3

GB

Dear Customer,

You have purchased a high quality technical

system which will provide you with many ye-

ars of enjoyable sauna bathing. This sauna

heating system was constructed in accor-

dance with state-of-the-art European safety

standards, inspected and manufactured in

accordance with the Quality Standard DIN

EN ISO 9001:2000.

This detailed installation and user‘s guide was

created for your information. Please note

especially the important information and the

data dealing with the electrical connection.

We wish you a richly invigorating and resto-

rative sauna bathing experience.

First of all, check whether the sauna system

has arrived at your site undamaged. Register

transport damage claims immediately with

the delivering transport company or please

consult the supplier who provided the equip-

ment to you.

General notes

Please note that an optimal sauna climate

can be reached only when the cabin, with

its air intake and exhaust, the sauna heating

unit and the control unit have been tuned for

compatibility with one another.

Please note all data and information provided

by your sauna supplier.

The sauna heating units warm your sauna

cabin through means of heated convection

currents. To this end, fresh air from the air

intake vent is drawn in, rises upon warming

(convection) and is then circulated through

the cabin. A part of the used air is pushed out

through the exhaust vent in the cabin. This is

the means by which the typical sauna climate

develops, reaching characteristic temperatu-

res of about 110° C directly under the ceiling

of your sauna, which fall off to about 30-40°C

in the floor area due to the temperature gra-

dient in the sauna cabin. Therefore, it is not

unusual when, for example, temperatures of

110°C prevail in the area of the temperature

sensor over the oven, while the thermometer,

which is installed 20-25 cm under the cabin

ceiling on the sauna wall, registers only 85°

C. With a temperature setting at maximum,

the mean bathing temperature lies between

80°C and 90°C in the area of the upper rec-

liner bench.

Please note that the highest temperature va-

lues in the cabin always develop in the area

above the sauna heating unit and that the

temperature sensor and safety limiter must

be installed in this area in accordance with

the control unit installation guide.

