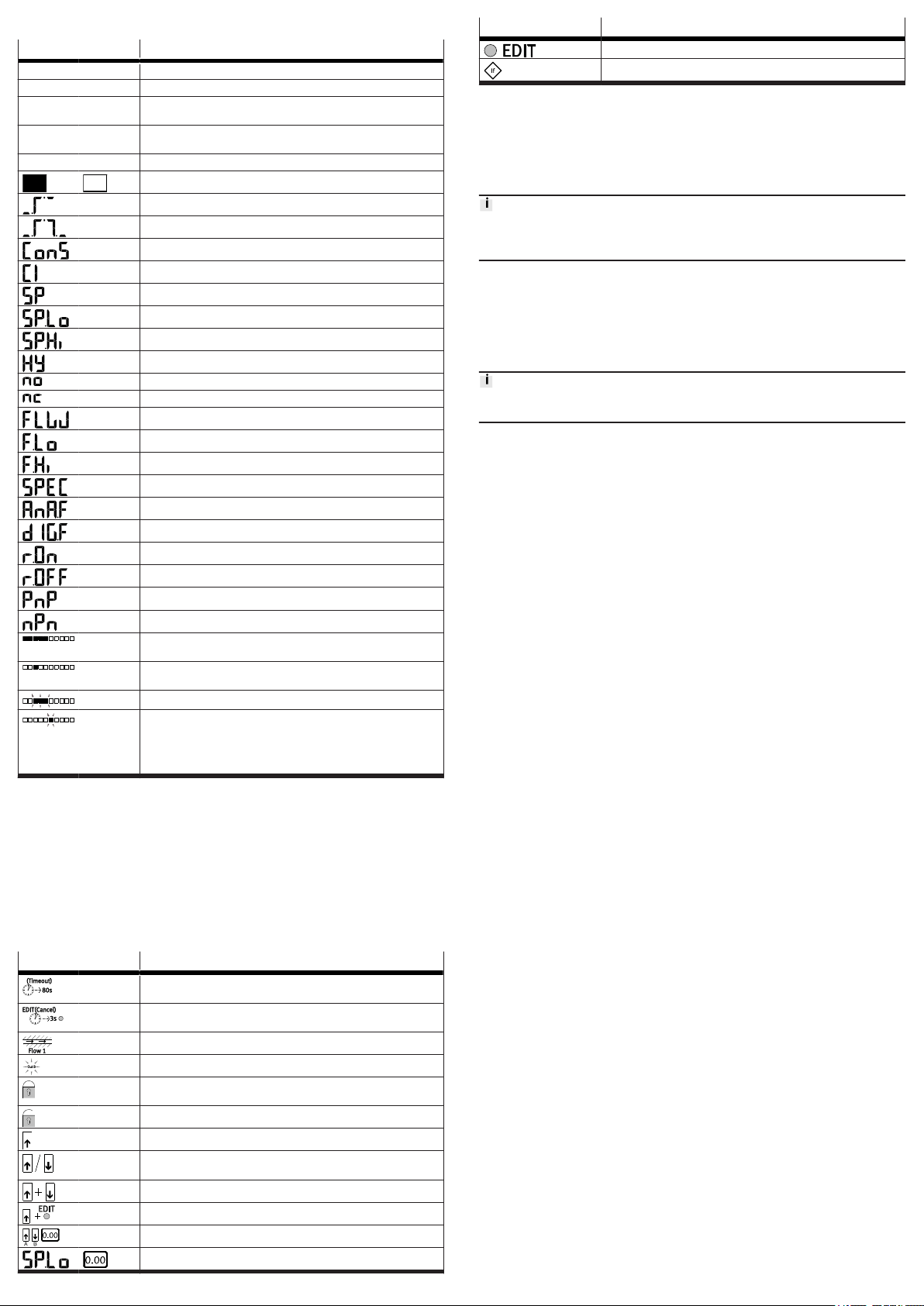

7.2 Display components

Symbol Description

OutA/OutB Switching output A/switching output B

Lock Security code active (blocked against unauthorised programming)

Run Accumulated air consumption measurement is active in RECORDER

mode

Option Sensor is set to a standard condition that differs from the factory

setting

Stop Air consumption measurement stopped

Switching output set/not set

Threshold value comparator

Window comparator

Air consumption switching mode (consumption – only for OutA)

Pulse for accumulated air consumption (consumption impulse)

