Pub 49440

Effective 01/02 5

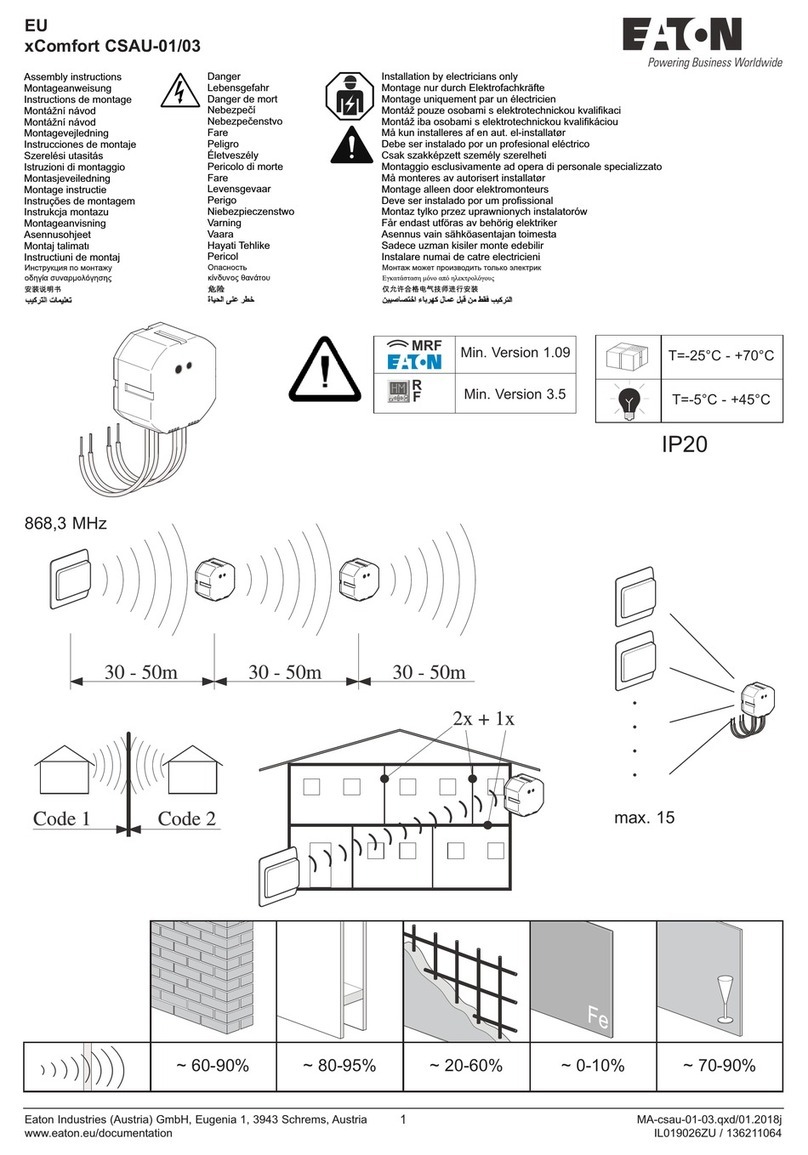

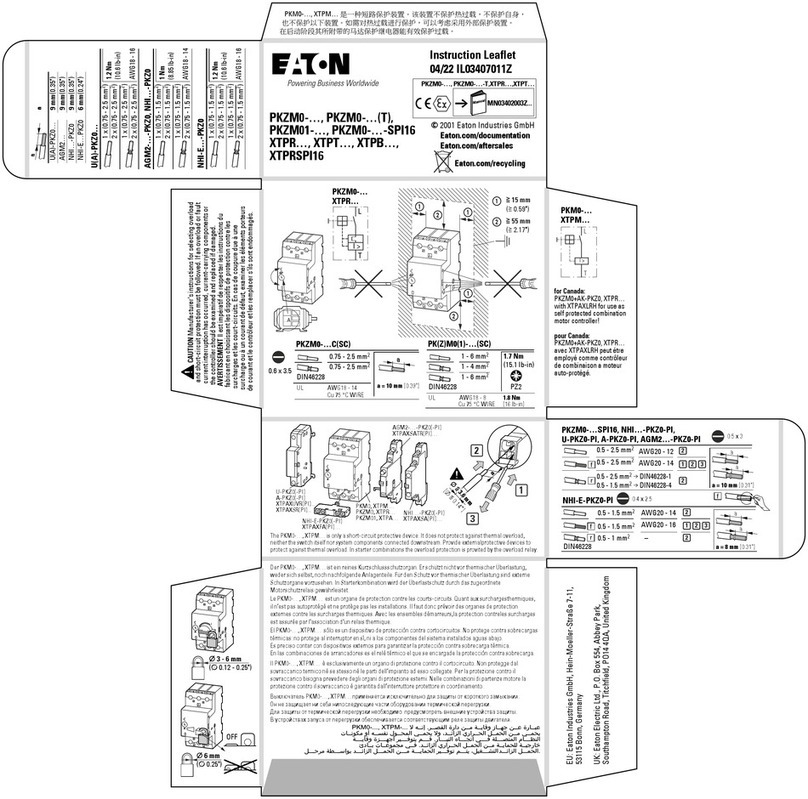

Figure 12. Adjust Time and Torque

How to Adjust Time and Torque, Fi

ure 12

Control of the motor torque is achieved b

actin

on the motor

volta

e.The motor speed depends on the torque produced b

the motor and the load on the motor shaft. A motor with little or

no load will reach full speed before the volta

e has reached its

maximum value.

NOTE: The soft start controller will read time and torque set-

tin

s in the OFF state. Repeated starts ma

trip the

motor protection rela

. DO NOT set the rotar

switches in between positions. This corrupts the time

and torque adjustment. Use screwdriver 2 mm x

0.5 mm.

Ratin

Index

Table 8. Rating Index

Ramp-Up Time and Initial Torque

Table 9. Ramp-Up Time and Initial Torque

(Standard Load)

Kick Start/Break Loose

If it is not possible to reach a time sufficient for the application,

it ma

be necessar

to kick start the load.

Table 10. Kick Start/Break Loose (High Inertia Loads)

Ramp-Down Time

Follow Table 9 to set Ramp-Up and Initial Torque.

Table 11. Ramp-Down Time, e.g. Pump Loads

200ms kick start with

Adj. Torque, 0 - 85%

0

100%

Motor Voltage

Time

Ramp-Up, 0.5 - 10 Sec.

Ramp-Down, 0.5 - 10 Sec.

