X-plore® 9500

Airline belt manifold Instructions for use

3363103 (A3-D-P)

1 For your safety

● Before using this product, carefully read these instructions for use and

those of the associated products.

● Strictly follow the instructions for use. The user must fully understand

and strictly observe the instructions. Use the product only for the

purposes specified in the intended use section of this document.

● Do not dispose of the instructions for use. Ensure that they are

retained and appropriately used by the product user.

● This product should only be used by appropriately trained and

competent personnel.

● Comply with all local and national rules and regulations associated

with this product.

● Only trained and competent personnel are permitted to inspect, repair

and service the product. Dräger recommend a Dräger service contract

for all maintenance activities and that all repairs are carried out by

Dräger.

● Properly trained service personnel must inspect and service this

product as detailed in the "Maintenance" chapter of this document.

● Use only genuine Dräger spare parts and accessories. Otherwise, the

proper functioning of the product may be impaired.

● Do not use a faulty or incomplete product. Do not modify the product.

● Notify Dräger in the event of any component fault or failure.

The latest version and other translations of these instructions for

use can be downloaded in electronic form from the Technical

Documentation database (www.draeger.com/ifu). In light of

product updates, Dräger recommend always using the latest version of the

instructions for use.

2 Conventions used in this document

2.1 Meaning of the warning notices

The following warning signs are used in this document to indicate and

highlight areas of the associated text that require particular attention by the

user. The meaning of each of the warning notices is defined as follows:

WARNING

Indicates a potentially hazardous situation. If not avoided, it could result in

death or serious injury.

CAUTION

Indicates a potentially hazardous situation. If not avoided, it could result in

physical injury. It may also be used to alert against unsafe practices.

NOTICE

Indicates additional information on how to use the product.

2.2 Trademarks

The following internet page lists the countries in which Dräger trademarks

are registered: www.draeger.com/trademarks.

