5

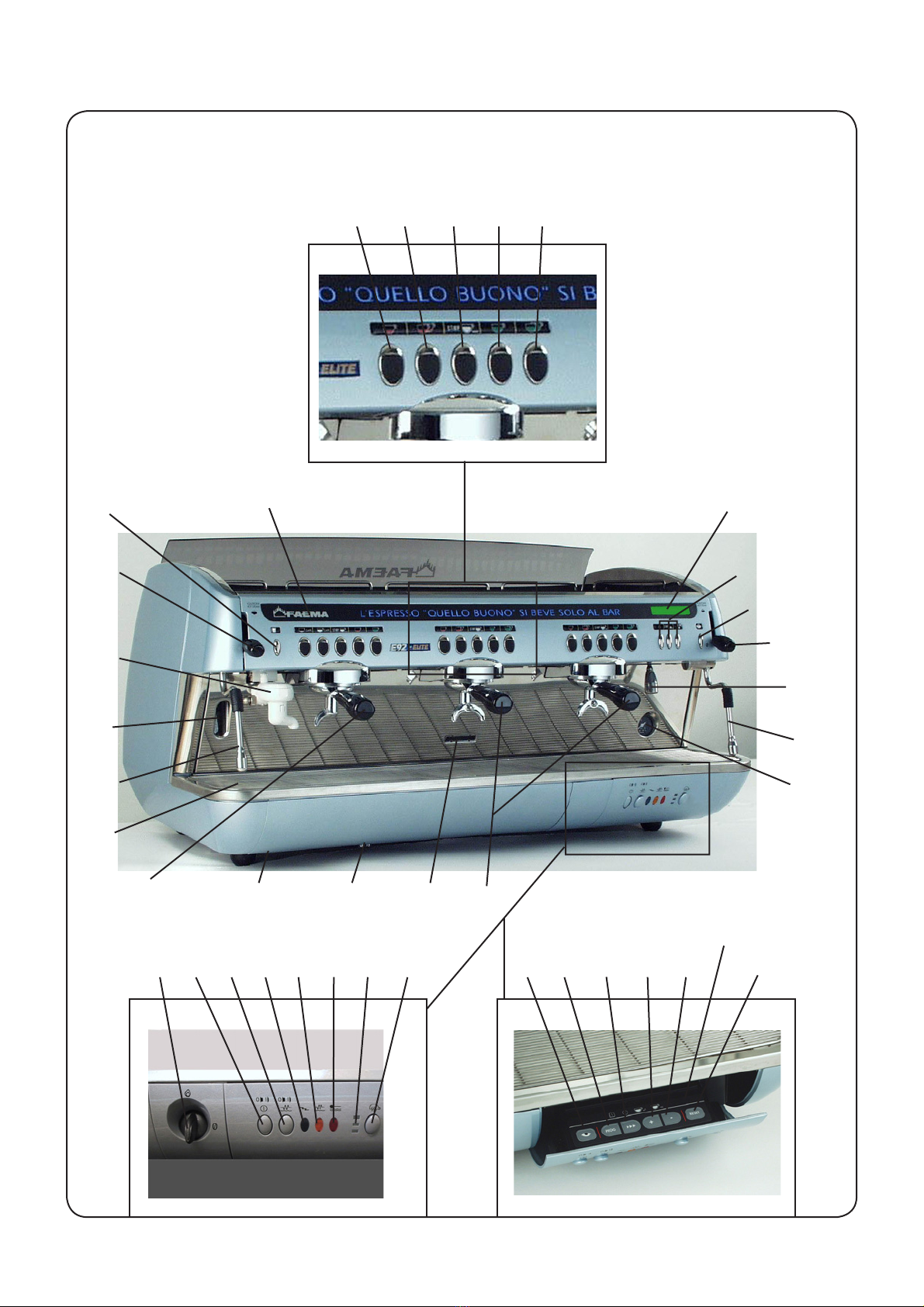

Legende - Leyenda - Legenda

LEGENDE

1Hauptschalter

1a Schalter zur Aktivierung der

Wasserkesselbeheizung

2Kontrolleuchte ‘Maschine

eingeschaltet’ (grün)

3Kontrolleuchte Heizelemente (orange)

4Kontrolleuchte (Standanzeige)

Wasserzuführung in Kessel (rot)

5Kontrolleuchte Tassenvorwärmer

/('

6Taste „Tassenvorwärmer"

8Manometer

9Dampfrohr rechs

10 Heißwasserausgabe

11 Hebel Dampfausgabe (9 Rechtes)

12 Taste „automatische Dampfabgabe“

$87267($0

13a Heißwasserausgabe (Dosis 1/STOP)

13b Stopp-Taste (Fortsetzung

Heißwasserabgabe)

13c Heißwasserausgabe (Dosis 2/STOP)

14 Display alfanymmering

15 Werbedisplay

15Idp Taste Werbedisplay

16 Taste „Milchabgabe

'DPSIDEJDEH

17 Hebel Dampfausgabe (20 Linkes)

18 Cappuccinatore

19 Optische Anzeige des

Wasserstandes im Kessel

20 Dampfrohr links

21 Filterhalter für 1 Tasse

22 Hebel manuelle füllung Wasser in

Kessel

23 .RQWUROO|IIRXQJIU*DVÀDPPH

24 5HJOHU7DVWH*DVYHQWLO

25 Filterhalter für 2 Tassen

26 Taste Kaffeeausgabe 1 Tasse

(Ristretto)

27 Taste Kaffeeausgabe 2 Tassen

(Ristretto)

28 Taste Kaffeeausgabe 1 Tasse

(gross)

29 Taste Kaffeeausgabe 2 Tassen

(gross)

30 Taste Kaffeeausgabe kontinuierlich

und STOP

31 Taste zur Menüabbildung

32 Programmiertaste (PROG)

33 Pfeiltasten

34 Plus-Taste (+)

35 Minus-Taste (-)

36 Taste Rücksetzung (Reset)

37 Tastenfeld zur Programmierung

91 Wanne zur Tassenablage

'LHPLWJHNHQQ]HLFKQHWHQ

Komponenten sind nur in bestimmten

Modellen installiert.

