Glossary

GATE: A moving barrier such as a swinging, sliding, raising, lowering, or the like, barrier, that is a stand-alone

passage barrier or is that portion of a wall or fence system that controls entrance and/or egress by persons or

vehicles and completes the perimeter of a defined area.

RESIDENTIAL VEHICULAR GATE OPERATOR – CLASS I: A vehicular gate operator (or system) intended for

use in a home of one-to four single family dwelling, or garage or parking area associated therewith.

COMMERCIAL / GENERAL ACCESS VEHICULAR GATE OPERATOR - CLASS II: A vehicular gate operator

(or system) intended for use in a commercial location or building such as a multi-family housing unit (five or more

single family units), hotels, garages, retail store, or other building servicing the general public.

INDUSTRIAL / LIMITED ACCESS VEHICULAR GATE OPERATOR - CLASS III: A vehicular gate operator (or

system) intended for use in an industrial location or building such as a factory or loading dock area or other

locations not intended to service the general public.

RESTRICTED ACCESS VEHICULAR GATE OPERATOR - CLASS IV: A vehicular gate operator (or system)

intended for use in a guarded industrial location or building such as an airport security area or other restricted

access locations not servicing the general public, in which unauthorized access is prevented via supervision by

security personnel.

VEHICULAR BARRIER (ARM) OPERATOR (OR SYSTEM): An operator (or system) that controls a cantilever

type device (or system), consisting of a mechanical arm or barrier that moves in a vertical arc, intended for

vehicular traffic flow at entrances or exits to areas such as parking garages, lots or toll areas.

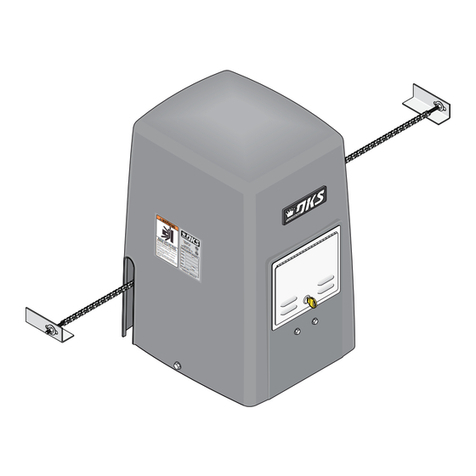

VEHICULAR HORIZONTAL SLIDE-GATE OPERATOR (OR SYSTEM): A vehicular gate operator (or system)

that controls a gate which slides in a horizontal direction that is intended for use for vehicular entrance and exit to

a drive, parking lot, or the like.

