ETK-S6.0 - User’s Guide 4

ETAS Contents

4.5 Debug Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.7 ECU Voltage Supervisor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.8 Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.9 Data Emulation and Data Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.10 Startup, Trigger and Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.10.1 Phases of the Startup Protocol for AUD-II Operation . . . . . . . . . . . 24

4.10.2 Phases of the Startup Protocol for H-UDI Operation . . . . . . . . . . . . 25

4.10.3 Triggering of Measurement Data Acquisition . . . . . . . . . . . . . . . . . 27

4.10.4 Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1 Connection to the ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2 Connection to the Debugger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.3 Connecting to the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3.1 Permanent Power Supply inside ECU available . . . . . . . . . . . . . . . . 31

5.3.2 Permanent Power Supply inside ECU not available . . . . . . . . . . . . . 31

5.3.3 Isolated Power Supply inside ECU . . . . . . . . . . . . . . . . . . . . . . . . . 32

6ETK Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.2 ETK Configuration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3 ETK-S6.0 Subtypes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4 Configuration Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.1 Subtype ETK-S6.0A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.2 Subtype ETK-S6.0B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

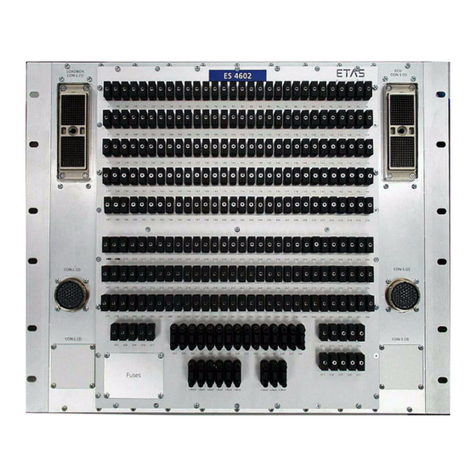

7.1 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1.1 ETAS Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.1.2 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.2 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.4 Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.4.1 Data Emulation Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.4.2 Measurement Data Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.5 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.6 Serial ETK Interface for Application System . . . . . . . . . . . . . . . . . . . . . . . . 40

7.7 Testcharacteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.7.1 ECU Interface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.8 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.8.1 ECU Interface Connector CON1 . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.8.2 Debug Interface Connector CON5 . . . . . . . . . . . . . . . . . . . . . . . . 44

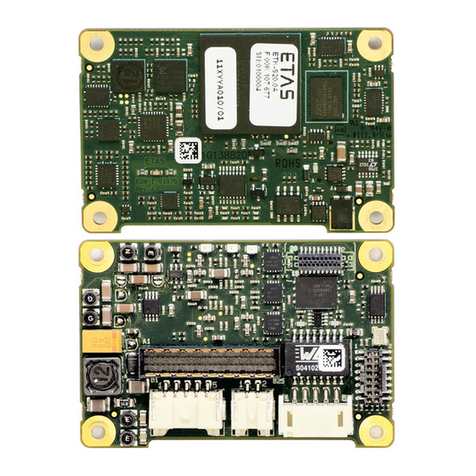

7.9 Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.9.1 ECU Interface Connector CON1 (ETK-S6.0 Configuration A) . . . . . 45

7.9.2 ECU Interface Connector CON1 (ETK-S6.0 Configuration B) . . . . . 46

7.9.3 Power Supply Connector CON2. . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.9.4 Debug Interface Connector CON5 . . . . . . . . . . . . . . . . . . . . . . . . 48

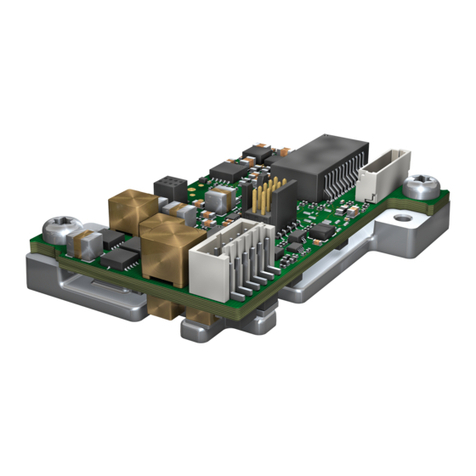

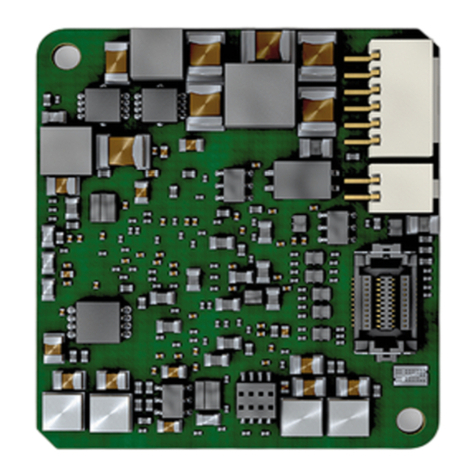

7.10 Mechanical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49