D+H ZA 35-HS User manual

Standard version

Version without tube (option "-OT")

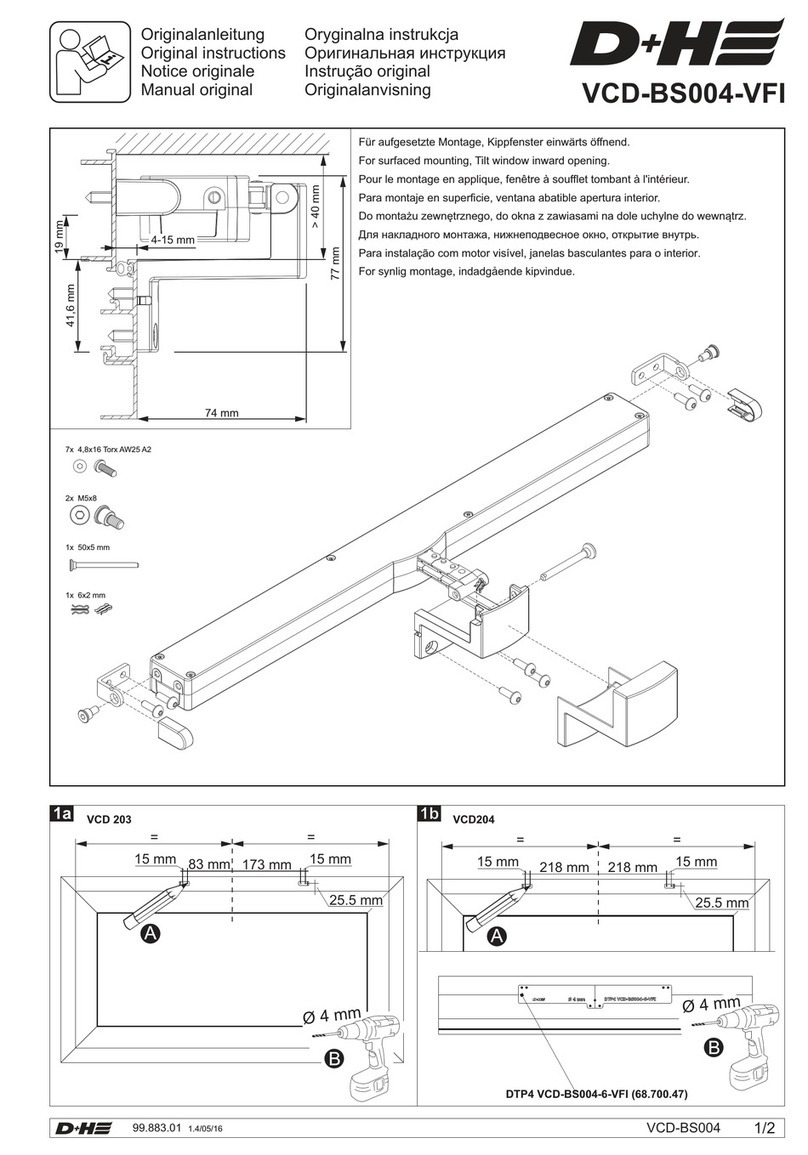

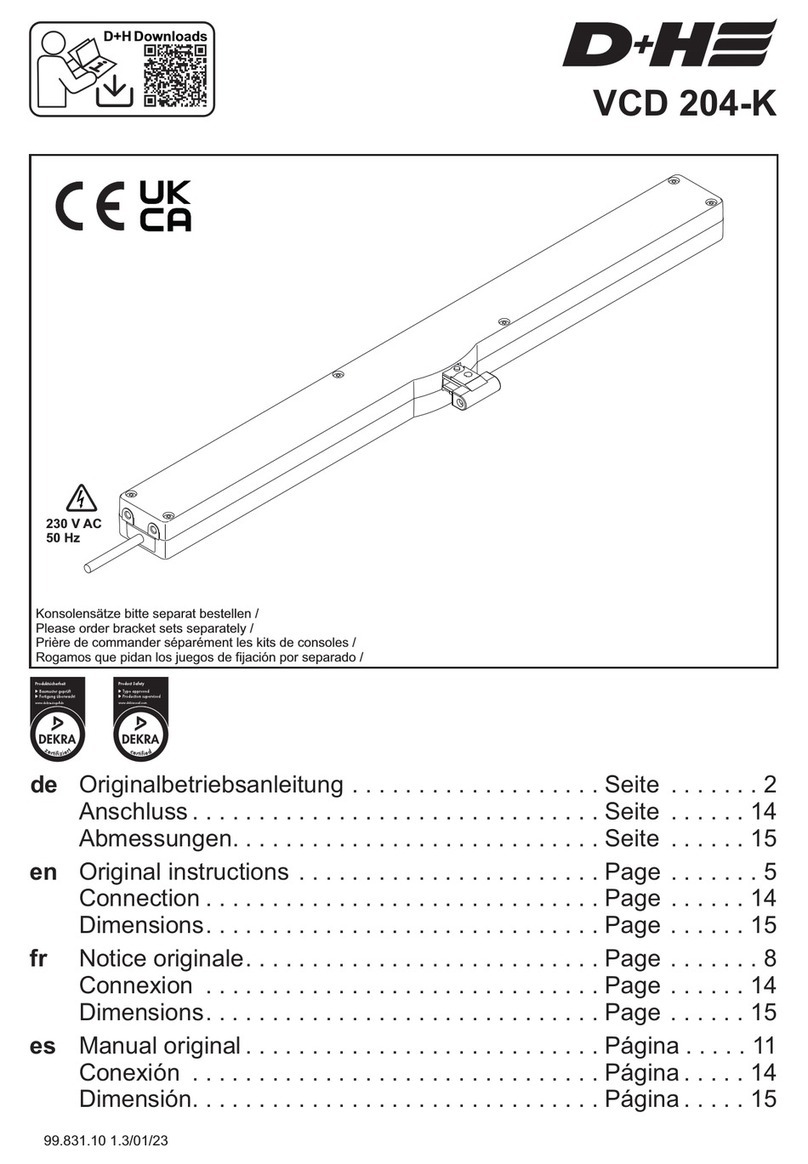

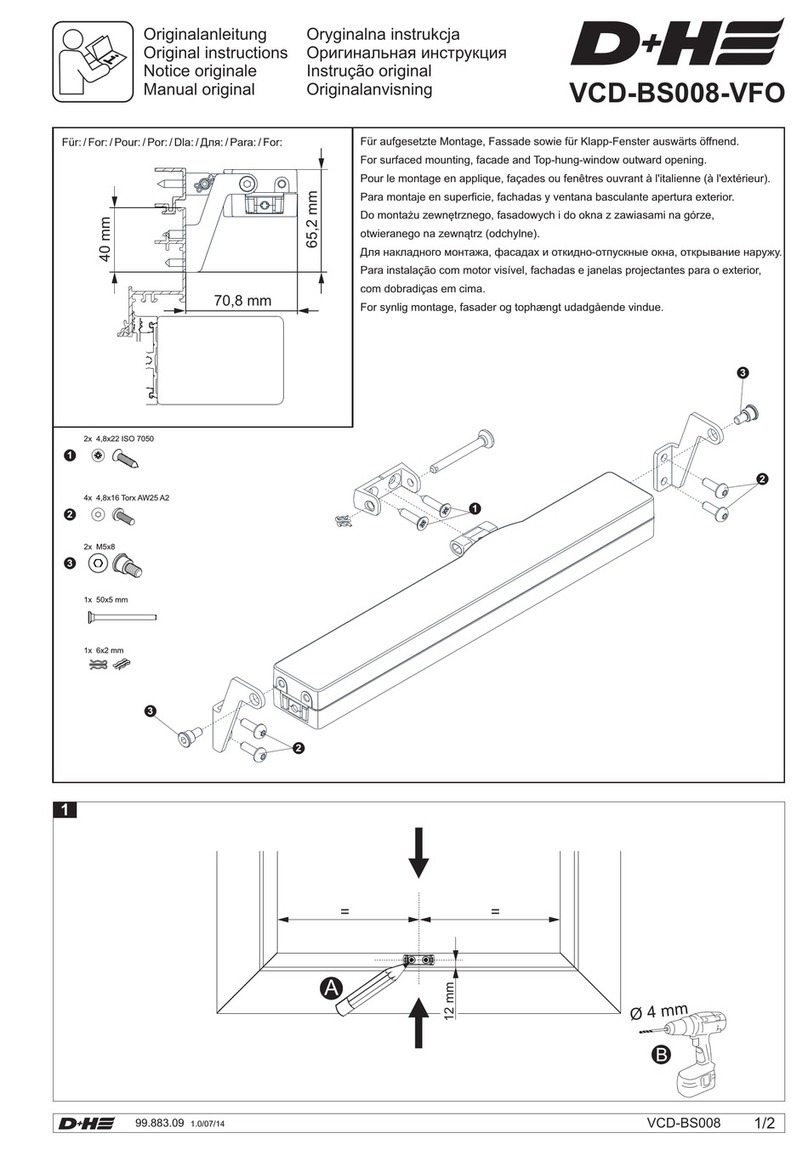

Please order bracket sets separately

B 08 11 22802 026

G 500001

ZA 35/85/105/155-BSY+(-HS) instructions

ZA-BSY+

ZA-BSY+ 7/20

English

Intended use

- Rack and pinion drive for electric opening and

closing of windows and flaps in the facade and

roof area

- Operating voltage 24 V DC

- Useable for smoke ventilation, D+H Euro-SHEV

according to DIN EN 12101-2 as well as daily

natural ventilation

- Only for inside mounting

Performance features

