LCN CLOSERS

121 W. RAILROAD AVE.

P.O. BOX 100

PRINCETON, IL, USA 61356-0100

PHONE 800-526-2400

FAX 800-248-1460

www.lcn.ingersollrand.com

3/10

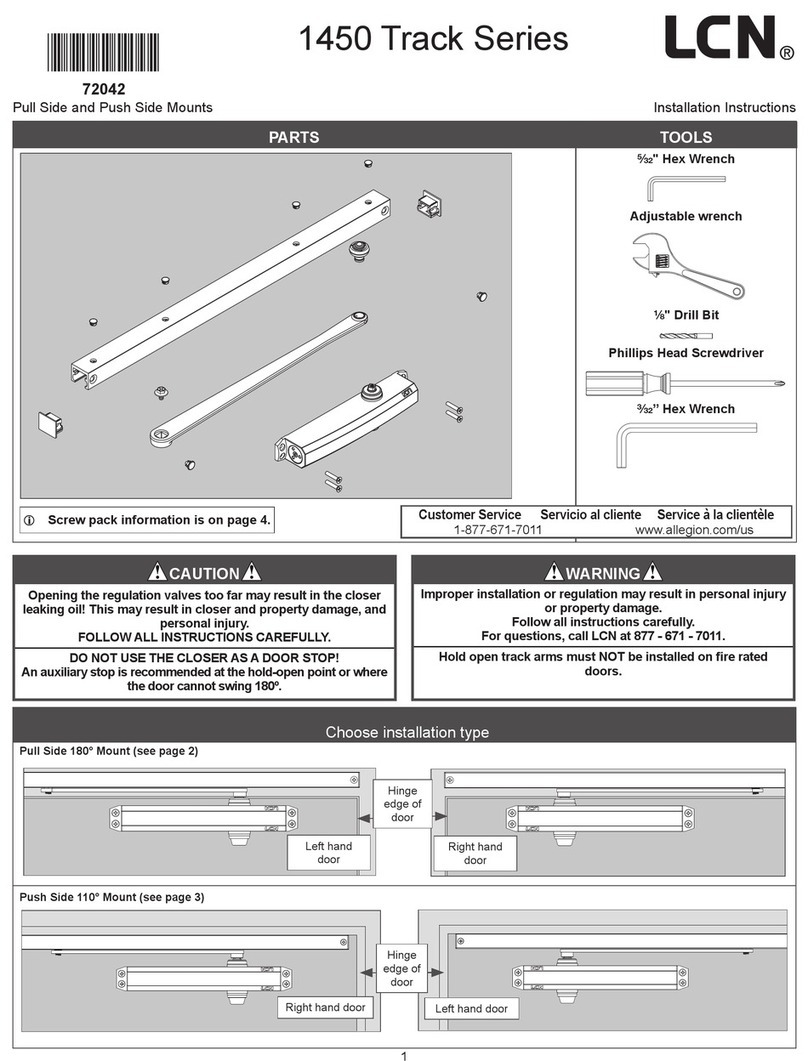

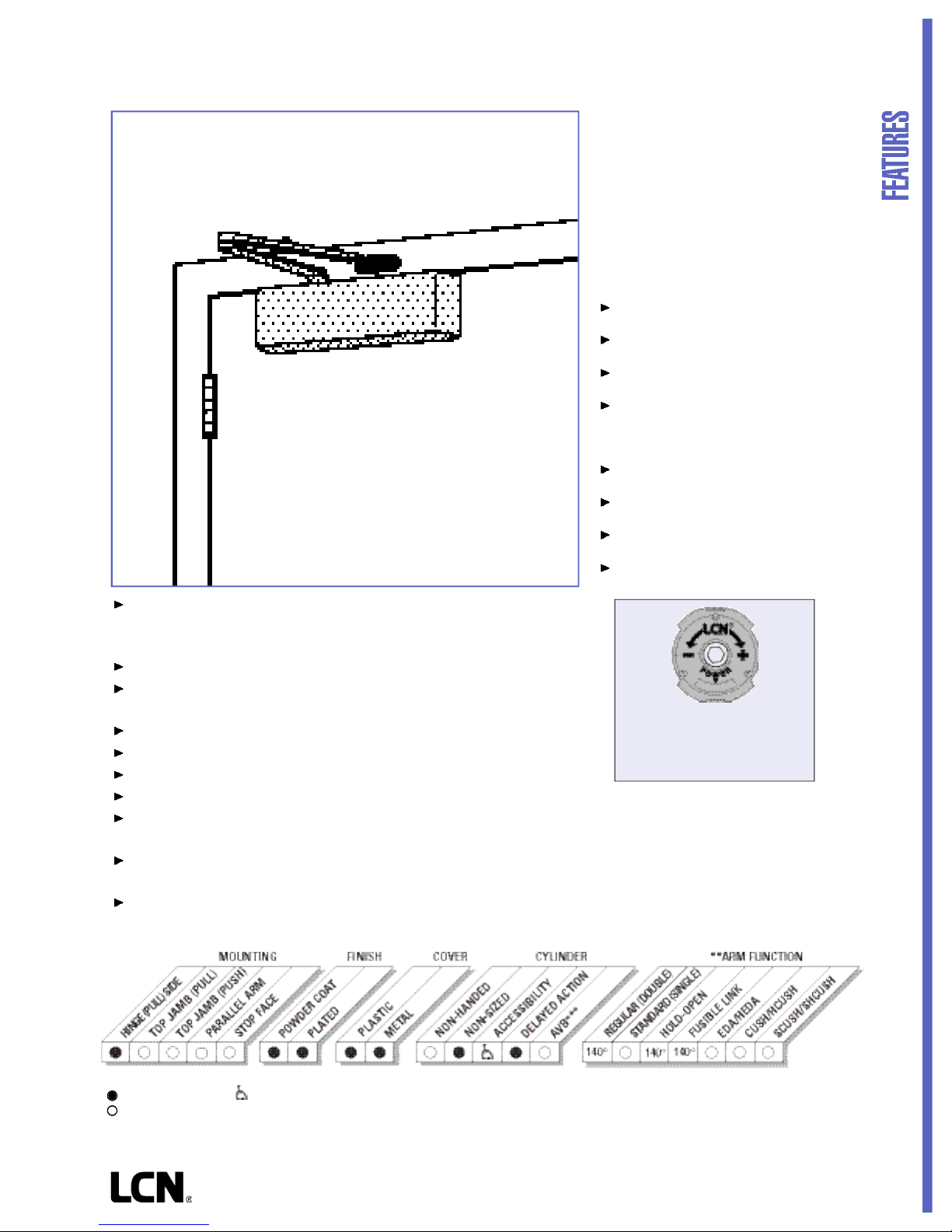

