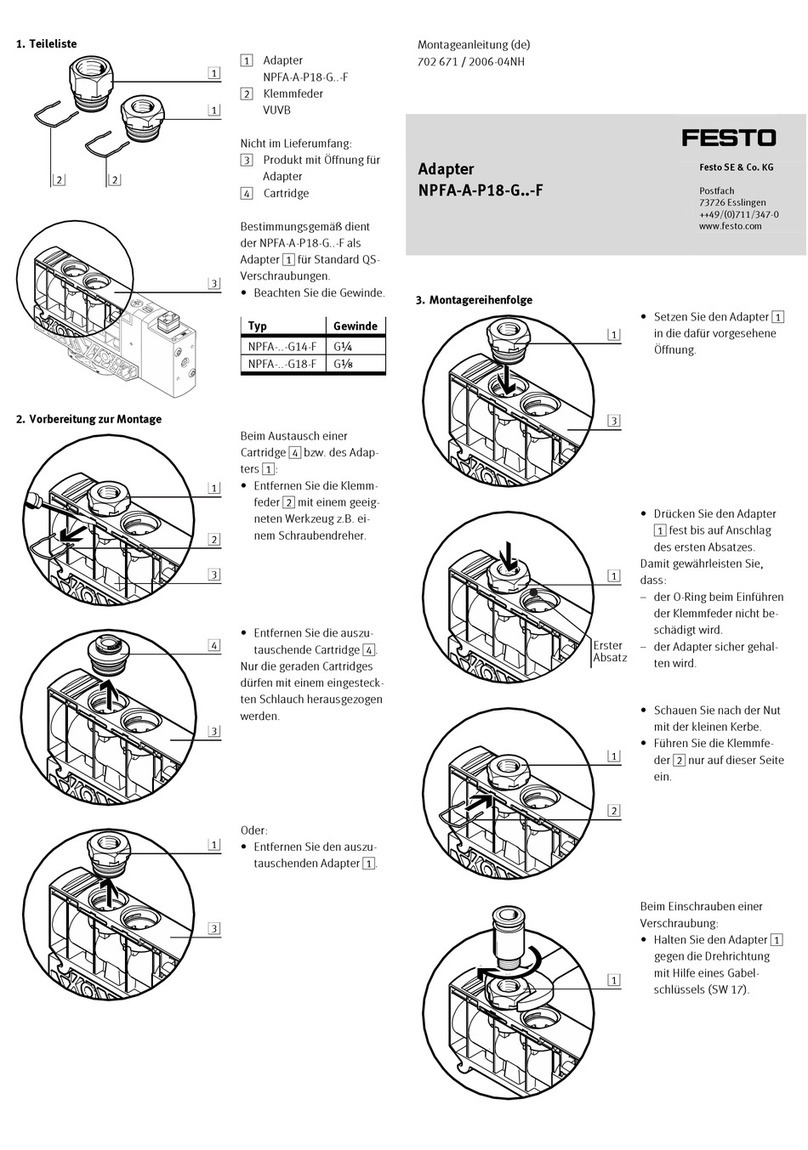

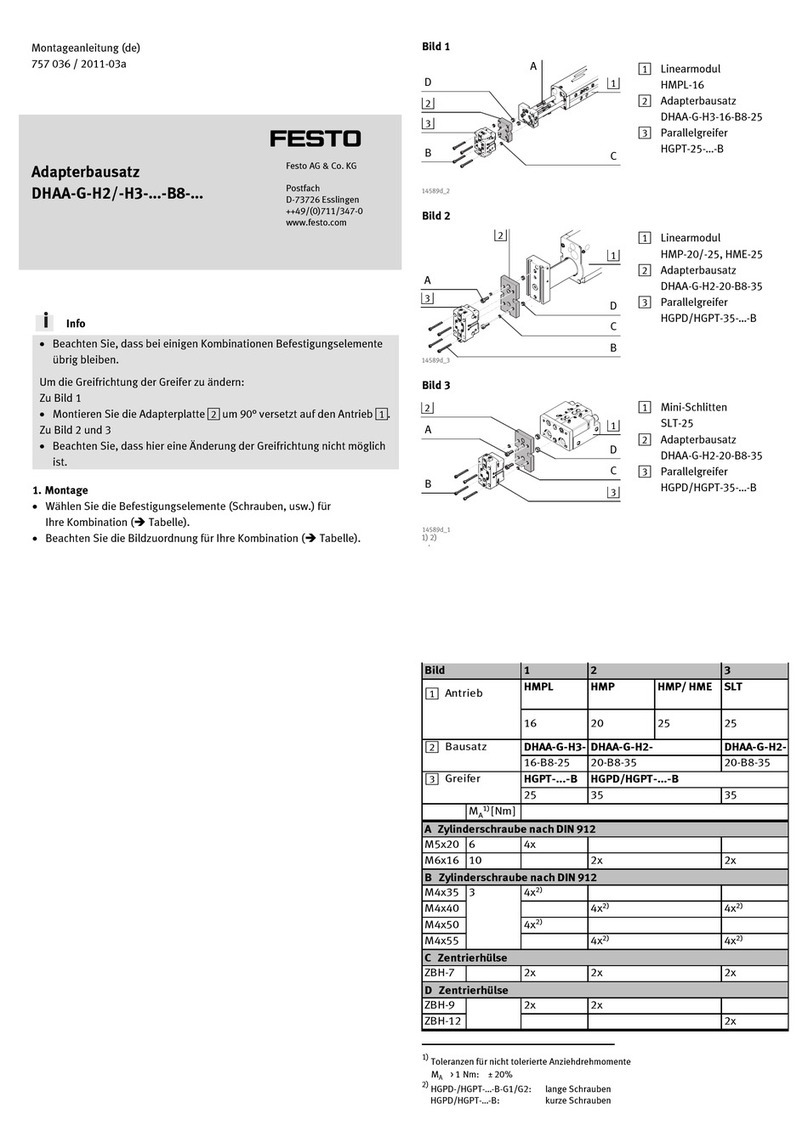

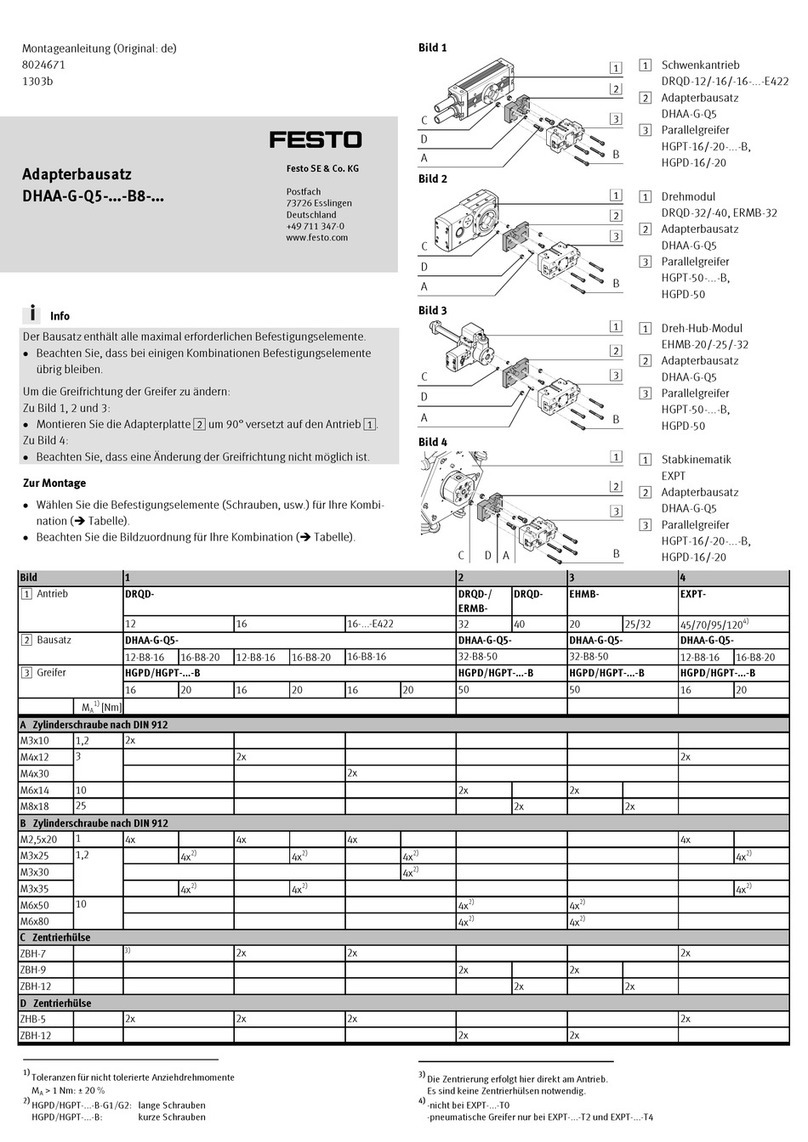

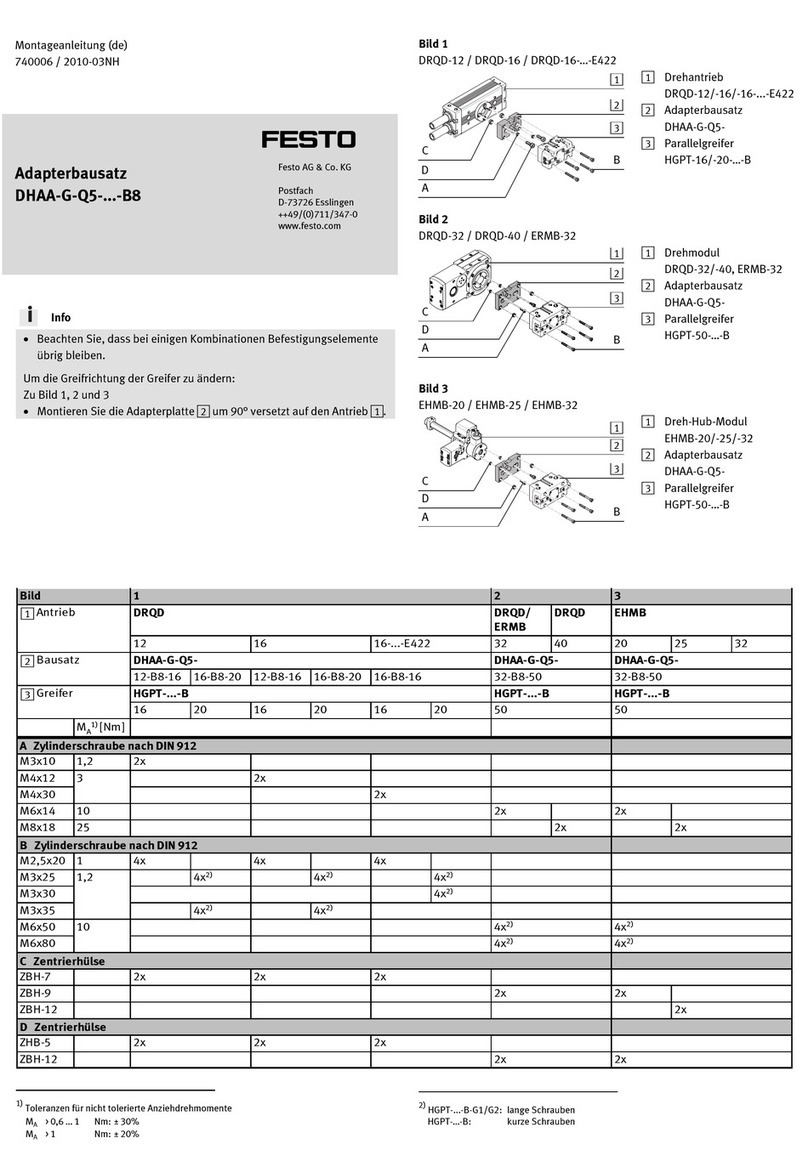

