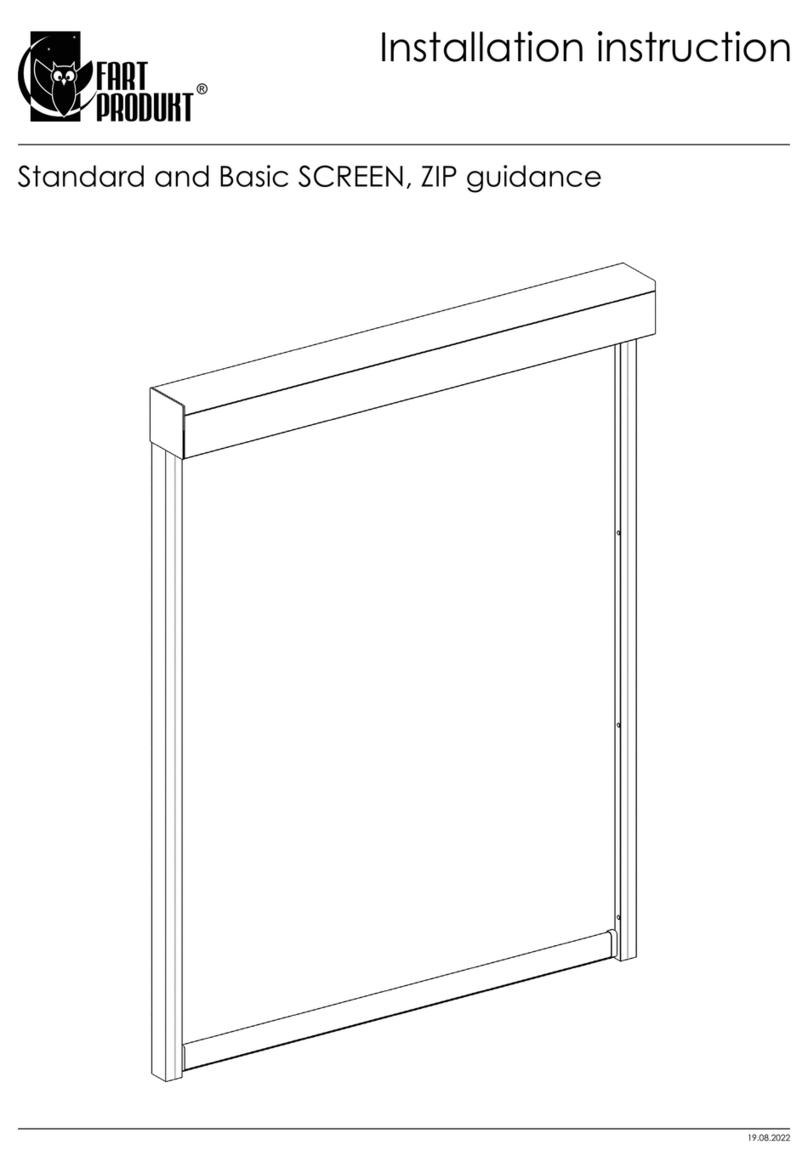

Section 1 - Preparation

Section 1.1

-

Preparing to Unpack the Screen

The shipping container is marked to indicate the top of the screen and to give instructions as to whether the screen will unroll from stage right or left.

Large screens should be properly located before removing to avoid unnecessary handling after removal from the shipping container.

Section 1.2

-

Removing Screen from Shipping Container

The screen should not be lifted from the shipping case, but should be handled by rolling the case on its side, after carefully removing the lid and making

certain that all nails, splinters of wood, or staples that might damage the screen are removed. This eliminates the danger of a large screen sagging as it would

if lifted by its ends alone.

Section 1.3 -

Supporting Screen Unrolled Across Frame

A rolling dolly or a plate and peg to insert in the bottom of the screen tube should be prepared before raising the screen to its vertical position.

This will hold the screen at the proper height relative to the frame and relieve the strain that would otherwise fall on the stagehands working on the bottom of

the screen. A swivel eye at the top of the screen mounting tube can perform the same function.

Section 1.4

-

Frame Assembly Location

The frame can be assembled on the floor, on the wall, or as it hoisted into position. If you are planning to suspend this screen,

it is advisable to use block and fall or other hoisting equipment to assemble and raise the screen section by section.

1. Assemble the top horizontal frame member, and attach the top of the viewing surface.

2. Raise this portion of the screen until the vertical members from each side can be attached.

3. Attach vertical frame pieces and hook the viewing surface to the frame, and raise as you go.

For wall mounting, the screen can be assembled on the wall or on the floor and then raised into place.

