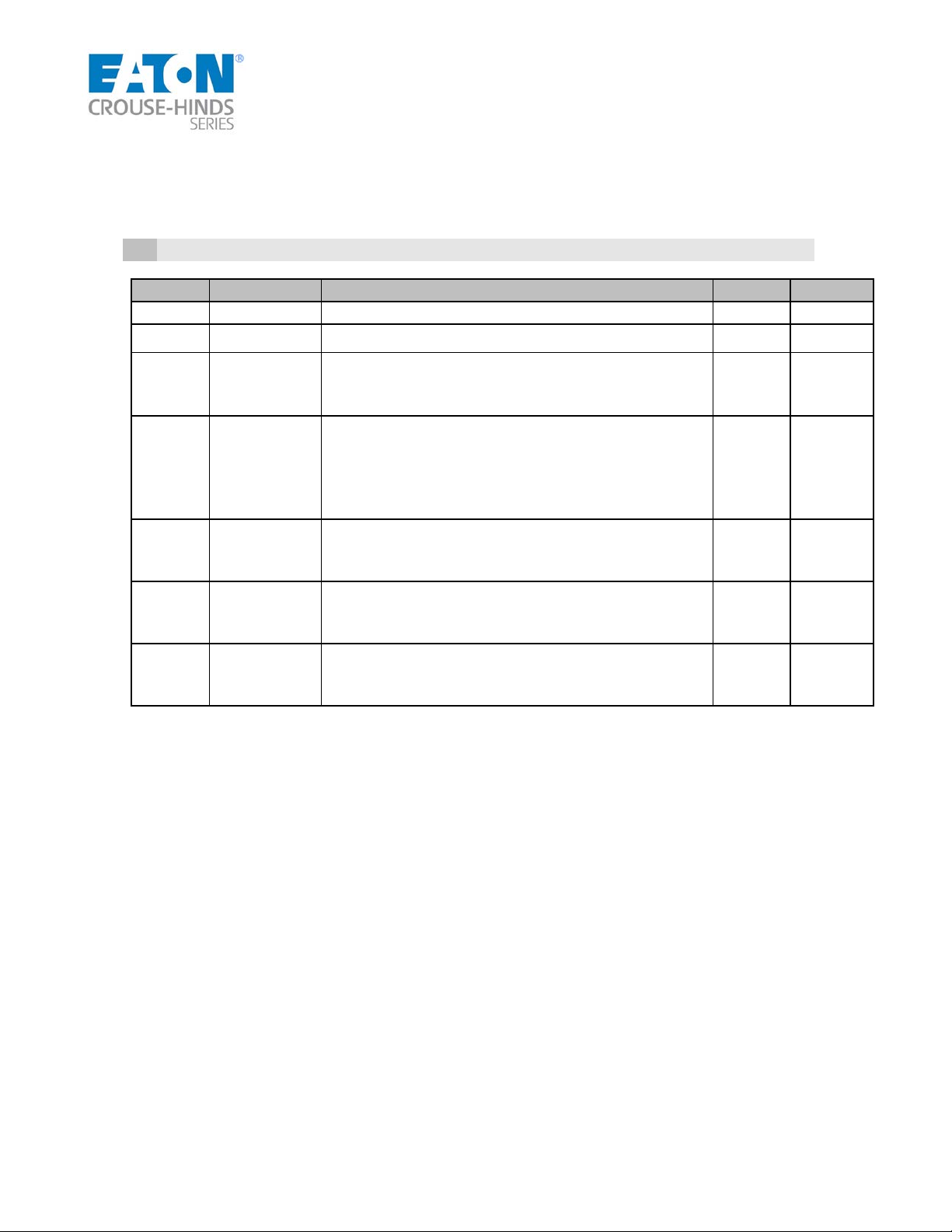

Style 3

RunwayCenterline,TouchdownZone

singlepiecealuminuminsetfixture

3

8 Installation

8.1 Installation

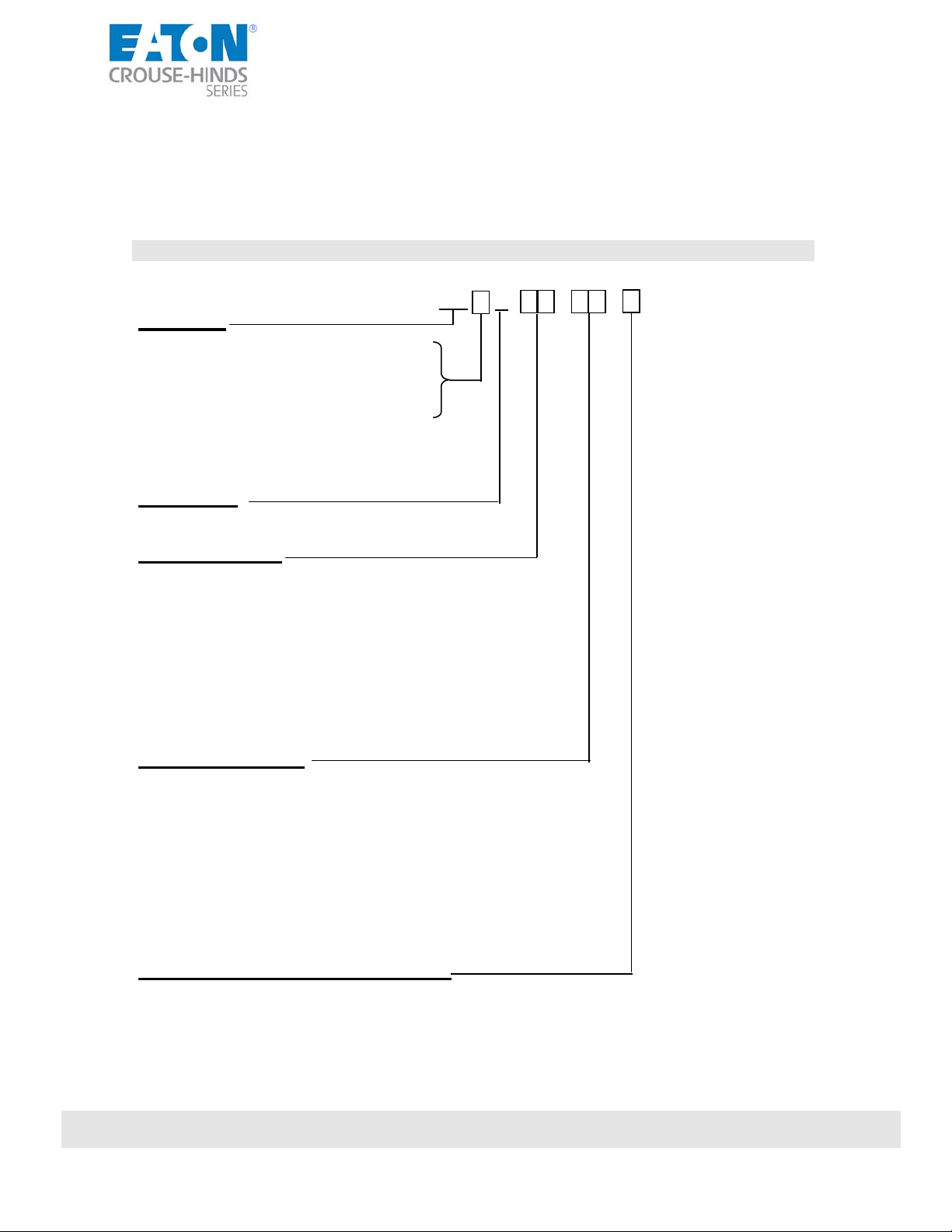

The Style 3 RCL/TDZ light units are shipped complete, including the lamp(s), and are ready for

installation as received. Installation of a light unit is to be donewith primary POWER OFF and

SECURED. At each light location, install a steel, Size B, 12 inch deep minimum, L-868 Light Base

per FAA AC 150/5340-4 (latest revision). Install the light base with two opposite bolt holes

perpendicular to the runway centerline. Place the properly sized isolation transformer(s) in the light

base and make necessary primary power connections using L-823 connectors. The RCLlight unit

requires either two 45 watt, 6.6Asecondary transformersfor the two lead version, or one 100 watt,

6.6A secondary transformer for the single lead version. The TDZlight unit requires one 45 watt,

6.6A secondary transformer. Verify that the mounting flange on the light base is clean and the

O-ring (optional on deep cans) is coated with Dow Corning FS 1292 grease and is in place on the

light base. Connect the plug(s) from the light unit to the secondary(ies) of the previously installed

isolation transformer(s). Installation tool, Crouse-Hinds P/N 19999, will ease in the installation and

removalof the light unit (See Figure 1). The threaded eyebolts on the lifting tool screw into

threaded holes in the light fixture. Lower the light unit straight down onto the base. The light fixture