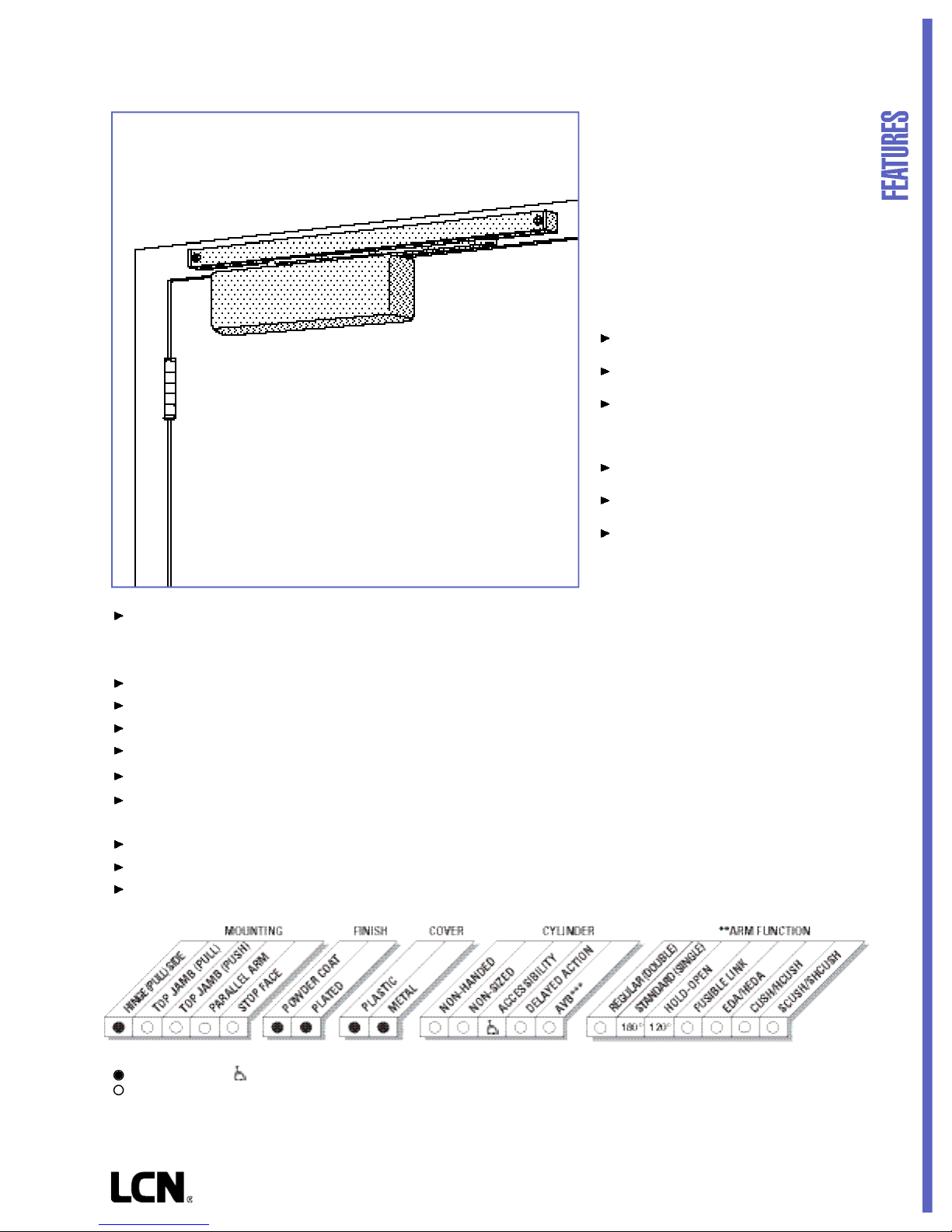

APPLICATIONS

For aluminum, hollow metal, or wood swinging doors and frames.

Can be used with hinge or pivot mounted door.

Adapter plates and other installation accessories available for

unusual conditions.

