ii

TABLE OF

CONTENTS

SAFETY RULES .......................................... 1

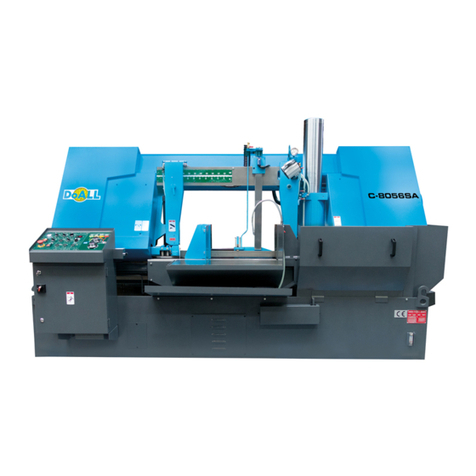

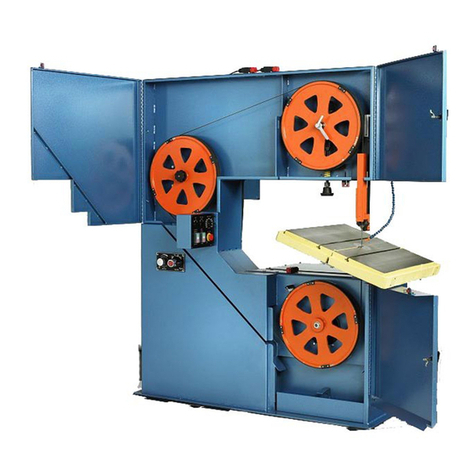

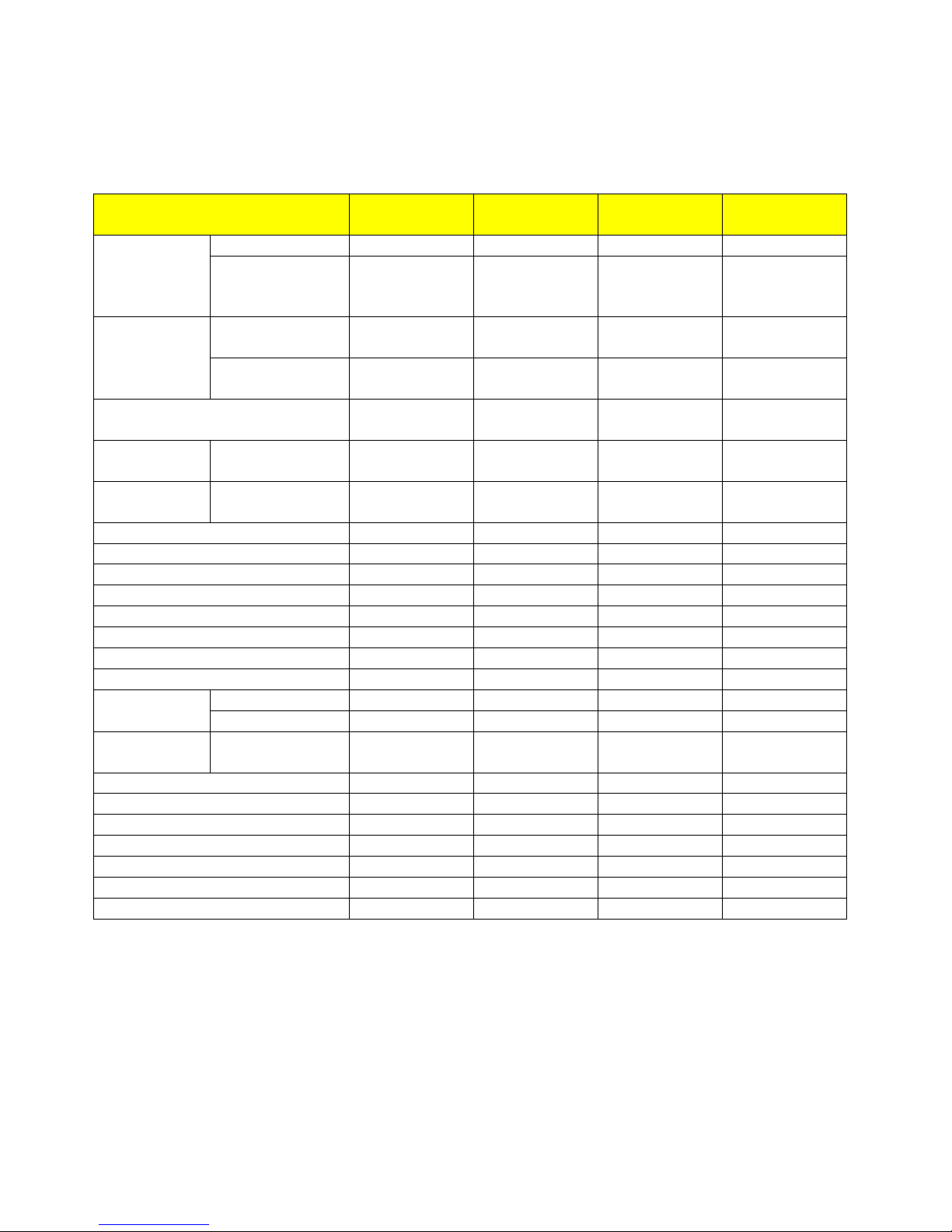

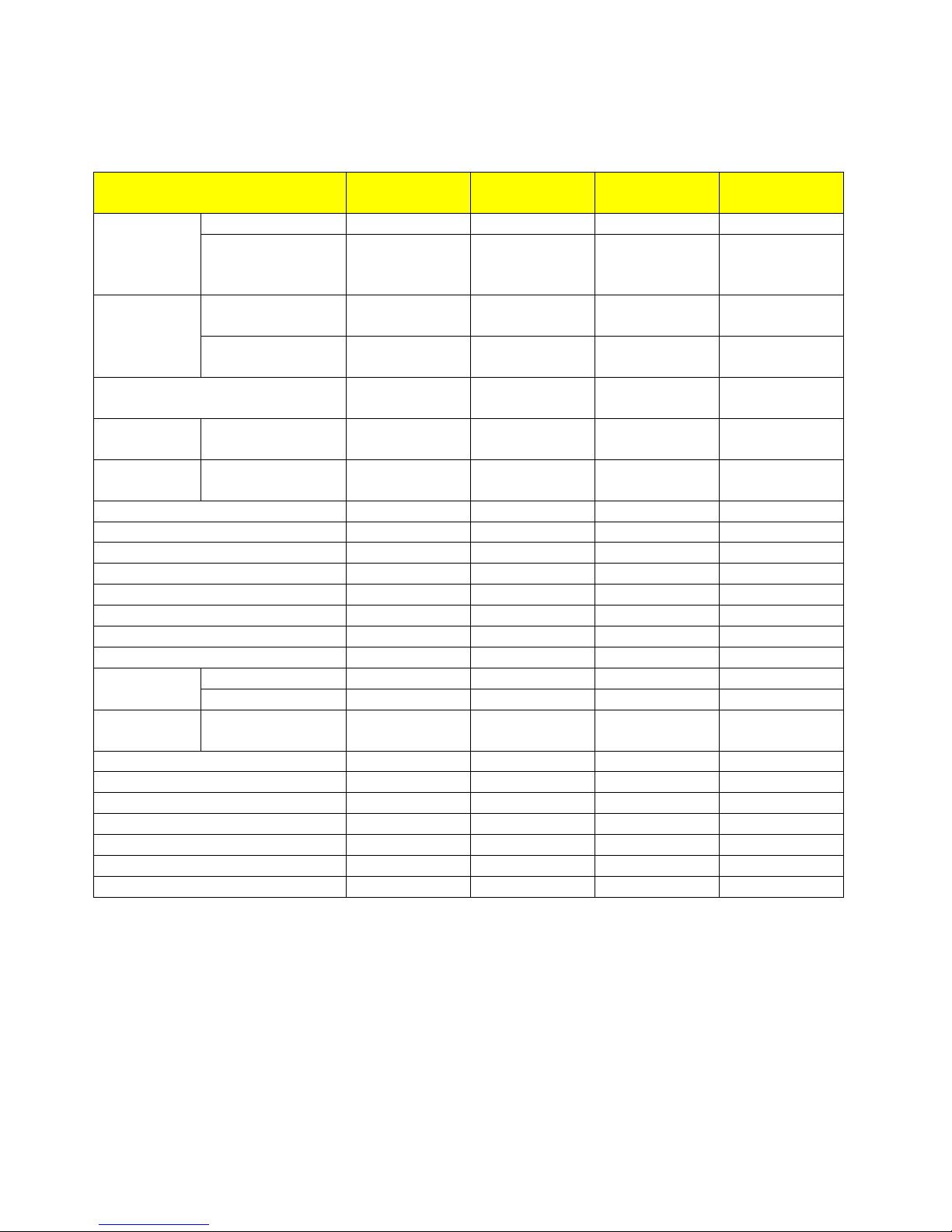

MACHINE SPECIFICATIONS .................. 2-3

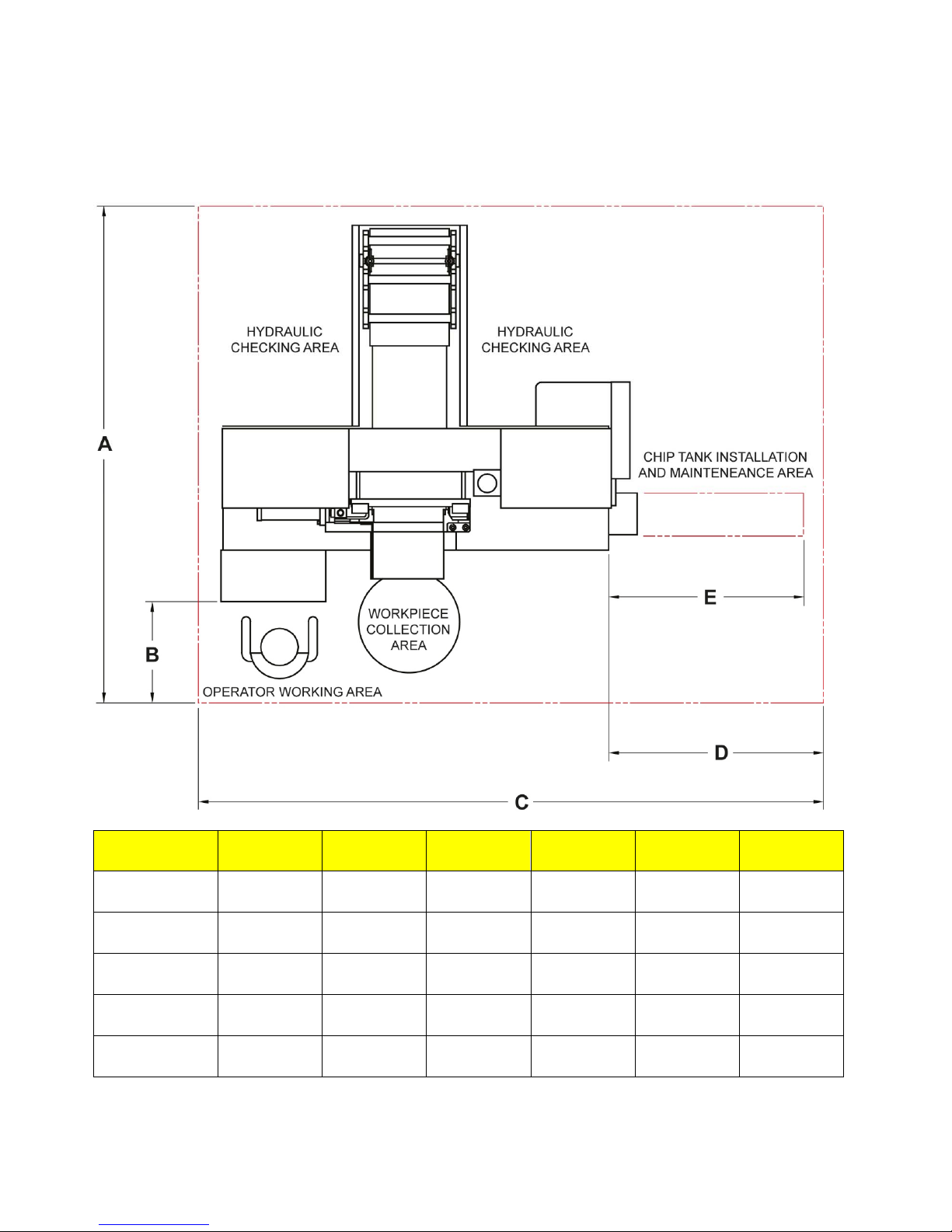

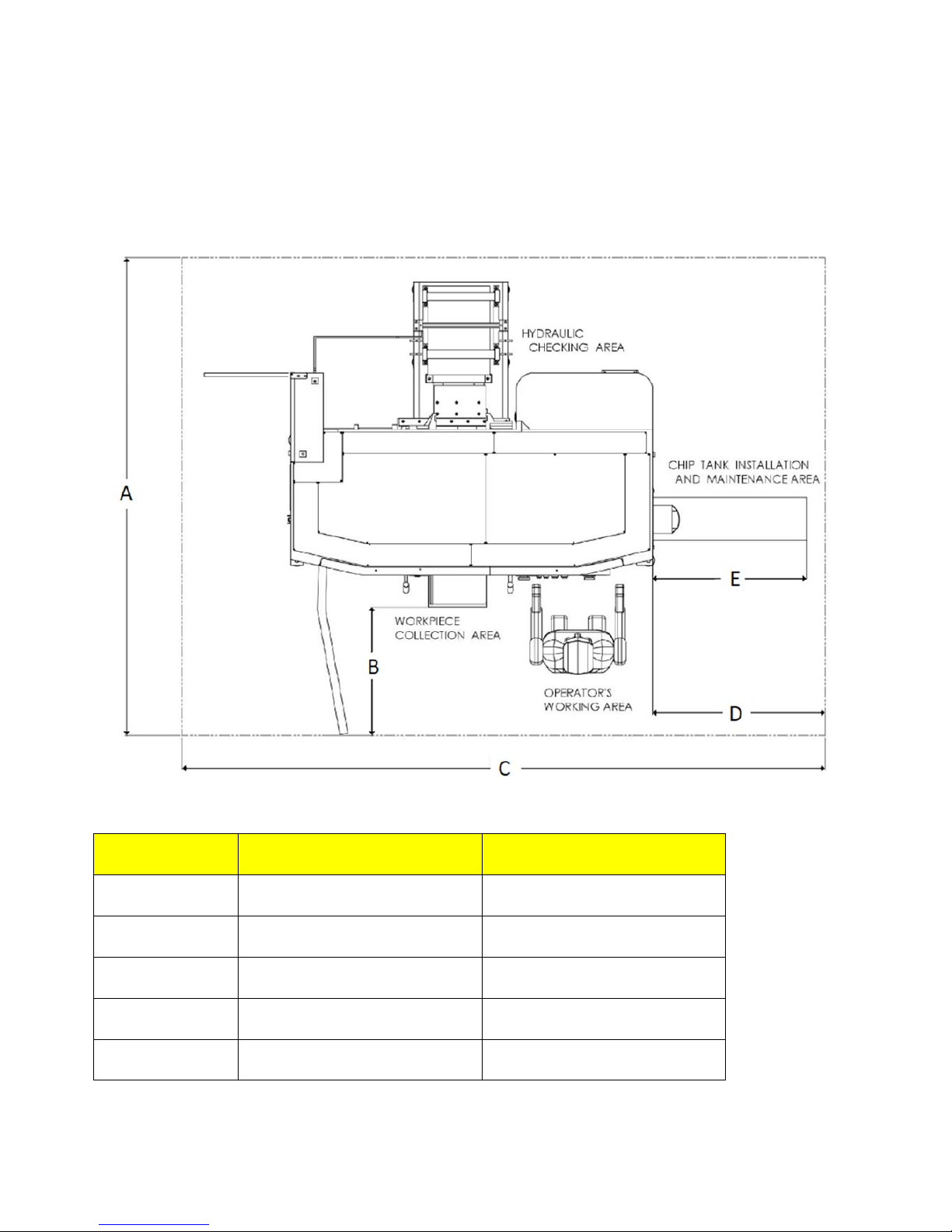

MACHINE DIMENSIONS

Installation dimensions .............................. 4-5

C-3028NC dimensions ................................. 6

C-3028NC Boxed dimensions ...................... 7

C-4033NC dimensions ................................. 8

C-420NC dimensions ................................... 9

