ii

TABLE OF CONTENTS

How to read your serial number:

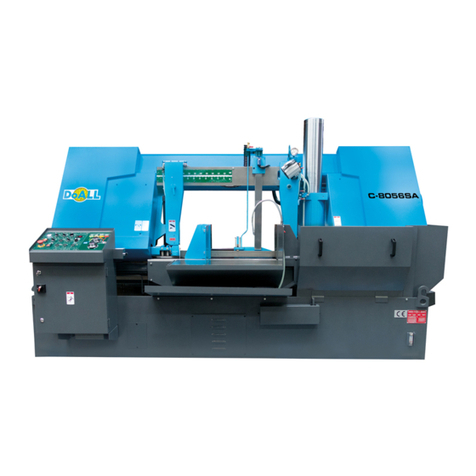

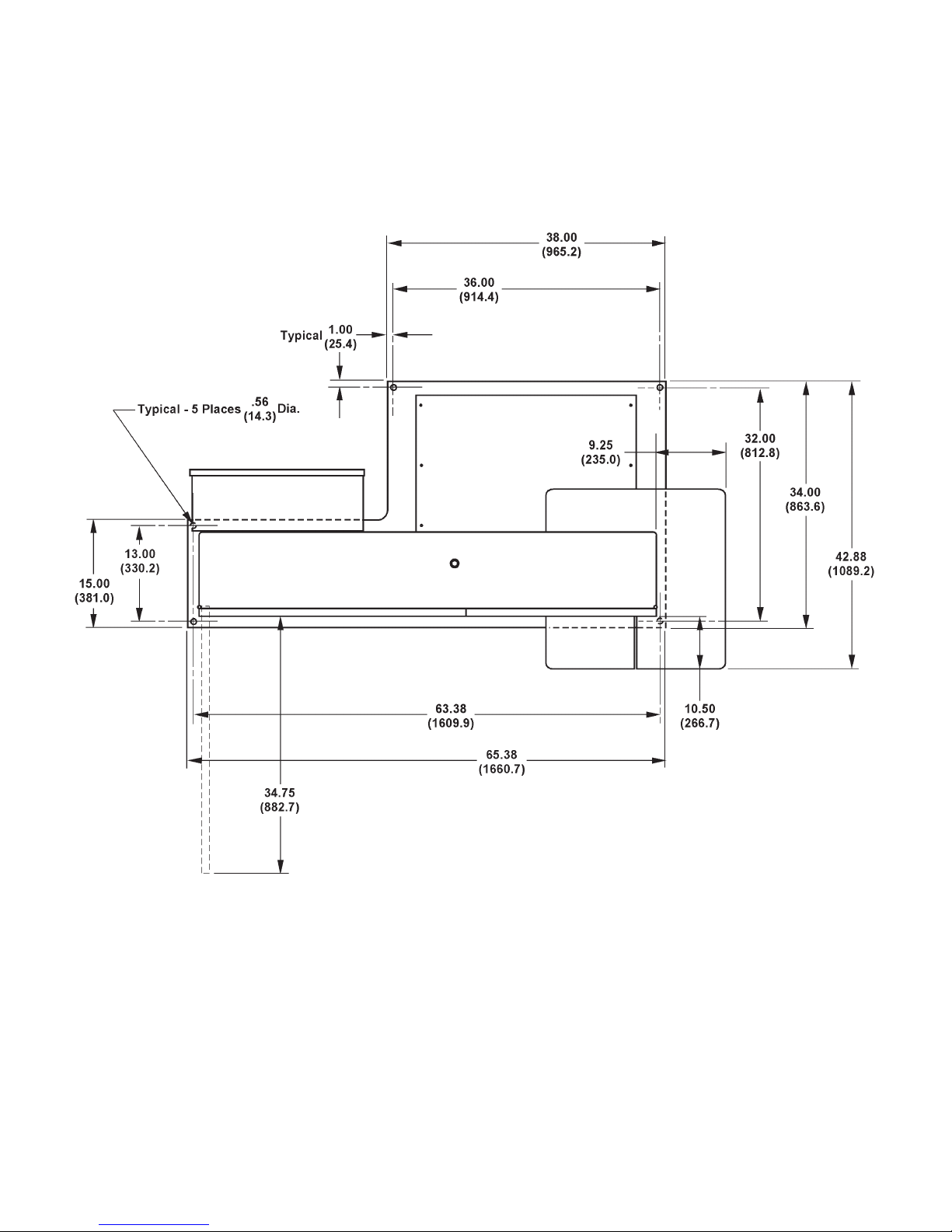

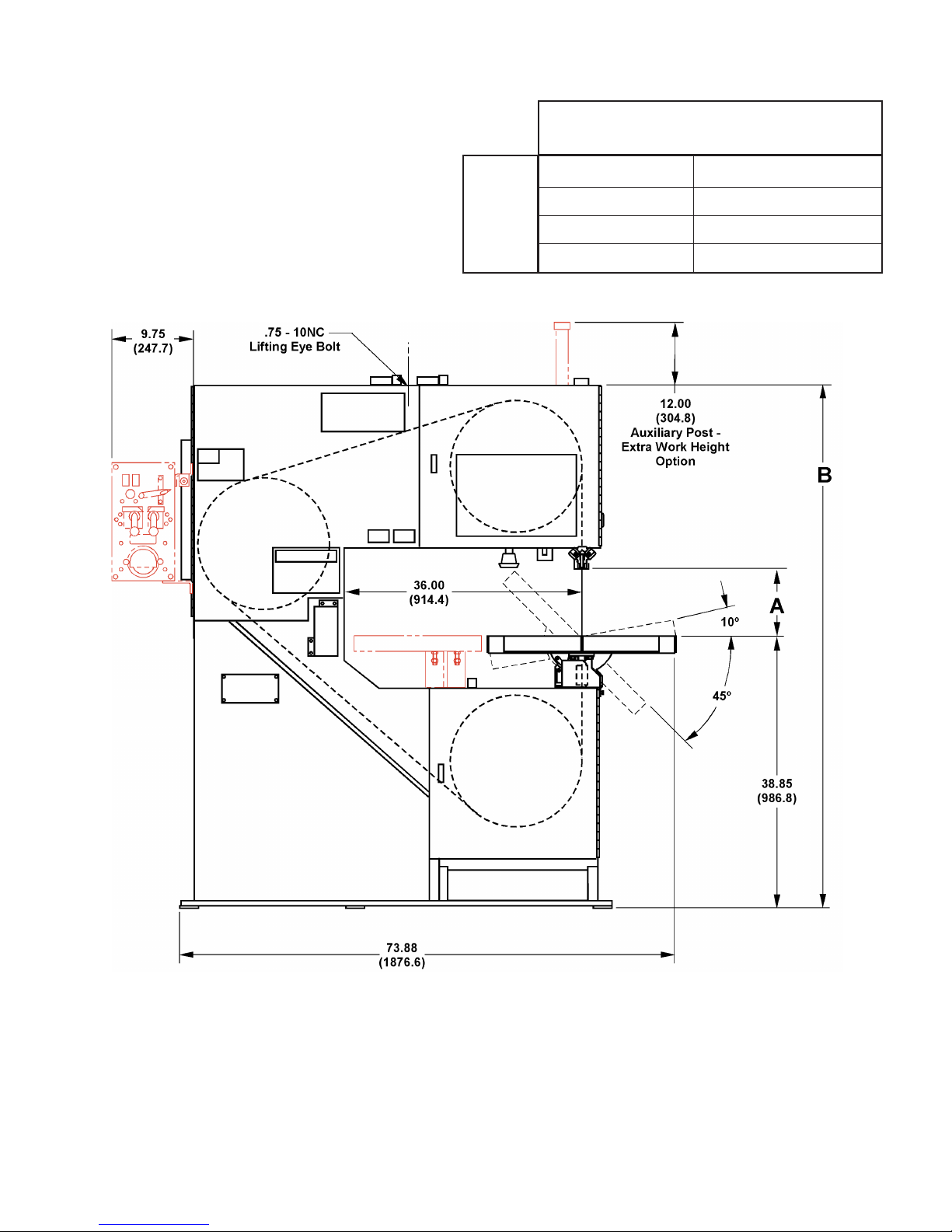

MACHINE DIMENSIONS

Floor Plan ............................................................... 1

Front View .............................................................. 2

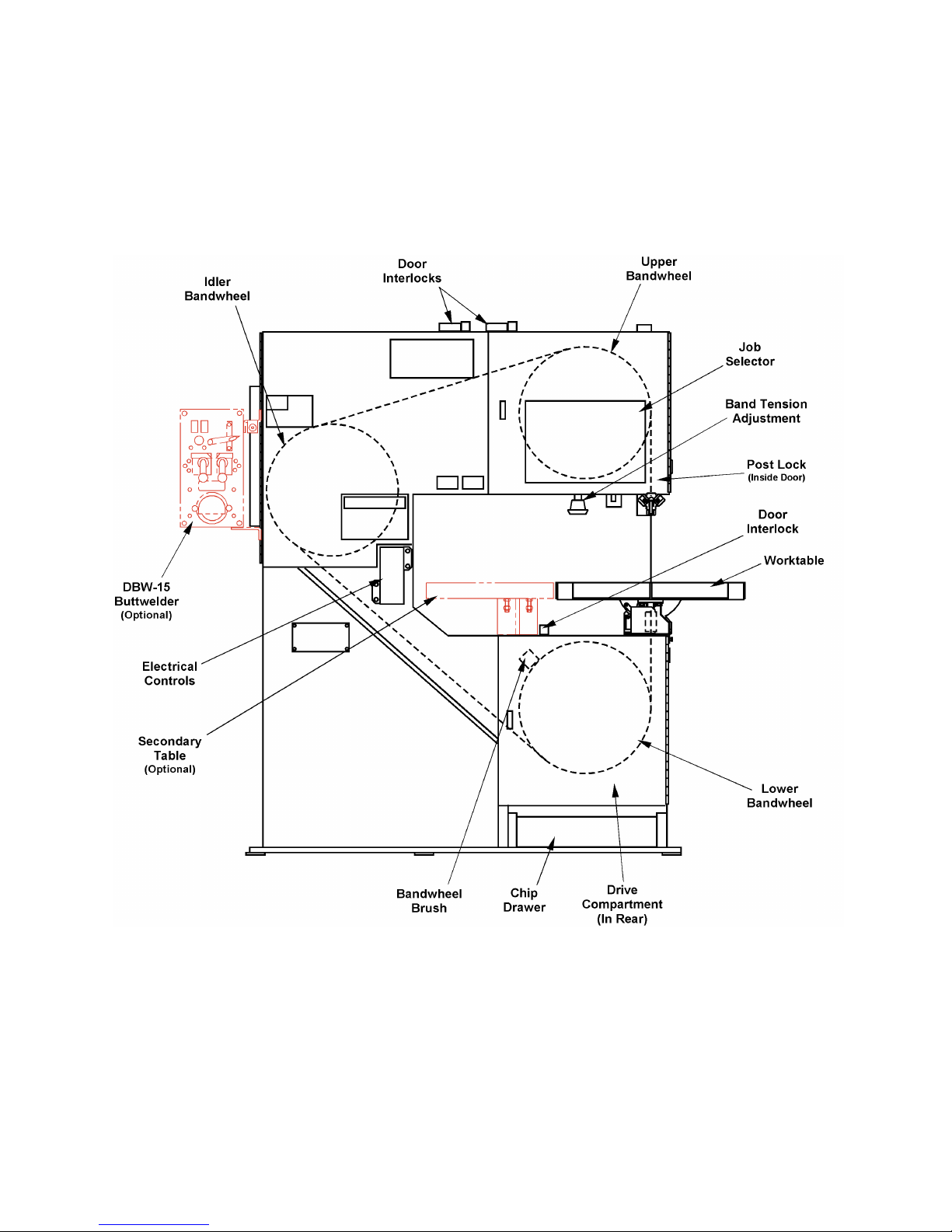

MACHINE FEATURES

Front View .............................................................. 3

Rear View ............................................................... 4

INSTALLATION

Location .................................................................. 5

OSHA Notice!! ........................................................ 5

Unpacking ............................................................... 5

Cleaning ................................................................. 5

Lifting ...................................................................... 5

Machine Alignment ................................................. 5-6

Electrical Installation ............................................... 6

Preparation for Use ................................................ 6