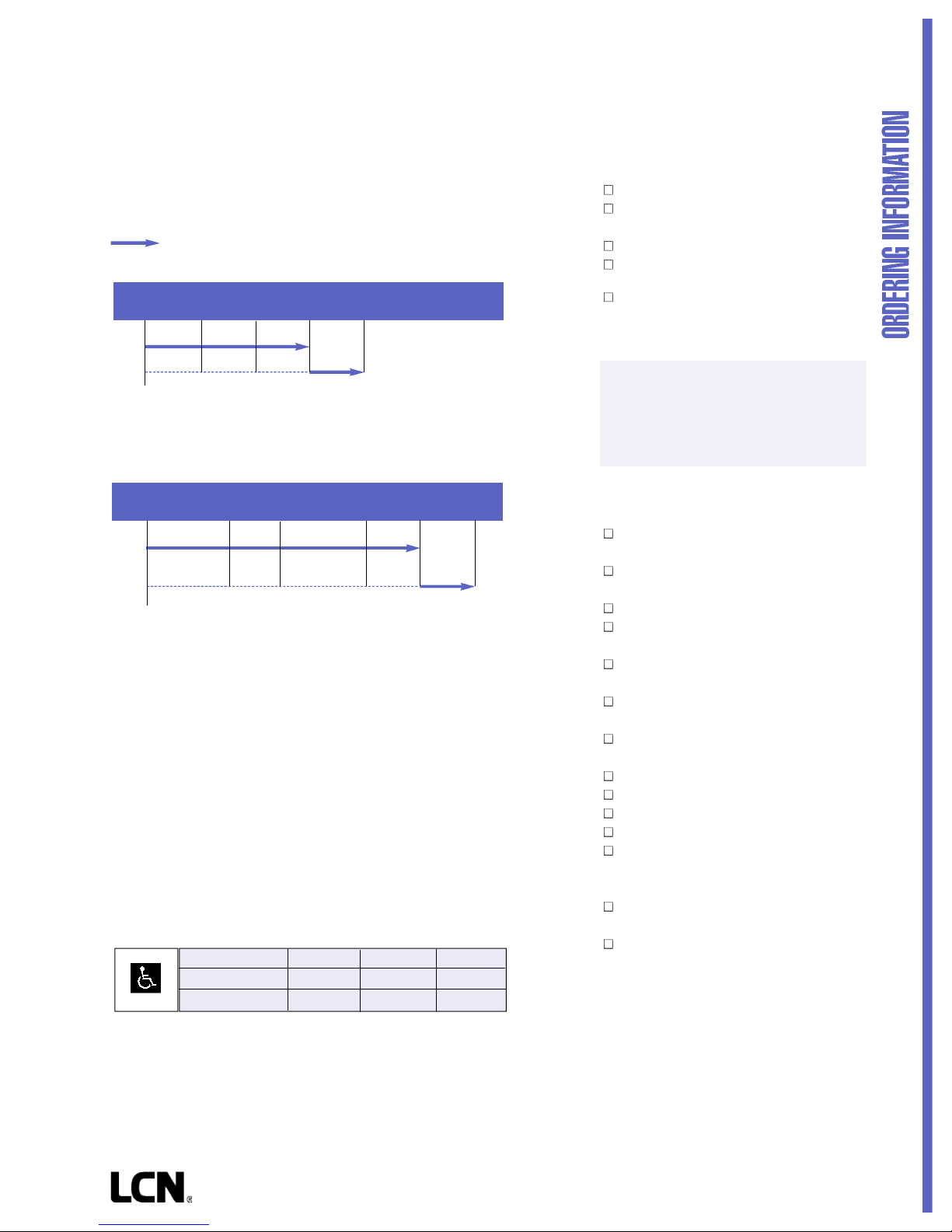

FEATURES COMMON TO 4000 SERIES

Each closer (except 4040, 4040T, 4030, 4030T) is designed for a

specific mounting; hinge side, top jamb, or parallel arm. 4040 closer

with regular or hold-open arm mounts hinge side or top jamb. P4030

& P4040 closers include 62PA SHOE required to parallel arm mount

either regular or hold-open arm.

Handed for right or left swinging doors, except 4000T, 4030, 4030T,

4040, and 4040T.

Closers to meet ADA reduced opening force requirements except

4000T.

Adjustable hydraulic backcheck cushions opening swing prior to 90°.

Separate regulation of general closing speed and latching speed.

Joints in regular arm and shoe adapt to uneven trim.

Reversible shoe to boost latching power on double lever arms.

Available in a wide range of standard or optional custom powder

coat finishes to blend with door and frame.

Plated finishes available to accent door and frame.

Not designed for exterior mounting or exposed to elements.

DESIGN ASSISTANCE

LCN has been providing reliable solutions to unique door control

problems for over 75 years. Design and specification assistance are only

a phone call away.

Contact LCN for assistance or technical information at 800-526-2400 or

FAX 800-248-1460 (Customer Service), Fax 815-879-1495 for

Application Engineering.

WARRANTY

10 year limited warranty. See General Section for complete warranty

details.

SPECIFICATIONS

Refer to ”SPECIFICATIONS” section for suggested architectural

specifications.

MATERIALS

High strength cast iron cylinder.