Section 1.5

-

Final Tensioning

Starting at the proper side, carefully begin to unroll the screen. Insert a hook in the top corner grommet and also a few equally spaced along the top to hold

it in position as the screen is unrolled. Do not attempt to insert hooks in every grommet as you proceed to unroll, but rather every fourth or fifth one until the

screen is temporarily suspended. Then go around again two or more times, placing only alternating hooks.This will permit the tension to be applied evenly

around the screen and fewer subsequent adjustments will be required to obtain a perfectly flat surface.

Section 1.6

-

For screens with curved frames

Use only minimum tension sufficient to hold screen in place at the sides in order to minimize reverse curvature in the center. This can be accomplished by

inserting hooks in every second or third grommet.

CAUTION! Stagehands must support top, the sides and bottom while the screen is being assembled and raised. Handle the viewing surface gently.

DO NOT CRUSH OR PINCH. PROTECT THE VIEWING SURFACE IN EVERY WAY POSSIBLE.

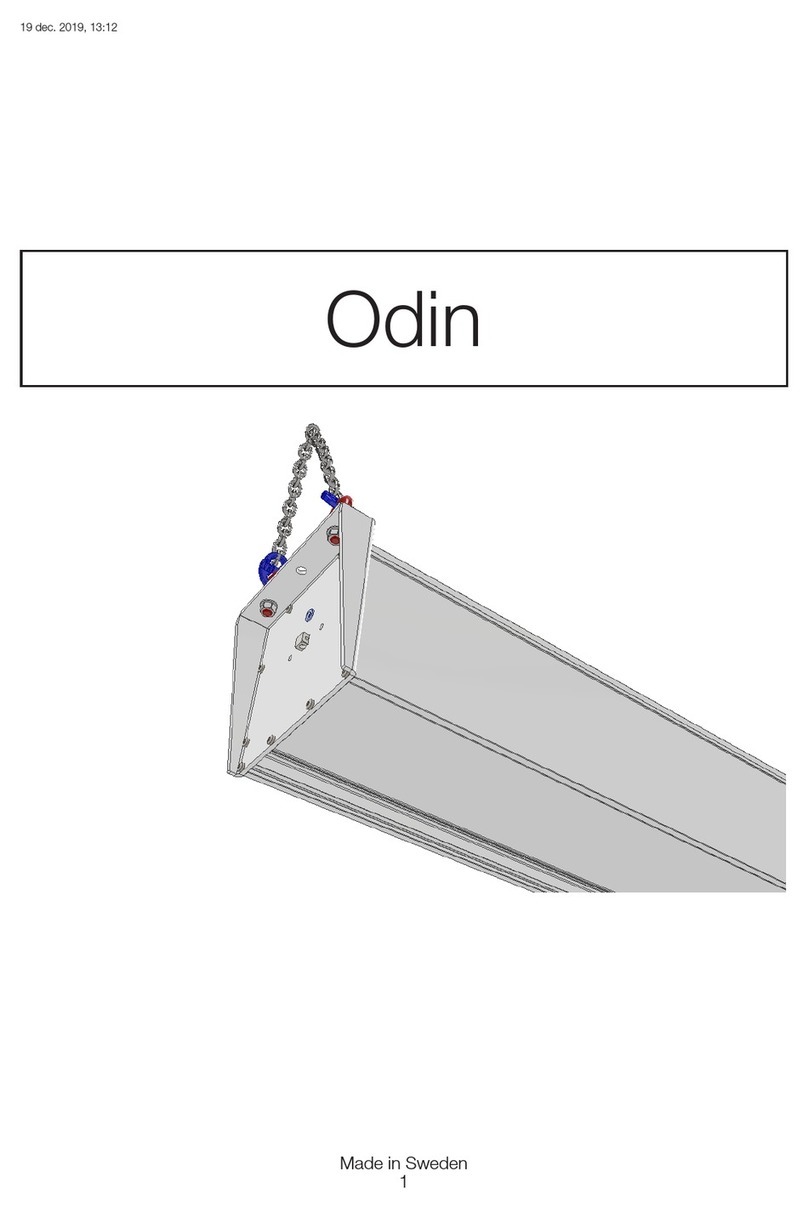

Lace & Grommet

Permanently Tensioned Projection Screen

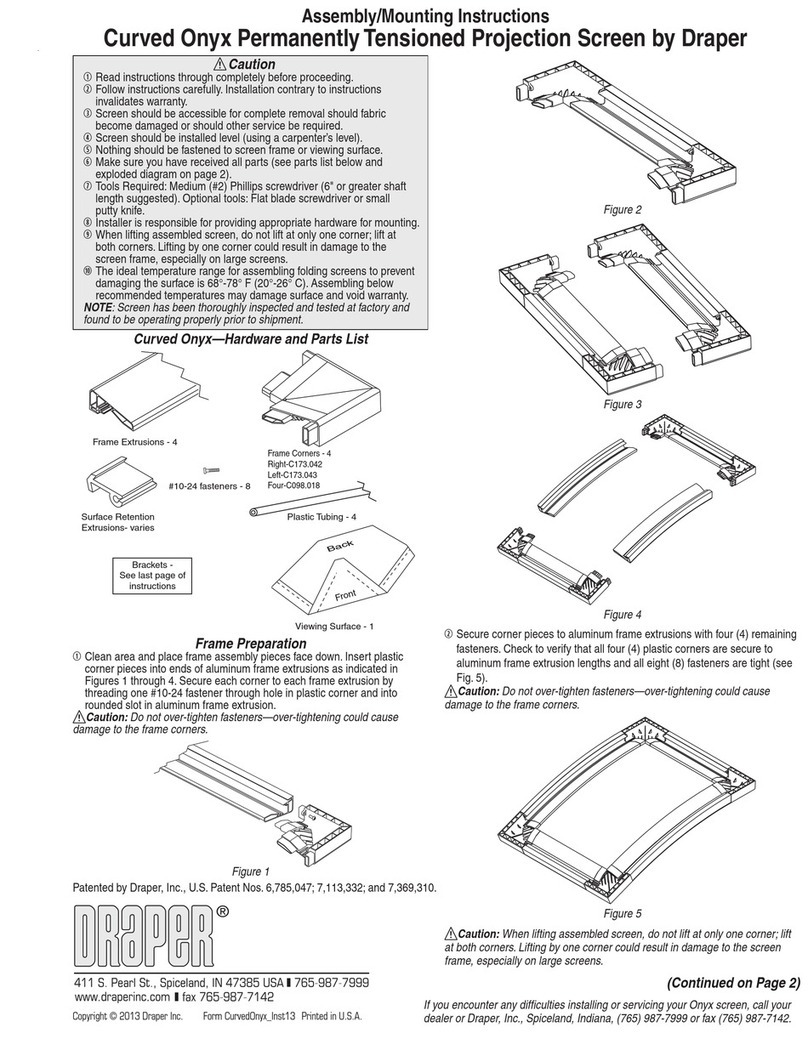

CAUTION

1. Please read all instructions before installing. Follow all instructions

carefully. Failure to install or use this product in accordance with the

enclosed instructions will void your warranty.

2. Screen is typically packed with all frame pieces packed together, but

individually wrapped and protected. Be careful when opening the

shipping container not to scratch or dent the tubing.

3. Handle the viewing surface gently. Don’t crush or pinch; protect the

front surface in every way possible.

4. Use extreme care when handling TecVision surfaces.

To prevent damaging the TecVision viewing surface, Draper strongly

reccommends using the provided white gloves.

Please Note:

Custom products/installations may not be reflected by this document.

Call Draper, Inc. if you have questions about your installation.