OPERATION

Safety Precautions ................................................. 7

Using the Job Selector ........................................... 7

Electrical Controls ................................................... 8

Band Speed Controls ............................................. 8

Saw Band Preparation ............................................ 8-10

Post Adjustment ...................................................... 10

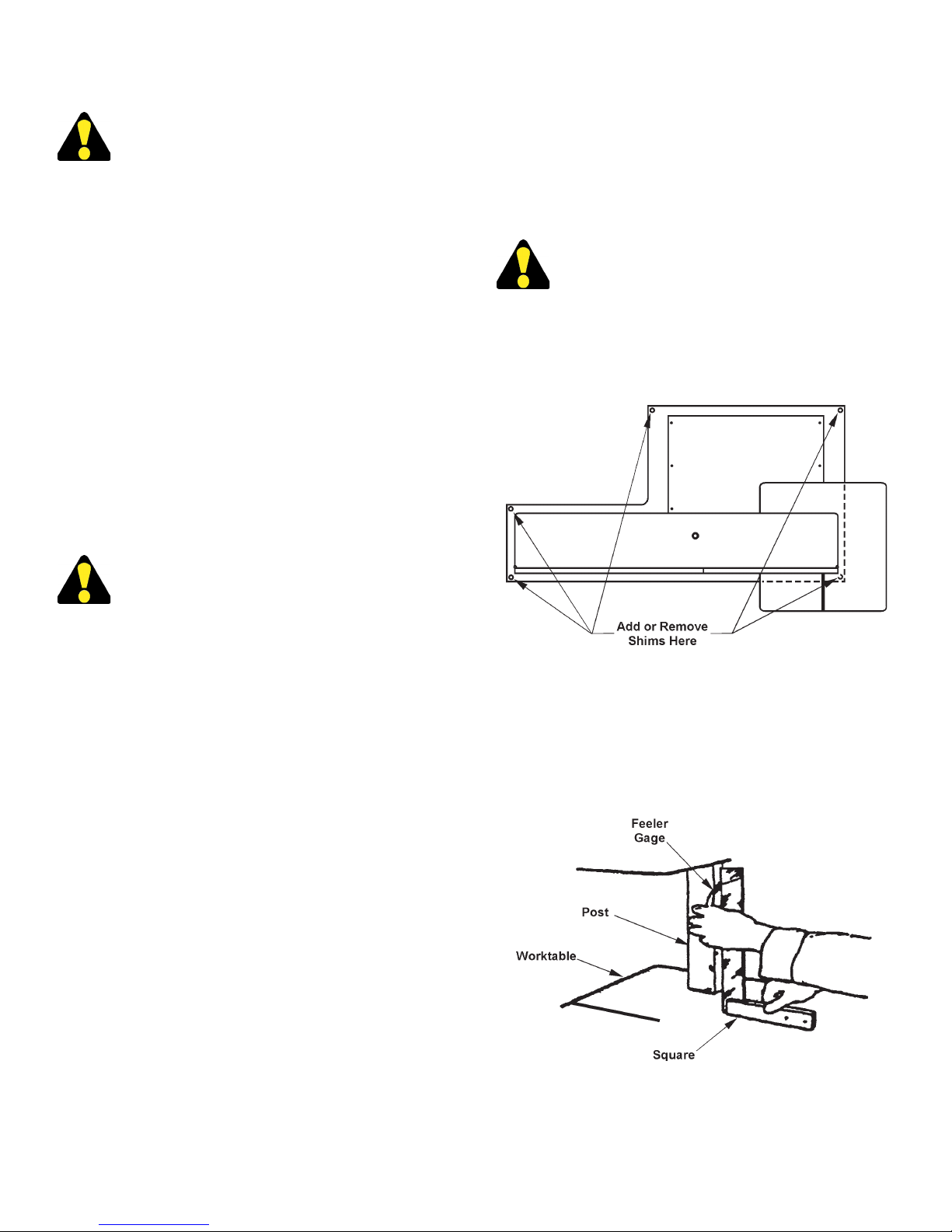

Worktable and Tilt Adjustment ................................ 10-11

Wheel Brush and Chip Removal ............................ 11

Typical Operation Procedures ................................ 11-12

LUBRICATION

Lubrication Chart .................................................... 14

Lubrication Diagram ............................................... 15

MAINTENANCE

Replacing Crowned Bandwheel Tires ..................... 16

Insert-Type Saw Guides ......................................... 16

Electric Motors ........................................................ 16

Head Components .................................................. 16

Spindle Drive Bearings ........................................... 16