Forged steel main arms.

One piece forged steel piston.

Double heat treated pinion.

All weather fluid eliminates seasonal adjustments temperatures

ranging from 120° F (49° C) to -30°F.(-35° C).

High efficiency, full complement, low friction bearings.

Tamper resistant regulating screws.

Full rack and pinion hydraulic action.

Quiet, low friction track and roller combination for all single lever

arm closers.

FINISHES

Available in six standard or optional custom powder

coat finishes to blend with door and frame.

4000 SERIES

LCN’s powder coat finish surpasses 100 hours of salt spray which

is over four times the ANSI standard for corrosion resistance.

For installations where a higher level of corrosive resistance is

required, LCN offers an optional special rust inhibiting (SRI) pre-

treatment. Closers that combine the exclusive LCN powder coat

finish and the SRI pre-treatment exceed the ANSI standard for

corrosion resistance even further.

Plated finishes are available as an option to accent door and frame.

(SRI not available with plated finishes)

LISTINGS & APPROVALS

UL listed for self-closing doors without hold-open under "SWINGING

DOOR CLOSERS"(GVEV) file R1943.

Tested and certified under ANSI Standard A156.4 Grade One. Consult

factory for details.

Consult factory for other listings such as; cUL, California State Fire

Marshal, Bureau of Standards and Appeals.

POSITIVE PRESSURE

LCN closers have been certified for three hours by UL to be in

compliance with UBC 7-2 (1997) and UL 10C. Contact LCN for specific

details on door closer fire ratings.