- Micro processor controlled synchro electronics

BSY + for a precise synchronous run of up to

8 drives

- Individually programmable (via software SCS)

- SHEV-high speed function (fast-running

feature in OPEN-direction)

- Protection system for the main closing edge

- Especially silent in ventilation operation

because of reduced motor speed

Drive unit with 2,5 m silicone cable. Dependent on

the type of window, different bracket sets are

available separately.

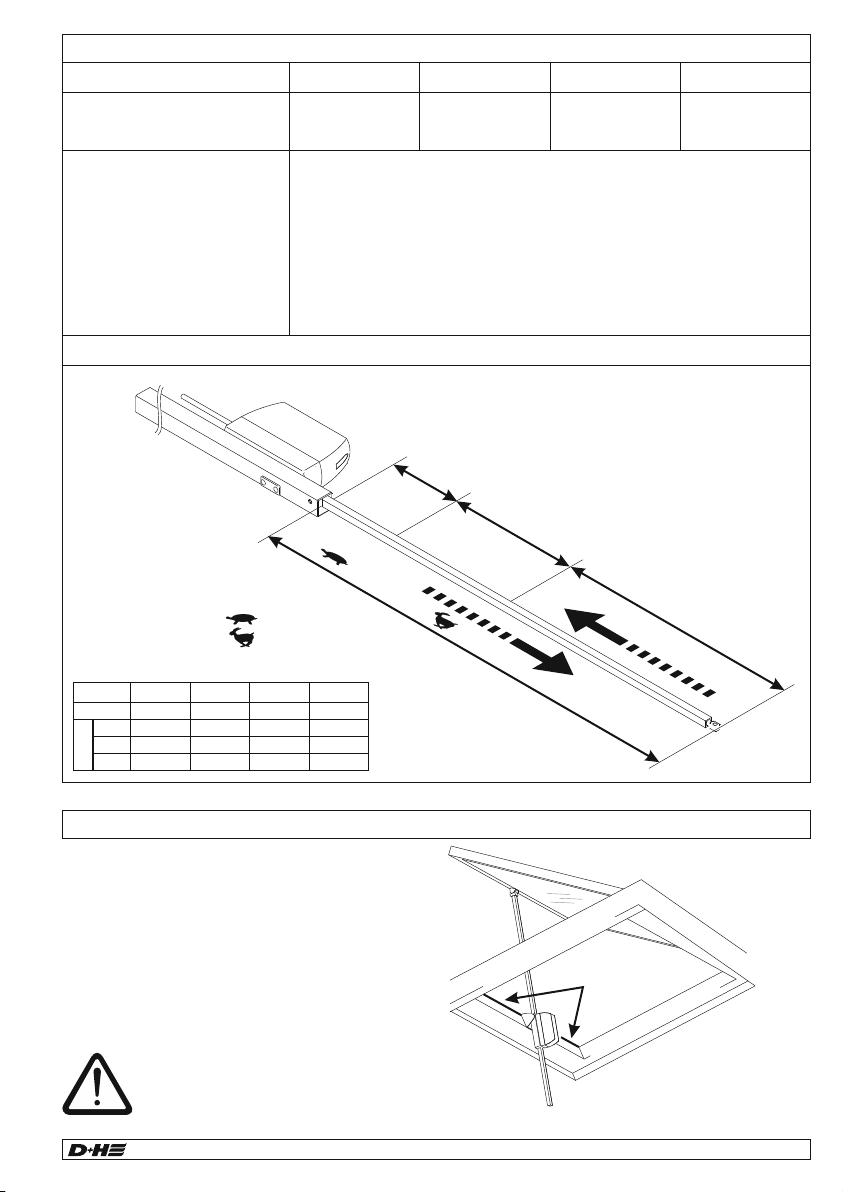

Extent of supply

500

600

800

1000

1100

1200

1300

1400

1500

1600

0

200

400

600

800

1000

1200

1400

max. Load (N)

