37Revisione - 13 Date 01-2016

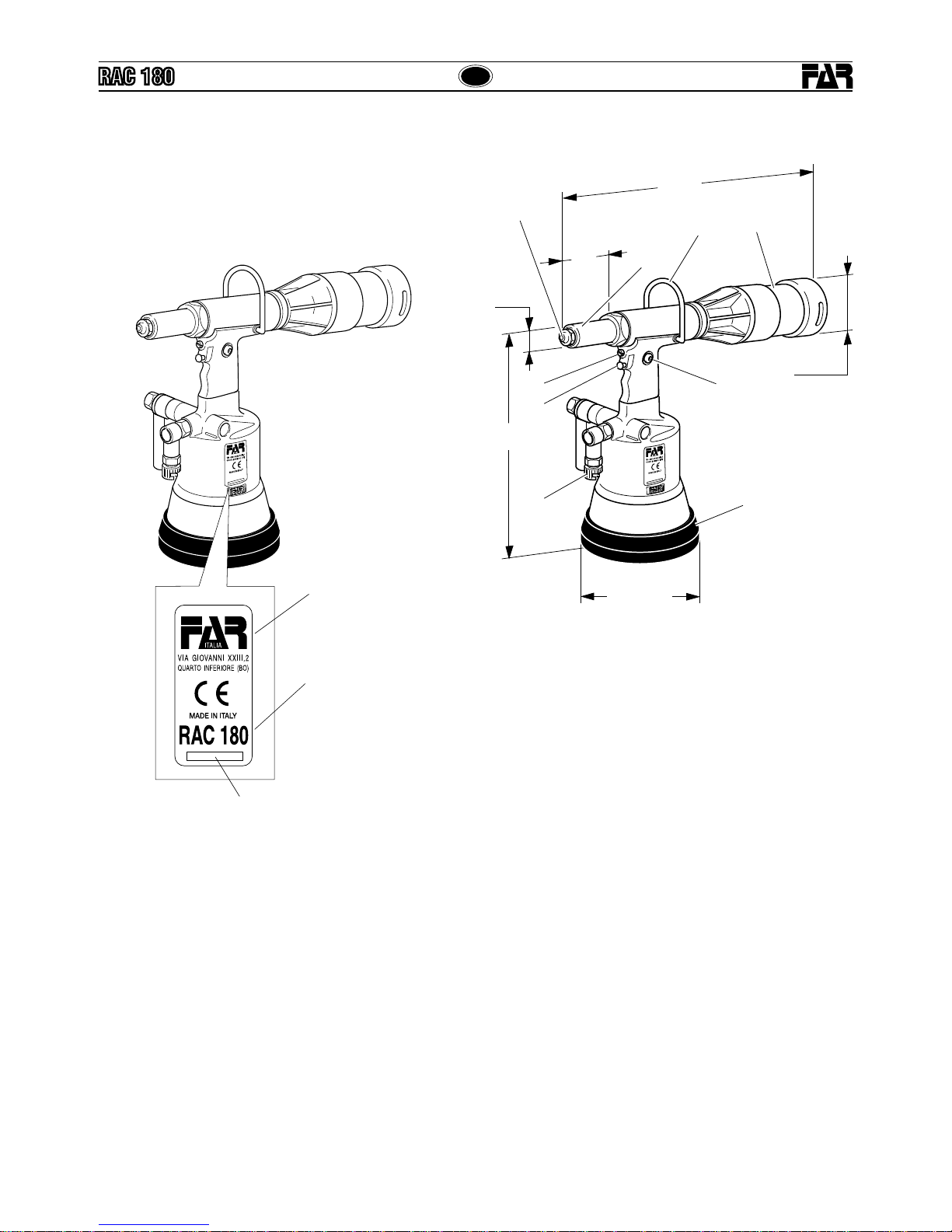

RAC 180 GB

002 712716 1 Body cover

003 710300 1 Gasket OR 020

004A 710837 1 Screw TE M9 x 20 A

005 710920 1 Gasket OR 2-337

006 720815 1 Pneumatic piston

007A 710836 1 Washer A

008 710860 1 Rod

009A 710829 1 Shock absorber A

010 710915 1 Gasket OR 2-124

011 710931 1 Gasket OR 614

012 710856 1 Rod guide connector

013 710390 1 Gasket B-075047

014 711827 1 Gasket TTS-12-19-5,7 / L

015 710914 1 Gasket OR 2-116

017 710402 1 Seeger ring 22 UNI 7437

018 710922 2 Gasket OR 018

019 712268 1 Spring guide plug

020 710905 1 Seeger ring 11 UNI 7437

021 710258 1 Gasket OR 5-612

022 710822 1 Valve piston

024 710916 2 Gasket OR 2-015

025 710841 1 Coil

026 710853 1 Springs

027B 710823 3 Cage B

028B 710921 3 Gasket OR 2-115 B

029B 710840 1 Valve spacer B

031 720811 1 Riveting tool body

032 710350 1 Gasket OR 2-109

033 711304 1 Silencer 1/4"

034 710906 1 Washer 400-020-4490

035 710839 1 Oil tank plug

038 710909 1 Connector 2023 - 1/4"- 1/4"

041 710838 1 Out put connector

042 710824 1 Push button

043 710919 1 Gasket OR 2-004

044 710847 1 Valve body

045 710528 2 Gasket OR 008

046 710848 1 Valve piston

047 710918 1 Gasket OR 2-005

048 710385 4 Gasket OR 2-006

049 710842 1 Suction regulation knob

050 720812 1 Handgrip

054 710816 1 Oil-dynamic cylinder

055 717004 1 Nozzle for rivet ø 4,8 Cu / Steel

056 710843 1 Sleeve carrying nozzle

057 710859 1 Clamps holding cone

058 71345507 3 High-performance clamps

059 710849 1 Clamps opener

060E 710819 1 Nails container E

061G 710834 1 Suction sleeve G

062 710102 1 Gasket OR 113

063G 710858 1 Cone holder G

064G 710832 1 Expeller extension G

065 710854 1 Balancer hook

066 710917 1 Gasket OR 2-118

067 710855 1 Sleeving gasket

068 710577 1 Gasket B-086055