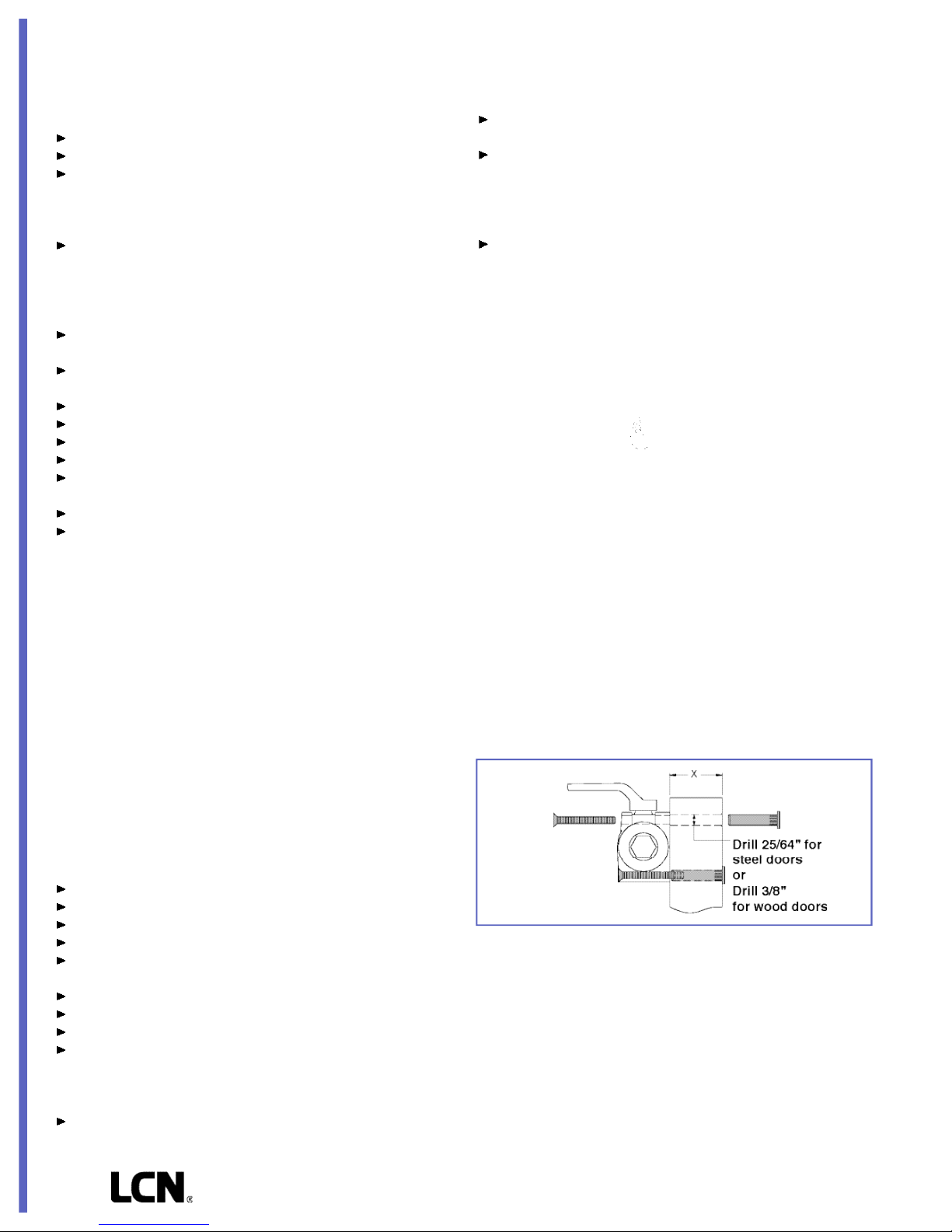

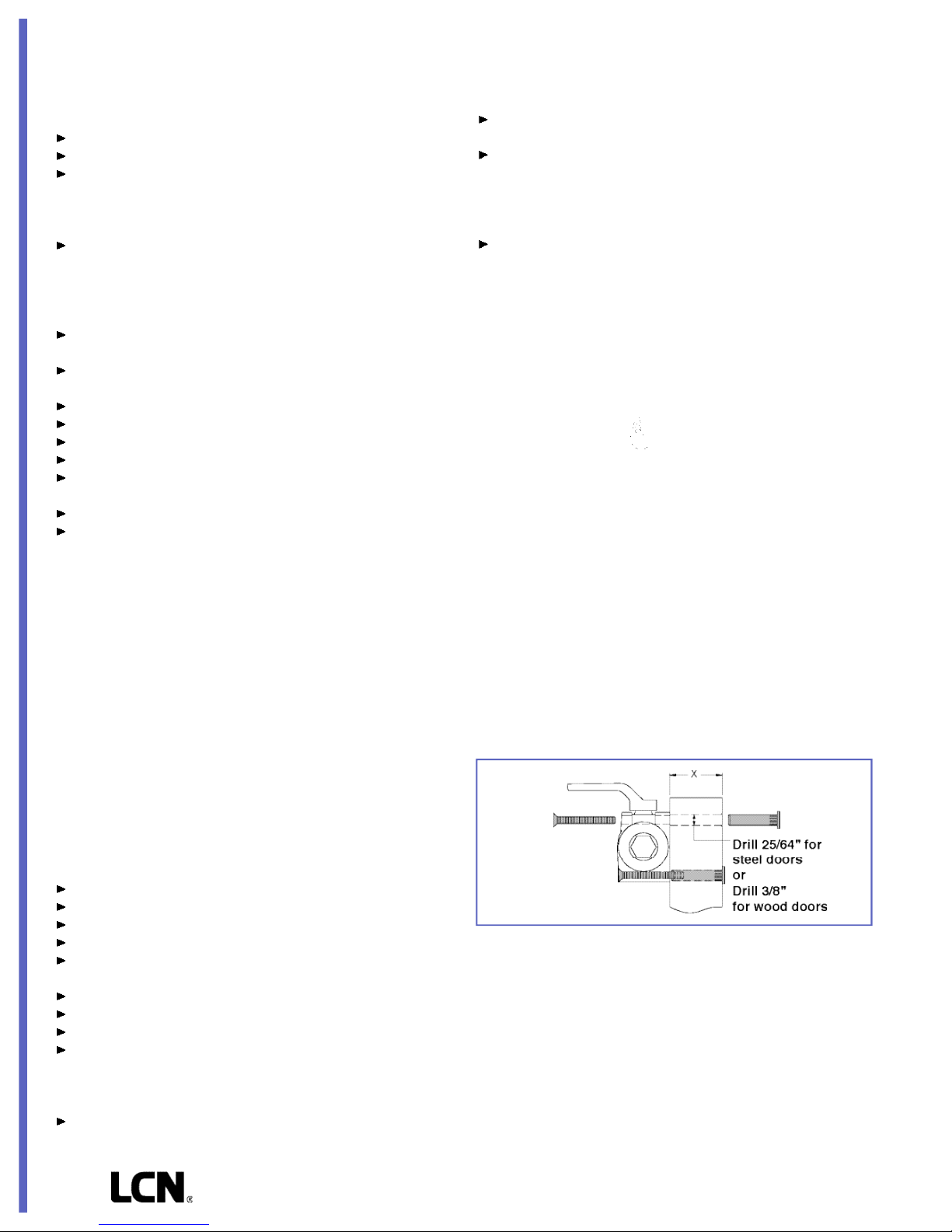

FASTENERS

4010, 4010T, 4020, 4020T, 4040, 4040T, 4110, 4110T series closers are

shipped with: A standard SELF-REAMING and TAPPING SCREW (SRT)

pack contains Philips head SRT screws to install the closer 4000T series

closers are shipped with: A standard WOOD and MACHINE SCREW

(WMS) pack contains Philips head wood and machine screws to install

the closer. 4030, 4030T series closers are shipped with: A standard

WOOD and SELF-TAPPING MACHINE SCREW (WMS) pack that contains

Phillips head wood and self-tapping machine screws to install the

c l o s e r .Standard LCN thru bolts (TB) can be installed on 1 3/4” (44 mm)

thick doors with 1/4-20 machine screws. Optional thru bolt (TB) sizes

are available for 1 5/8” (41 mm) or 1 3/8” (35 mm) door thickness, but

this must be specified when ordering.

Notes:

1. For Thru Bolts, specify door thickness if other than 1 3/4” (44mm).

2. Phillips head, metric machine screws are available, please specify.

3. LCN recommends the use of wood screws, available in optional

WMS screw packs, for wood door applications.

MAINTENANCE

Closers mounted according to LCN installation instructions require no

periodic maintenance or adjustments.

2