Draper, Inc. | 411 S. Pearl St. Spiceland, IN 47385

draperinc.com | 765.987.7999 | 800.238.7999

© 2017 All Rights Reserved

|

FORM: LaceGrommet_Inst17.indd

INSTRUCTIONS

INSTALLATION & OPERATION

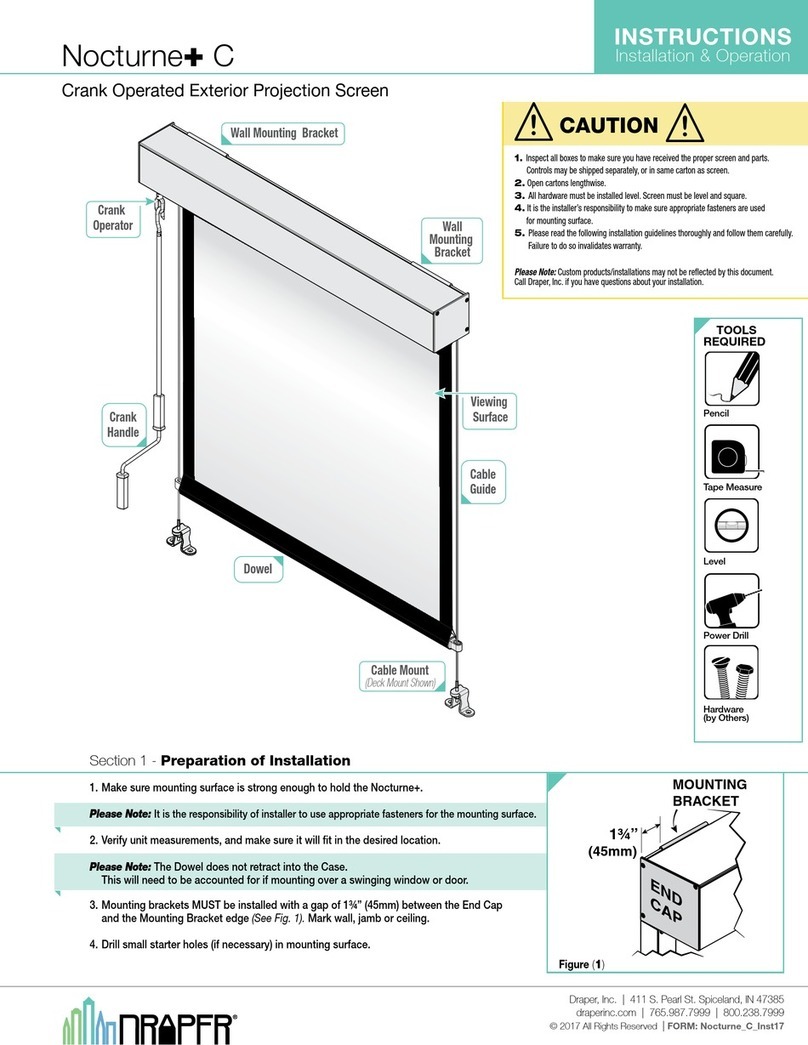

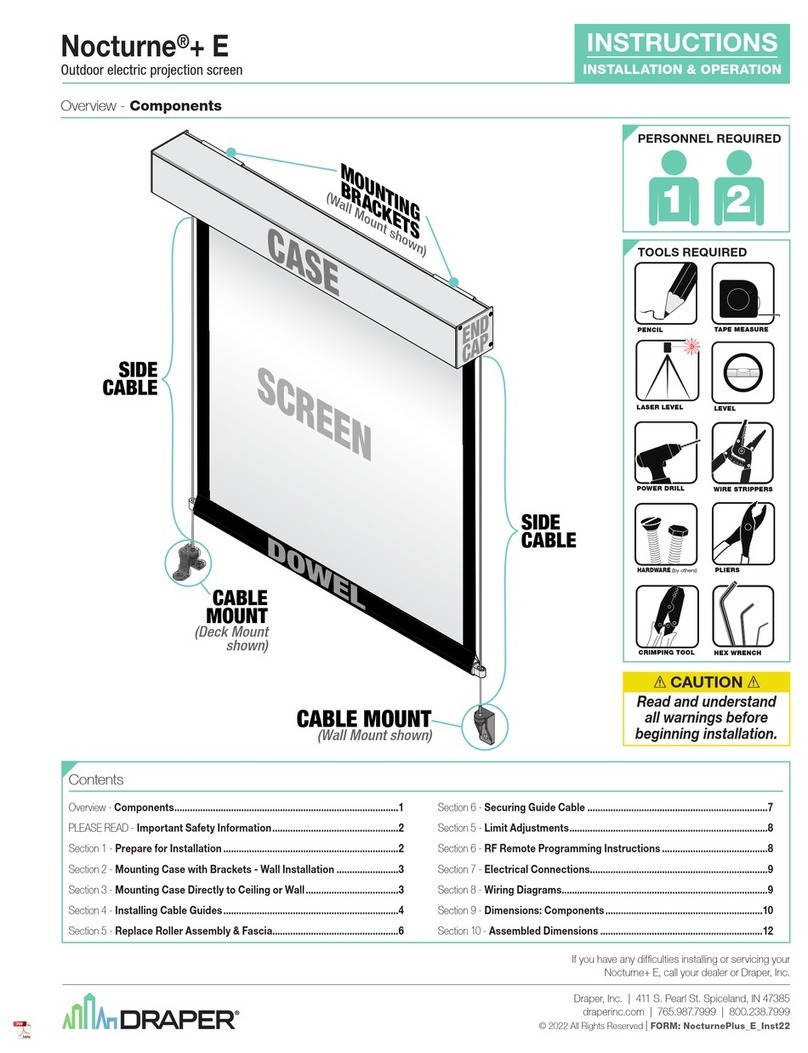

TOOLS REQUIRED

PENCIL TAPE

MEASURE

POWER

DRILL

LEVEL GLOVES

(TecVision Only)

MOUNTING

HARDWARE

(by Others)