C-PRO NANO HARDWARE MANUAL

Page 6

3Technical characteristics

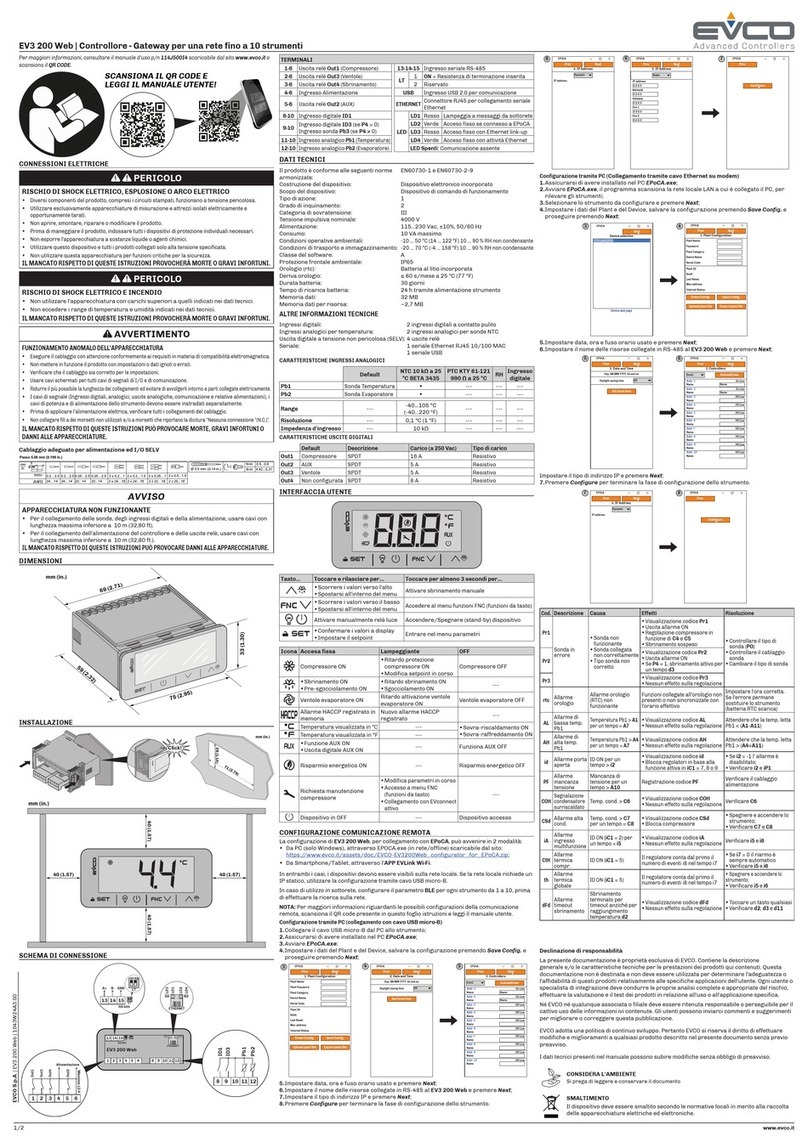

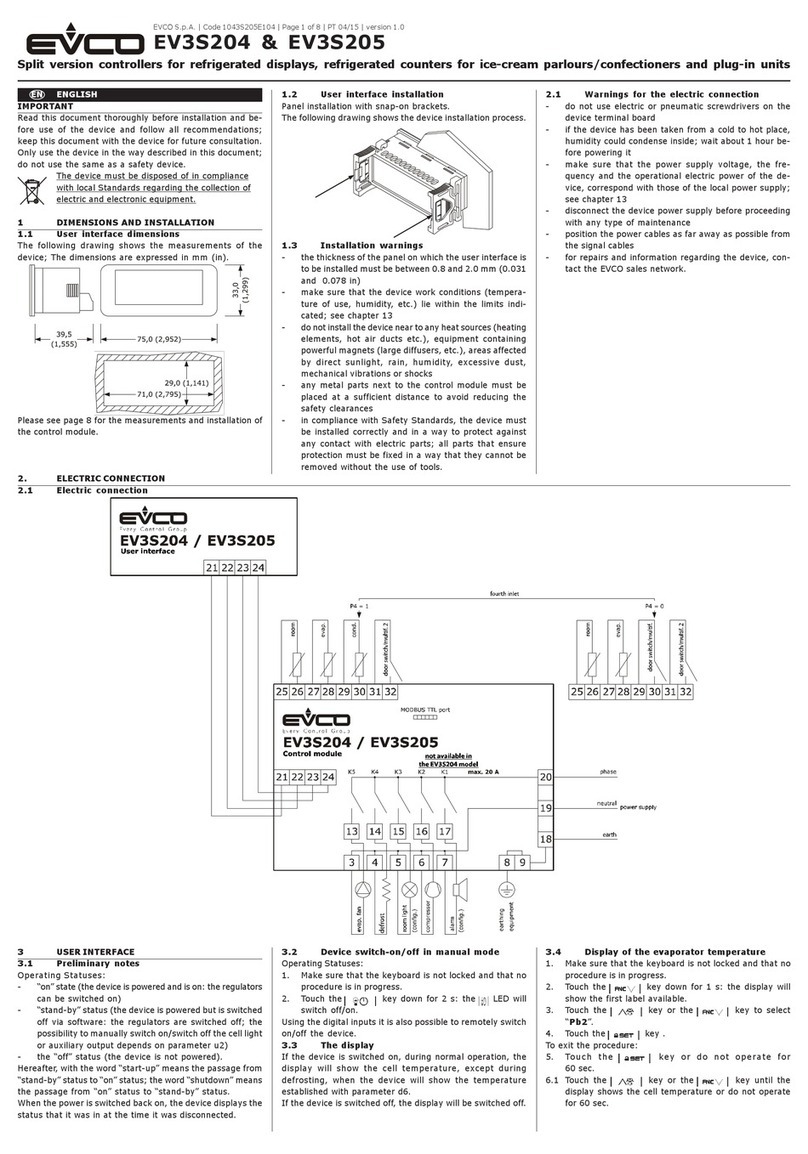

3.1 Connections

Power supply:

The C-PRO NANO is powered by a 12 V AC supply. It may also be powered by a 12 V DC supply; in this

case, there is no option for controlling the fan cut-off modules. The maximum length of the power supply

connecting cables is 1 m.

Analogue input connections:

The C-PRO NANO has two analogue inputs for NTC probes and two for NTC probes or for 0/4-20 mA or 0-5V

ratiometric transducers. Selection is made by the UNI-PRO development system. The current transducers may

be supplied by means of the 12 V DC terminal (refer to the physical layout) with a non-stabilised voltage equal

to 12 V DC. The maximum length of the analogue input connecting cables is 3 m.

Digital input connections:

The C-PRO NANO has 5 non-optoisolated digital inputs (clean contact). The maximum length of the digital

input connecting cables is 3 m.

Digital output connections:

The C-PRO NANO has up to 6 electromechanical relay digital outputs. The maximum length of the digital

output connecting cables is 3 m.

Analogue output connections:

The C-PRO NANO has 1 pulse modulation analogue output to drive the cut phase modules. The maximum

length of this analogue output connecting cables is 1 m.

The C-PRO NANO has 2 voltage or current (optional) analogue outputs. The maximum length of these

analogue outputs connecting cables is 3 m.

Remote terminal connections (IntraBus):

The connection between the C-PRO NANO and the terminal is made using a 3 way cable. The maximum

length of the terminal connection cables is 1 m if using a DC supply from the controller; 30 m where the wall-

mounted keypad is supplied using a separate transformer.

Remote expansions connection (IntraBus):

The connection between the C-PRO NANO and the I/O expansion units is made using a 3 way cable. The

maximum length of the remote I/O expansion units connecting cables is 1 m.

User interface connections (CAN):

The connection between C-PRO NANO and the remote user interface is made using a 2 way cable (better if it

is two weaved couples) plus possible ground.

The maximum length of the connection cables to the remote user interface depends of the CAN port baud rate .

- 1.000 m with 20.000 baud

- 500 m with 50.000 baud

- 250 m with 125.000 baud

- 50 m with 500.000 baud.

The CAN port baud rate is settable by parameter.