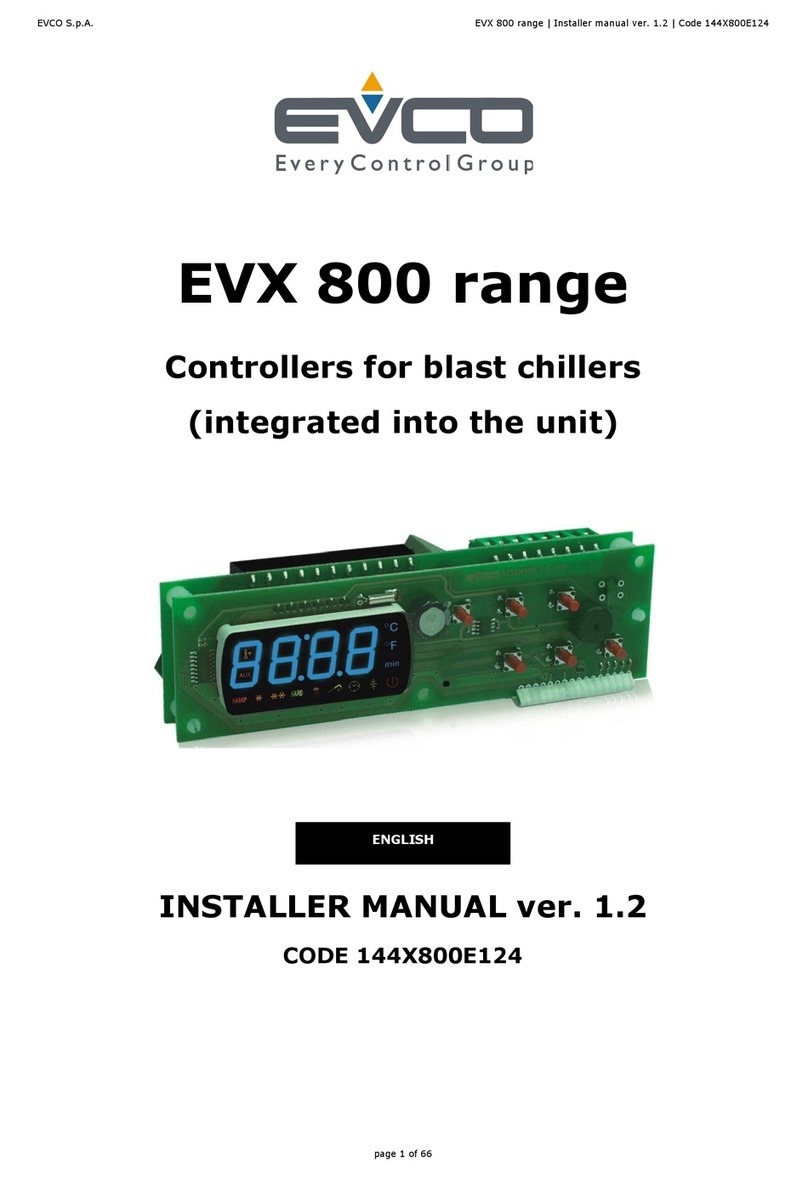

EVCO S.p.A. EVJS 800 | Installer manual ver. 1.1 | Code 144JS800E114

page 3 of 50

Index

1

INTRODUCTION ......................................... 4

1.1

Product description ..................................... 4

1.

