Evco S.p.A. • Code 104K004E05 • page 2/6

• press any key (the first key press does not trigger the associated effect).

If parameter u1 is set to 4 (or the service controlled by the fourth output

is the alarm output) and parameter u4 is set to 1, then pressing he key

will also deactivate the alarm output.

3 SETTINGS

3.1 Setting the date and time (clock)

• ensure the keyboard is not blocked and that no procedures are

running

• press for 2 s: the display will show the first available label

• press or to select “rtc”.

To modify the year:

• press within 60 s: the display will show "yy" followed by the

last two digits of the year

• press or within 15 s.

To modify the month:

• press within 15 s: the display will show "nn" followed by the

two digits for the month

• press or within 15 s.

To modify the day of the month:

• press within 15 s: the display will show "dd" followed by the

two digits for the day

• press or within 15 s.

To modify the hours:

• press within 15 s: the display will show "hh" followed by the

two digits for the hour

• press or within 15 s.

To modify the minutes:

• press within 15 s: the display will show "nn" followed by the

two digits for the minutes

• press or within 15 s

• press or do not operate the keypad for 15 s.

To exit the procedure:

• press or until the display shows the quantity assigned by

parameter P5 or do not operate the keypad for

60 s.

Alternatively:

• press

3.2 Setting the operational setpoint

• ensure the keyboard is not blocked and that no procedures are

running

• press the LED will flash

• press or within 15 s; also see parameters r1, r2 and r3

• press or do not operate the keypad for 15 s.

It is also possible to set the operational setpoint by means of parameter

SP.

3.3 Setting the configuration parameters

To access the procedure:

• ensure no procedures are running

• press and for 4 s: the display will show “PA”

• press

• press or within 15 s to set “-19”

• press or do not operate the keypad for 15 s

• press and for 4 s: the display will show “SP”.

To select a parameter:

• press or

To select a parameter:

• press

• press or within 15 s

• press or do not operate the keypad for 15 s.

To exit the procedure:

• press and for 4 s or do not operate the keypad for 60 s.

Interrupt the device power supply after altering the param-

eters.

3.4 Resetting configuration parameter default values

• ensure no procedures are running

• press and for 4 s: the display will show “PA”

• press

• press or within 15 s to set “743”

• press or do not operate the keypad for 15 s

• press and for 4 s: the display will show “dEF”

• press

• press or within 15 s to set “149”

• press or do not operate the keypad for 15 s: the display will flash

"dEF" for 4 s, after which the device will exit the proce-

dure

• interrupt the power to the device.

Ensure that the parameter default values are appropriate,

particularly if the probes are PTC or Pt 1000 type.

4 HACCP

4.1 Introductory comments

The device is capable of storing up to 9 HACCP alarms, after which the

most recent alarm will overwrite the oldest.

The device can furnish the following information:

• the critical value

• the data and time at which the alarm occurred

• the alarm duration (from 1 minute to 99 hours and 59 minutes,

partial if the alarm is ongoing).

CODE ALARM TYPE (AND CRITICAL VALUE)

AL minimum temperature alarm (the minimum temperature

of the cabinet, the minimum CPT temperature or the mini-

mum temperature detected by the auxiliary probe during

the alarm state)

AH maximum temperature alarm (the maximum temperature

of the cabinet, the maximum CPT temperature or the maxi-

mum temperature detected by the auxiliary probe during

the alarm state)

id microport input alarm (the maximum temperature of the

cabinet or the maximum CPT temperature during the alarm

state); see also parameter i4

PF power failure alarm (the temperature of the cabinet or the

CPT temperature on restoration of the power supply); see

also parameter AA

Warnings:

•the device records minimum temperature alarms and

maximum temperature alarms providing the temperature

associated with the alarm is the cabinet

temperature(parameters A0 and A3 = 0 and parameter

P4 = 0, 1, 2 or 3), the CPT temperature (parameters A0 and

A3 = 0 and parameter P4 = 4) or the temperature meas-

ured by the auxiliary probe, providing its function is that

of display probe (parameter P4 = 1 and parameters A0 = 2

and A3 = 1)

•in order to avoid repeatedly recording power failure alarms,

disconnect the device power supply while in stand by

mode

•if the duration of a power failure alarm is such as to

cause a clock error, then the device will not provide any

information regarding alarm duration

•no alarms will be recorded if the device is in stand-by

mode.