Stroke (mm)

Permanent

Temporary

Pressure load diagram

Maximum pressure load of the toothed rack is not

automatically identical with maximum pressure force

of the drive!

Loads from over 1000 N to 1500 N are only briefly

permissible (e.g. to throwing off snow or with wind

loads). These may arise up to a stroke of 800 mm.

Safety notes

Safety extra low voltage 24 V DC!

Do not connect directly to the mains supply!

- Connection has to be carried out only by an

authorized electrical specialist

- Danger of violent pressure in handaccessible area

- Keep away People from the operating area of the

drive

- Keep away children from the control

- Observe pressure load diagram of the toothed rack!

- Only for inside mounting.

Use rain detector with danger of rain

(e.g. at domelights or roof windows)

- Use option “-W“ in case of outside mounting!

- Just use unchanged original D+H parts

- Observe mounting instructions of bracket set!

Observe enclosed r ed safety slip!

99.824.31 1.4/04/16

Closing edge protection

Main closing edge

Beside closing edge

Beside closing edge

In "CLOSE" direction the drive has an active

protection for the main closing edge. With an

overload in the closing range 3 and 2 the drive runs

"OPEN" for 10 seconds, then drive "CLOSE" again. If

after three attempts a closing is not possible, the

drive remains in this position.

In addition, the drive has a passive protection. The

closing speed in closure Range 2 and 1 is reduced to

5 mm/s.

Higher forces can occur on besides

closing edges. Danger of violent

pressure in handaccessible area.

WARNING

Read all safety warnings, instructions, illustrations

and specifications provided with this product.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

Type ZA 35-BSY+(-HS) ZA 85-BSY+(-HS) ZA 105-BSY+(-HS) ZA 155-BSY+(-HS)

Power supply 24 V DC, ±15% 24 V DC, ±15% 24 V DC, ±15% 24 V DC, ±15%

Nominal current 0,5 A (1,2 A) 1,0 A (2,0 A) 1,2 A (2,2 A) 1,4 A (2,5 A)

Nominal force 300 N 800 N 1000 N 1500 N

Nominal locking force 1100 N

Lifetime >20 000 double strokes

Duty cycle 30 % (With cycle time 10 minutes)

Housing Aluminium powder-coated (~RAL 9006), polycarbonate

Ingress protection IP 65 (“-W“ = IP 54)

Temperature range -5 ... +75°C

Fire stability 30 min / 300°C

Emission sound pressure level LpA ≤ 70 dB(A)

Nominal stroke length* see type plate

Additional functions * closing edge protection activated (3 stroke repeatings)

* Programmable with software SCS

Running speed and forces

Normal operation =

SHEV- fast running =

IIII

77mm

23mm

7,1 mm/s

5 mm/s

5 mm/s

~7,1 mm/s / ~8 mm/s (~17 mm/s)

II

Closure Ranges

Technical data

All forces

+ approx. 20 % switch-off reserve

(temporary)

OPEN

Forces

CR III

CR II

CR I

300 N

300 N

300 N

300 N

800 N

800 N

800 N

800 N

1000 N

1000 N

1000 N

800 N

1500 N

1000 N

1000 N

800 N

ZA 35 ZA 85 ZA 105 ZA 155

CLOSE

ZA-BSY+

6/20 ZA-BSY+

English

Intended use

- Rack and pinion drive for electric opening and

closing of windows and flaps in the facade and

roof area

- Operating voltage 24 V DC

- Useable for smoke ventilation, D+H Euro-SHEV

according to DIN EN 12101-2 as well as daily

natural ventilation

- Only for inside mounting

Performance features

- Micro processor controlled synchro electronics

BSY + for a precise synchronous run of up to

8 drives

- Individually programmable (via software SCS)

- SHEV-high speed function (fast-running

feature in OPEN-direction)

- Protection system for the main closing edge

- Especially silent in ventilation operation

because of reduced motor speed

Drive unit with 2,5 m silicone cable. Dependent on

the type of window, different bracket sets are

available separately.

Extent of supply

500

600

800

1000

1100

1200

1300

1400

1500

1600

0

200

400

600

800

1000

1200

1400

max. Load (N)

Stroke (mm)

Permanent

Temporary

Pressure load diagram

Maximum pressure load of the toothed rack is not

automatically identical with maximum pressure force

of the drive!

Loads from over 1000 N to 1500 N are only briefly

permissible (e.g. to throwing off snow or with wind

loads). These may arise up to a stroke of 800 mm.

Safety notes

Safety extra low voltage 24 V DC!

Do not connect directly to the mains supply!

- Connection has to be carried out only by an

authorized electrical specialist

- Danger of violent pressure in handaccessible area

- Keep away People from the operating area of the

drive

- Keep away children from the control

- Observe pressure load diagram of the toothed rack!

- Only for inside mounting.

Use rain detector with danger of rain

(e.g. at domelights or roof windows)

- Use option “-W“ in case of outside mounting!

- Just use unchanged original D+H parts

- Observe mounting instructions of bracket set!

Observe enclosed red safety slip!

99.824.31 1.4/04/16

Closing edge protection

Main closing edge

Beside closing edge

Beside closing edge

In "CLOSE" direction the drive has an active

protection for the main closing edge. With an

overload in the closing range 3 and 2 the drive runs

"OPEN" for 10 seconds, then drive "CLOSE" again. If

after three attempts a closing is not possible, the

drive remains in this position.