Models available and hardware features ........ 5

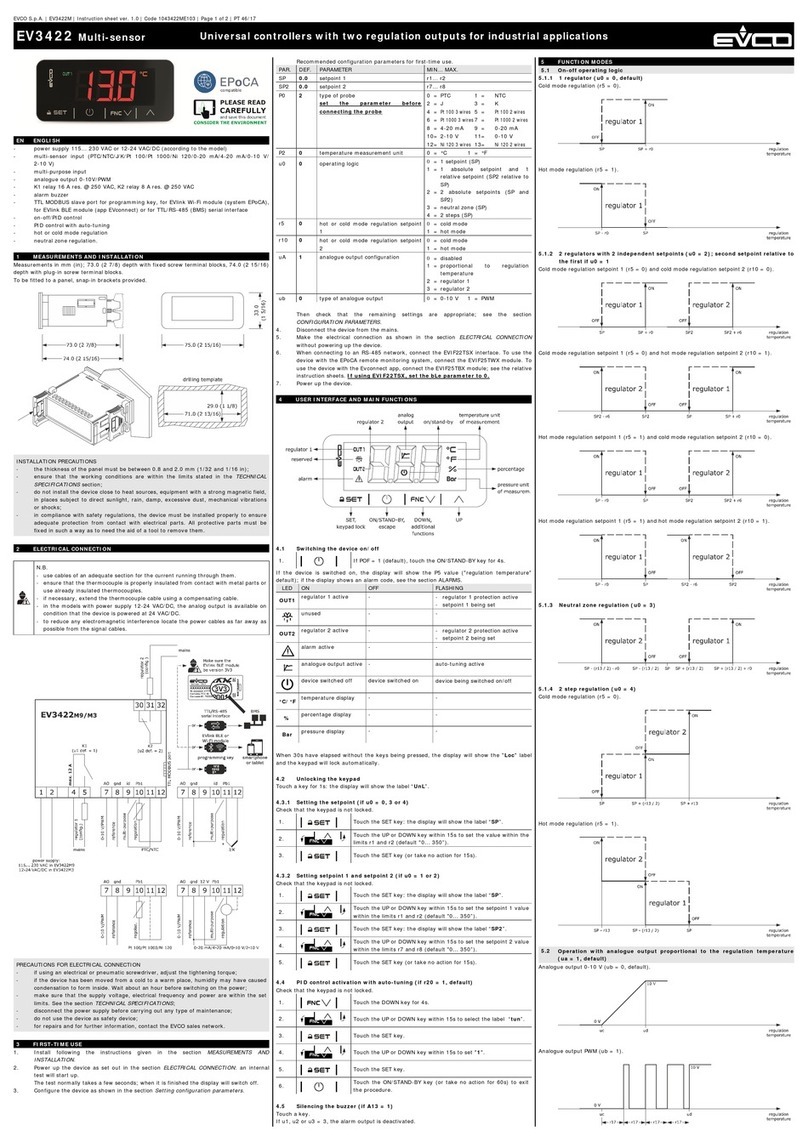

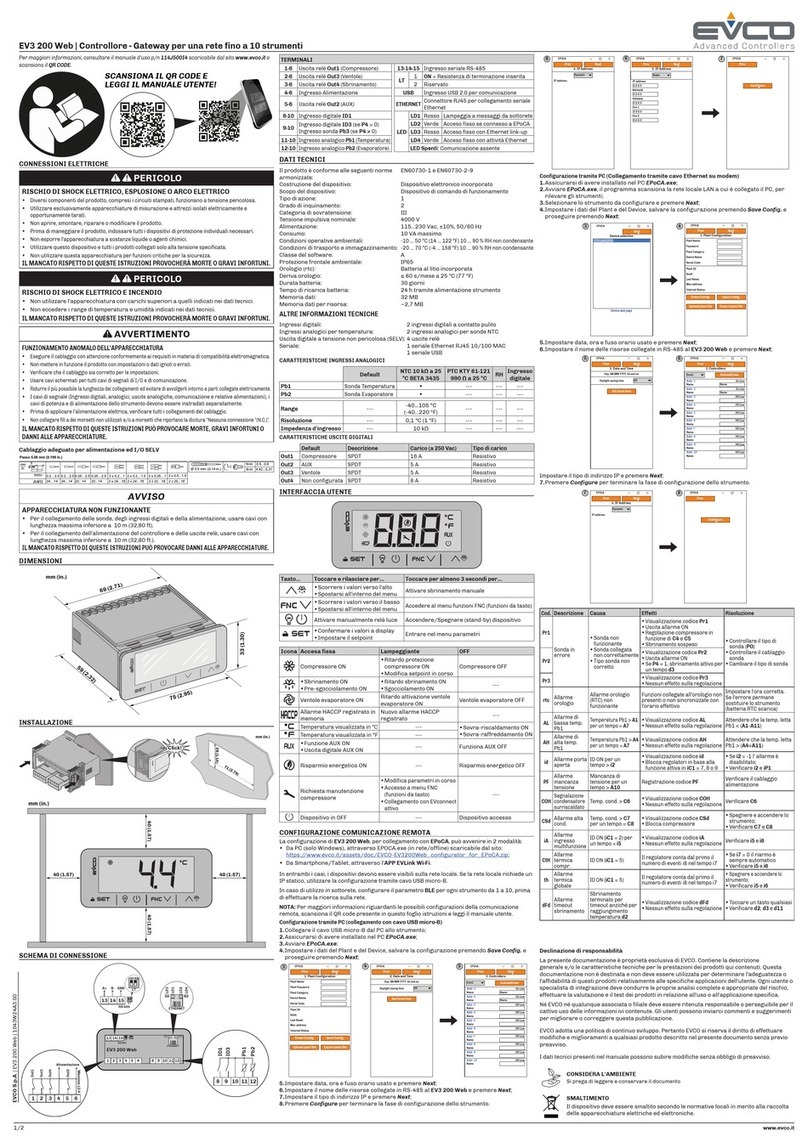

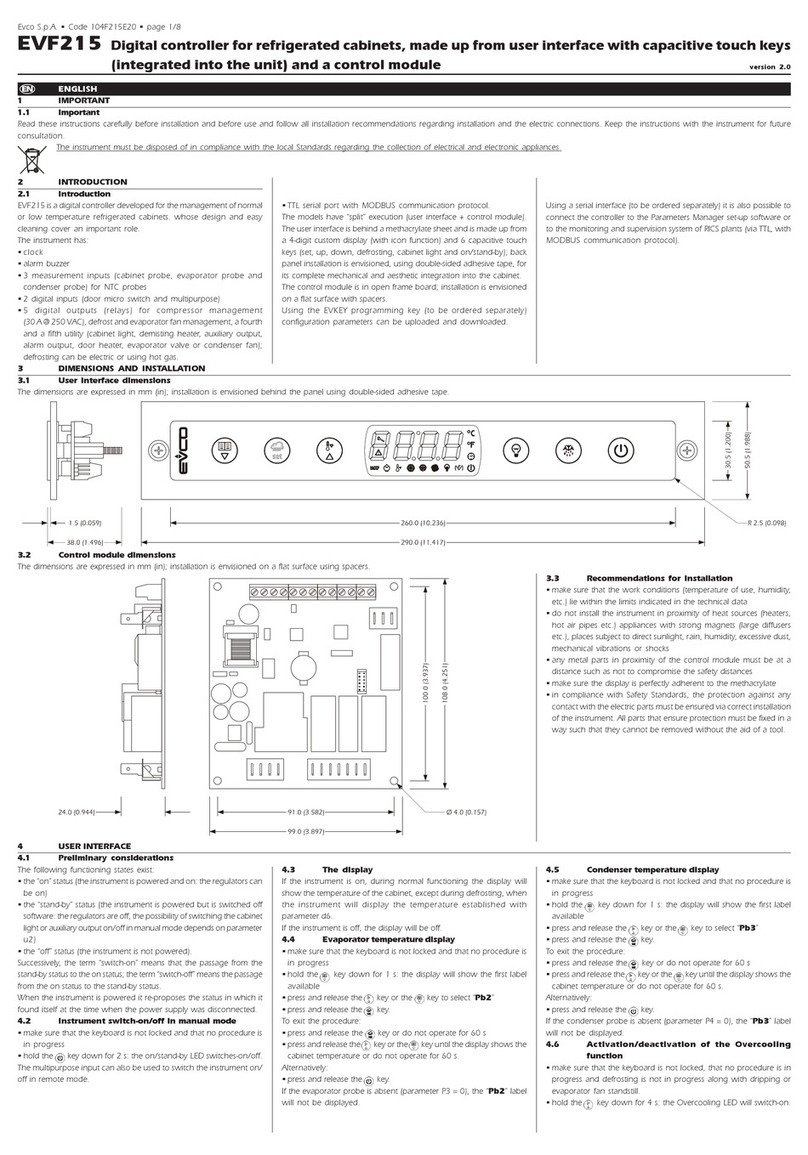

INSTALLATION........................................... 6

.1

Format features ......................................... 6

.

Measurements and installation ..................... 6

.3

Electrical connection ................................... 8

3

OPERATING THE DEVICE ............................. 9

3.1

Initial switch-on ......................................... 9

3.

Power failure ............................................. 9

3.3

Silencing the buzzer ................................... 9

4

DISPLAY ................................................. 10

4.1

Keys ....................................................... 10

4.

Icons ...................................................... 11

5

SETTINGS ............................................... 13

5.1

Initial information .................................... 13

5.

Languages .............................................. 13

5.3

Internal status ......................................... 13

5.4

Parameters ............................................. 13

5.5

HACCP alarms ......................................... 14

5.6

Restore data ............................................ 14

5.7

Real time clock ........................................ 14

6

FUNCTIONS ............................................. 15

6.1

Operating cycles ...................................... 15

6.

Needle probe insertion test........................ 16

6.3

Blast chilling/blast freezing and conservation ...

............................................................. 16

6.4

Pre-cooling .............................................. 18

6.5