When the cause of the alarm is resolved, the display returns to normal,

except in the case of a power failure alarm where normal display

function must be restored manually.

To restore the normal display manually:

• press any key.

If parameter u1 is set to 4 (or the service controlled by the fourth output

is the alarm output), then pressing any key will also deactivate the

alarm output.

The HACCP LED provides information relating to the status of the

HACCP alarm memory; please refer to paragraph 6.1.

4.2 Viewing HACCP alarm information

To access the procedure:

• ensure the keyboard is not blocked and that no procedures are

running

• press for 2 s: the display will show the first available label

• press or to select “LS”

• press the display will show the most recent alarm code, or one

of the codes reported in the table in paragraph 4.1 fol-

lowed by the number "1" (the higher the number follow-

ing the code, the older the alarm).

To select an alarm:

• press or (to select "AH3" for example).

To display the information relating to the alarm:

• press the HACCP LED will stop flashing and remain on and the

display will show the following information in succes-

sion (for example):

INFO MEANING

8,0 the critical value is 8.0 °C/8 °F

StA the display is about to show the data and time at which the

alarm occurred

y07 the alarm occurred in 2007 (continued ...)

n03 the alarm occurred in the month of march (continued ...)

d26 the alarm occurred on 26 March 2007

h16 the alarm occurred at 16 hours (continued ...)

n30 the alarm occurred at 16:30 hours

dur the display is about to show the alarm duration

h01 the alarm lasted for 1 hour (continued ...)

n15 the alarm lasted for 1 hour and 15 minutes

AH3 the selected alarm

The display shows each piece of information for 1 s.

To exit the information series:

• press the display will show the selected alarm.

To exit the procedure:

• exit the information series

• press or until the display shows the quantity assigned by

parameter P5 or do not operate the keypad for

60 s.

Alternatively:

• exit the information series

• press

If the instrument has stored no alarm, the label “LS” will not be shown.

4.3 Deleting the HACCP alarm list

• ensure the keyboard is not blocked and that no procedures are

running

• press for 2 s: the display will show the first available label

• press or to select “rLS”

• press

• press or within 15 s to set “149”

• press or do not operate the keypad for 15 s: the display will flash

"- - - -" for 4 s and the HACCP LED will be turned off, after

which the device will exit the procedure.

If the instrument has stored no alarm, the label “rLS” will not be shown.

5 COMPRESSOR OPERATION TIME COUNTER

5.1 Introductory comments

The device is capable of recording up to 9,999 hours of compressor

function, after which the number "9999" flashes.

5.2 Displaying the compressor operation time

• ensure the keyboard is not blocked and that no procedures are

running

• press for 2 s: the display will show the first available label

• press or to select “CH”

• press

To exit the procedure:

• press or do not operate the keypad for 60 s

• press or until the display shows the quantity assigned by

parameter P5 or do not operate the keypad for

60 s.

Alternatively:

• press

5.3 Resetting the compressor operation time

• ensure the keyboard is not blocked and that no procedures are

running

• press for 2 s: the display will show the first available label

• press or to select rCH”

• press

• press or within 15 s to set “149”

• press or do not operate the keypad for 15 s: the display will flash

"- - - -" for 4 s, after which the device will exit the procedure.