069 710908 1 Washer

070C 711973 1 Seeger ring AV 16 C

071C 710845 1 Stop ring C

072 710901 1 Gasket B-102070

073C 710821 1 Anti-extrusion ring C

074 712281 1 Piston

075D 710852 1 Spring D

076D 710851 1 Spring D

077 710850 1 Spring guide plug

078 710818 1 Container connector

079 717006 1 Nozzle for rivet ø 2,4

080 717001 1 Nozzle for rivet ø 2,5 ÷ 3,4

No. CODE Q.ty DESCRIPTION KIT

081 717002 1 Nozzle for rivet ø 4

082 717003 1 Nozzle for rivet ø 4,8 All.

083 717005 1 Nozzle for rivet ø 6 / 6,4

084 721387 1 Oil container

085 711092 1 Wrench 5 mm

086B 711158 1 Spring B

087E 711136 1 Air conveyor E

088 711305 1 Connector 1631-01 - 1/4"

089F 710186 1 Gasket OR 010 F

090F 711401 1 End bush F

095 711974 1 Seeger ring JV 22

096 711736 1 Protection bottom

097 712162 1 Outside silencer protection

098 710831 1 Tube ø 8 x 7

099 712117 1 Washer

100 712133 1 Rotating connector

KIT

No. CODE Q.ty DESCRIPTION

KITA 740837 Screw stem kit

004A 710837 1 4DSFX5&.Y

007A 710836 1 Washer

009A 710829 1 Shock absorber

KITB 740840 Valve spacer kit

027B 710823 3 Cage

028B 710921 3 Gasket OR 2-115

029B 710840 1 Valve spacer

086B 711158 1 Spring

KITC 740821 Anti-extrusion ring kit

070C 711973 1 Seeger ring AV 16

071C 710845 1 Stop ring

073C 710821 1 "OUJFYUSVTJPOSJOH

KITD 740851 Spring reversal piston Kit

075D 710852 1 Spring

076D 710851 1 Spring

KITE 740819 Nails container kit

060E 710819 1 Nails container

087E 711136 1 Air conveyor

KITF 741401 End bush kit

089F 710186 1 Gasket OR 010

090F 711401 1 End bush

KITG 740858 Cone holder kit

061G 710834 1 Suction sleeve

063G 710858 1 Cone holder

064G 710832 1 &YQFMMFSFYUFOTJPO

KIT It indicates that the part is sold in kits consisting of different

parts in different quantities.

No. CODE Q.ty DESCRIPTION KIT

SPARE PARTS