In addition, the drive has a passive protection. The

closing speed in closure Range 2 and 1 is reduced to

5 mm/s.

Higher forces can occur on besides

closing edges. Danger of violent

pressure in handaccessible area.

WARNING

Read all safety warnings, instructions, illustrations

and specifications provided with this product.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

Type ZA 35-BSY+(-HS) ZA 85-BSY+(-HS) ZA 105-BSY+(-HS) ZA 155-BSY+(-HS)

Power supply 24 V DC, ±15% 24 V DC, ±15% 24 V DC, ±15% 24 V DC, ±15%

Nominal current 0,5 A (1,2 A) 1,0 A (2,0 A) 1,2 A (2,2 A) 1,4 A (2,5 A)

Nominal force 300 N 800 N 1000 N 1500 N

Nominal locking force 1100 N

Lifetime >20 000 double strokes

Duty cycle 30 % (With cycle time 10 minutes)

Housing Aluminium powder-coated (~RAL 9006), polycarbonate

Ingress protection IP 65 (“-W“ = IP 54)

Temperature range -5 ... +75°C

Fire stability 30 min / 300°C

Emission sound pressure level LpA ≤ 70 dB(A)

Nominal stroke length* see type plate

Additional functions * closing edge protection activated (3 stroke repeatings)

* Programmable with software SCS

Running speed and forces

Normal operation =

SHEV- fast running =

IIII

77mm

23mm

7,1 mm/s

5 mm/s

5 mm/s

~7,1 mm/s / ~8 mm/s (~17 mm/s)

II

Closure Ranges

Technical data

All forces

+ approx. 20 % switch-off reserve

(temporary)

OPEN

Forces

CR III

CR II

CR I

300 N

300 N

300 N

300 N

800 N

800 N

800 N

800 N

1000 N

1000 N

1000 N

800 N

1500 N

1000 N

1000 N

800 N

ZA 35 ZA 85 ZA 105 ZA 155

CLOSE

A synchron-group (ZA-BSY+) can be count up to 8

drives, which communicate by a bus. Each drive has

it’s own adress. This adress is configurable with

SCS.

The last drive of a synchron-group is the master,

which controls the other drives, the slaves. Different

forces between the drives of a group will balanced

with intelligent force- and position control. In case of

malfunction respective cutoff of a drive, all drives will

shut down from the master-drive.

Functional description

ZA-BSY+

ZA-BSY+ 9/20

English

Visual inspection:

Only one master-drive allowed.

The master has, according to common drives,

the last adress.

The adress is sticked on the drive. Slaves are

nubered downwards.

Example: In a group, composed of 3 drives,

there is a master 3, a slave 2 and a slave 1drive.

Attention: only applies by factory set. as soon as

the drives were reprogramized with SCS

he factory set adressing does not apply any

longer.

Wiring:

Is the group wired correctly?

Therefore look connection diagrams.

Null balance:

It should be null balanced.

Software SCS or the special magnet

MAG 502 is required.

Call D+H Service:

Drives must be configured.

Software SCS is required.

