Installation/Operating Instructions

Ambassador Electric Projection Screen by Draper

Copyright © 2002 Draper Inc. Form Ambassador_Inst02 Printed in U.S.A.

Caution

➀Read instructions through completely before proceeding.

➁Follow instructions carefully. Installation contrary to instructions

invalidates warranty.

➂Entire bottom of screen case should be unobstructed to permit proper

operation of automatic trap door, and access to bottom panel for

making electrical connections or servicing.

➃Screen should be installed level (using a carpenter’s level).

➄Nothing should be fastened to screen dowel, viewing surface or

automatic trap door.

➅Operating switch(es) packed separately in screen carton. Do not

discard with packing material.

➆Screen operates on 110-120v, 60 hz. current.

NOTE: Screen has been thoroughly inspected and tested at factory and

found to be operating properly prior to shipment.

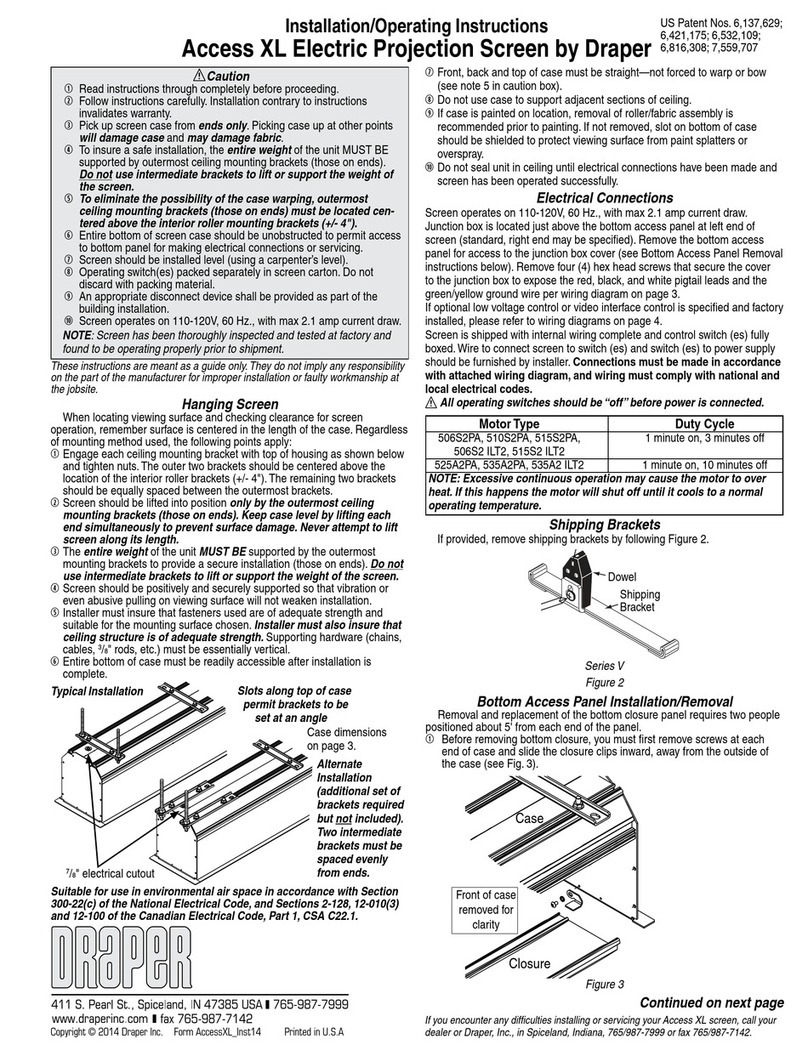

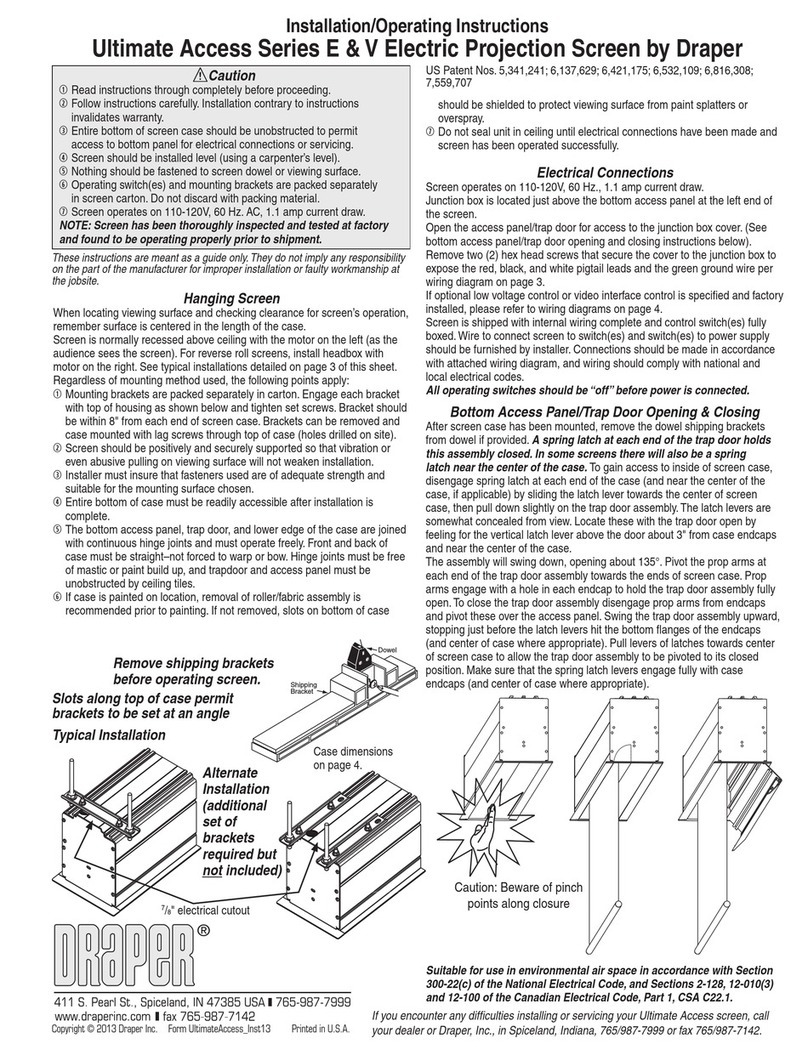

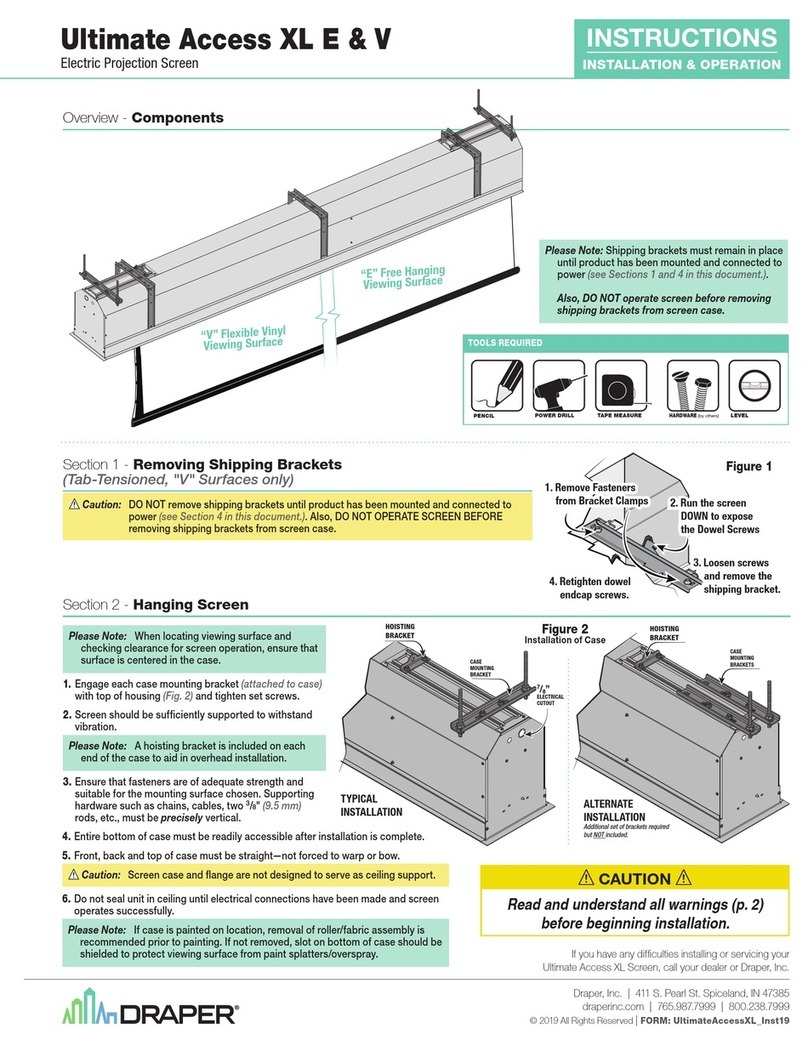

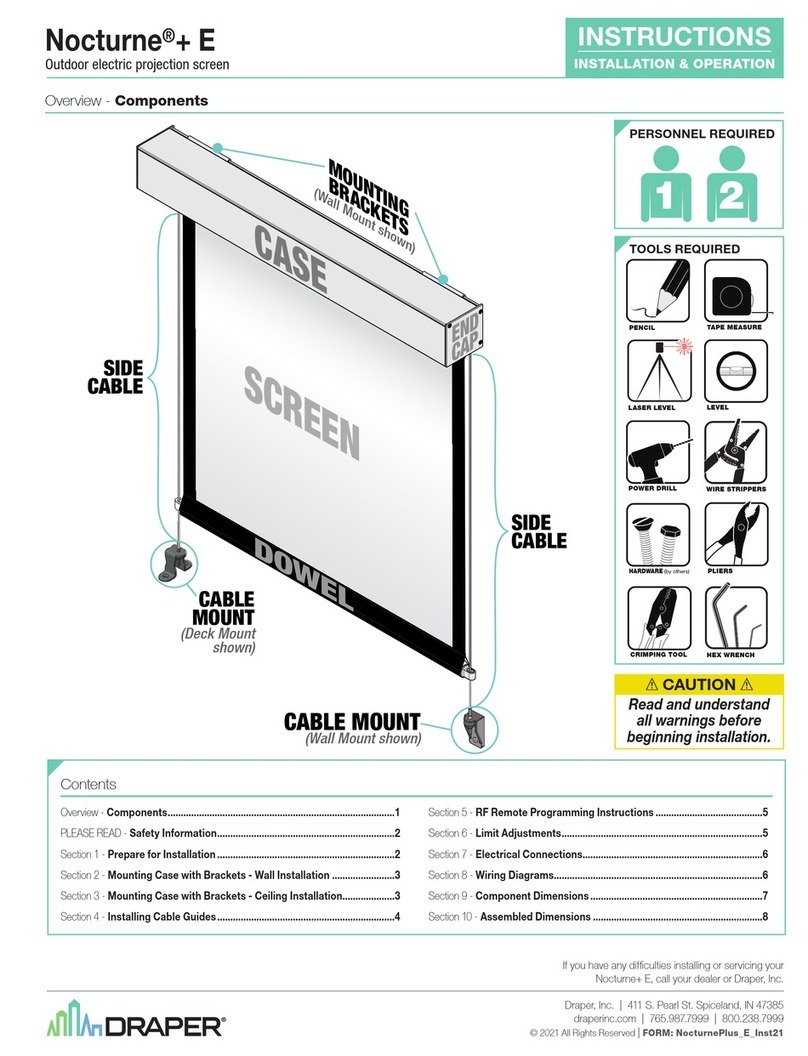

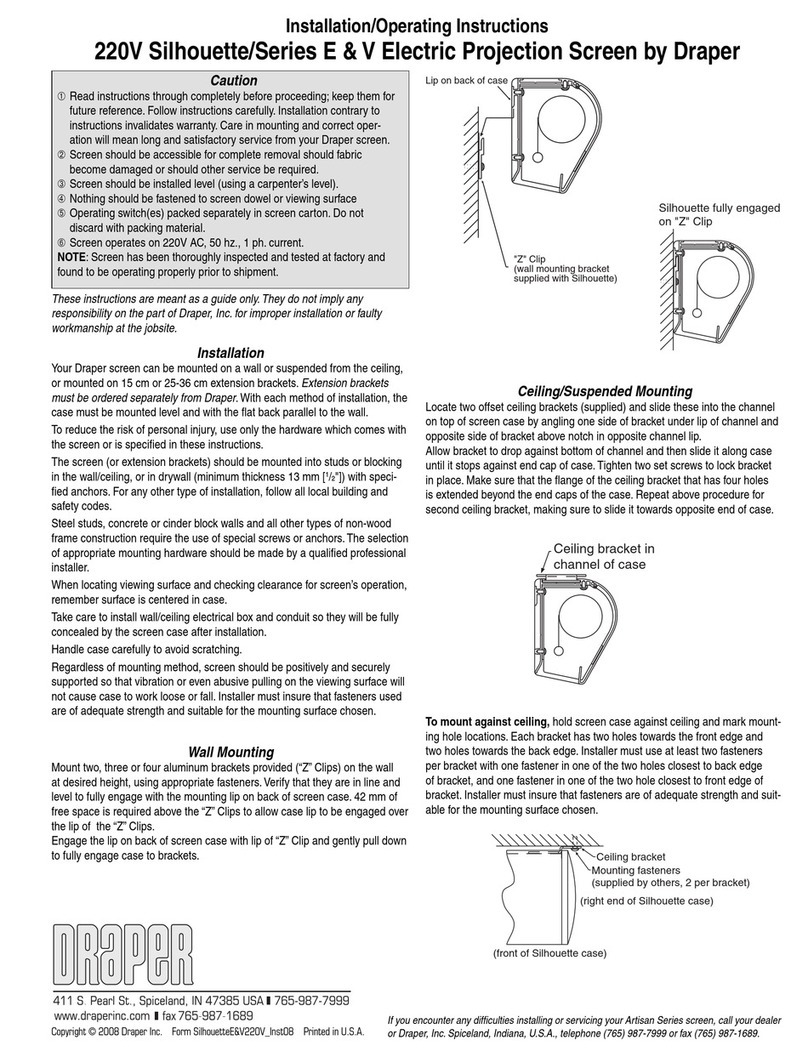

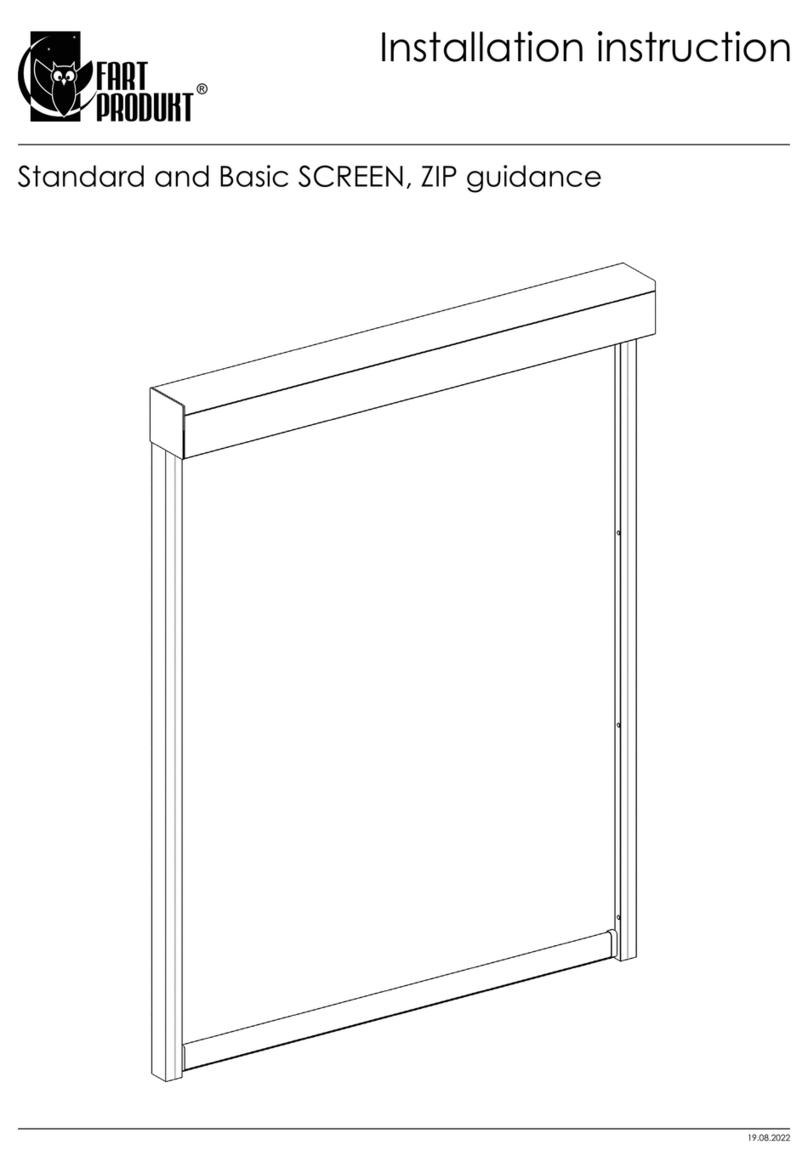

Hanging Screen

General:

