Felix Storch 2.0 User manual

Instruction manual

Felix 2.0, 3d printer-kit

Version2 –12-April-2013

Copyright Information

This document contains proprietary information that is protected by copyright. No part of this document may be photocopied, reproduced, or translated

to another language without the prior written consent of FELIXrobotics.

FelixRobotics

Wapendragervlinder 17

3544DL Utrecht

Netherlands

Copyright © 2013 FELIXrobotics.

1CONTENTS

2Introduction............................................................................................................................................................................................................................................... 4

3Specifications ............................................................................................................................................................................................................................................ 5

4Required toolset........................................................................................................................................................................................................................................ 6

5Required skills........................................................................................................................................................................................................................................... 7

6Important note.......................................................................................................................................................................................................................................... 7

7Module 1: Frame (time: 10-30 minutes).............................................................................................................................................................................................. 8

8Module 2: Z-axis (time: 45-90 min.)..................................................................................................................................................................................................12

9Module 3: The Extruder (time: 30-90 min.).......................................................................................................................................................................................18

10 Module 3: The X-axis (time: 30-60 min.)...........................................................................................................................................................................................24

11 Module 5: Table (time: 1-2 hours) ......................................................................................................................................................................................................29

12 Module 6: Y-axis (time: 10-30 min.)...................................................................................................................................................................................................31

13 Module 7: Electronics (time: 2-4 hrs.).................................................................................................................................................................................................36

13.1 Mount the powersupply. .........................................................................................................................................................................................................38

13.2 Guide wires.................................................................................................................................................................................................................................40

13.3 Connect all wires to the electronics board............................................................................................................................................................................42

14 Finishing touches (time: 30-45 min.)..................................................................................................................................................................................................45

15 Calibration of table (5-15 mins) ..........................................................................................................................................................................................................47

16 Making printer ready for operation. (30 –60 mins) .......................................................................................................................................................................48

16.1 Printer preparation....................................................................................................................................................................................................................48

16.2 Printer software –Repetier-Host...........................................................................................................................................................................................49

16.3 Calibrate the Z-direction/ Connect to printer......................................................................................................................................................................50

16.4 OPTIONAL: Firmware installation .........................................................................................................................................................................................55

17 It’s time for printing! (15- 30mins)......................................................................................................................................................................................................57

18 Quest to high quality printing..............................................................................................................................................................................................................59

18.1 Thermodynamics.......................................................................................................................................................................................................................59

18.2 Mechanics...................................................................................................................................................................................................................................59

18.3 Software......................................................................................................................................................................................................................................59

19 FAQ ...........................................................................................................................................................................................................................................................60

20 Terms Of Service.....................................................................................................................................................................................................................................61

21 BOM Felix 2.0..........................................................................................................................................................................................................................................64

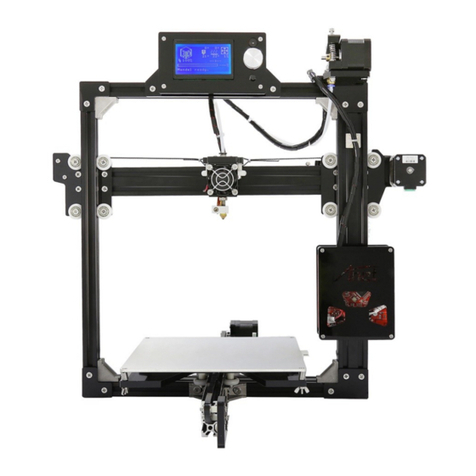

2INTRODUCTION

First of all thank you choosing FELIXprinters! To get your Felix printer up and running as fast

and painless as possible please follow this manual carefully. When things are unclear or if you

looking on our forum and get yourself a forum account. You will benefit from the ability to get

downloadable and printable upgrades for your printer. Also it is a great source to obtain more

knowledge about your printer and printing in general.

Depending on your skills this kit will take approximately 4-12 hours to assemble and to make

your first print. Please read the manual carefully and follow it step by step. Please don’t make

any shortcuts unless you know what you’re doing. It’s better to spend a few minutes extra on

reading, than to wait a week for new parts.

