Introduction 1

Introduction

About DataTrack

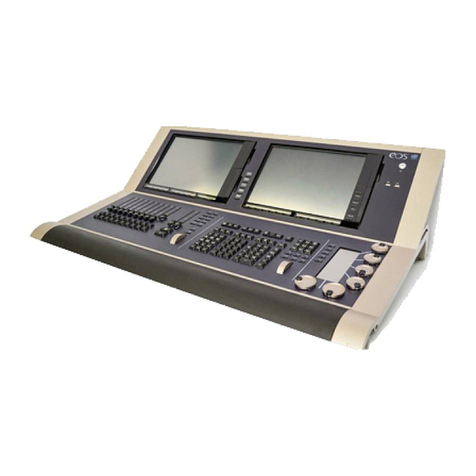

The DataTrack System from ETC is a professional-grade track system that offers built-in

DMX/RDM wiring with two separate circuits that can be independently switched or dimmed.

DataTrack can be used for hybrid systems using both conventional and LED fixtures.

DataTrack easily blends into its surroundings, providing power and data reliably and

discretely. It's the solution for a variety of permanent applications, including art galleries,

museums, retail displays, lobbies, comedy clubs, nightclubs, and venues with low ceilings or

the need to feed power and data to track-mounted luminaires.

The DataTrack System includes an extensive selection of adapters, feeds, end caps, couplers,

hanging accessories, and other accessories to fit most any installation requirements.

DataTrack offers:

• Two-circuit track with separate neutrals

• Up to 32 DMX devices per data run

• Up to 20 RDM devices per data run

• Suspended or surface mounting (recessed mounting also available; contact your local ETC

representative for more information)

• 3-amp, 5-amp, 8-amp, and 12-amp current-limiting breakers located directly at the track

• Up to 22 pounds of weight per foot when properly supported

• Two-year warranty

• White, black powder-coated, and silver anodized finishes

• 4 ft, 8 ft, and 12 ft (1.21 m, 2.43 m, and 3.65 m) sections that can be field-cut to custom lengths

as required

• Easy surface mounting using pre-punched holes positioned every 8 in (20.32 cm) in the track

(self-tapping screws can be used in places where there are no pre-punched holes)

Data

DataTrack provides integrated wiring for DMX-512A (ANSI E.1.11) and bidirectional RDM

(ANSI E1.20-2010) control signals. The electrical specifications of these DMX512A and RDM

standards are based on ANSI/TIA/EIA-485-A-1998.

DMX512A standards require a continuous daisy-chain data-link topology with a terminating

switch or resistor with a value of 100–120 ohms to eliminate ringing and signal reflection. No

"Tees" or "Stars" are permitted.

Wire used for bringing the DMX signal into the DataTrack system must be Belden 9729 or

equivalent with shield connected to ground at one end, preferably the signal source.

Load Capacity

DataTrack distributes one or two 120VAC circuits, up to 20A each. Each circuit has an

independent neutral for individual control and a common ground.

• Maximum Feed: 2 x 20A branch circuits

• Maximum Load: 2 x 2,400W (2.4kW)

• Supply Wiring: 5 x 12 AWG feed wires