When locating viewing surface and checking clearance for screen operation,

remember surface is

not

centered in case; it is offset to audience’s right (see

drawing on back). Normally viewing surface, not case, should be centered in

room.

Screen is normally recessed above ceiling and may be installed in a variety of

ways. See typical installation detailed on back of this sheet. Regardless of

mounting method used, the following points apply:

➀ Screen should be positively and securely supported so that vibration or

even abusive pulling on viewing surface will not weaken installation.

➁Installer must insure that fasteners used are of adequate strength and

suitable for the mounting surface chosen. Screen must be level for

satisfactory operation. Use carpenter’s level.

➂Entire bottom of case must be readily accessible after installation.

(Operating door must be free to open; access door must open to permit

electrical connections and limit switch adjustment; semi-permanent bottom

panel must be removable in case fabric replacement is ever required.)

➃Hinge on bottom board and particularly hinge on automatic trap door of

screen must be permitted to operate freely. Front and back of case must

be straight—not forced to warp or bow. Hinges must be free from mastic or

paint buildup, and doors must be unobstructed by ceiling tiles.

➄Do not use screen case to support adjacent sections of ceiling.

➅If trim pieces must be attached to case, do not permit screws to protrude

through ¾" wall of case. Do not attach trim with nails.

➆Extended hinges are available to allow gluing of ceiling tile when recessed.

➇If case is painted, slots around doors should be shielded to protect viewing

surface from paint splatters or overspray.

➈Do not seal unit in ceiling until electrical connections have been made and

screen has been operated successfully.