The manual is build up as follows: Each module starts with a short introduction. After that a Bill

of Materials (BOM) is presented. The BOM doesn’t contain the small bolts and nuts, because for

the assembly of the printer the assortment box of bolts and nuts is required. Further to not bloat

the manual, a picture of each part is only displayed in the complete BOM of the printer. This can

be found in the Supplement at the end of the manual.

Before starting the build of your printer, it’s recommended to check if all parts are present by

comparing it with the bill of materials.

3SPECIFICATIONS

Printing

Electrical

Print Technology

Fused Filament Fabrication

AC input:

100-240V, 50-60 Hz

Build Volume

25.5 x 20.5 x 23.5 cm

Power Requirements

12V DC, 15 Amps

Print Quality

Extreme

High

Medium

Low

50 microns

100 microns

250 microns

320 microns

Connectivity

USB

Postioning Precision

XY: 13 microns

Z: 0.4 microns

Filament Diameter

1.75 mm

Mechanical

Nozzle Diameter

0.35 mm

Chassis

Aluminum profiles

Build platform

Aluminum plate

Software

XY Bearings

Linear ball bearings

Software Bundle:

RepetierHost + Skeinforge/SFACT

Z bearing

Linear ball bearings

File Types:

.STL

Stepper Motors

1.8 deg angle

1/16 micro-stepping

Supports:

Windows, XP and newer

Linux (Ubuntu 12.04+)

Mac OS X [10.6/10.7/10.8]

Physical Dimensions

Weight

7.5kg

Shipping Weight

11 kg

Shipping Box

50x30x30 cm, DIY kit

50x50x60 cm, Assembled unit

Temperature

Ambient operating temperature

15-32 ˚C [60 –90 ˚F]

Storage temperature

0 –32 ˚C

Warmup time

Heated bed (60 degC)

3 min

Nozzle (200degC)

1 min

4REQUIRED TOOLSET

The following tools are minimally required to assemble and use the Felix printer

Wrenches 7 and 13mm

Tweezers. (included in kit)

Nippers.

Caliper

Allen Key set. IMPORTANT: they

need to be preferably long and

have a round head at the end.

Pliers

Drill with a variable speed. When

plastic parts need to be drilled out,

it should be done with care

Level

Drill bits 4, 5mm

Hammer

Wire stripper, recommended

Detergent (Spirit, Acetone, Alcohol)

5REQUIRED SKILLS

The following skills are required to put the Felix printer together:

-Basic soldering skills

-Skills to assemble a mechanical construction

-Technical insight

-Common sense

If you lack any of these skills or are unsure please get help from someone who can guide you or do this for you

6IMPORTANT NOTE

To save paper the flow of the document is built up as follows:

First words at beginning of chapter1

Column 1

Column 2

7MODULE 1: FRAME (TIME: 10-30 MINUTES)

Required for this module

Tools

-Allen key set

-Level reference surface

-Level

Parts

-Bag with description ‘frame module’.

-Aluminum beams.

The goal of this module is to create the frame on the right. Try to make everything as perpendicular as possible to each other. Let surfaces align as good as

possible. A good idea is to use a level tool.

BOM for frame module

Part

Amount

40x40x400 profile, incl 2xM8

1

40x40x400 profile, incl 1xM8, 1xD7

2

40x40x400 profile, incl 3xD7

1

80x40x440 incl work

1

40x40 protective caps

4

80x40 protective caps

1

frame connector set

6

handle incl protective cap

1

hex sockethead bolt M6x1(or M8, depends on the used

handle type)

2

t-slot nut - 8 ST M6 (or M8, depends on the used handle

type)

2

t-slot nut - 8 ST M4

15

dampning feet

6

strip for putting away cable pieces of 40 cm

2

Collect the parts shown above. Notice the holes in the beams.