LEYENDA

1Interruptor general

1a Interruptor accionamiento

resistencias caldera

2Indicador luminoso máquina

encendida (verde)

3Indicador luminoso conexión

resistencias caldera (naranja)

4Indicador luminoso (nivel) carga

agua en la caldera (roja)

5Indicador luminoso calienta-tazas

HQFHQGLGR/('

6Botón calienta-tazas

8Manómetro

9Tubo derecho erogación vapor

10 Tubo erogación agua caliente

11 Palanca erogación vapor tubo

(9derecha)

12 Botón vapor automático

$87267($0

13a Botón erogación agua caliente

(dosis 1/STOP)

13b Botón stop – continuo agua

caliente

13c Botón erogación agua caliente

(dosis 2/STOP)

14 Visualizador alfanumérico

15 Display publicitario

15Idp Interruptor display publicitario

16 %RWyQOHFKHYDSRU

17 Palanca erogación vapor tubo

(20 sx)

18 Cappuccinador

19 Indicador nivel óptico agua en la

caldera

20 Tubo izquierdo erogación vapor

21 3RUWD¿OWURSDUDXQDWD]D

22 Palanca llenado manual agua en la

caldera

23 Ventanilla para control llama

24 0DQJRERWyQJULIRJDV

25 3RUWD¿OWURSDUDGRVWD]DV

26 Botón erogación un café corto

27 Botón erogación dos cafés cortos

28 Botón erogación un café largo

29 Botón erogación dos cafés largos

30 Botón erogación continua/STOP

31 Botón visualización cuadros

32 Botón PROG

33 %RWyQÀHFKDV

34 Botón incremento valores (+)

35 Botón disminución valores (-)

36 Botón reset

37 Panel mandos de programación

91 Bandeja apoya-tazas

/RVGHWDOORVVHSXHGHQDSOLFDUVyORHQ

DOJXQDVFRQ¿JXUDFLRQHVGHOSURGXFWR

LEGENDA

1Interruptor geral

1a Interruptor de inserimento de

resistências da caldeira

2Indicador luminoso da máquina

acesa (verde)

3Indicador luminoso de inserimento

das resistências da caldeira (laranja)

4Indicador luminoso (nível) de

carregamento da água na caldeira

(vermelho)

5Indicadoresluminososdoaquecedor

GHFKiYHQDVDFHVR/('

6 %RWmRGRDTXHFHGRUGHFKiYHQDV

8Manómetro rede/bomba

9 /DQoDGLUHLWDGHGLVWULEXLomRGRYDSRU

10 /DQoDGHGLVWULEXLomRGDiJXDTXHQWH

11 $ODYDQFDGHGLVWULEXLomRGRYDSRU

QDODQoD9 dir)

12 %RWmRGHYDSRUDXWRPiWLFR

$87267($0

13a %RWmR GH GLVWULEXLomR GD iJXD

quente (dose 1/STOP)

13b %RWmRVWRS±FRQWtQXRGDiJXDTXHQWH

13c %RWmR GH GLVWULEXLomR GD iTXD

quente (dose 2/STOP)

14 Mostrador alfanumérico

15 Mostrador publicitário

15Idp Interruptor do mostrador, publicitário

16 %RWmRGROHLWHYDSRU

17 $ODYDQFDGHGLVWULEXLomRGRYDSRU

ODQoD20 esq)

18 3UHSDUDGRUGHFDSSXFFLQR

19 Indicador de nível óptico da água

na caldeira

20 /DQoDHVTXHUGDGHGLVWULEXLomRGR

vapor

21 3RUWD¿OWURSDUDXQDFKiYHQD

22 Alavanca de enchimento manual

da água na caldeira

23 Janelinha para o controle da chama

24 0DQtSXORERWmRGDWRUQHLUDGRJiV

25 3RUWD¿OWURSDUDGXDVFKiYHQDV

26 %RWmRGHGLVWULEXLomRGHXPFDIpIRUWH

27 %RWmRGHGLVWULEXLomRGHGRLVFDIpV

fortes

28 %RWmRGHGLVWULEXLomRGHGRLVFDIpV

cimbalinos

29 %RWmRGHGLVWULEXLomRGHGRLVFDIpV

cimbalinos

30 %RWmRGHGLVWULEXLomRFRQWtQXD6723

31 %RWmRGHYLVXDOL]DomRGRVTXDGURV

GHSURJUDPDomR

32 %RWmR352*

33 %RWmRGDVVHWDV

34 %RWmRGHDXPHQWRGRVYDORUHV

35 %RWmRGHGLPLQXLomRGRVYDORUHV

36 %RWmRGHUHDUPH

37 7HFODGRGHSURJUDPDomR

91 Bacia para apoiar as chávenas

2VFRPSRQHQWHV³³±VmRDSOLFDGRVDSHQDV

VREUHDOJXPDVFRQ¿JXUDo}HVGHSURGXWRV

D E P