I

STRUCTIO

&

P

ARTS

M

AUAL

Page 4

Edition 2007-A

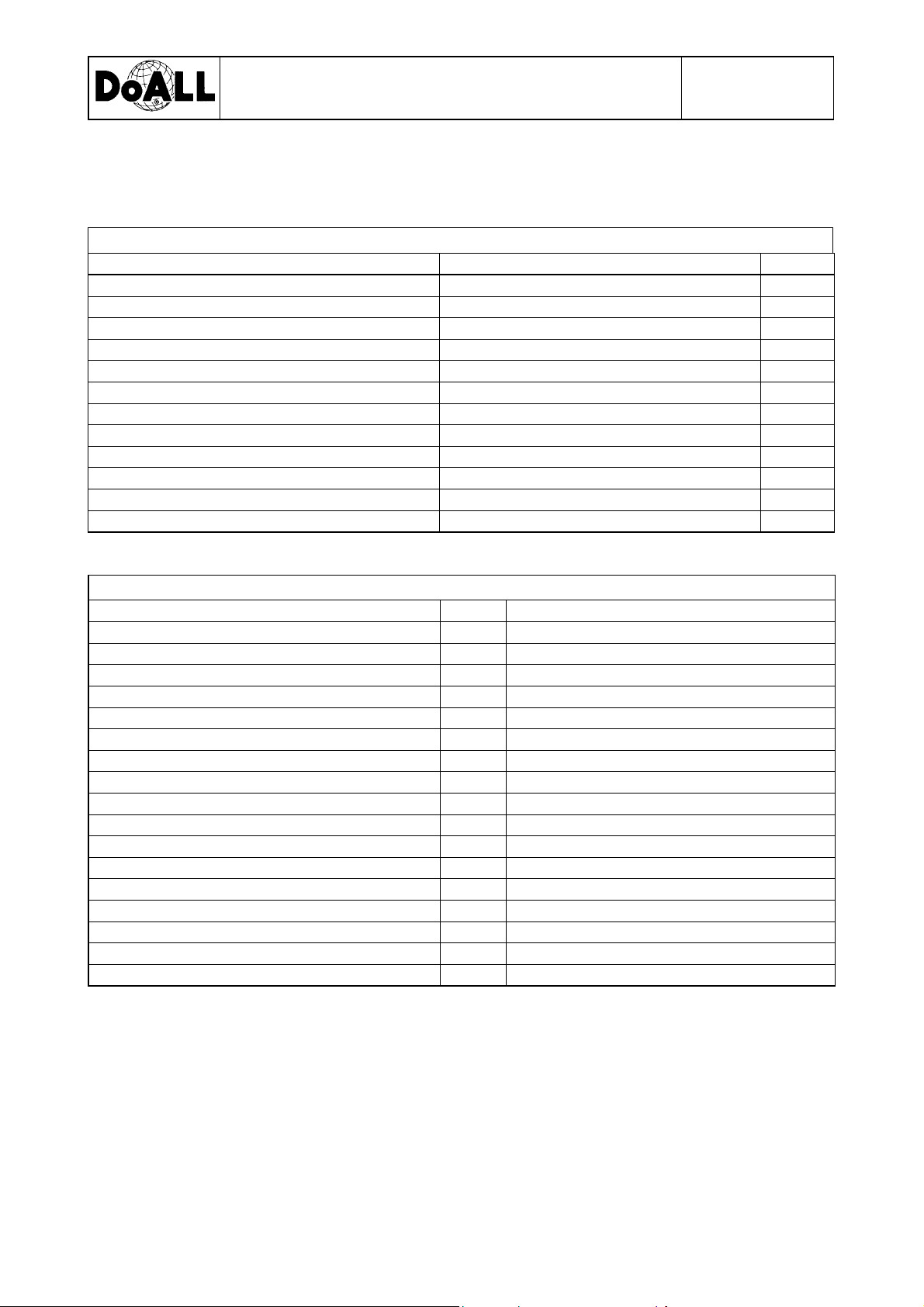

6.3.1 Motor- um assembly ....................................................................................................... 18

6.3.2 Oil reservoir ....................................................................................................................... 19

6.3.3 Solenoid valves ................................................................................................................. 19

6.4. Electrical system ....................................................................................................................... 19

6.4.1 Control console ................................................................................................................. 19

6.4.2 Control enclosure .............................................................................................................. 19

7. MACHIE PROTECTIOS ...................................................................................................... 2

8. HOW TO MOVE THE MACHIE ........................................................................................... 2

9. HOW TO ISTALL THE MACHIE ...................................................................................... 2

1 . WHAT TO DO TO PREPARE THE MACHIE TO OPERATE ...................................... 21

11. SAFETY DEVICES ................................................................................................................... 22

11.1 Limit switches and signal devices ............................................................................................ 22

11.1.1. Limit switches ................................................................................................................ 22

11.1.2. S eed reducer ................................................................................................................. 22

11.1.3. Mechanical extra stroke .................................................................................................. 22

11.1.4. Signals ............................................................................................................................ 22

11.1.5. Led, indicators and signals to avoid danger situations .................................................. 22

11.1.6. Protection devices........................................................................................................... 22

11.2. Fix rotections ......................................................................................................................... 22

11.3. Movable rotections ................................................................................................................ 22

11.4. Safety features set-u ............................................................................................................... 22

12. MACHIE COTROLS ........................................................................................................... 23

12.1. How to o erate the machine .................................................................................................... 23

12.1.1 Control anel with ushbuttons & selector switches ...................................................... 23

12.1.2 To start the machine ........................................................................................................ 24

12.1.3 To make a cut .................................................................................................................. 25

12.1.4 To sto the machine ........................................................................................................ 25

12.1.5 When an emergency occur .............................................................................................. 25

12.2. How to o erate machines equi ed with a saw1 control ........................................................ 25

12.2.1 Dis lay ............................................................................................................................. 25

12.2.2 Standard controls ............................................................................................................. 25

12.2.3 Piece counter ................................................................................................................... 26

12.2.4 Coolant status .................................................................................................................. 26

12.2.5 Menu scroll ...................................................................................................................... 27

12.2.6 Machine emergency codes ............................................................................................... 27

12.3. Head feeding control ............................................................................................................... 27

13. CALIBRATIO AD TUE-UP ............................................................................................. 28

13.1. Calibration ............................................................................................................................... 28

13.2. Machine tuning-u ................................................................................................................... 28

13.3. Blade motor inverter ................................................................................................................ 28

13.3.1 Control anel ................................................................................................................... 28

13.3.2 Dis lay ............................................................................................................................ 29

13.3.3 Hel - function and language - selection ......................................................................... 29

13.3.4 Inverter status ................................................................................................................. 29

13.3.5 Warnings ......................................................................................................................... 30

13.3.6 O erating error messages ................................................................................................ 30

13.3.7 Hardware error messages ................................................................................................ 31

13.3.8 Programming structure .................................................................................................... 32

14. DISMATLIG OF THE MACHIE .................................................................................... 34

15. ORDIARY PROBLEMS......................................................................................................... 34