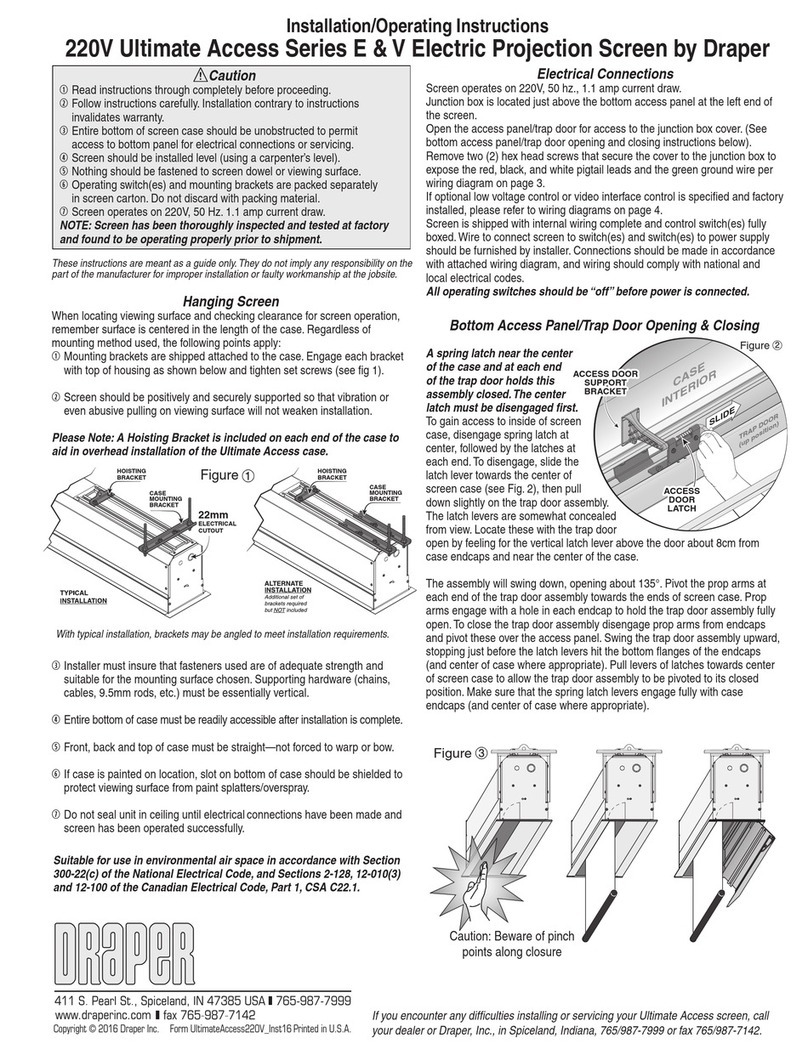

Electrical Connections

Screen operates on 110-120v, 60 hz. current.

Junction box for electrical hook-up is located at left end of screen and may be

exposed by opening access door and removing box cover.

Removal of junction box cover plate exposes red, black and white pigtail leads

and green internal ground wire per wiring diagram on reverse.

Screen is shipped with internal wiring complete and control switch(es) fully

boxed. Wire connecting screen to switch(es), and switch(es) to power supply

should be furnished by installer. Connections should be made in accordance

with attached wiring diagram, and wiring should comply with National and

local electrical codes.

All operating switches should be “off” before power is connected.

