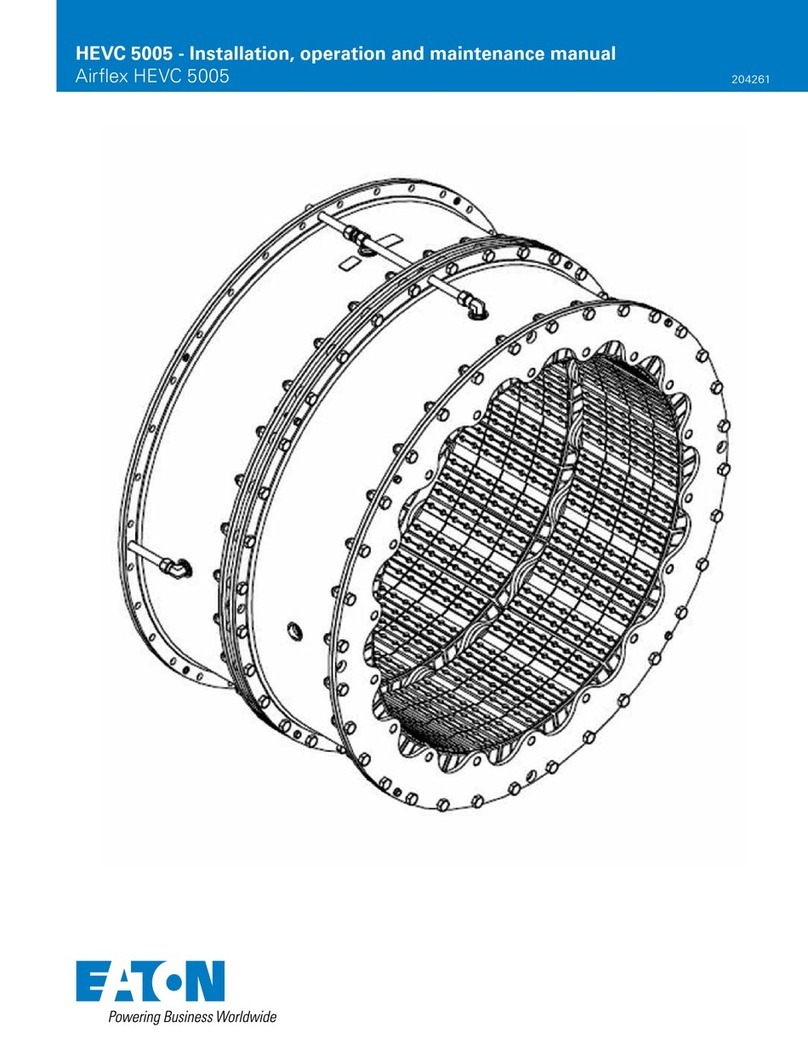

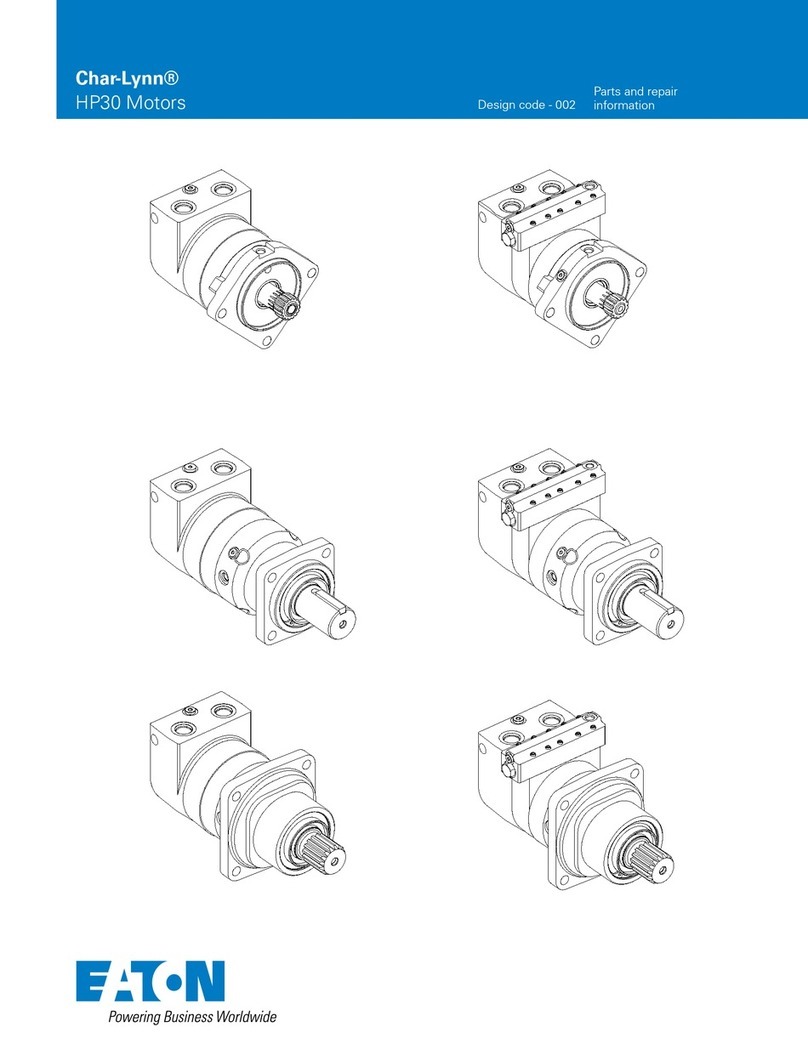

mm A B

EAM4 238 163

EAMMP65 238 163

EAM7 292 217

EAM10 346 271

EAM13 440 365

EAM9M/MB 440 365

EAM16 454 379

EAM12M/MB 454 379

EAMSL66M/MB 454 379

EAMSL93M/MB 454 379

= =

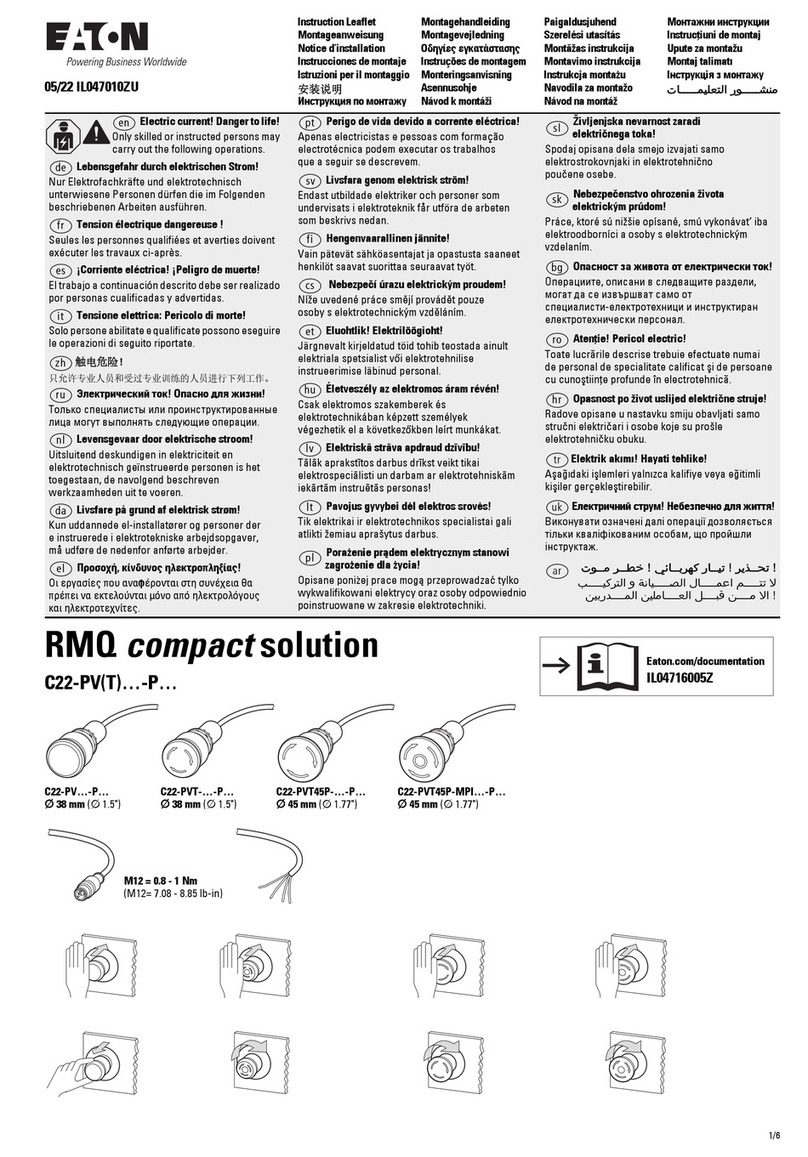

Remove

Plastic Knob

Insert Lock into hole tighten back nut

Warning-

IntellectualPropertyRights

Eaton wishestomake it clearthat it owns intellectual property rights inthe

product which it manufactures (whether or notlistedin this leaflet) and that

it will take legal action against any partyfoundtobe manufacturing, using,

or selling any article whichinfringesthe company’s intellectualproperty.All

marksinthisdocument identified with an R symbol oraTMsymbol adjacent

tothe markaretrademarks of Eaton.

C2019 EatonElectricLimited.

