DS-320SA

Instruction Manual - 2 - www.doallsaws.com

1. CONTENT

1. CONTENT ...................................................................................................................................................... 2

2. INTRODUCTION ............................................................................................................................................ 4

2. DESCRIPTION OF THE MACHINE ............................................................................................................... 4

2.1 OPERATING CYCLE ............................................................................................................................... 4

2.2 CONTROL SYSTEM ................................................................................................................................ 4

2.3 CONSTRUCTION .................................................................................................................................... 5

2.4 STANDARD EQUIPMENT ....................................................................................................................... 5

2.5 BASIC EQUIPMENT OF MACHINE ........................................................................................................ 5

2.5.1 SET OF TOOLS FOR COMMON SERVICE ................................................................................ 6

2.6 PURPOSE OF THE MACHINE ................................................................................................................ 7

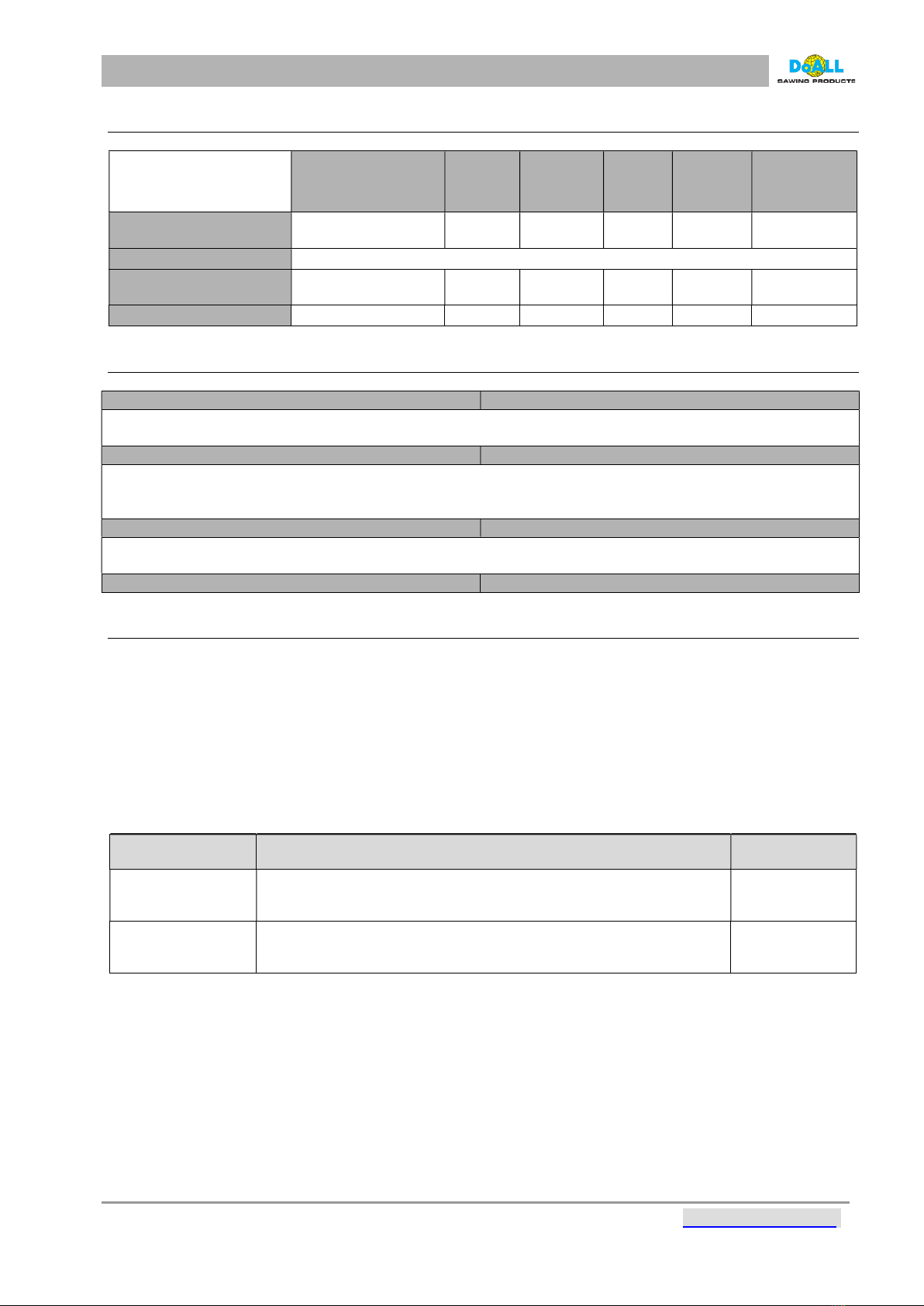

3. TECHNICAL DATA ........................................................................................................................................ 8