At the initial heating, you may notice a slight

odor arising from evaporation of substances

from the manufacturing process. Air out your

cabin after this cycle before you begin with

the sauna bath

Intended use

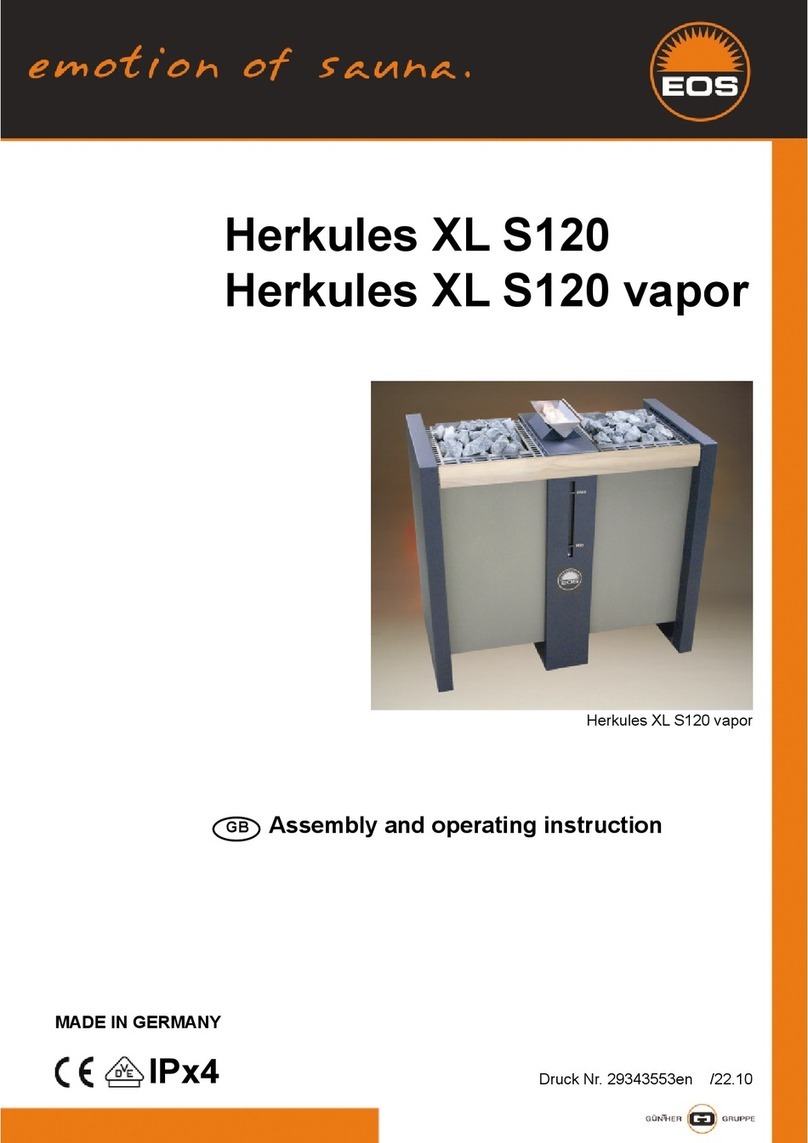

This sauna heater is exclusively designed

for the heating of sauna cabins, in connec-

tion with an appropriate control unit.

Any use apart from the defined application

shall be regarded as non-intended use. Ad-

herence to the conventional operating, main-

tenance and servicing conditions is also part

of the intended use.

The manufacturer cannot be made respon-

sible for deviating alterations undertaken on

the authority of the user and any consequen-

tial damage. The risk for such measures

shall be borne solely by the person carrying

out the alterations and causing the damage.

Sauna heaters, with the exception of tho-

se used for household purposes, must be

equipped with a safety device vis-à-vis the

cover per DIN EN 60335-2-53.

