Instruction & Parts Manual

Pag.3

Edition 2008-A

CE

DECLARATIO .........................................................................................................................

1.

GEERAL IFORMATIO

......................................................................................................................... 7

1.1. Goal of this manual. .......................................................................................................................... 8

1.2. Regulations to refer. .......................................................................................................................... 8

1.3. Manual description ........................................................................................................................... 8

2.

MACHIE IDETIFICATIO DATA

.............................................................................................................. 9

2.1 Main costructi e characteristics. .......................................................................................................... 10

2.2. Blade speed .................................................................................................................................. 10

2.3. Working surface ............................................................................................................................ 10

2.4. Indexing ....................................................................................................................................... 11

2.5. Vises ........................................................................................................................................... 11

3.

H

OW TO USE THE ISTRUCTIO MAUAL

................................................................................................. 11

3.1. Who should read the instruction manual................................................................................. 11

3.2. Where to keep this manual ............................................................................................................... 11

3.3. Strength of this manual .................................................................................................................... 11

3.4. Manual update............................................................................................................................... 11

3.5. How to obtain more copies ............................................................................................................... 12

3.6. If the machine change owner ............................................................................................................ 12

3.7. Suggestions .................................................................................................................................. 12

4.

LIABILITY LIMITS

................................................................................................................................. 12

4.1 Inappropriate use of the machine ......................................................................................................... 12

5.

TYPE

OF

USE

ALLOWED ................................................................................................................ 14

5.1. machine ADDRESSEE ................................................................................................................. 14

5.2. Operator ....................................................................................................................................... 14

5.3. Regulation .................................................................................................................................... 14

5.4 Typical use .................................................................................................................................... 14

5.5. Limits using the saw ....................................................................................................................... 15

5.6. Workable materials ......................................................................................................................... 15

5.7. Work area .................................................................................................................................... 15

This area must be marked by an appropriate signal. ...................................................................................... 15

5.8. Work place ................................................................................................................................... 15

5.9. Command modes, stop, emergency stop and out of ser ice. ..................................................................... 15

5.9.1 Command modes ..................................................................................................................... 16

5.9.1.1. Stop ................................................................................................................................... 16

5.9.1.2. Emergency stop .................................................................................................................... 16

5.9.1.3. Out of ser ice ....................................................................................................................... 16

5.9.1.4. Safety precautions .................................................................................................................. 16

.

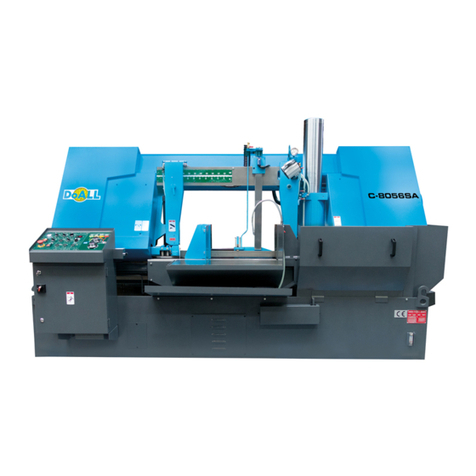

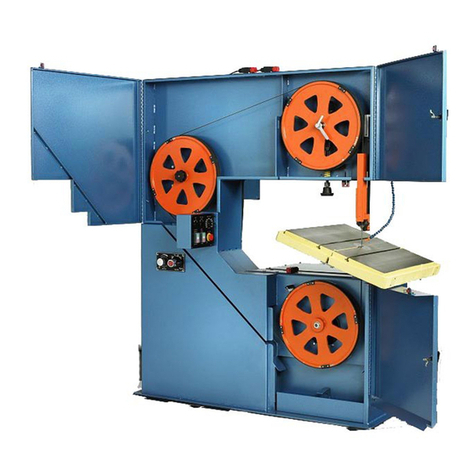

TECHICAL DESCRIPTIO

...................................................................................................................... 17

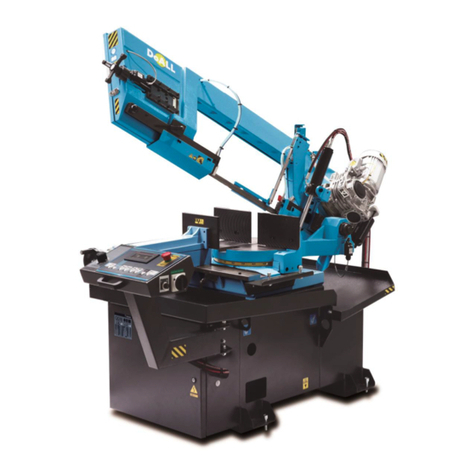

6.1. Machine structure ........................................................................................................................... 17

6.1.1. Base frame ............................................................................................................................. 17

6.1.2. Chip con eyor ........................................................................................................................ 17

6.1.3. Index assembly........................................................................................................................ 17

6.1.4. Vices .................................................................................................................................... 17

6.2. Cutting bridge................................................................................................................................ 18

6.2.1 Cutting bridge frame ................................................................................................................. 18

6.2.2 Guiding columns ...................................................................................................................... 18

6.2.3 Columns connection ................................................................................................................. 18