ii

TABLE OF CONTENTS

LUBRICATION

Lubrication Chart .................................................... 22

Lubrication Diagram ............................................... 23

MAINTENANCE

Replacing Saw Guide and Back-Up Inserts ........... 24

Hydraulic System .................................................... 24-25

Coolant Ststem ....................................................... 25

Machine Cleaning ................................................... 25

Machine Alignment ................................................. 25

Brush Adjustments .................................................. 25

Wear Plate Replacement ........................................ 25

Bandwheels ............................................................ 26

Chip Conveyor ........................................................ 26

Miter Meter ............................................................. 26

TROUBLE SHOOTING .................................. 27-29

ACCESSORIES

Variable Vise Pressure ........................................... 30

Filler Plates ............................................................. 30

Nesting Fixture ....................................................... 30-31

Roller Stock Conveyors .......................................... 31-32

Workstop ................................................................ 32

Vertical Guide Rollers ............................................ 32

Mist Lubricator ........................................................ 32

Right Hand Vise ...................................................... 32

Lift Rollers ............................................................... 32

Laser Line Option ................................................... 33

Fixed Frame (Non-Tilting) ....................................... 33

Extra Work Height .................................................. 33

Band Twist Indicator ............................................... 33-34

Medium Torque Drive ............................................. 34

Saw Band Modication ........................................... 34

Head Travel Indicator ............................................. 34

Reinforcing Legs (Heavy Work Support) ................ 34

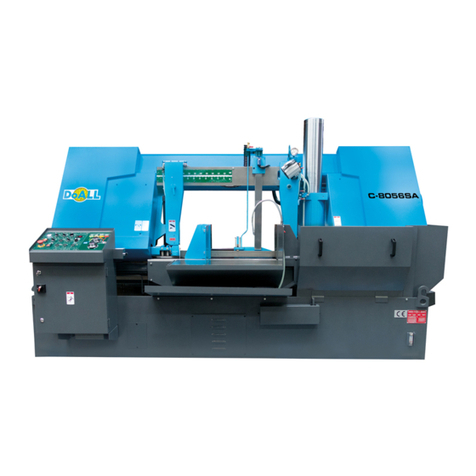

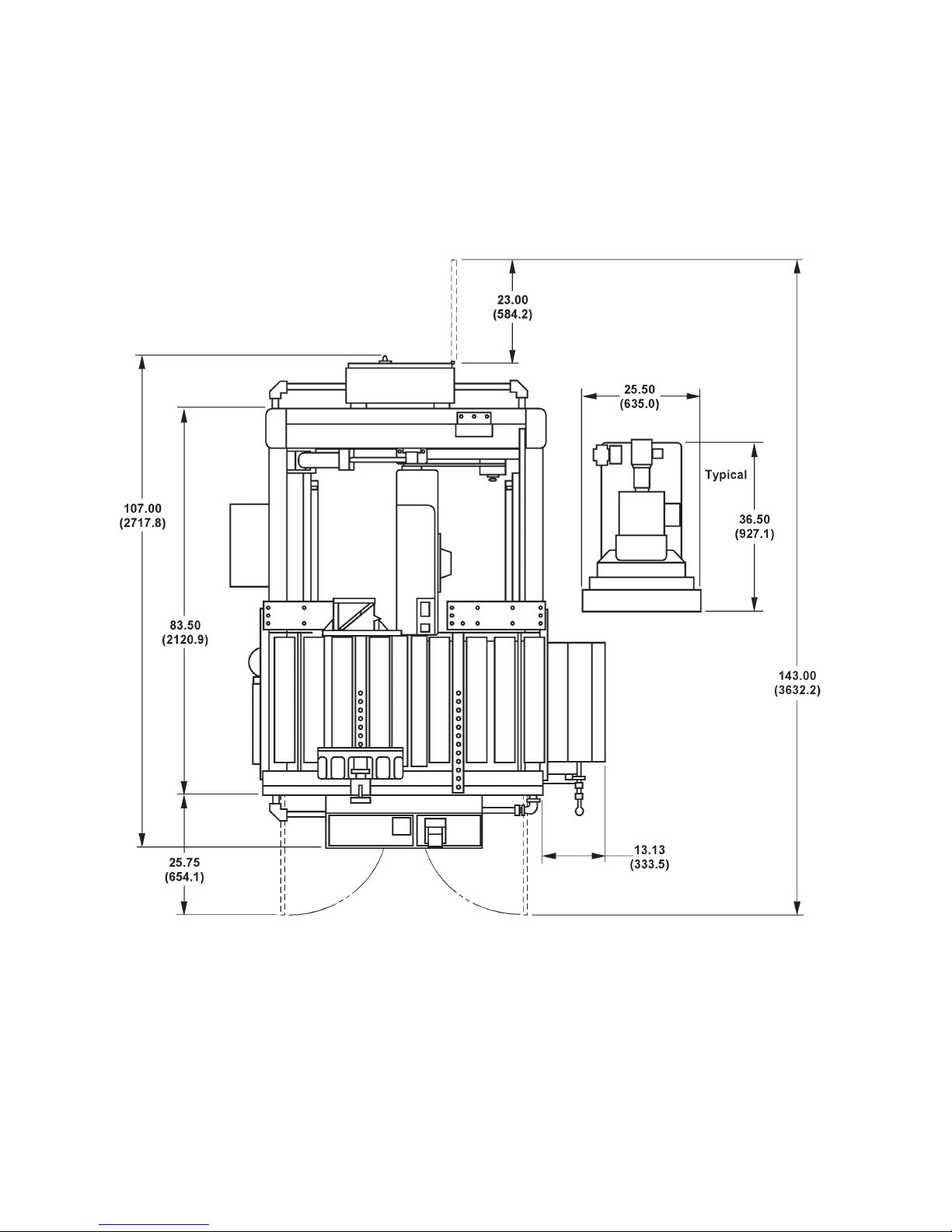

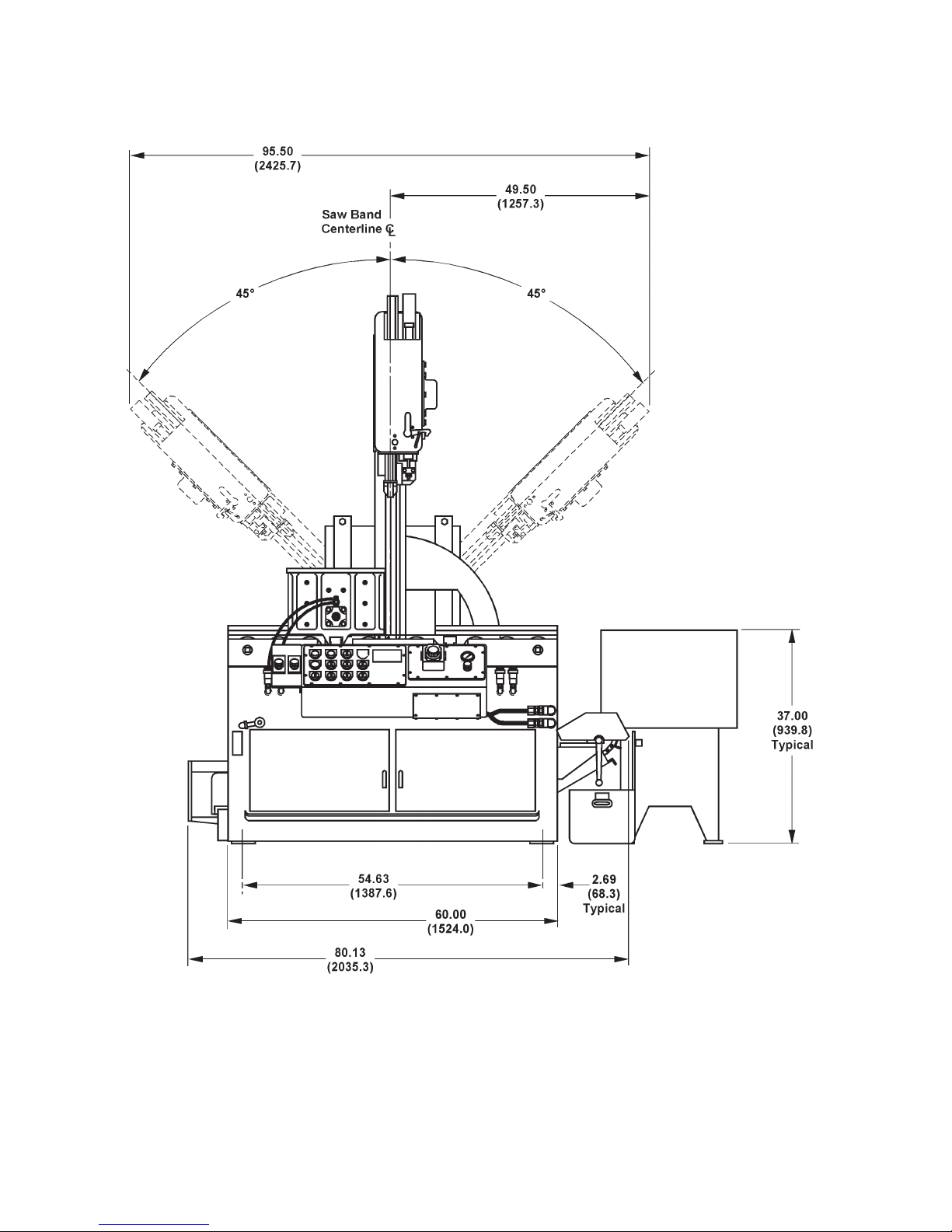

MACHINE DIMENSIONS

Floor Plan ............................................................... 1

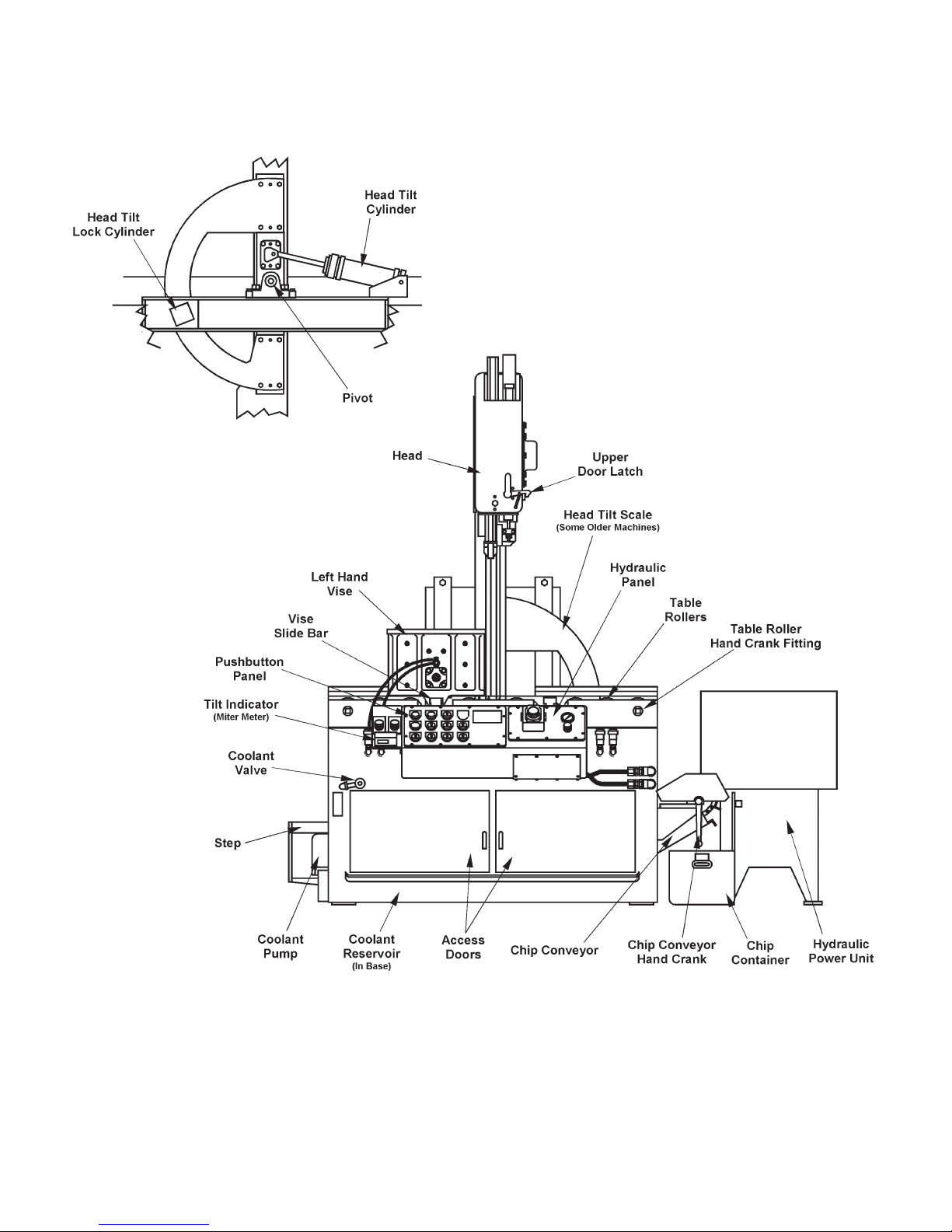

Front View .............................................................. 2

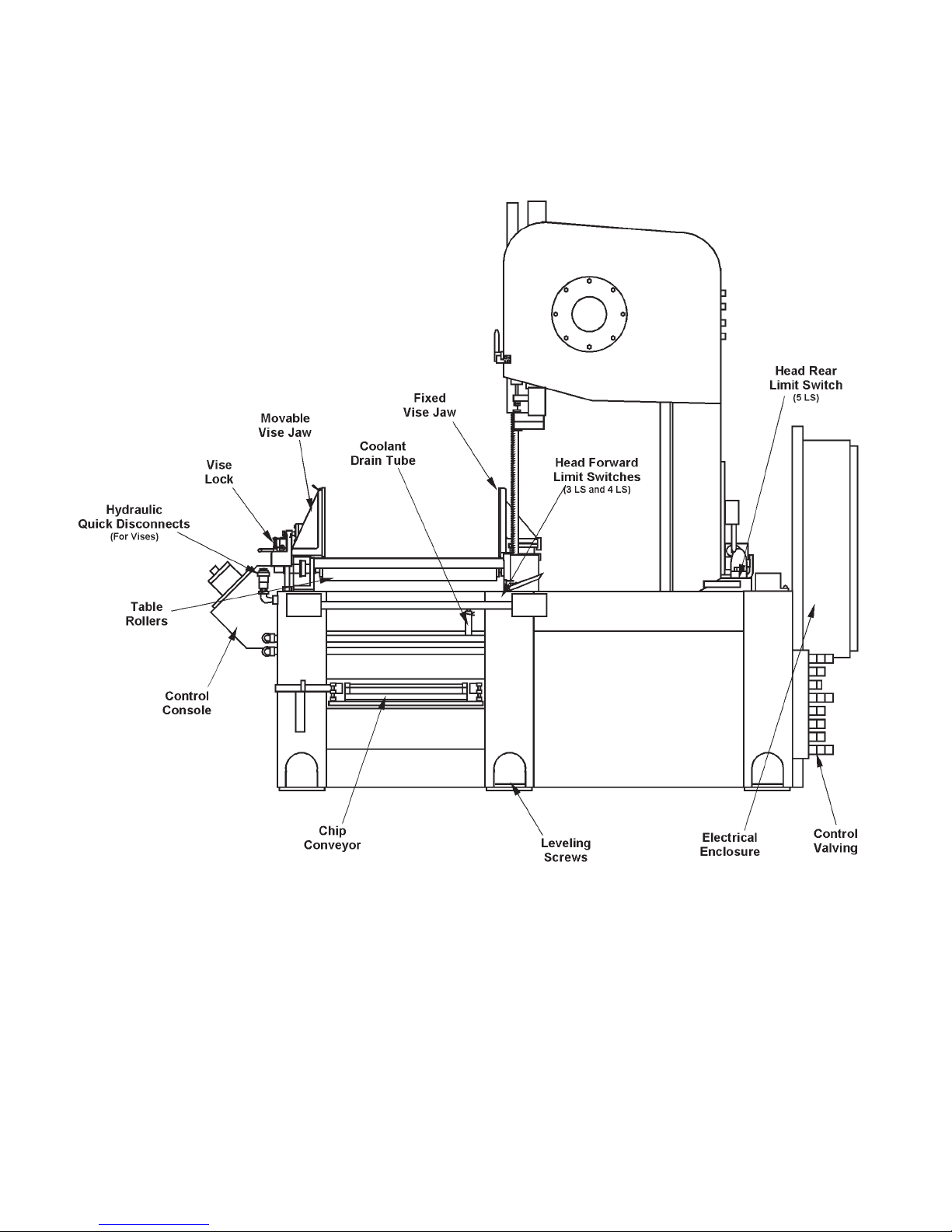

Side View ................................................................ 3

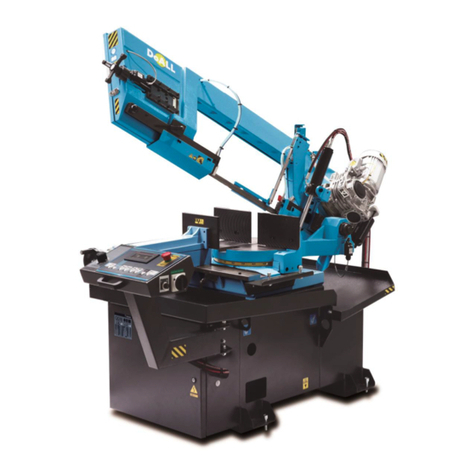

MACHINE FEATURES

Front and Rear Views ............................................. 4

Side View ................................................................ 5

Head Assembly ....................................................... 6

INSTALLATION

Location .................................................................. 7

OSHA Notice!! ........................................................ 7

Unpacking ............................................................... 7

Cleaning ................................................................. 7

Lifting ...................................................................... 7

Floor Installation and Alignment ............................. 7

Electrical Installation ............................................... 8

Hydraulic Installation .............................................. 8

Coolant Installation ................................................. 9

Preparation for Use ................................................ 9

OPERATION

Safety Precautions ................................................. 10

Using the Job Selector ........................................... 10

Cutting Capacity ..................................................... 11

Control Console ...................................................... 11-14

Saw Band Preparation ............................................ 14-15

Post Adjustment ...................................................... 15

Head Reverse Rate ................................................ 16

Head Tilt Adjustments ............................................. 16

Miter Meter ............................................................. 16

Roller Table ............................................................. 16

Vise Adjustments .................................................... 16-17

Band Feed Adjustments ......................................... 17

Coolant System ..................................................... 18

Hydraulic System .................................................... 18

Chip Removal ......................................................... 18-19

Typical Operation Procedures ................................ 19-20

How to read your serial number: