttons located on the DM-70 display module. All setting items are

available in the level meter menu.

* ashes intermittently when receiving a reected

signal (echo) from the measured level

warning and

information signs

The level meter, type CLM-70_-__-_-_-_-L, is supplied without the DM-70 display

module. To set up the level meter it is necessary to connect a display module (or it

can be congured via HART). When the set-up is complete, the display module can

be disconnected and the level meter takes measurements without it.

• Status indication (lower left corner of the display):

symbol -lights permanently - the level meter is locked against unauthorized

settings; a password is required for unlocking (see MENU – PASSWORD)

• Warning signs:

FIXED OUTPUT - the output current is xed to a constant value (see MENU – DIAGNOS-

TIC – CURRENT)

LOW POWER - low supply voltage (it must be within the specied range – see TECH-

NICAL SPECIFICATIONS)

NO PASSWORD - when changing the locked level meter settings

NO DATA AVAILABLE - display module doesn't communicate with the electronics of

the level meter (e.g. incorrectly inserted display module into

connector or measuring module is not functional).

• Information signs:

CAPACITY - actual capacity displayed (see DIAGNOSTIC – CAPACITY)

CURRENT - actual current displayed (see DIAGNOSTIC – CURRENT)

• Error codes:

(see chapter 21. Error Codes)

15

© Dinel, s.r.o. CLM–70

10 . setting the leVel meter

UNITS

LEVEL: mm

DISPLAY: %

TEMPERATURE °C

STARTING

Dinel®

The level meter is controlled by 3buttons located on the re-

movable DM-70 display module (see the Control Units chapter,

p. 14).

Saving of values is indicated by the word “SAVED” at the display

bottom (see Fig.). Values that have not been conrmed with the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button will not be saved! After inactivity lasting 5 min-

utes, the level meter automatically goes back to the measuring

mode. If the password is active, the level meter locks besides.

No changes in settings are possible to be made after locking!

When attempting to edit, “NO PASSWORD” appears on the dis-

play. How to unlock, see p. 20.

After connecting the supply voltage, the manufacturer's logo

and the text “Starting” appear on the level meter display. Then, the level meter goes into the

measuring mode, and the actually measured value is displayed.

MIN CAPACITY (MAX CAPACITY)

Here, the CAPACITY range (in the CAPACITY line), within which the level meter should meas-

ure, must be set. The output current range (the OUTPUT line) of 4mA/20mA output is then

assigned to this range. And the value shown on the meter display (DISPLAY line).

In the upper right corner below the sign “ACTUAL CAPACITY”, the value of the currently meas-

ured level is displayed.

ACTUAL CAPACITY: current meas-

ured capacity

CAPACITY: denition of the min/max

capacity

DISPLAY: the value show on the

display

BASIC SETTINGS

SERVICE

DIAGNOSTIC

CLONE SETTINGS

PASSWORD

INFO

SAVED

UNITS

CAPACITY: PF

DISPLAY: %

SAVED

STARTING

BASIC SETTINGS

SERVICE

DIAGNOSTIC

CLONE SETTINGS

PASSWORD

LANGUAGE

INFO

MIN CAPACITY

MAX CAPACITY

UNITS

DAMPING

SENSITIVITY

TEACHING

MIN ACTUAL CAPACITY

023.56 pF

OUTPUT: 04.00 mA

CAPACITY: 013.33 pF

DISPLAY: 00000 %

MAX

OUTPUT: 20.00 mA

CAPACITY: 157.77 pF

DISPLAY: 00100 %

MIN CAPACITY

MAX CAPACITY

UNITS

DAMPING

SENSITIVITY

TEACHING

10 .1 . Basic settings

After the rst start of the level meter, the basic conguration

(setting of the measuring range, selecting units and possible

damping) must be performed. The settings are accessible in

the basic menu by pressing the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button under “BASIC SET-

TINGS”.

ACTUAL CAPACITY

023.56 pF

CLM–70 © Dinel, s.r.o.

16

CAPACITY: pF

DISPLAY: %

CAPACITY: only units pF

DISPLAY: the unit shown on the

display (%, mm, cm, m, in, ft, l, hl, m3,

gal, bbl, and mA)

The damping time can be set within

the interval of 0 to 99 seconds.

1. Press the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button to enter the menu; use the same button to select “BASIC SETTINGS”.

Then, use the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC OK

1745

mm

and

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

buttons to select “UNITS”.

2. Now, the “UNITS” item is displayed. Use the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

and

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC OK

1745

mm

buttons to set each item.

