EVCO S.p.A. EV3 HP & EVD HP | Installer manual ver. 1.1 | Code 1443DHPE114

page 3 of 50

Index

1INTRODUCTION ......................................................................................................................................................... 5

1.1 Introduction .............................................................................................................................................................. 5

1.2 Models available, purchasing codes and technical features .............................................................................................. 6

2DESCRIPTION............................................................................................................................................................ 8

2.1 Description of EV3 HP ................................................................................................................................................. 8

2.2 Description of EVD HP................................................................................................................................................. 9

2.3 Description of EV3K01 .............................................................................................................................................. 10

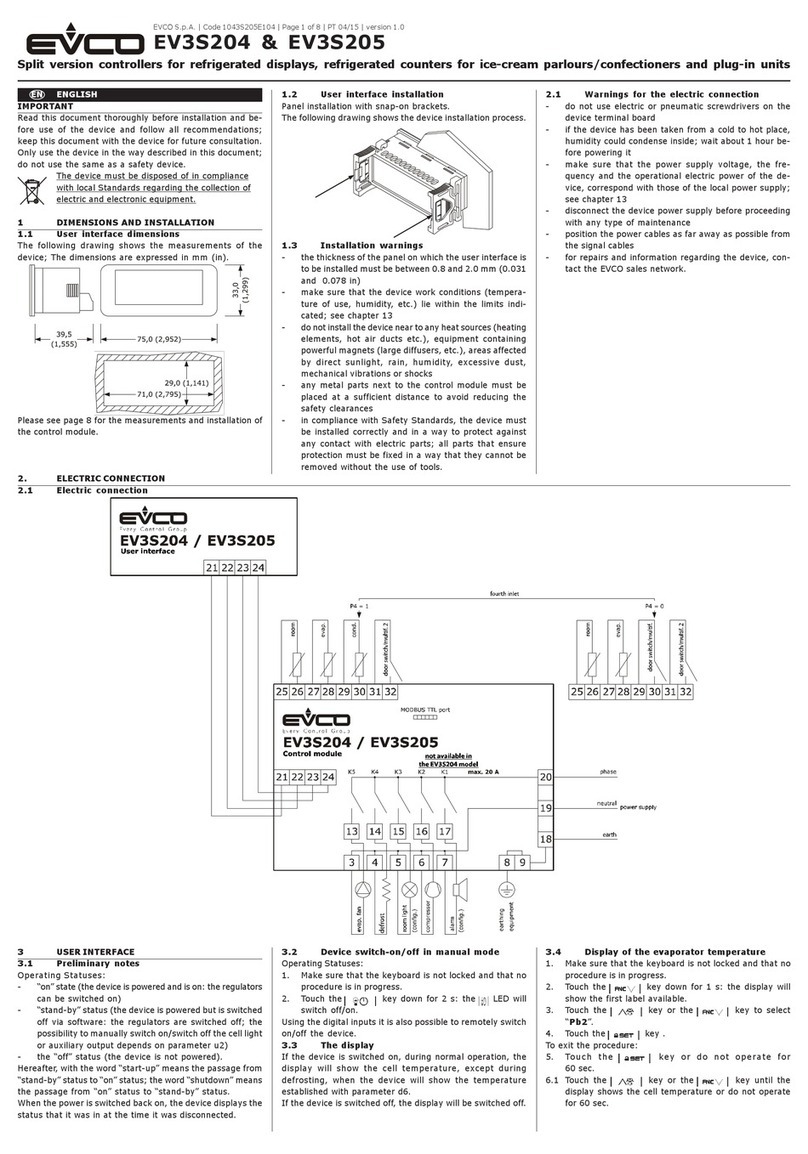

3MEASUREMENTS AND INSTALLATION ......................................................................................................................... 11

3.1 Measurements and installation of EV3 HP .................................................................................................................... 11

3.2 Measurements and installation of EVD HP ................................................................................................................... 11

3.3 Measurements and installation of EV3K01 ................................................................................................................... 13

3.4 Installation precautions............................................................................................................................................. 13

4ELECTRICAL CONNECTION ........................................................................................................................................ 14

4.1 I/O configuration ..................................................................................................................................................... 14

4.2 Description of connectors .......................................................................................................................................... 15

4.2.1 Description of connectors for EV3 HP .......................................................................................................................... 15

4.2.2 Description of connectors for EVD HP.......................................................................................................................... 17

4.2.3 Description of EV3K01 connectors .............................................................................................................................. 19

4.3 Fitting the termination resistor to the RS-485 MODBUS slave port.................................................................................. 20

4.4 Example of electrical connection ................................................................................................................................ 21

4.4.1 Example of EV3 HP electrical connection ..................................................................................................................... 21

4.4.2 Example of EVD HP electrical connection ..................................................................................................................... 22

4.5 Precautions for electrical connection ........................................................................................................................... 23

5DESCRIPTION OF USER INTERFACE ........................................................................................................................... 24

5.1 Key functions .......................................................................................................................................................... 24

5.2 Display ................................................................................................................................................................... 24

5.3 Signals ................................................................................................................................................................... 25

5.4 Menu ...................................................................................................................................................................... 27

5.4.1 Access levels ........................................................................................................................................................... 27

5.4.2 Menu list................................................................................................................................................................. 27

6LIST OF PARAMETERS .............................................................................................................................................. 28

6.1 Initial information .................................................................................................................................................... 28

7REGULATORS .......................................................................................................................................................... 33

7.1 Initial information .................................................................................................................................................... 33

7.2 Function mode......................................................................................................................................................... 33

7.3 Compressor............................................................................................................................................................. 33

7.3.1 Adjustment in cold mode .......................................................................................................................................... 33

7.3.2 Adjustment in hot mode ........................................................................................................................................... 34

7.3.3 Oil refresh............................................................................................................................................................... 34

7.4 Hydraulic pump ....................................................................................................................................................... 35

7.4.1 Initial information .................................................................................................................................................... 35

7.4.2 Function modes ....................................................................................................................................................... 35

7.4.3 Antifreeze function ................................................................................................................................................... 35

7.5 Electric heating elements .......................................................................................................................................... 36

7.5.1 Initial information .................................................................................................................................................... 36

7.5.2 Heating elements in integration mode ........................................................................................................................ 36

7.5.3 Heating elements in antifreeze mode.......................................................................................................................... 36

7.6 Condensation control ................................................................................................................................................ 37

7.6.1 Initial information .................................................................................................................................................... 37

7.6.2 Adjustment in cold mode .......................................................................................................................................... 37

7.6.3 Adjustment in hot mode ........................................................................................................................................... 38

7.7 Defrost ................................................................................................................................................................... 39

7.7.1 Initial information .................................................................................................................................................... 39

7.7.2 Start defrost control ................................................................................................................................................. 39