All rightsreserved. www.eaton.com/recycling

The use to which thisproductisputand itsplaceof installationis outsideour

control.Particularcareshouldthereforebetakentofollowtheinstructionsgiven

here and to ensure their continuedavailabilityin conjunction withtheuseof the

product.

No responsibilitycan beacceptedby usif theseinstructions are disregarded.

Further copiesof theseinstructionsand informationconcerningthe installation

and properuseof thisproductcan be obtainedby contactingthe:

Technical ServicesDepartment

Eaton Electric Limited, Middleton, Manchester, M24 1GQ. UK

Tel:+44(0)8700545333,

email: ukcommorders@eaton.com

Suitable for Indoor, Stationary applications

Mechanical Protection : IK06

IP Rating : IP3X

EMC Classification : B

Pollution Degree : 3

Construction Type : Fixed

Frequency (fn): 50Hz

MCB (2A –50A) = Rating as marked, (63A)= 55A Inc. Subject to applicable RDF - per table 101, IEC/EN61439-3

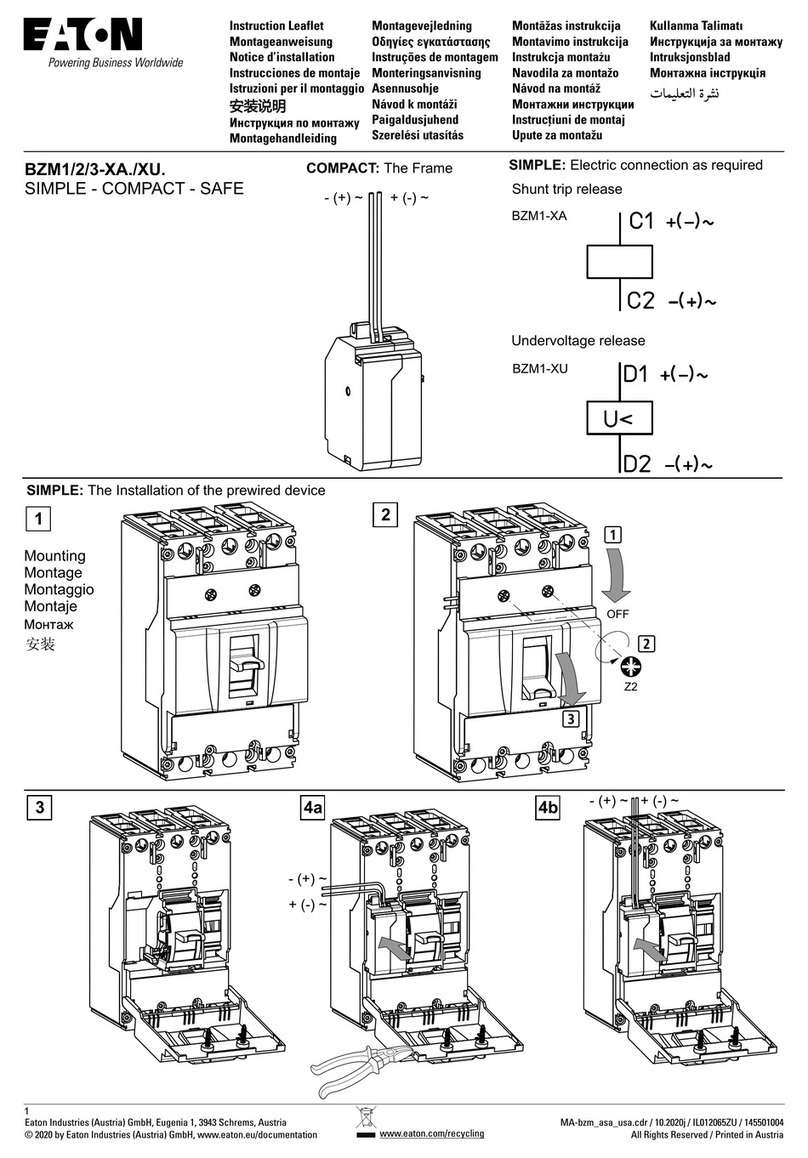

INTERFACE CHARACTERISTICS

Type A DBO to IEC/EN61439-3

Rated Voltage / Rated Operational voltage (Un / Ue) : 240V a.c.

Rated Impulse Withstand Voltage (Uimp) : 4kV

Rated Insulation Voltage (Ui) : 415V

Rated Conditional Short Circuit Current (Icc) : 15kA

Rated Current of the Assembly (InA) : See DB Rating label (65A - 125A)

Rated Diversity Factor(s) RDF : 0.7

Rated Current of each Circuit (Inc) :

RCCB (100A) = 90A Inc.

RCBO (6A-45A) = Rating as marked –subject to applicable RDF