Trouble shooting

99.824.31 1.4/04/16

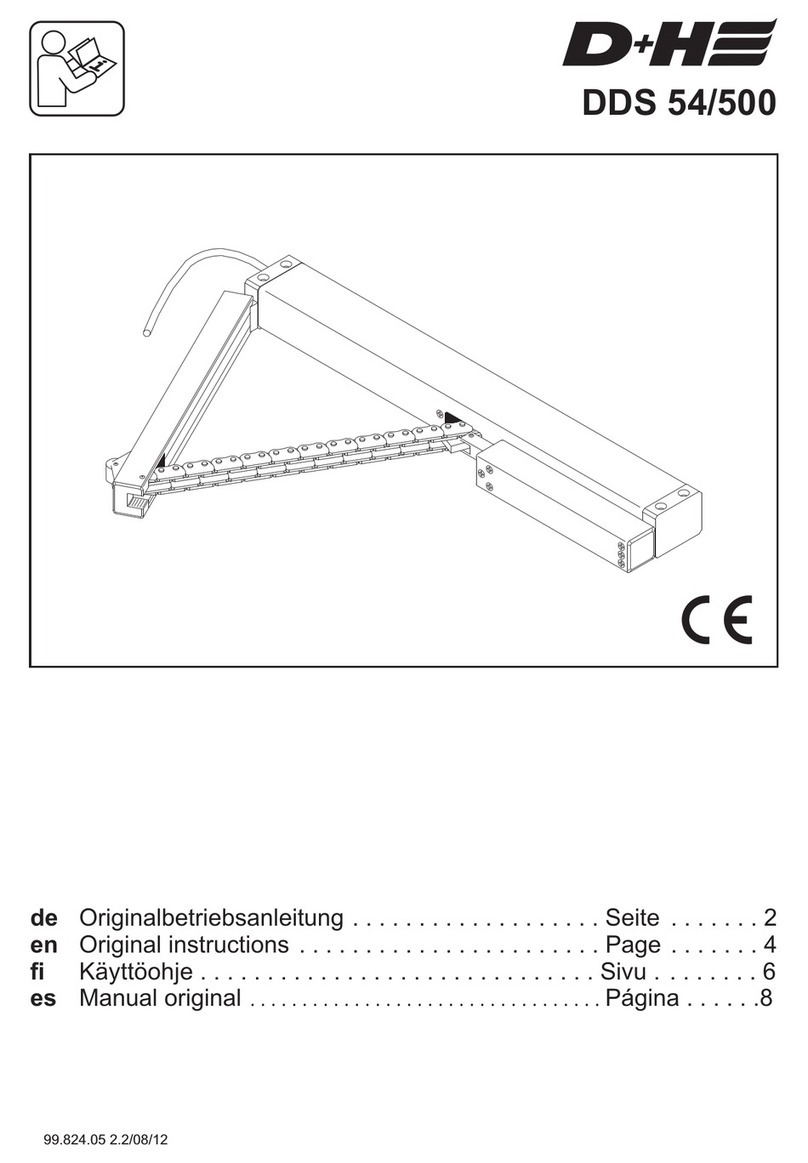

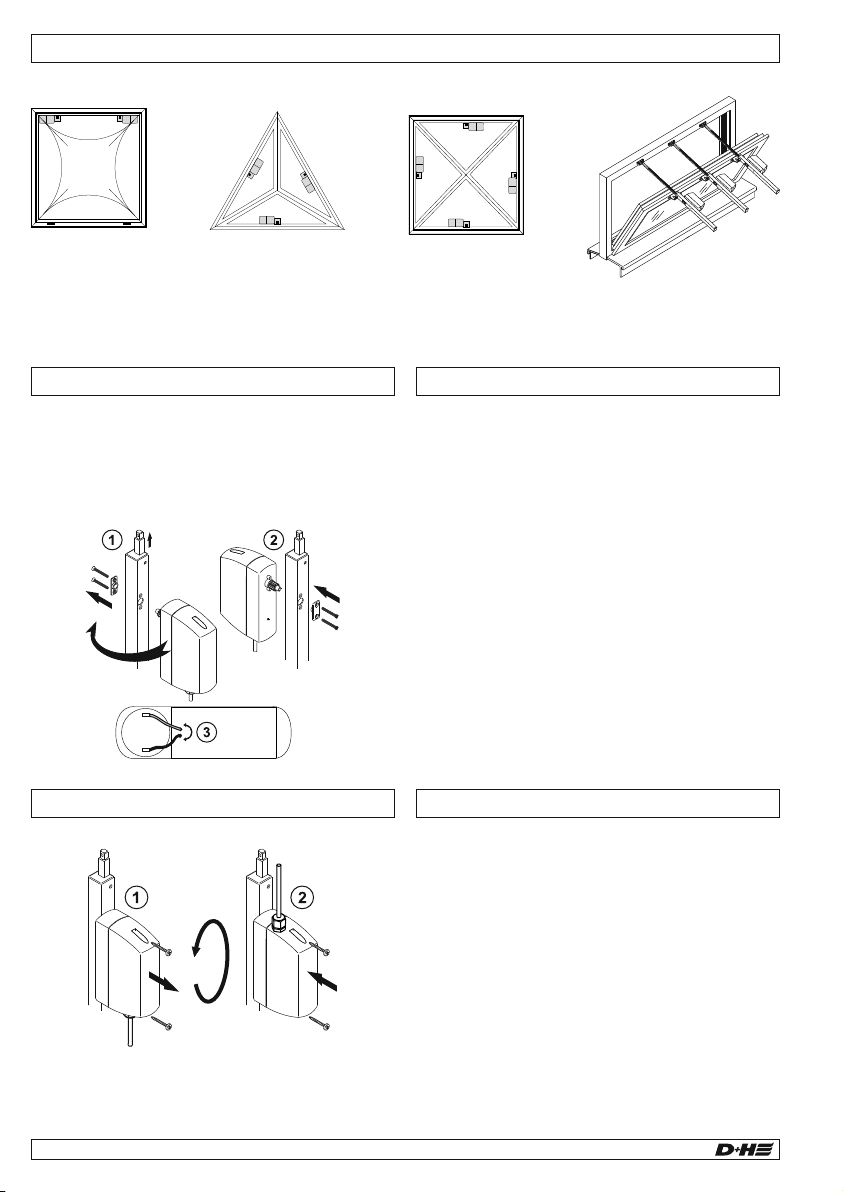

Mounting examples

Triangular pyramid *

Domelight Pyramid * Weighty wing

Uncritical load distribution Critical load distribution

* Guiding device required by customer in case of complete lift-off of pyramid/domelight,

because of possible lateral load due to wind pressure!

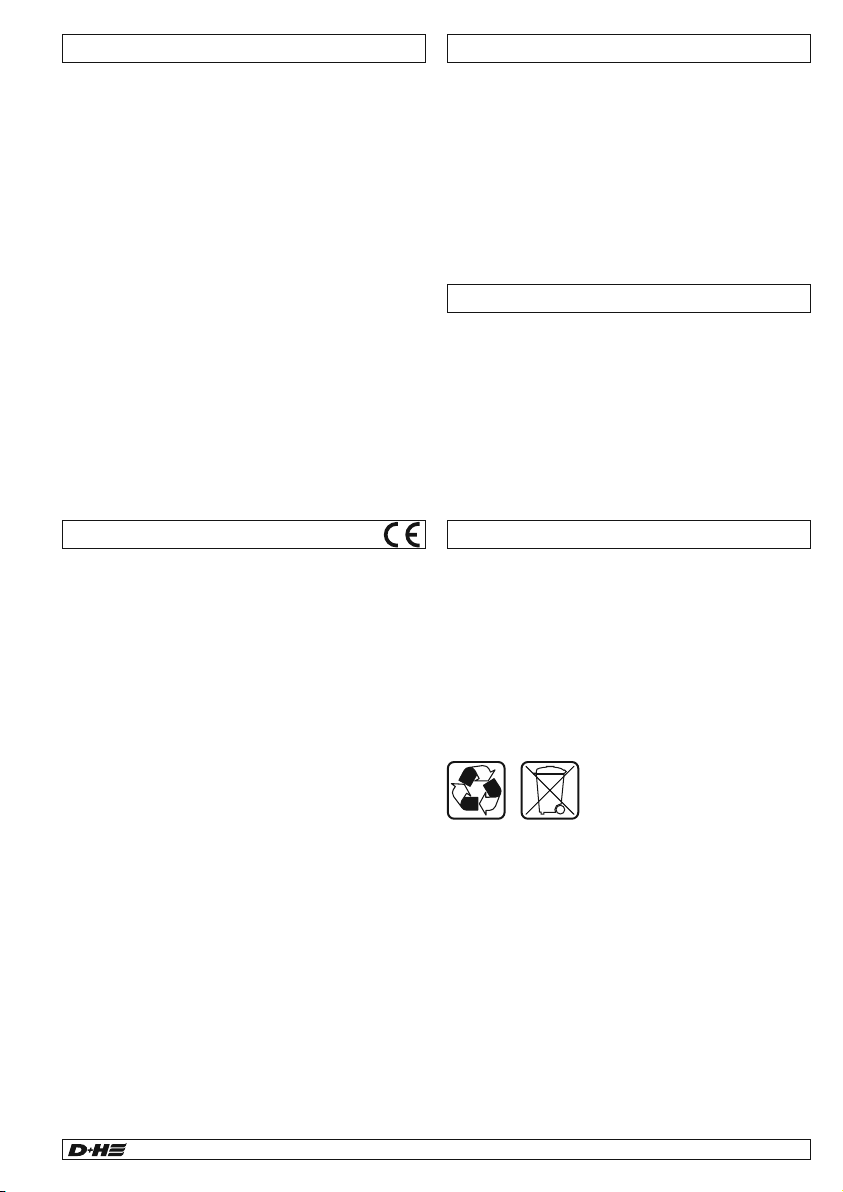

Shifting of drive cable

Disconnect drive from electric voltage!