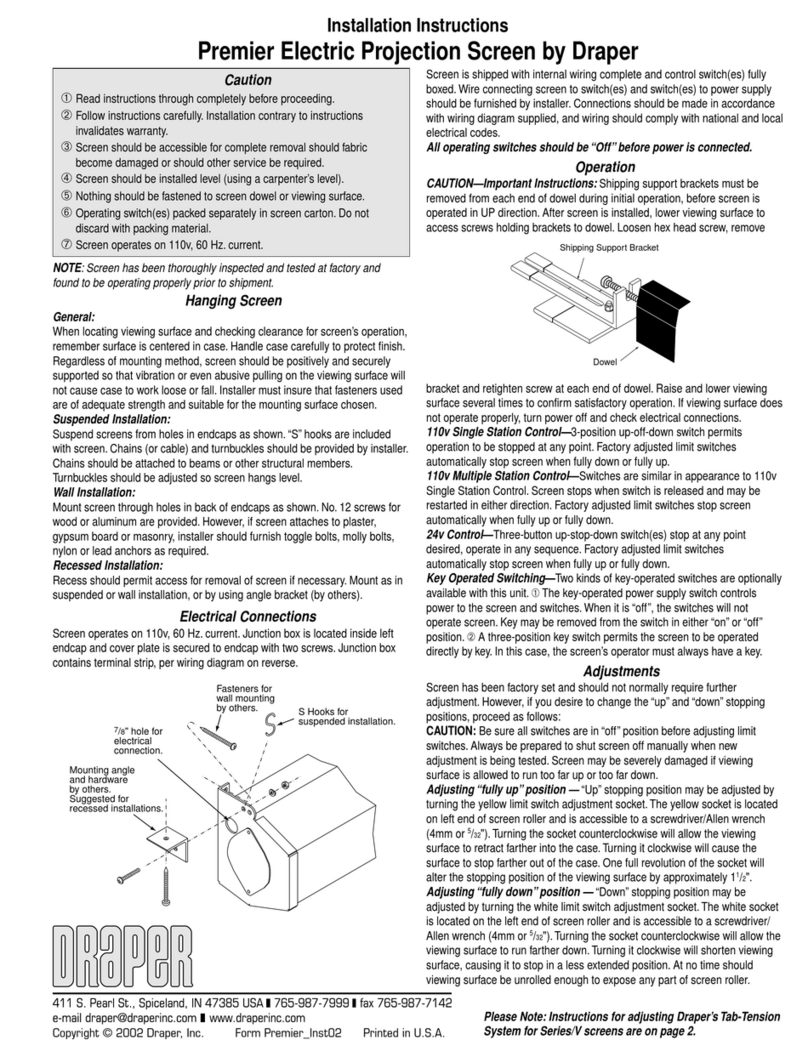

Adjustments

Screen has been factory set and should not normally require further

adjustment. However, if you desire to change the “up” and “down” stopping

positions, proceed as follows:

CAUTION: Be sure all switches are in “off” position before adjusting limit

switches. Always be prepared to shut screen off manually when new

adjustment is being tested. Screen may be severely damaged if viewing

surface is allowed to run too far up or too far down.

Adjusting “fully up” position —

“Up” limit switch is located on bracket at left

end of operating door. Raising switch slightly will permit door to close farther;

lowering switch will cause door not to close as far.

Adjusting “fully down” position —

“Down” limit switch is located on left side

of limit switch assembly immediately behind access door on left end of case.

Left hand, hex head machine screw contacts limit switch button to shut screen

off in “Down” position. Turning this machine screw clockwise will allow viewing

surface to run farther down before stopping. Turning it counterclockwise will

cause surface to stop in a less extended position.

At no time should viewing surface be unrolled far enough to expose any part

of screen roller. Be sure nut on machine screw is tight against steel plate

before closing access door.

If you encounter any difficulty installing or servicing your

Ambassador screen, call your dealer or Draper, Inc.,

Spiceland, Indiana, (765) 987-7999; fax (765) 987-7142; or e-

mail draper@draperinc.com.

Operation

When screen is first operated, be cautious! If automatic trap door does not

drop open immediately when switch is flipped “down”, return switch to “off” and

free trap door and/or recheck electrical connections before proceeding. Cycle

unit down and up several times to confirm satisfactory operation.