To make it understandable, the beams are described as follows:

Beam 1: 40x40x400mm beam, has 3 drilled holes

Beam 2: 40x40x400mm beam, has 1 drilled hole and one thread at the

far end of the beam

Beam 3: 40x40x400mm beam, has 2 threads at the far ends.

Beam 4: 80x40x440mm beam has one drilled hole and one thread at

the bottom.

Some of the beams have a screw thread on the far ends of the beam.

These are present for the frame connectors.

Overview of frame module

1

2

3

4

Take beam 4 and 1. They must be connected as oriented in the above

picture.

Screw the frame connectors in the bottom of beam 4 as indicated in

the figure. Then slide beam 4 onto beam 1.

Slide beam 4 in position. On the side of beam 1 where the hex-key is

positioned there are two drilled holes. Tighten the frame connectors by

sticking the hex-key through the holes. Do not fix it too tight because

fine-tuning/leveling is needed later on.

Slide one of the two beams number 2 onto beam 1. Watch the

orientation of the drilled hole.

Turn the frame and fix beam 2 onto beam 1. Again not too tight.

Take beam 3. Screw both frame connectors on the far-ends. Slide it

onto beam 2 and tighten it.

Take beam 2 again and screw the frame connector on it’s far end. Then

slid it on beam 3 as indicated on the picture.

Next try to slide it also on beam 4.

Thighten the screws, again not too tight.

Now it is time for fine-tuning. Try to get every beam as level as

possible. Also align the beams as good as possible. See an example in

the picture below

When all the beams are aligned and leveled, it is time to firmly tighten

the frame connectors.

Get the protective caps and mount them carefully with a hammer

Put the damping feet underneath the frame near the edge

The handle should be mounted in the final stages of assembly.

Topview of frame

8MODULE 2: Z-AXIS (TIME: 45-90 MIN.)

Note: Most holes are designed to minimize the need for any post processing, like filing and drilling. Sometimes, however the bolts will not fit smoothly

and it therefore needs to be drilled out slightly. Required drill sizes can be 3, 4 and 5mm.

BOM Z-axis

Part description

Amount

Hiwin lineair ball bearing set -

HGW15CC1R300Z0

1

Trapezium spindle + bronze nut

1

motor nema 17

2

z-spindelmount bottom - v2

1

pulley_motor_HTD

1

z-axis-motor-bracket_v10_F2

1

z_axis_carrier_pt1_v15_F2_0

1

z_axis_carrier_pt2_v11_F2_0

1

optosensor

2

small bearing

4

z-axis-limitswitch_vane_v6_F2_0

1

Get the parts indicated in the list above.

IMPORTANT: DO NOT let the cart of

the linear bearing go off the rail.

There are small balls in there which

might fall out when the cart rolls of

the rail.

Place the frame on a table let the back face of the wide beam rest on the

table surface.

Put three

t_slot nut - 8 ST M4

in the frame as indicated in the picture

above.

Put some tape on the far edge of the rail to prevent the cart from sliding

off.

First mount the linear guide loosely onto the frame with M4x20 bolts.

Then mount the

z-axis-motor-bracket_v10_F2

onto the frame, indicated

above with m4x20 bolts and important use small washers.

Put the motor in place and guide the wires through the hole

Before mounting the motor make sure the wires are orientated as above

Mount a motor with the m3x8 CSK (countersunk head) bolts.

Motor wires

M4x20 bolt + small washer

Make sure part touches frame

Start to align the z-axis guide. Push the bottom side against the printed

part. Measure the distance of the edge as indicated above. The distance

should be 12mm.

Mount the z_axis_carrier_pt2_v11_F2_0 onto the cart with two M5x16

bolts. Don’t forget to place the m5 washers. Mount a motor onto the

plastic part. IMPORTANT: match the orientation of the wires according

to the picture.

Mount the 2 bearings.

Order from right to left.

M4x25 bolt, 2x small bearing, small washer, plastic part, small washer,

M4 self locking nut.

Then insert 2x m4 selflocking nuts besides the just mounted rolls into

the plastic part as shown in the picture above.