1. Move out toothed rack about 10 ... 20 mm.

Disconnect drive from electric Voltage!

2. Take off drive unit and shift

3. Attention! Moving direction of drive is changed.

Drive cable on the shutdown pcb, switch

red (+) with black (-)

Shifting of Motor Mounting informations

- Swivel radius of the drive must go free over entire

range of stroke. Otherwise, the toothed rack and

the suspension can be damaged

- Drives with a stroke of ≥800 mm must not be moun-

ted „hung up at the bottom“ (e.g. bracket UK)

- The drive set will be full configured by factory.

The drives must be reconfigured in case of

alterations (e.g. removing of drives from existing

set or integrating a new drive) with SCS

- Use only drives with the same force.

- Ensure evenly load distribution on all the drives

- Eyebolt has to be adjusted so, that the drive is

disconnected with closed flap through it’s inside

stop position damping. Brackets can be damaged

by to rigid adjustment!

10 ... 20 mm

Electrical devices, accessories, batteries and packa-

ging should be sorted for environmental-friendly

recycling. Do not dispose electrical devices and

batteries into household waste!

Only for EC countries:

According the European Guideline 2012/19/EU for

waste electrical and electronic equipment and its

implementation into national right, electrcal devices

that are no longer usable must be collected separa-

tely and disposed of in an environmentally correct

manner.

DisposalDeclaration of Conformity

We declare under our sole responsibility that the

product described under “Technical Data” is in

conformity with the following directives:

2014/30/EU, 2014/35/EU

Technical file at:

D+H Mechatronic AG, D-22949 Ammersbek

Dirk Dingfelder Maik Schmees

Member of the Board Authorized signatory, Technical Director

31.03.2016

Maintenance and cleaning

Maintenance work is only allowed when the device is in

a de-energized condition! Inspection and maintenance

has to be carried out according to D+H maintenance

notes. Only original D+H spare parts may be used.

Repairis tobecarried out exclusively by D+H.

Wipe away debris or contamination with a dry, soft

cloth.

Donot use cleaningagentsor solvents.

Guarantee

You will get 2 years guarantee for all D+H products

from date of verified handing over of the system up to

maximal 3 years after date of delivery, when

mounting and starting has been carried out by an

authorized D+H-distributor.

D+H guarantee is expired, with connection of D+H

components with external systems or with mixing of

D+H products with parts of other manufacturers.

A synchron-group (ZA-BSY+) can be count up to 8

drives, which communicate by a bus. Each drive has

it’s own adress. This adress is configurable with

SCS.

The last drive of a synchron-group is the master,

which controls the other drives, the slaves. Different

forces between the drives of a group will balanced

with intelligent force- and position control. In case of

malfunction respective cutoff of a drive, all drives will

shut down from the master-drive.

Functional description

ZA-BSY+

8/20 ZA-BSY+

English

Visual inspection:

Only one master-drive allowed.

The master has, according to common drives,

the last adress.

The adress is sticked on the drive. Slaves are

nubered downwards.

Example: In a group, composed of 3 drives,

there is a master 3, a slave 2 and a slave 1drive.

Attention: only applies by factory set. as soon as

the drives were reprogramized with SCS

he factory set adressing does not apply any

longer.

Wiring:

Is the group wired correctly?

Therefore look connection diagrams.

Null balance:

It should be null balanced.

Software SCS or the special magnet

MAG 502 is required.

Call D+H Service:

Drives must be configured.

Software SCS is required.

Trouble shooting

99.824.31 1.4/04/16

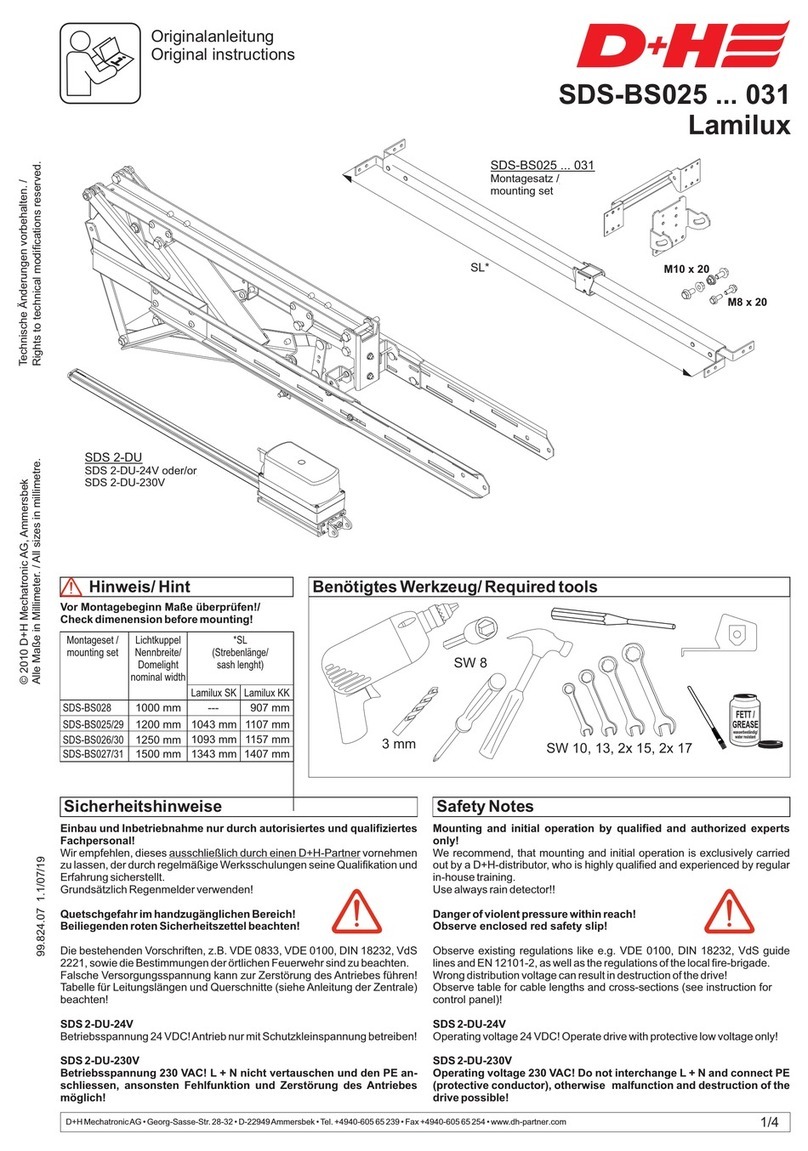

Mounting examples

Triangular pyramid *

Domelight Pyramid * Weighty wing

Uncritical load distribution Critical load distribution

* Guiding device required by customer in case of complete lift-off of pyramid/domelight,

because of possible lateral load due to wind pressure!