3. After nishing the settings, press the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button to save the data. Press the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button suc-

cessively to exit the menu; the level meter returns to the measuring mode.

1. Press the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button to enter the menu; use the same button to select “BASIC SETTINGS”.

Then, use the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC OK

1745

mm

and

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

buttons to select “DAMPING”.

2. Now, the “DAMPING” item is displayed. Use the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

and

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC OK

1745

mm

buttons to set damping.

3. After nishing the settings, press the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button to save the data. Press the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button suc-

cessively to exit the menu; the level meter returns to the measuring mode.

A) THE SETTING METHOD AT LIMIT POINTS OF RANGE (if the tank is possible to be completely

emptied and ooded with a medium) – this method is preferred

UNITS

MIN CAPACITY

MAX CAPACITY

UNITS

DAMPING

DAMPING

05

MIN CAPACITY

MAX CAPACITY

UNITS

DAMPING

DAMPING

The time constant of the output variable lter is set here. The time constant is given in sec-

onds. The response progress of the output variable to a step change of the level is exponential.

The time constant indicates the time, within which the output value reaches approximately

63% of the maximum value.

Higher values are useful for suppressing display uctuations during rapid changes (whirling

level). Conversely, if a rapid response is required, a low damping value must be set.

The damping time can be set within the interval of 0 to 99 seconds.

SETTING PROCEDURE FOR THE LEVEL METER

The level meter must be installed properly in the tank and connected to the power supply.

Then, the basic level meter settings can be made.

UNITS

The CAPACITY line – the units, in which the measuring and adjustment of the level meter (pF)

takes place

The DISPLAY line – the setting of the units to be displayed on the main display screen (%; pF;

mm; cm; m; in; ft; l; hl; m3; gal; bbl; and mA).

17

© Dinel, s.r.o. CLM–70

1. Bring the measured medium to the minimum capacity. In the BASIC SETTINGS – MIN CA-

PACITY menu, the value of electrical capacity measured by the level meter in real time is

displayed in the upper right corner under the sign “ACTUAL CAPACITY”. This value must be

copied to the CAPACITY line. The value which is shown on the display at this minimum capac-

ity is entered in the DISPLAY line. The OUTPUT line is not editable and displays the value of

an output variable at the minimum capacity.

2. Bring the measured medium to the maximum capacity. In the BASIC SETTINGS – MAX CA-

PACITY menu, the value of electrical capacity measured by the level meter in the real time is

displayed in the upper right corner under the sign “ACTUAL CAPACITY”. This value must be

copied to the CAPACITY line. The value which is shown on the display at this maximum ca-

pacity is entered in the DISPLAY line. The OUTPUT line is not editable and displays the value

of an output variable at the maximum capacity. The conversion to the shown value on the

display and the output (current) is always linear depending on the capacity to be measured.

3. In the BASIC SETTINGS – UNITS menu, the required units for display on the main screen of

the meter display are set in the DISPLAY line. The CAPACITY line is not editable and indicates

in which units the level meter measures the capacity.

4. The time constant of the output variable lter is set in the BASIC SETTING – DAMPING menu.

B) THE SETTING METHOD AT ANY POINT WITHIN THE RANGE (if the tank cannot be completely

emptied or ooded with a medium)

1. Flood the tank to a known level H1(e.g. 15%). In the SERVICE – CAPACITY menu item, the

capacity at this known ooding (15%) can be found. This capacity is noted down and denoted

as C1 (e.g. 35 pF).

2. Flood the tank to another known level H2(e.g. 78%). In the SERVICE – CAPACITY menu

item, the capacity at this known ooding (78%) can be found. This capacity is noted down

and denoted as C2 (e.g. 126 pF).

3. The capacities at the limit points of the measuring range can be calculated using the follow-

ing formulas.

For capacity at the lower limit point of the measuring range:

CMIN = C1– H1 ∙ (C2– C1) / (H2– H1)

Example: CMIN = 35 – 15 ∙ (126 – 35) / (78 – 15) = 13.33 pF

For capacity at the upper limit point of the measuring range:

CMAX = CMIN + 100 ∙ (C2– C1) / (H2– H1)

Example: CMAX = 13.33 + 100 ∙ (126 – 35) / (78 – 15) = 157.77 pF

4. The calculated value of CMIN is to be entered into the meter’s BASIC SETTINGS – MINIMUM

CAPACITY menu in the CAPACITY line. The value to be displayed at the minimum capacity

is entered in the DISPLAY line. The OUTPUT line is not editable and displays the value of an

output variable at the minimum capacity.