Torque Adjustment, 0 - 85%

8,2

5,6

3,9

0,8

1,2

1,8

0

2,7

8,2

5,6

3,9

0,8

1,2

1,8

0

2,7

J

t

Ramp up

U

t

Ramp down

U

t

Initial torque

U

t

Kick start

0

4

6

6

4

2

0

2

6

4

20

2

6

0

4

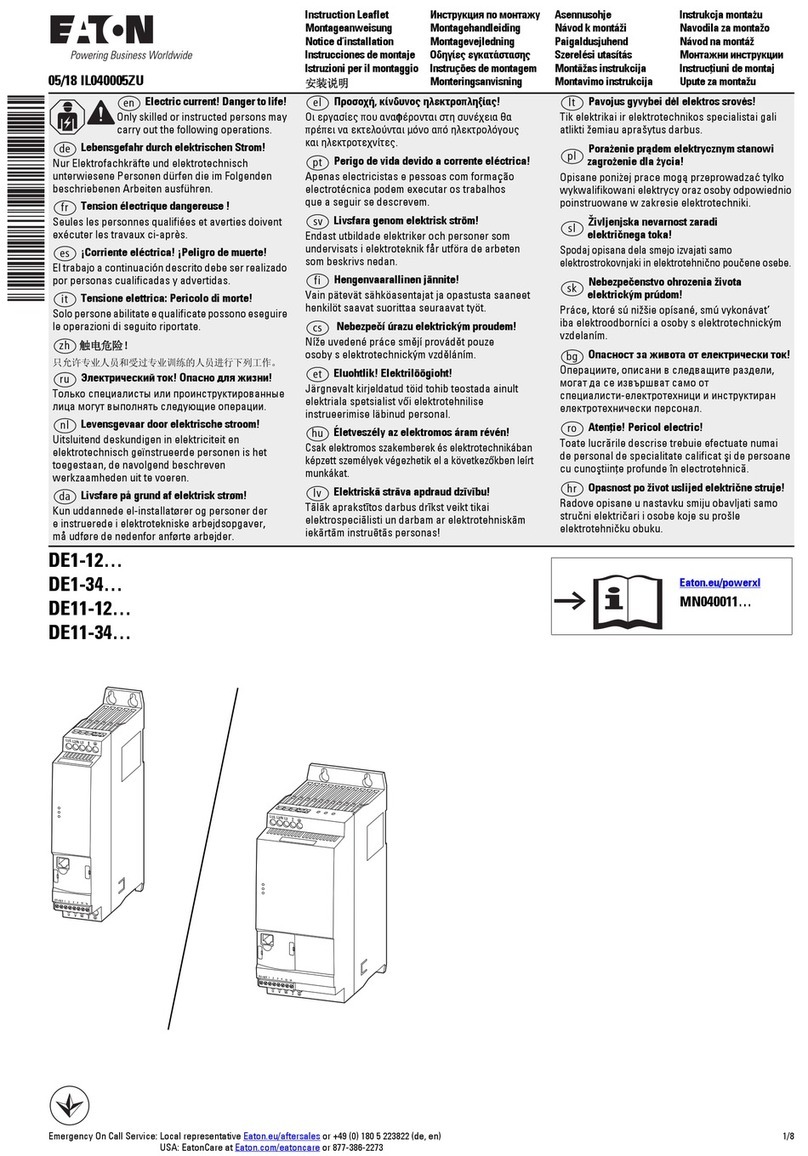

A1 A2

2 /T1 4/T2 6/T3

11 12

1/L1 3 /L2 5/L3

S701E25N3S

92EQ10005A0001A

S701_15N3S S701_25N3S

15A: AC-52a: 4-13 : 100 –3000 25A: AC-52a: 4-13 : 100 –3000

15A: AC-53a: 8-3 : 100 –3000 25A: AC-53a: 8-3 : 100 –3000

15A: AC-58a: 6-6 : 100 –3000 25A: AC-58a: 6-6 : 100 –3000

Position Setting/Adjustment

Set the Ramp-Up switch to maximum.

Set the Ramp-Down switch to minimum.

Set the Initial Torque switch to minimum.

Apply control signal for a few seconds. If the load does not

rotate immediately, increment the Initial Torque and try

again. Repeat until the load starts to rotate immediately on

startup.

Adjust Ramp-Up time to the estimated start time (the

scale is in seconds) and start the motor.

Decrease the Ramp-Up time until mechanical surge is

observed during start.

Increase the time one step to eliminate the surge.

8,2 0

0

0

Position Setting/Adjustment

Set the Ramp-Up switch to maximum.

Set the Ramp-Down switch to minimum.

Set the Initial Torque switch to minimum kick

start torque.

Apply control signal for a few seconds. If the load stops

right after the 200ms “kick”, increment the Initial Torque

and try again. Repeat until the load continues to rotate

after the “kick”.

Adjust Ramp-Up time to the desired start time (the scale is

in seconds) and start the motor.

Position Setting/Adjustment

Set the Ramp-Down switch to maximum.

Switch off the control voltage and observe any mechanical

surges on the load. If there are none, decrement Ramp-

Down switch and try again. Repeat until mechanical surge

on the load is observed.

Increase the time one step to eliminate the surge.

8,2 0

0

0

8,2 0

0