Manual defrosting .................................... 19

6.6

Fish sanitation (if E13 = 1) ........................ 0

6.7

Ice cream hardening (if E13 = 1) ............... 1

6.8

Thawing .................................................. 1

6.9

Cabinet sterilisation .................................. 3

6.10

Heating the needle probe ...................... 3

6.11

Drying (only EVS815) ........................... 4

6.1

Recipes ............................................... 5

7

MANAGING THE LOADS ............................. 7

7.1

Door frame heating .................................. 7

7.

Compressor ............................................. 7

7.3

Evaporator fans ....................................... 8

7.4

Condenser fans ........................................ 8

7.5

Alarm ..................................................... 9

7.6

Needle probe heating ................................ 9

7.7

Cabinet sterilisation .................................. 9

7.8

Defrosting ............................................... 9

7.9

Thawing heaters ...................................... 9

7.10

Cabinet light ........................................ 9

8

CONFIGURATION PARAMETERS .................. 30

9

ALARMS .................................................. 39

9.1

Alarms .................................................... 39

10

ACCESSORIES ......................................... 43

10.1

Programming key ................................. 43

10.

TTL/RS-485 signal conversion module ..... 43

10.3

EVlinking BLE module ........................... 43

10.4

EVlinking Wi-Fi TTL module .................... 43

10.5

EV3 Web IoT Gateway........................... 44

11

TECHNICAL SPECIFICATIONS .................... 45

11.1

Technical specifications ......................... 45