5. The calculated value of CMAX is to be entered into the meter’s BASIC SETTINGS – MAXIMUM

CAPACITY menu in the CAPACITY line. The value to be displayed at the maximum level is

entered in the DISPLAY line. The OUTPUT line is not editable and displays the value of an

output variable at the maximum capacity. The conversion to the display value and the output

quantity (current) is always linear depending on the capacity to be measured.

6. In the BASIC SETTINGS – UNITS menu, the required units for display on the main screen of

the meter display are set in the DISPLAY line. The CAPACITY line is not editable and indicates

in which units the level meter measures the capacity.

7. The time constant of the output variable lter is set in the BASIC SETTING – DAMPING menu.

CLM–70 © Dinel, s.r.o.

18

FAILURE MODE

HART

FACTORY DEFAULT

RESET

10 .2 . service settings

FAILURE MODE

It determines the current value at the level meter output if the self-diagnostics of the level

meter detects an internal fault. It is possible to set the following currents: 3.75 mA; 4 mA; 20

mA; 22 mA; LAST VALUE

For address “00”, point to point mode

is activated. The range from “01” to

“15” is reserved for multidrop mode

addresses (current is xed at 4 mA).

The failure mode is displayed on the

main screen. For the error code de-

scription, see chapter 21.

SENSITIVITY

TEACHING

MEDIUM TEMPERATURE

FAILURE MODE

HART

FACTORY DEFAULT

RESET

FAILURE MODE

HART

FACTORY DEFAULT

RESET

HART

00

POLLING ADDRESS

HART®

This item is a part of the menu of the level meter with a current output, CLM-70_-_-_-I. Set-

tings of the HART®protocol (point to point, multidrop) and multidrop mode address. In the

multidrop mode, up to 15devices can be connected to one 2-wire cable.

After pressing the button, “RUN-

NING” appears for a short time. After

loading the default values, the display

shows “DONE” and the message: “Press

Esc to exit”.

FACTORY DEFAULT

ARE YOU SURE?

RUNNING

DONE

PRESS ESC TO EXIT

FAILURE MODE

HART

FACTORY DEFAULT

RESET

FACTORY DEFAULT FACTORY DEFAULT

FAILURE MODE

HART

FACTORY DEFAULT

RESET

RESET

ARE YOU SURE?

During the restart, the display shows

“RUNNING”. Then, the level meter

switches o automatically and re-

starts.

FACTORY DEFAULT

Loading the factory default values. The loading is performed by pressing the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button.

The table of the default settings is shown on p. 29.

RESET

This option performs a complete restart of the level meter. A short-term interruption of the

supply voltage has the same eect. Reset is

activated by the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button.

FAILURE MODE

4.00

MEASUREMENT ERROR

mA

BASIC SETTINGS

SERVICE

DIAGNOSTIC

CLONE SETTINGS

PASSWORD

LANGUAGE

INFO

In the service settings, the failure state behaviour or HART®com-

munication can be congured. It is also possible to set the sensor

into its default settings or reset it. The settings are accessible in

the basic menu under “SERVICE”.

19

© Dinel, s.r.o. CLM–70

1. Press the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button to enter the menu; select “

CLONE SETTINGS

”. To copy the settings

from the level meter body to the display module, select “SENSOR

→

DISPLAY MODULE”.

To transfer the settings from the display module to another level meter, select “DISPLAY

MODULE

→

SENSOR”.

2. Press the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button to run the selected mode, “NOW CLONING” appears on the display

during transfer.

3. When the process is complete, “DONE” appears in the display centre. Then, it is possible to

press the

ESC OK

www.dinel.cz

Ultrasonic Level Meter ULM-70

ESC

OK

1745

mm

button again and exit the mode as well as the menu.

BASIC SETTINGS

SERVICE

DIAGNOSTIC

CLONE SETTINGS

PASSWORD

LANGUAGE

INFO

CLONE SETTINGS

SENSOR DISPLAY

MODULE

DISPLAY

MODULE

SENSOR

CLONE SETTINGS

SENSOR MODULE

DISPLAY

MODULE

DISPLAY

SENSOR

CLONE SETTINGS

This mode is for copying the CLM–70 level meter (body) conguration to the DM–70 display

module (display) and vice versa. Then, the display module can be removed from the level

meter body, and its settings can be transferred to the other level meter body.

The “CLONE SETTINGS” mode transfers all data except the “TEACHING” mode settings and

the HART® protocol conguration.

10 .3 . additional functions

Additional functions include modes for copying settings or detecting the actual loop cur-

rent. Further, they include password-based locking of modication and the level meter (dis-

play module) version information. All these functions are accessible from the main menu.

DIAGNOSTIC

CAPACITY: Displays the actual value of the capacity that the sensor is currently measuring.

BASIC SETTINGS

SERVICE

DIAGNOSTIC

CLONE SETTINGS

PASSWORD

LANGUAGE

INFO

CAPACITY

CURRENT

CAPACITY

CURRENT

BASIC SETTINGS

SERVICE

DIAGNOSTIC

CLONE SETTINGS

PASSWORD

LANGUAGE

INFO

ON DISPLAY:

YES – Diagnostics value (CAPACITY or CURRENT) is displayed on the main screen.

NO – The standard measured value as set in the BASIC SETTINGS, MIN/MAX – DISPLAY is

displayed on the main screen.

SET VALUE: Set the current to a xed value (3.75 mA – 4mA – 12mA – 20mA – 22mA –

MEASUR.). If the MEASUR. option is selected, the current corresponds to the

measured value.

CURRENT: Displays the actual value of the output current owing through the loop

The SET VALUE option can be used to diagnose the connected evaluation device. If

the current is set to a xed value, “FIXED OUTPUT” is displayed on the main display,

and the text “FIXED” is displayed in the SET VALUE section.

CAPACITY

012.20 pF

ON DISPLAY: YES

CURRENT

17.30 mA

ON DISPLAY: YES

SET VALUE: MEASUR.

CLM–70 © Dinel, s.r.o.

20

Incompatible electrode type and length. Settings can only be

transferred for the level meters of the same type and with the

same electrode length.

The setting data is not saved in the DM-70 display module. The

transfer cannot be performed. It is necessary to repeat the proce-

dure of copying the settings in the “CLONE SETTINGS” mode from

the sensor to the display.

CLONE SETTINGS

!WARNING!

CLONING IS NOT POSSIBLE

WRONG SENSOR TYPE

PRESS ESC TO EXIT ESC

CLONE SETTINGS

NO DATA AVAILABLE

PRESS ESC TO EXIT ESC

!WARNING!

CLONING IS NOT POSSIBLE

1. Use the and buttons in the “PASSWORD” menu to select the mode for entering the

password – “ENTER” – or changing the password – “CHANGE” – (when activated, both messages

are displayed inversely). Press the button again to conrm the selection. The password

can only be changed when the level meter is unlocked. Otherwise, “NO PASSWORD” appears.

2. Now, you can enter (edit) the password. The actual item for editing is displayed inversely. Press

the button to move to the next position (direction from left to right); the button is

used to change the values (0 ... 9).

3. The data is saved using the button.

PASSWORD

Here, the level meter can be locked to prevent unauthorised data editing. Once the password

is activated, the data can be read, but cannot be edited. When attempting to edit, the “NO

PASSWORD” message appears on display.

The password can have any ve-digit combination. The combination of 00000 is reserved for

the password deactivation.

Displaying the status after conrming the

data:

“YES” – correct password entered

“NO” – wrong password entered

“OK” – save the password (only for

“CHANGE”)

The password is automatically hidden after

entering or changing (displayed as “00000”).

Enter the number combination of “00000”

in the “CHANGE” mode to deactivate the

password.

PASSWORD

ENTER

00000

PASSWORD

CHANGE

00000

BASIC SETTINGS

SERVICE

DIAGNOSTIC

CLONE SETTINGS

PASSWORD

LANGUAGE

INFO

LANGUAGE

The setting of the display menu language.

BASIC SETTINGS

SERVICE

DIAGNOSTIC

CLONE SETTINGS

PASSWORD

LANGUAGE

INFO

LANGUAGE

ENGLISH

There are three language options to

choose from:

ČESKY – ENGLISH – по русски

If you lose your password, contact the manufacturer.

The level meter with the password activated is locked automatically after ve minutes

of inactivity or ve minutes after switching to the measuring mode. Locking the level

meter is indicated by a padlock symbol ( ) in the left bottom corner of the display.

Table of contents

Other Dinel Measuring Instrument manuals

Dinel

Dinel DLM-35 User manual

Dinel

Dinel ULM - 54 User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel ULM -70 Series User manual

Dinel

Dinel ULM-70 Series User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel CLM-36 User manual

Dinel

Dinel ULM-53 series User manual

Dinel

Dinel PDU-40-W Series User manual

Dinel

Dinel ULM -70 Series User manual