12mm

On the bottom insert the bronze nut into the plastic part.

Take the

z_axis_carrier_pt1_v15_F2_0

part and slide it as indicated on

the picture above onto the already mounted plastic part.

As indicated screw on both sides m4x20 bolts into the part to clamp the

2 big plastic parts together.

Mount the big part onto the cart of the linear bearing with M5x16 bolts,

don’t forget the M5 washers!

Put a piece of the supplied double side tape underneath 2 opto-sensors

Mount the opto-sensors with the small Philips head screws. (Depending

on the delivered batch it could be bronze or stainless steel screws)

Place the pulley upside down on the motorshaft. The distance of the

bottom of the pulley to the faceplate of the motor should be 1-2mm.

Take the z-axis_limitswitchvane and slide the nut into the slot. On top

screw in an m4x20 bolt. Don’t screw it all the way in, let the tip of the

bolt touch the flange as indicated in the picture.

Mount the z-axis-limitswitch vane with an m4x20 bolt + washer. The

bracket should be approx. 1cm from the top of the rail. This is the

adjusting mechanism for the z-axis height and will be covered later for

finetuning.

Distance pulley to motorface = 1-2mm

M4x20 bolt

M4 thin nut

CAREFULLY Screw in the z-axis spindle from the top until it reaches the

motor and place the z-axis assembly in the middle. Make sure the brass

nut is inside the z-axis carrier assembly.

NOTE: It is important not to force the spindle in because when it is not

straight anymore it will affect print-quality.

Congratulations, you’ve finished the z-axis module.

9MODULE 3: THE EXTRUDER (TIME: 30-90 MIN.)

Collect the following tools

-Allen key set

-Large file

-Drill 4mm

BOM Extruder

Part description

Amount

Extru_base_v9_F1_5

1

Extru_base_pt2_v5_F1_5

1

Extru_base_pt4_F1_5

1

Extru_arm_v5_F_1_5

1

Extru_airduct_v2

1

motor nema 17

1

Fan 40x40x10mm

2

small bearing

1

extruder_insert_piece

1

We need the above printed parts

We will create small sub assemblies and then join them together

Get the extu_arm part and clean out the hole with a 4mm drill as shown

above slowly.

Insert a thin nut m4 as shown above. Before doing that clean the hole out

a little and insert the nut.

Mount parts onto the extruder arm:

From right to left. M4x20 bolt, 2x small washer, bearing, small washer,

plastic part, thin nut.

Mount the extruder wheel onto the motor with the little set-screw from

the bag of the extruder wheel. The set-screw should not stick out more

then 0.5mm, because it might then scrape the surrounding plastic parts..

NOTE 1: sometimes the tolerances of the extruder wheel are tight. It is very

difficult to get it on the motor-axle. DO NOT force it on there, but try to

drill out the hole with a 5mm drill, until it fits smoothly on the motor-shaft.

Insert the m4 self locking nuts into the hexagon holes of the

extru_base_pt4, use an m4x20 bolt including washer as indicated above.

Make sure the wires match and also the orientation of the sticker on the

fan. The fan blows out air at the side of the sticker.

Take the extru_base_pt2 and drill out the hole with a 4mm drill as shown

above.

Mount the motor onto the extru_base_pt2 part displayed above and

match the orientation of the wires.

Table of contents

Other Felix Storch 3D Printer manuals

Felix Storch

Felix Storch Pro L User manual

Felix Storch

Felix Storch 3.2 User manual

Felix Storch

Felix Storch Pro 3 User manual

Felix Storch

Felix Storch 3.1 Single User manual

Felix Storch

Felix Storch Pro 3 L User manual

Felix Storch

Felix Storch Pro BIOprinter User manual

Felix Storch

Felix Storch Tec 4.0 to Tec 4.1 Upgrade Kit Quick start guide

Felix Storch

Felix Storch Pro L Series User manual

Felix Storch

Felix Storch FELIXFOOD 3D User manual

Felix Storch

Felix Storch Pro 3 User manual