C-420NC Boxed dimensions ...................... 10

C-5650NC dimensions ............................... 11

C-560NC dimensions ................................. 12

C-6260NC dimensions ............................... 13

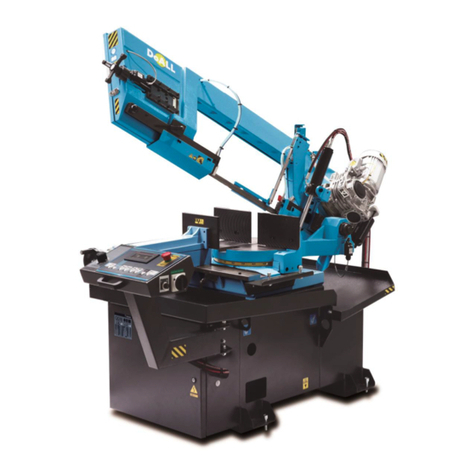

MACHINE FEATURES .............................. 14

INSTALLATIONS

Locations.................................................... 15

OSHA Notice .............................................. 15

Unpacking .................................................. 15

Lifting ......................................................... 15

Cleaning ..................................................... 16

Floor installation ......................................... 16

Electrical installation .................................. 16

Preparation for use .................................... 17

OPERATION

Selecting band speed and cutting rate ....... 18

Control console .................................... 19-21

Operator workstation ............................. 21-25

Setup for creating jobs .......................... 25-26

Machine preparation ............................. 26-27

Band speed range ...................................... 27

Left saw guide arm adjustment .................. 27

Feed force adjustment .......................... 27-28

Feed rate ................................................... 28

Head elevation and sensing arm ............... 28

Minimum bar end ....................................... 28

Vertical guide rollers .................................. 29

Hydraulic system ....................................... 29

Coolant system ......................................... 29

Chip removal ......................................... 29-30

Nesting fixture ....................................... 30-31

Typical operating procedures ................ 31-32

LUBRICATION

Lubrication chart ........................................ 33

Lubrication diagrams.................................. 34

MAINTENANCE

Replacing saw guide and backup inserts ... 35

Band/brush drive belt replacement ............ 35

Hydraulic system ....................................... 35

Coolant system .......................................... 35

Band drive gear box ................................... 36

Machine cleaning ....................................... 36

Machine alignment ..................................... 36

Band brush ................................................ 36

Band tension measurement ....................... 36

Wear plate replacement ........................ 36-37

Band wheels .............................................. 37

Cleaning chip conveyor .............................. 37

TROUBLE SHOOTING ........................ 38-40