Switching point

Lower switching point (switching point - low)

Upper switching point (switching point - high)

Hysteresis

N/O contact (normally open)

N/C contact (normally closed)

Switching mode flow rate (flow - only for OutA)

Minimum flow rate (flow low)

Maximum flow rate (flow high)

Special menu

Analogue filter

Digital filter

Display red with switching status ON and/or logic 1

Display red with switching status OFF and/or logic 0

Positive switch output

Zero switch output

Segments are lighted: graphic display of the current measured value

related to the maximum measured value of the measuring range

Running light (1 segment): air consumption measurement for OutA or

RECORDER mode active

3 segments flash: hysteresis value is displayed

1 segment flashes:

–Segment 6: switching point SP or SP.Lo is displayed

–Segment 8: switching point SP.Hi is displayed

–Segment 1: min. flow rate (F.Lo) is displayed

–Segment 10: max. flow rate (F.Hi) is displayed

Tab. 6: Symbols on the display

7.3 Preparing commissioning

The product in basic status is in RUN mode. The current measurement values are

displayed. The basic status can be reached from other modes by:

–Pressing Edit button for 3 seconds

–Expiration of monitoring time, timeout

1. Switch on operating voltage.

ÄThe SFAB is in RUN mode.

2. Check the SFAB settings è 7.6 SHOW mode.

7.4 Symbols for representing the menu structure

Symbol Description

Automatic return to the basic status (RUN mode) when the monitoring

time has expired (here 80 seconds)

In order to return manually to the basic status (RUN mode), press the

EDIT button for 3 seconds.

Generate flow rate (for teaching the measured value - here Flow 1)

The symbol on the display flashes (here OutB)

Security code active (lock - blocked against unauthorised program-

ming)

Security code inactive (lock)

Press key (here A key).

Press A key or B key. SFAB switches to the setting indicated by the

arrows.

Press A and B keys simultaneously.

Press key (here A key) and EDIT button simultaneously.

Press A key or B key to set the desired value.

Display for a value or switching point. Value can be set.

Symbol Description

Press the Edit button.

Branching in the menu

Tab. 7

7.5 RUN mode

The following values are displayed in RUN mode:

–Measurement values for the flow rate (in l/min, scfm or l/h)

–Measurement values for air consumption (in m³, scf or l)

–Signal states of the switching outputs OutA, OutB (set, not set)

If the measured value display flashes, one of the following errors has occurred:

• Measured value outside the permissible measuring range

• Incorrect tubing è 6.1 Pneumatic installation

7.6 SHOW mode

In SHOW mode, the current settings for the switching outputs Out A and Out B are

displayed.

The SFAB must be in RUN mode.

•To start the SHOW mode for the respective switching output, press the A key

(OutA) or B key (OutB).

If there are errors, the corresponding error numbers are displayed first after

pressing the A / B pushbutton.

•To display the settings one by one, press the A/B pushbutton repeatedly.

When all settings have been displayed, the SFAB goes back into RUN mode when

the A pushbutton / B pushbutton are pressed again and displays the current

measurement value for the corresponding output.

Thus, the SHOW mode can also be used to switch the display, e. g. to switch

between the displayed measured values for a combination of air consumption

measurement and flow rate measurement.

The following settings will be displayed for outA:

–With flow measurement [FLW]:

–Switching function [threshold value or window comparator]

–Switching point [SP], Switching points [SP.Lo] and [SP.Hi]

–Hysteresis [Hy]

–Switching element function [no/nc] (N/O contact/N/C contact)

–Minimum flow rate [F.Lo] (flow low)

–Maximum flow rate [F.Hi] (flow high)

To delete the minimum or maximum value, press the EDIT button.

–For air consumption measurement [ConS]:

–Air consumption switching impulse [CI]

–Switching element function [no/nc] (N/O contact/N/C contact)

–Minimum value flow rate [F.Lo]

–Maximum value flow rate [F.Hi]

To delete the minimum or maximum value, press the EDIT button.

The following settings will be displayed for OutB:

–Switching function [threshold value or window comparator]

–Switching point [SP], Switching points [SP.Lo] and [SP.Hi]

–Hysteresis [Hy]

–Switching element function [no/nc] (N/O contact/N/C contact)

–Status colour change [bLUE/rON/rOFF]

–Minimum value flow rate [F.Lo]

–Maximum value flow rate [F.Hi]

To delete the minimum or maximum value, press the EDIT button.