Shifting of drive cable

Disconnect drive from electric voltage!

1. Move out toothed rack about 10 ... 20 mm.

Disconnect drive from electric Voltage!

2. Take off drive unit and shift

3. Attention! Moving direction of drive is changed.

Drive cable on the shutdown pcb, switch

red (+) with black (-)

Shifting of Motor Mounting informations

- Swivel radius of the drive must go free over entire

range of stroke. Otherwise, the toothed rack and

the suspension can be damaged

- Drives with a stroke of ≥800 mm must not be moun-

ted „hung up at the bottom“ (e.g. bracket UK)

- The drive set will be full configured by factory.

The drives must be reconfigured in case of

alterations (e.g. removing of drives from existing

set or integrating a new drive) with SCS

- Use only drives with the same force.

- Ensure evenly load distribution on all the drives

- Eyebolt has to be adjusted so, that the drive is

disconnected with closed flap through it’s inside

stop position damping. Brackets can be damaged

by to rigid adjustment!

10 ... 20 mm

Electrical devices, accessories, batteries and packa-

ging should be sorted for environmental-friendly

recycling. Do not dispose electrical devices and

batteries into household waste!

Only for EC countries:

According the European Guideline 2012/19/EU for

waste electrical and electronic equipment and its

implementation into national right, electrcal devices

that are no longer usable must be collected separa-

tely and disposed of in an environmentally correct

manner.

DisposalDeclaration of Conformity

We declare under our sole responsibility that the

product described under “Technical Data” is in

conformity with the following directives:

2014/30/EU, 2014/35/EU

Technical file at:

D+H Mechatronic AG, D-22949 Ammersbek

Dirk Dingfelder Maik Schmees

Member of the Board Authorized signatory, Technical Director

31.03.2016

Maintenance and cleaning

Maintenance work is only allowed when the device is in

a de-energized condition! Inspection and maintenance

has to be carried out according to D+H maintenance

notes. Only original D+H spare parts may be used.

Repair is to be carried out exclusively by D+H.

Wipe away debris or contamination with a dry, soft

cloth.

Do not use cleaning agents or solvents.

Guarantee

You will get 2 years guarantee for all D+H products

from date of verified handing over of the system up to

maximal 3 years after date of delivery, when

mounting and starting has been carried out by an

authorized D+H-distributor.

D+H guarantee is expired, with connection of D+H

components with external systems or with mixing of

D+H products with parts of other manufacturers.

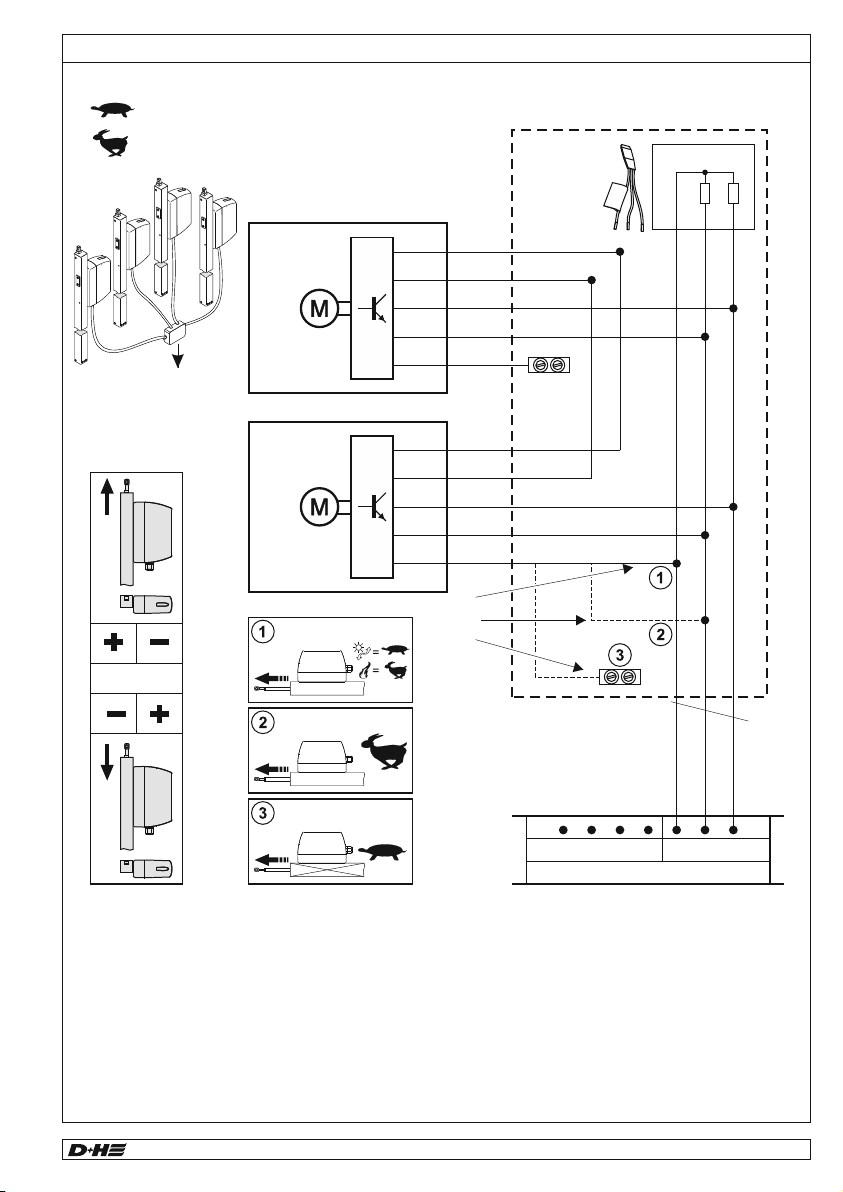

Pin Assignment

Connection

(WH) white

(BN) brown

(OG) orange

(YE) yellow

(GN) green

(PK) pink

(GY) grey

Option-SA-SZ

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY (-SZ)

GN (-SZ)

PK (-SA)

YE (-SA)

WH (n.c.)