110-120v Single Station Control —

3-position up-off-down switch permits

operation to be stopped at any point. Factory adjusted limit switches

automatically stop screen when fully down or fully up.

110-120v Multiple Station Control

—Switches are similar in appearance to

110-120v Single Station Control. Screen stops when switch is released and

may be restarted in either direction. Factory adjusted limit switches stop

screen automatically when fully up or fully down.

24v Control —

Three-button up-stop-down switches stop at any point desired,

operate in any sequence. Factory adjusted limit switches automatically stop

screen when fully up or fully down.

Key Operated Switching —

Two kinds of key-operated switches are

optionally available with this unit. ➀The key-operated power supply switch

controls power to the screen and switches. When it is “off”, the switches will

not operate screen. Key may be removed from the switch in either “on” or “off”

position. ➁A three-position key switch permits the screen to be operated

directly by key. In this case, the screen’s operator must always have a key.

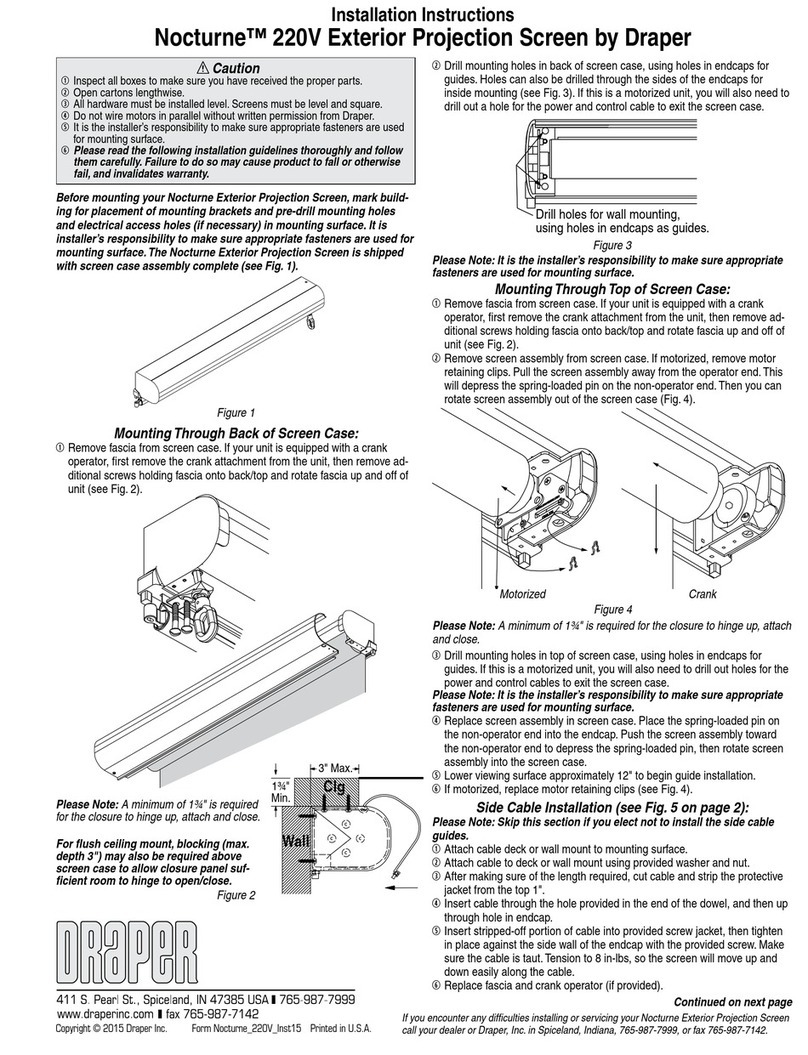

4"

3"

9

7/8"5"

10"

10

1/4"

Mounting brackets

(rods, angles, & attaching

hardware by others)

Conduit connection

on left end

Wood case

Incl. brackets

Ceiling Tile

and grid

(by others)