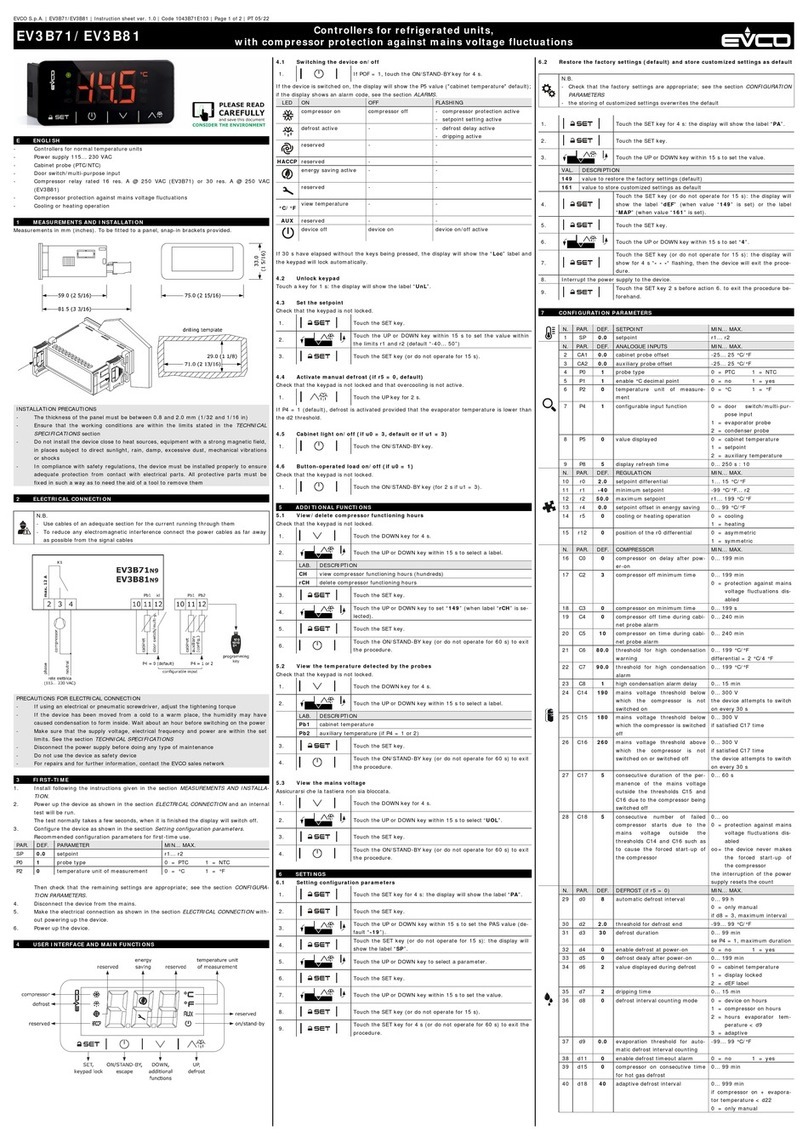

6 INDICATORS

6.1 Indicators

LED MEANING

compressor LED

if on then the compressor is on

if flashing:

• the operational setpoint is being changed

• compressor protection is ongoing (parameters C0, C1,

C2 and i7)

defrosting LED

if on, defrosting ongoing

if flashing:

• defrosting has been requested, but compressor protec-

tion is ongoing (parameters C0, C1 and C2)

• drip-draining is ongoing (parameter d7)

• refrigerant fluid heating is ongoing (parameter dA)

Evaporator fan LED

if on then the evaporator fan is on

if flashing, then evaporator fan stop is ongoing (parameter

F3)

HACCP HACCP LED

if on, you will have not shown all the information on the

HACCP alarms

if flashing, the instrument will have stored at least one new

HACCP alarm

if off, you will have shown all the information on the HACCP

alarms or you will have cancelled the list of the HACCP

alarms

Maintenance LED

if on, compressor maintenance will be required (param-

eter C10)

alarm LED

if on, an alarm state or an error is ongoing

on/stand-by LED

if on, the device is in stand-by mode

°Cdegree Celsius LED

if on, the unit of measurement for temperature is degrees

Celsius (parameter P2)

if flashing, then the Energy Saving function is in operation

(parameters r4, i5, HE1 and HE2)

°Fdegree Fahrenheit LED

if on, the unit of measurement for temperature is degrees

Fahrenheit (parameter P2)

if flashing, then the Energy Saving function is in operation

(parameters r4, i5, HE1 and HE2)

Multifunction LED

parameter u1 is set to 0 (i.e. the service control-

led by the fourth output is the cabinet light)

if on, the cabinet light will have been switched on manu-

ally

if flashing, the cabinet light will have been turned on re-

motely (parameter i0)

parameter u1 is set to 1, 4, 5, 6 or 7

if on, the service controlled by the fourth output will be

turned on

parameter is set to 2 (i.e. the service controlled

by the fourth output is the auxiliary output)

if on, the auxiliary output will have been turned on manu-

ally

if flashing, the auxiliary output will have been turned on

remotely (parameter i5)

parameter u1 is set to 3 (i.e. the service control-

led by the fourth output is compressor 2)

if on, compressor 2 is on

if flashing, compressor 2 delay is ongoing (parameter C9)