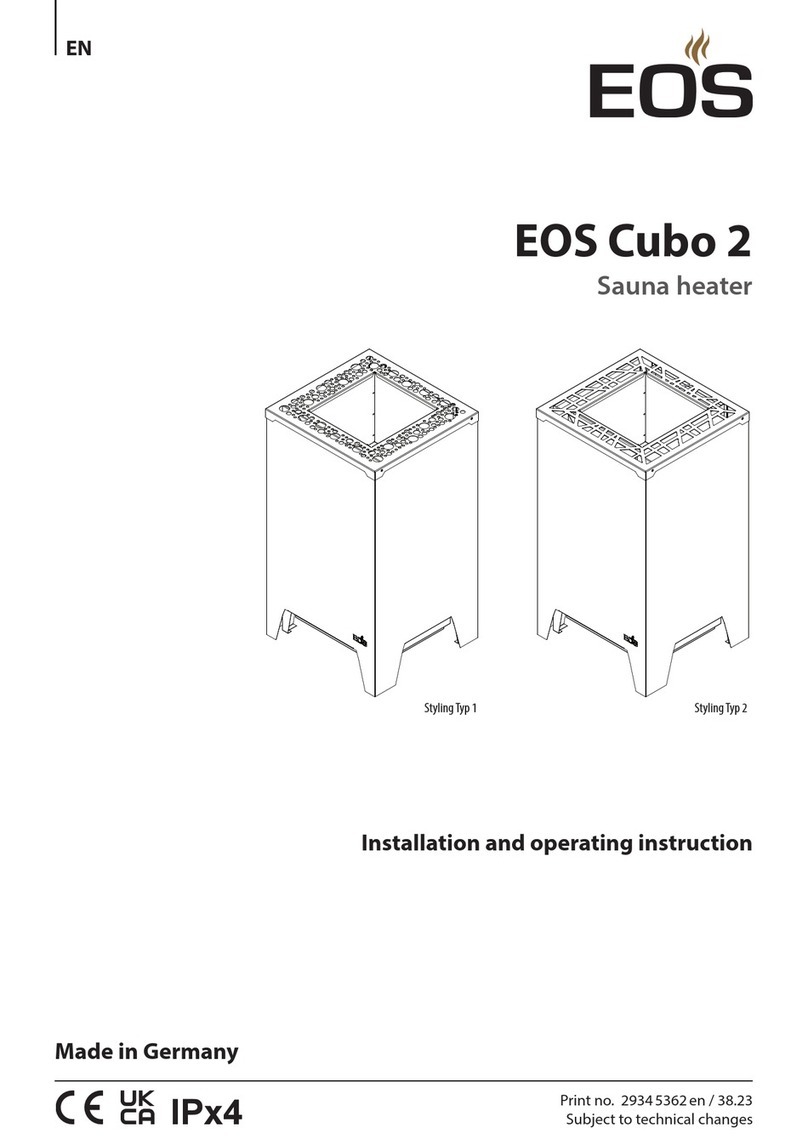

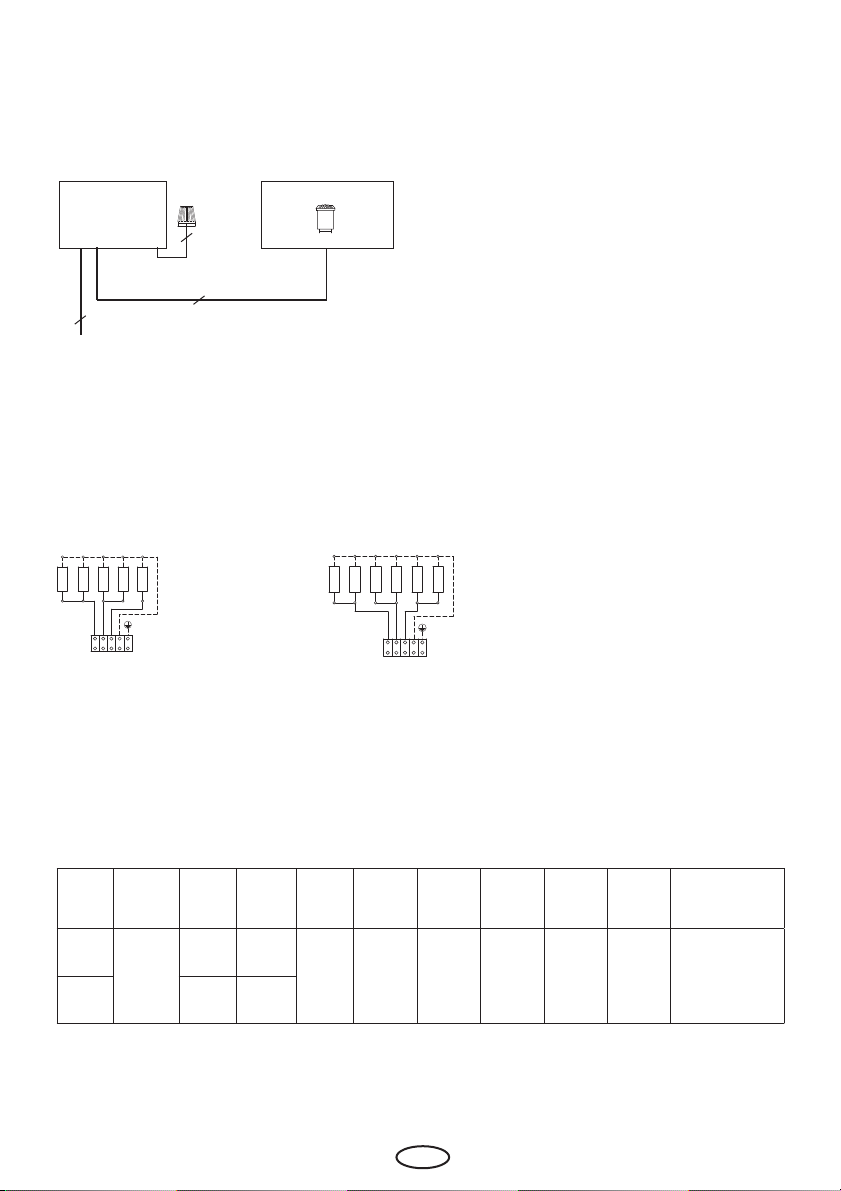

As suitable measure, and depending on the

sauna heater, a rocker switch Type I or Type

II may be installed above the heater.

(The rocker switch is not included in the de-

livery scope of the sauna heater.)

For installation and electrical connection of

the rocker switch follow the installation in-

structions supplied with this part.