Wheel Brush ........................................................... 16

Transmission .......................................................... 16

Variable Pulley ........................................................ 16

Band Drive Belt ....................................................... 16

Mist Coolant ............................................................ 16

Machine Cleaning ................................................... 16-17

TROUBLE SHOOTING .................................. 18-19

ACCESSORIES

Disc Cutter .............................................................. 20

Miter No. 2 Cut-Off (Side Mount) ............................ 20

Rip Fence ............................................................... 20

Heavy Work Slides ................................................. 20-21

Workholding Jaws .................................................. 21

Air-Operated Power Feed ....................................... 21

Chip Blower ............................................................ 22

Mist Coolant ............................................................ 22

Band Mist Lubricator ............................................... 22

Worklight ................................................................. 22

Magnier ................................................................. 22

Post Elevating Handwheel ...................................... 22

Worktable Options .................................................. 22-23

Air-Powered Worktable ........................................... 23

Universal Calibrated Work Fixture .......................... 23-24

Protractor Workstop and Alignment Gage .............. 24

DBW-15 Buttwelder ................................................ 24

Optional Saw Guides ..............................................24-26

90° Saw Guide Brackets ........................................ 26

Adjustable Angle Saw Guides ................................ 26

Dust Spout .............................................................. 26

Extra Work Height .................................................. 26

Band Filing .............................................................. 27

Band Polishing ........................................................ 28

Laser Line Generator Option .................................. 28