3 Description

3.1 Product overview

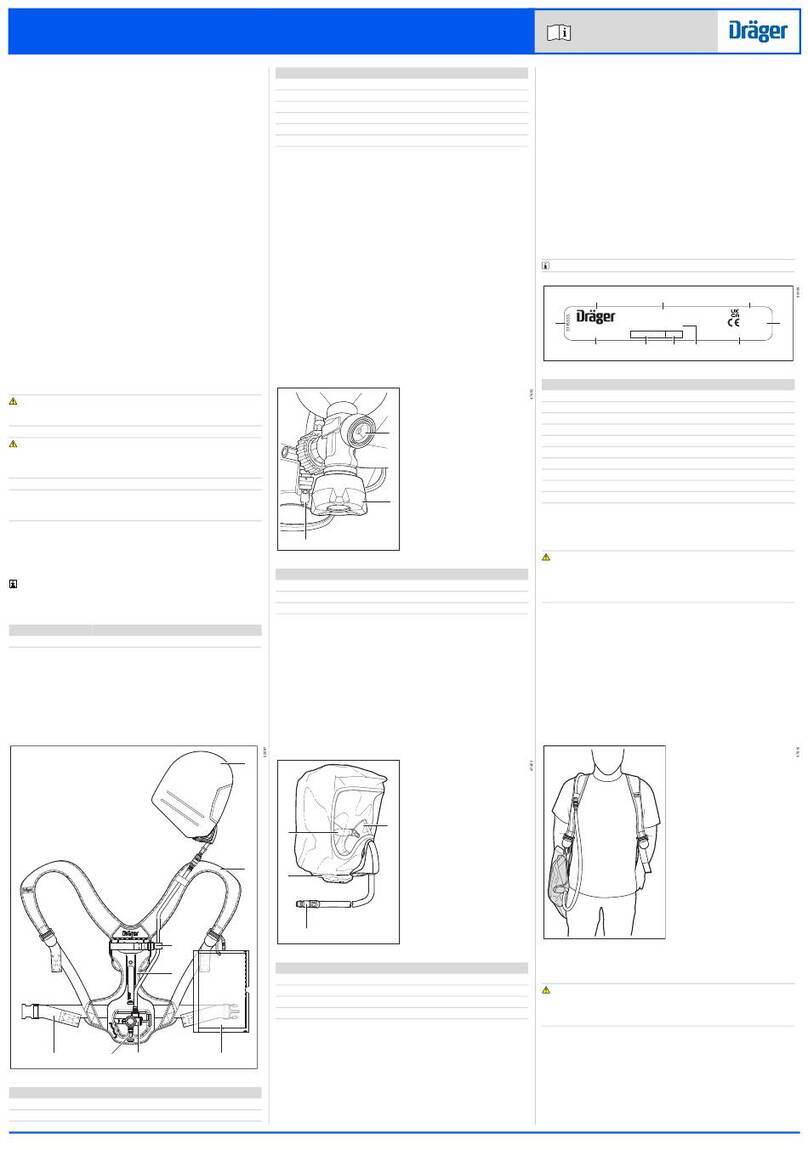

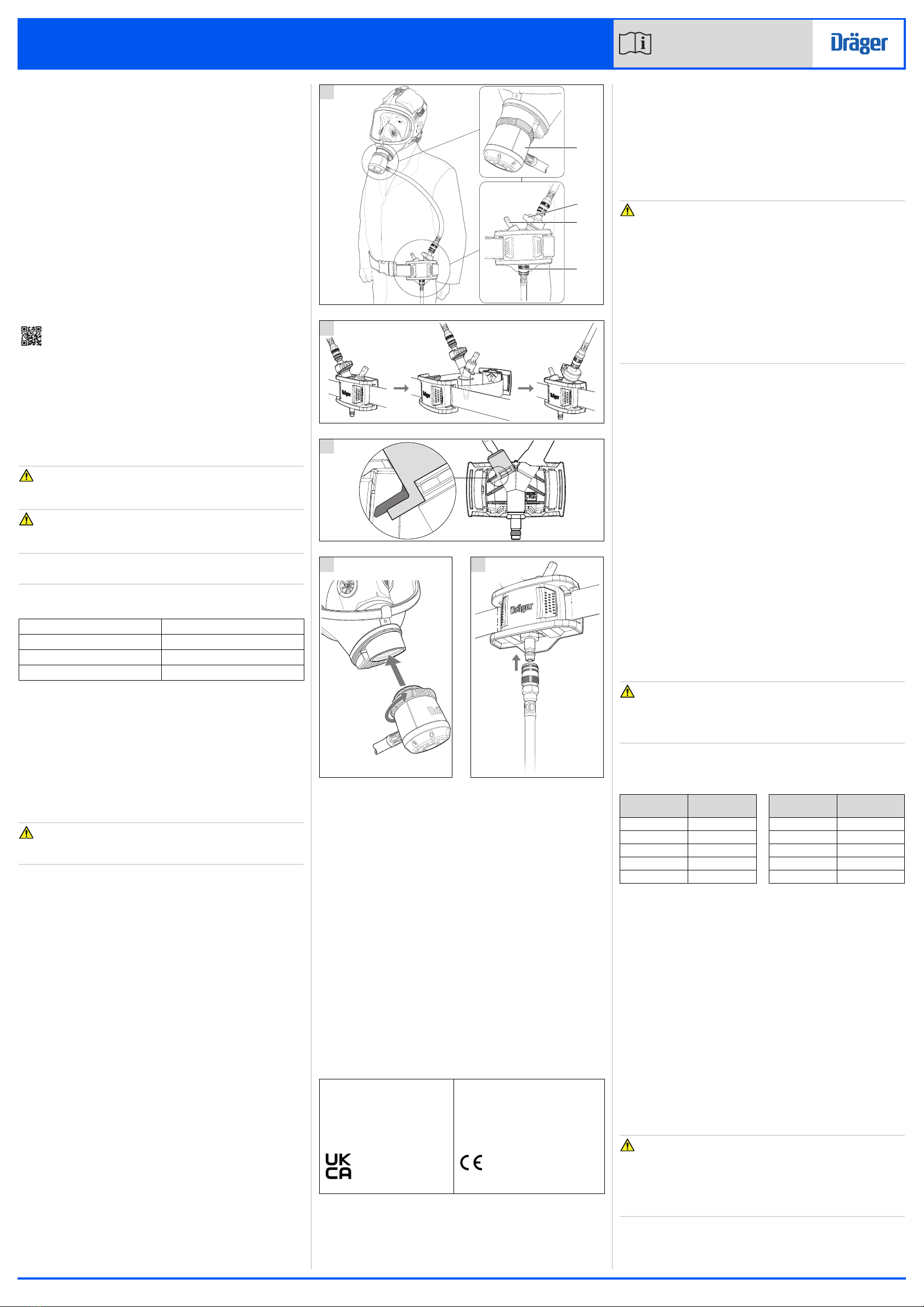

The Dräger X-plore® 9500 (see Fig. A) is a manifold carried on a belt that

is used to connect an external breathing air supply (compressed air line) to

a mask. For this purpose, the manifold has an input connection (4) for

connecting the compressed air line and a coupling on the mask adapter (1)

for connecting the mask.

CAUTION

Only apply pressure to the input side, see (4). A pressure load on the

output side can cause damage to the device.

During use, the pressure reducer in the manifold ensures a continuous flow

of air from the compressed air line to the mask. The air flow lies within the

safe limit values required by the mask. The surplus valve in the mask

adapter is used to continuously release excess air, ensuring a supply of the

correct pressure during use. The control valve (2) of the pressure reducer

allows individual adjustment of the air volume within the preset limits.

The warning whistle (3) is a warning device for low input pressure. The

whistle will sound during use to alert the wearer in the event that the

pressure of the breathing air supply falls below the level necessary for a

sufficient supply.

The X-plore® 9500 is compatible with the following Dräger respirator

series: FPS®7000 series (RA), X-plore 6000 series and Panorama Nova®

series (RA). (The X-plore 6300 is shown here). The compatible Dräger

masks are classified as Class 4B according to EN 14594:2018.

The air line breathing apparatus and other accessories used with this

product must be certified Dräger components in an approved

configuration. Otherwise, use of the product may be impaired. Contact

Dräger for further information.

This device is optionally available with radio frequency identification (RFID)

to facilitate electronic management and location of devices by means of a

radio frequency reader. When fitted, the passive RFID tag is positioned

inside the manifold casing.

3.1.1 Breathing air supply

The breathing air supply (supply from a compressed air line) is an external

breathing air source that is fed from a breathing air cylinder or a

compressor unit; the breathing air supply delivers the specified air quality

with the required pressure and required flow rate (see Section 4.1 for more

information).

3.2 Intended use

The X-plore® 9500 is designed for use with approved Dräger compressed

air respiratory protection equipment and protects the breathing system

from the effects of harmful substances. The equipment is only suitable for

use with a compressed air line.

Use in potentially explosive atmospheres

The suitability for use in potentially explosive atmospheres depends on the

components used. Approval information is specified on the component

name plates. The component with the lowest zone determines the

suitability of the system.

Contact Dräger for more information.

3.3 Limitations on use

The device is not suitable for CBRN hazard situations (chemical,

biological, radiological and nuclear hazard situations).

3.4 Approvals

This product is approved per:

● EN 14594:2018

● (EU) 2016/425

● Regulation 2016/425 on personal protective equipment, as amended

to apply in GB

Declarations of conformity: see www.draeger.com/product-certificates.

Important notice regarding the Pressure Equipment Directive (German:

DGRL): The X-plore® 9500 is solely intended for use with air line breathing

apparatuses. It is classified as safe pressure equipment according to the

DGRL under the requirement of good engineering practice. The equipment

cannot be DGRL-certified.

3.5 Marking and symbols

The product type is specified on the label on the manifold casing. The

product's serial number is located on the manifold body.

The marking on the air supply hose indicates whether the hose is heat

resistant (H) and/or antistatic (S).

4Use

4.1 Breathing air supply

WARNING

The quality of the air supply must meet the requirements for breathing air

in accordance with EN 12021 in EU countries or AS/NZS 1715:2009 in

Australia and New Zealand. Oxygen or oxygen-enriched breathing air

must not be used. The moisture content of breathing air should be

controlled within the limits specified in the standard in order to prevent the

device from freezing.

Carry out a risk assessment of the location of use to ensure that no air

supply other than breathable air can be connected.

Sufficient protection by the equipment is not guaranteed in highly toxic

environments.

The user must ensure that the capacity of the air supply system is

sufficient for every single connected user. In addition, safe retraction must

be ensured if the supply through the compressed air line fails.

Use a compressed air cylinder with pressure reducer or a stationary or

mobile compressor with suitable filter and air heating or air cooling system.

Compliance of the breathing air supply with the quality criteria is

mandatory. It must meet the following requirements for pressure and flow:

● Input pressure 2.8 to 10 bar

● Flow rate 350 to 1200 litre/minute

The maximum number of users that can be connected to the Dräger

breathing air supply system at any one time can be found in the associated

instructions for use.

When using a compressed air cylinder for breathing air supply, it must be

possible to move the air supply around an explosion-hazard area.

Conductive floors are mandatory in zone 1 and zone 21 if combustible

dusts with a minimum ignition energy of less than 10 mJ are present.

4.1.1 Compressed air supply hose

● Air hose coupling and input coupling of the respective product must be

compatible. As standard, the Rectus 96 series or a CEJN quick

connect coupling plug is supplied as the input coupling.

● The maximum working pressure of the Dräger compressed air supply

hose is 10 bar.

● Ensure that supply hoses with a total length greater than 50 m have an

appropriate earth connection.

EU countries

The following applies when using hoses approved by Dräger: A maximum of

100 m of hose may be used. In addition, a maximum of four individual hoses

(i.e. a maximum of five hose connections) are permitted on one air supply.

4.1.2 Pressure drop in the compressed air supply hose

CAUTION

The use of extension hoses causes a pressure drop between the

breathing air supply and the manifold.

► To compensate for the resulting pressure drop, increase the pressure

from the breathing air supply (e.g. ring pipe, compressor) accordingly.

The following table is a guide that lists examples of breathing air supply

pressures necessary so that a sufficient flow of air is available at the

manifold input.

This table only applies if using approved Dräger compressed air supply

hoses. If using hoses from other manufacturers, the minimum pressure of

3.3 bar must be available at the manifold input.

If the warning whistle still sounds, there may be a pressure loss in the hose

due to the specific conditions of the breathing air supply. In this case, the

pressure must be increased until the warning whistle stops sounding. If the

warning whistle does not respond, the user is supplied with sufficient

breathing air.

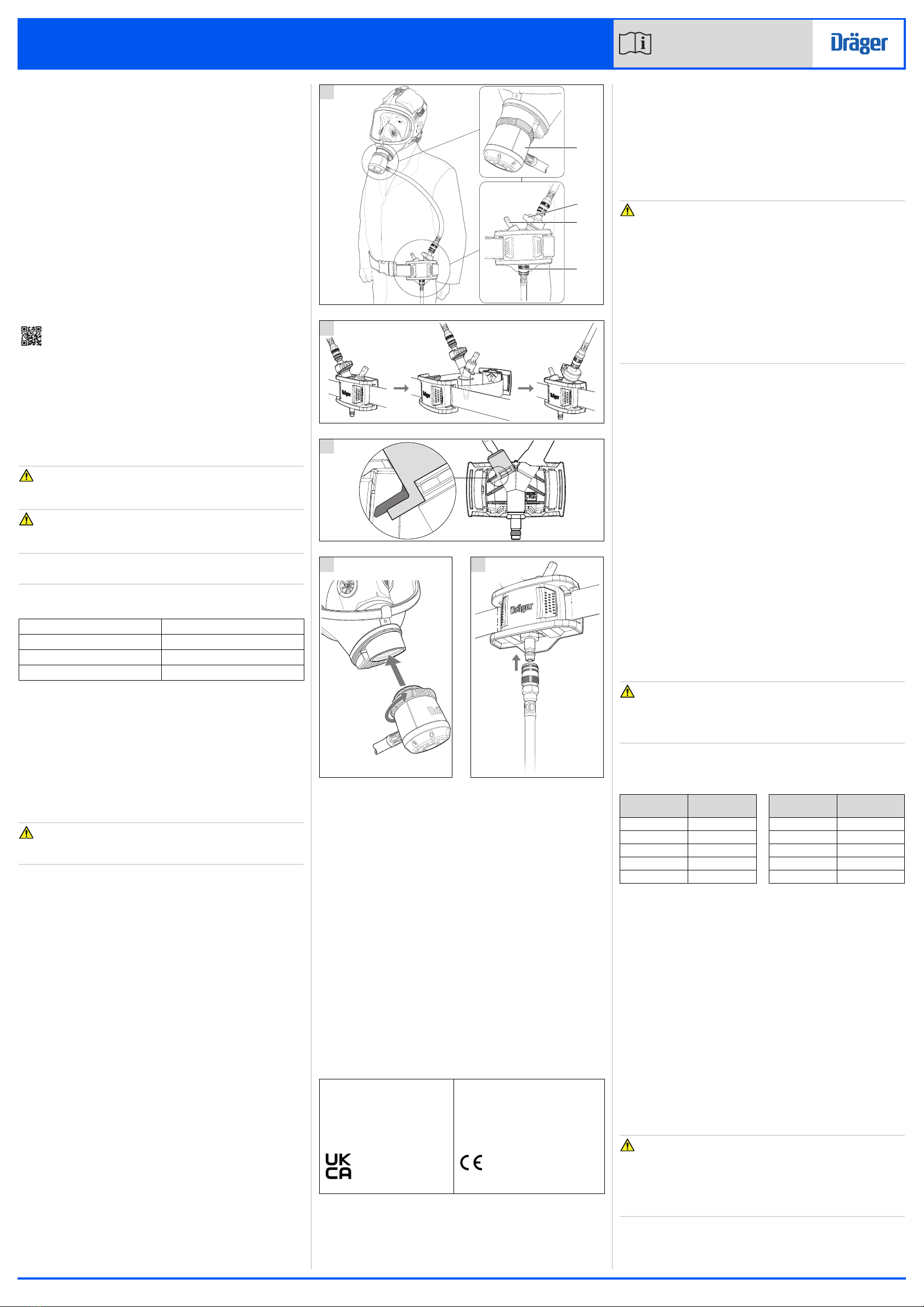

4.2 Preparation for use

4.2.1 Product preparation

The belt with air manifold can be worn on the left or right as required. To

change the carrying side, loosen the belt, remove the case if necessary

and then turn the manifold (see Fig. B). When fitting, always ensure that

the shoulder of the whistle cover sits below the rib in the manifold housing

(see Fig. C). With the belt and air distributor in place, the wearer must be

able to move their head freely without pulling on the hose or getting

tangled.

1. Always carry out a visual inspection first (see Section 6.2).

2. Don the belt. Ensure that the X-plore 9500 is fitted close to the body.

3. Connect the mask adapter to the mask (see Fig. D).

WARNING

Correct fit of the mask can only be achieved if the entire mask seal makes

contact with skin. Head hair, facial hair (including beard stubble and

sideburns), earrings, other facial piercings and normal spectacles will

interfere with the mask seal and are not permitted in the sealing area.

Additionally, head hair that could affect the mask fit (buns, pony-tails,

hairpieces, etc.) is not permitted.

4. Set the regulation knob to the minimum position (see Fig. F).

5. Connect the air supply to the input coupling (see Fig. E). The warning

whistle will sound briefly when the pressure increases.

Trademark Trademark owner

X-plore®Dräger

FPS®Dräger

Panorama Nova®Dräger

Approved body:

BSI Assurance UK Ltd.

Kitemark Court Davy Avenue

Knowlhill

Milton Keynes

MK5 8PP

United Kingdom

Identification number:

Notified body

involved in type approval and quality

control:

DEKRA Testing and Certification GmbH

Handwerkstrasse 15

70565 Stuttgart

Germany

Reference number:

0086 0158

Hose length

(in m)

Pressure

(in bar)

Hose length

(in m)

Pressure

(in bar)

1-10 3.8 51-60 6.3

11-20 4.3 61-70 6.8

21-30 4.8 71-80 7.3

31-40 5.3 81-90 7.8

41-50 5.8 91-100 8.3