3.1 CUTTING PARAMETERS ....................................................................................................................... 8

3.2 DIMENSIONS FOR TRANSPORT .......................................................................................................... 8

3.3 INFORMATION ON DRIVE ...................................................................................................................... 9

3.4 THE AMOUNT OF SERVICE/OPERATING FLUIDS .............................................................................. 9

3.5 EMISSIONS – MACHINE NOISE LEVEL ................................................................................................ 9

3.6 PRODUCTION LABEL ........................................................................................................................... 10

4. MAIN PARTS AND FUNCTIONS ................................................................................................................ 11

4.1 VICE ....................................................................................................................................................... 12

4.2 ARM ....................................................................................................................................................... 13

4.3 HYDRAULIC UNIT ................................................................................................................................. 14

5. SAFETY RULES .......................................................................................................................................... 15

5.1 SAFETY DURING OPERATION ............................................................................................................ 15

5.2 LIST OF POSSIBLE DANGERS WHEN WORKING WITH MACHINE ................................................. 16

5.2.1 MECHANICAL RISK ................................................................................................................... 16

5.2.2 ELECTRICAL RISKS .................................................................................................................. 16

5.3 FIRE PROTECTION .............................................................................................................................. 16

5.4 ELECTRICAL EQUIPMENT................................................................................................................... 17

5.5 IT IS PROHIBITED TO ........................................................................................................................... 17

5.6 SAFETY REGULATIONS ...................................................................................................................... 18

5.6.1 SAFETY COMPONENTS ........................................................................................................... 19

5.7 DESCRIPTION OF LABELS .................................................................................................................. 20

6. INSTRUCTIONS FOR TRANSPORT .......................................................................................................... 22

7. DIRECTIVES FOR STORAGE .................................................................................................................... 22

8. MACHINE INSTALLATION ......................................................................................................................... 23

8.1 INSPECT MACHINE FOR SHIPPING DAMAGES ................................................................................ 23

8.2 SHIPPING BRACKETS .......................................................................................................................... 23

8.3 INSTALLING THE MACHINE ................................................................................................................ 23

8.3.1 FOUNDATION REQUIREMENTS .............................................................................................. 23

8.3.2 ACHORING INSTRUCTIONS: ................................................................................................... 24

8.4 INSTALLING THE ROLLER TABLE ...................................................................................................... 25

8.5 HOW TO ANCHOR MACHINE TO THE FLOOR .................................................................................. 26

8.6 CONNECTING TO THE ELECTRICAL NET ......................................................................................... 26

9. DESCRIPTION OF MAIN PANEL ............................................................................................................... 27

9.1 KEYPAD ................................................................................................................................................. 28

9.2 HMI PANEL ............................................................................................................................................ 29

9.2.1 STARTING SCREEN .................................................................................................................. 29

9.2.2 MENU ......................................................................................................................................... 30

9.2.3 NUMERIC KEYPAD ................................................................................................................... 30

9.3 /1.PAR/ USER PARAMETERS .............................................................................................................. 31

9.4 /2.MAN/ MANUAL SAW CONTROL ...................................................................................................... 33

9.5 PREPARATIONS BEFORE CUTTING .................................................................................................. 34

9.6 INITIATION OF THE MACHINE INTO THE STAND-BY MODE ........................................................... 35

9.7 ANGLE SETTING .................................................................................................................................. 36

9.7.1 CUTTING OF THE RIGHT ANGLE CUTS ................................................................................. 36

9.7.2 CUTTING OF THE LEFT ANGLE CUTS .................................................................................... 36

9.7.3 DIGITAL POINTER OF THE ANGLE (ACCESSORIES) ........................................................... 37

9.8 ADJUSTMENT OF THE WORKING POSITION .................................................................................... 38

9.8.1 ADJUSTMENT OF THE UPPER WORKING POSITION ........................................................... 38