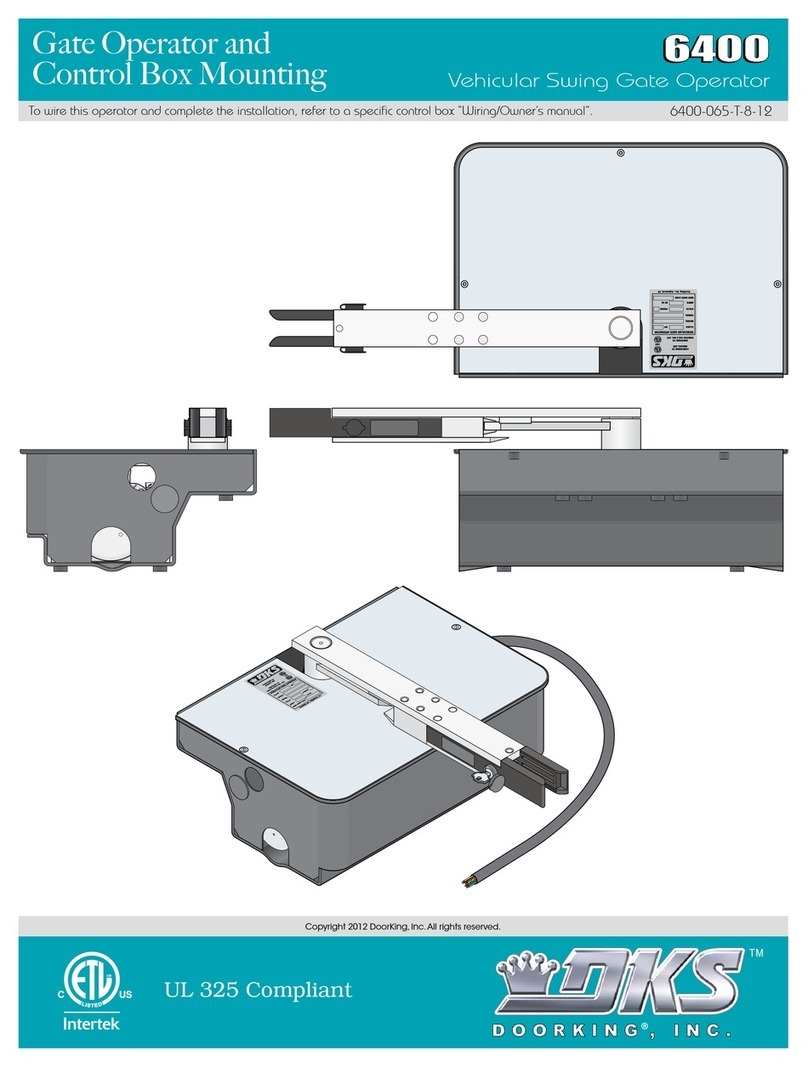

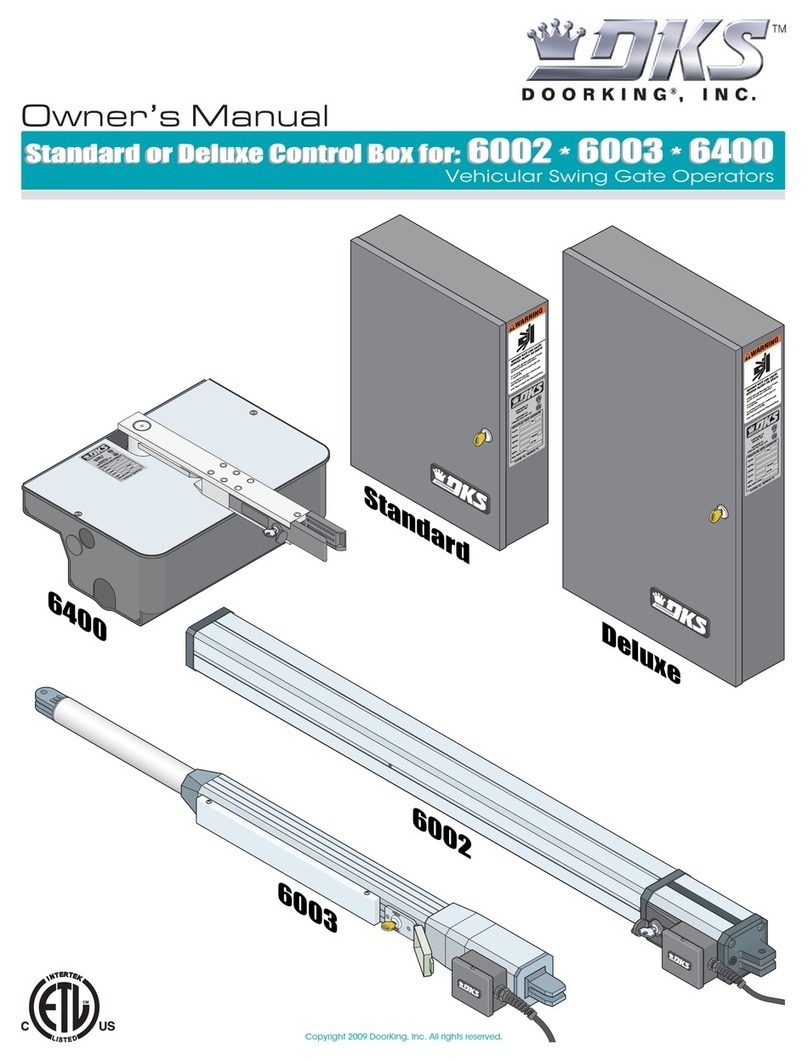

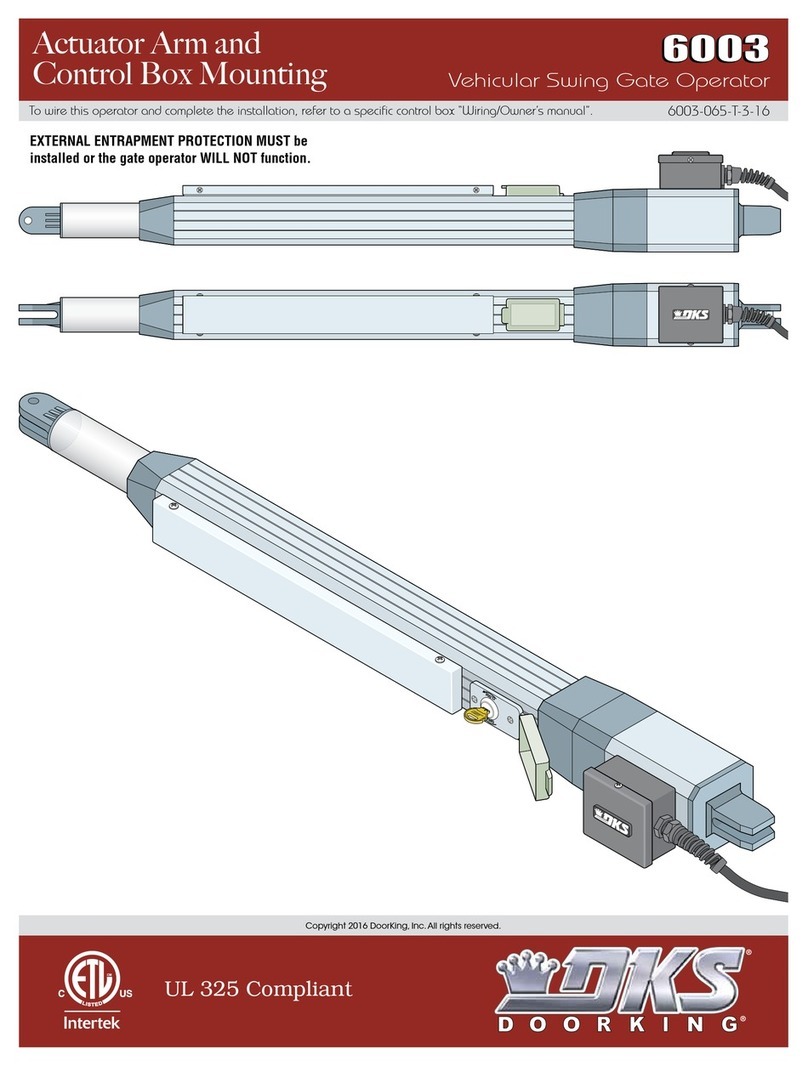

VEHICULAR SWING-GATE OPERATOR (OR SYSTEM): A vehicular gate operator (or system) that controls a

gate which moves in an arc in a horizontal plane that is intended for use for vehicular entrance and exit to a

drive, parking lot, or the like.

SYSTEM: In the context of these requirements, a system refers to a group of interacting devices intended to

perform a common function.

WIRED CONTROL: A control implemented in a form of fixed physical interconnections between the control, the

associated devices, and an operator to perform predetermined functions in response to input signals.

WIRELESS CONTROL: A control implemented in means other than fixed physical interconnections (such as

radio waves or infrared beams) between the control, the associated devices, and an operator to perform

predetermined functions in response to input signals.

INHERENT ENTRAPMENT PROTECTION SYSTEM: A system, examples being a motor current or speed

sensing system, which provides protection against entrapment upon sensing an object and is incorporated as a

permanent and integral part of the operator.

EXTERNAL ENTRAPMENT PROTECTION DEVICE: A device, examples being an edge sensor, a photoelectric

sensor, or similar entrapment protection device, which provides protection against entrapment when activated

and is not incorporated as a permanent part of an operator.

ENTRAPMENT: The condition when an object is caught or held in a position that increases the risk of injury.

Page 4 9100-065-D-5-07