BN (n.c.)

OG (n.c.)

max. 50 V / 0,5 A

s

r

ZA-BSY+ 19/20

Français / Español

ZA-BSY+ 99.824.31 1.4/04/16

Anschluss / Connection / Connexion / Conexión

?

123 4 5

L

6

N–

7

ZA E/X ab

LT

Gruppe / Group / Groupe / Grupo

Mot. a

Mot. b

MOT

(BK)

(BK)

(OG)

2x47kW

Endmodul

Terminal module

Module terminal

EM 47 K *

(WH)

(WH)

(BN)

(BN)

(OG)

(OG)

(YE)

(YE)

(GN)

(GN)

Mot. a

Mot. a

Mot. b

Mot. b

HS

HS

Data a

Data a

Data b

Data b

ZA-BSY+

ZA-BSY+

Slave(s)

Master

Abzweigdose / Junction box /

Boîte de dérivation / Caja de conexión

****

***

**

**

Mot. b

(BN)

Mot. a

(WH)

zur Zentrale /

to control panel /

vers la centrale /

para central

Überwachung /

Monitoring /

Surveillance /

Supervisión*

Normalbetrieb / Normal mode /

Activité normale / Servicio normal

RWA- Schnelllauf / SHEV- fast running /

EFC fonctionnement rapide / Marcha rápida SVHC

High-Speed

High-Speed

***

High-Speed

* Nicht bei / Not in case of / Pas pour / No en el caso : GVL -E/ -K/ -M

** Gegen Kurzschluss sichern / protect against short circuit /

Protéger contre les courts-circuits / Proteger contra cortacircuitos

*** Bei Anschluss an D+H RWA Zentralen mit E/HS Leitungsüberwachung /

In case of connection to D+H SHEV control panels with E/HS line monitoring /

En cas de raccordement à des centrales D+H RWA, avec une surveillance des lignes E/HS /

En caso de conexión a paneles de control SVHC D+H con control de línea E/HS

**** Kabel gemäß D+H Kabelverlegetabelle (Siehe Gebrauchsanleitung der Zentrale) /

Cable acc. to D+H table for layout of cables (see instructions for use of control panel) /

Câble selon le tableau de pose de câbles D+H (cf. le mode d'emploi de la centrale) /

Cable de acuerdo con tabla D+H sobre cables (ver instrucciones de uso de los paneles de control)

Option-BRV

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY (-BRV)

PK (n.c.)

Standard

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

Option-SGI

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY (-SGI)

PK (+SGI)

Option-SKS

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY (SKS)

PK (SKS)

Option-SZ

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY (-SZ)

PK (-SZ)

max. 50 V / 0,5 A

s

Option-SA

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY (-SA)

PK (-SA) r

max. 50 V / 0,5 A

second connecting cable

Aderbelegung Stecker / Pin Assignment / Brochage des fiches / Asignación de cables

Anschluss / Connection / Connexion / Conexión

(WH) weiss / white / blanc / blanco

(BN) braun / brown / brun / marrón

(OG) orange / orange / orange / naranja

(YE) gelb / yellow / jaune / amarillo

(GN) grün / green / vert / verde

(PK) rosa / pink / rose / rosa

(GY) grau / grey / gris / gris

Option / Opción

-SA-SZ

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY (-SZ)

GN (-SZ)

PK (-SA)

YE (-SA)

WH (n.c.)

BN (n.c.)

OG (n.c.)

max. 50 V / 0,5 A

s

r

ZA-BSY+

ZA-BSY+

18/20 Deutsch / English 99.824.31 1.4/04/16

Connection

?

123 4 5

L

6

N–

7

ZA E/X ab

LT

Group

Mot. a

Mot. b

MOT

(BK)

(BK)

(OG)

2x47kW

Endmodul

Terminal module

Module terminal

EM 47 K *

(WH)

(WH)

(BN)

(BN)

(OG)

(OG)

(YE)

(YE)

(GN)

(GN)

Mot. a

Mot. a

Mot. b

Mot. b

HS

HS

Data a

Data a

Data b

Data b

ZA-BSY+

ZA-BSY+

Slave(s)

Master

Junction box

****

***

**

**

Mot. b

(BN)

Mot. a

(WH)

to control panel

Monitoring

Normal mode

SHEV- fast running

High-Speed

High-Speed

***

High-Speed

* Not in case of GVL -E/ -K/ -M

** Protect against short circuit

*** In case of connection to D+H SHEV control panels with E/HS line monitoring

**** Cable acc. to D+H table for layout of cables (see instructions for use of control panel)

Option / Opción

-BRV

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY (-BRV)

PK (n.c.)

Standard /

Estándar

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

Option / Opción

-SGI

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY (-SGI)

PK (+SGI)

Option / Opción

-SKS

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY (SKS)

PK (SKS)

Option / Opción

-SZ

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY(-SZ)

PK (-SZ)

max. 50 V / 0,5 A

s

Option / Opción

-SA

WH (Mot. a)

BN (Mot. b)

OG (-HS)

YE (Data A)

GN (Data B)

GY (-SA)

PK (-SA) r

max. 50 V / 0,5 A

zweites Anschlußkabel /

second connecting cable /

second câble de raccordement /

segundo cable de conexión

Dimensions

Stroke ≥ 165 mm Stroke 82 mm, 100 mm

225

15 - 35

Nominal stroke

+ 162

12

160

46

104

9

13

Ø 6

30

30

9

7

Version without tube (option "-OT")

216

9

13

30 - 55

Nominal stroke

+ 223

Dyer Environmental Controls Ltd

Unit 10 Lawnhurst Trading Estate, Cheadle Heath,

Stockport SK3 0SD

Tel: +44 (0)161 491 4840

E-Mail: [email protected]

www.dyerenvironmental.co.uk

This manual suits for next models

11

Table of contents

Other D+H Door Opening System manuals