is subject to opticalmisalignment or mechanicaldamageif not seated properly. Verify the light

beam(s)/color/toe-in are properly orientated for the individual location. Secure the light fixture to

the base see section 8.2.

8.2 InstallationBolt Torque

•Usefully threaded,3/8-16bolts meetingrequirements ofFAAEB83A.(P/N 21716 is recommended.)

•UseHeico-LockorNord-Lock stainless steellock-washersperFAAspecifications*.

•Mountingbaseholesmustbedegreased,cleaned,anddriedpriortoboltinstallation.

•Base-to-fixturemating surfacesmustbedegreased,cleaned,anddriedpriortoinstallation.

•Applymarinegradeanti-seize (K=.18) permanufacturer’s instructions toeachbolt.

•Installthe3/8-16 bolts withlock-washersperlock-washermanufacturer’sguidelines.

•SeeSection 8.3 forHeico-Lockinstallation guidelines (2014)

•Achieveafullfinaltorqueof28FT-LBS (37.9 N-m) ±10% with acalibrated torquewrench.

•Impactwrenchesarenotrecommended as installation tools.

•Checktorqueandre-torqueallbolts within 2weeks of initial installation.

•Maintain allbolts bycheckingandre-torqueingperFAAspecifications*.

•If anylubricantsorthreadlockingcompoundsareused(notrecommended),torquemustberecalculatedbasedonK

factorprovided bylubricantorcompoundmanufacturer.

•Newbolts andlock-washersshallbeusedeachtimealightunit is removedfromits base.

*RefertothefollowingspecificationsforFAAinstallationandmaintenancerecommendations:

•AC150/5340-26 “MaintenanceofAirportVisualAids”

•AC150/5345-46 “Specification forRunwayand TaxiwayLightFixtures”

•FAAEngineeringBriefNo.83A “In-pavementLightFixtureBolts”