Product design of the central lubrication system EGC-HD-BS-C

1Lubrication adapter

2Lubrication port on rear guide,

rear

3Lubrication port on front guide,

front

4Lubrication port with ball screw

drive

Fig. 5 Product design of the central lubrication system EGCHDBSC

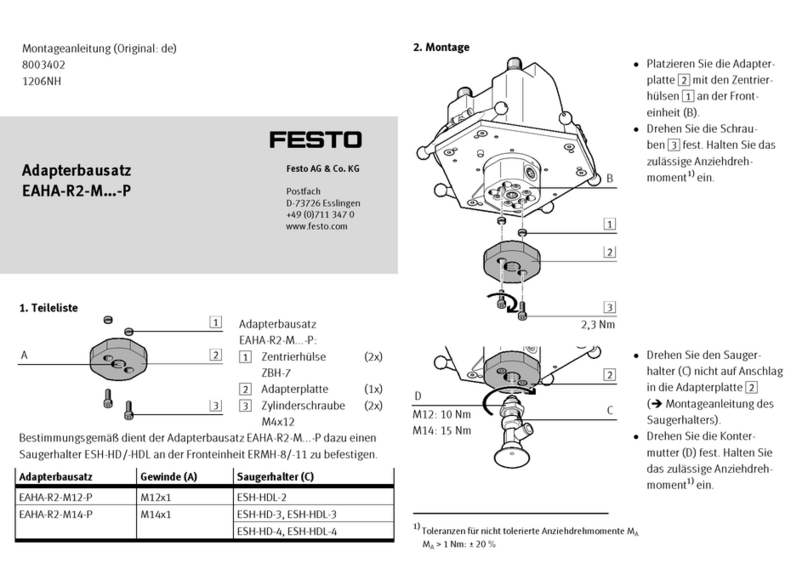

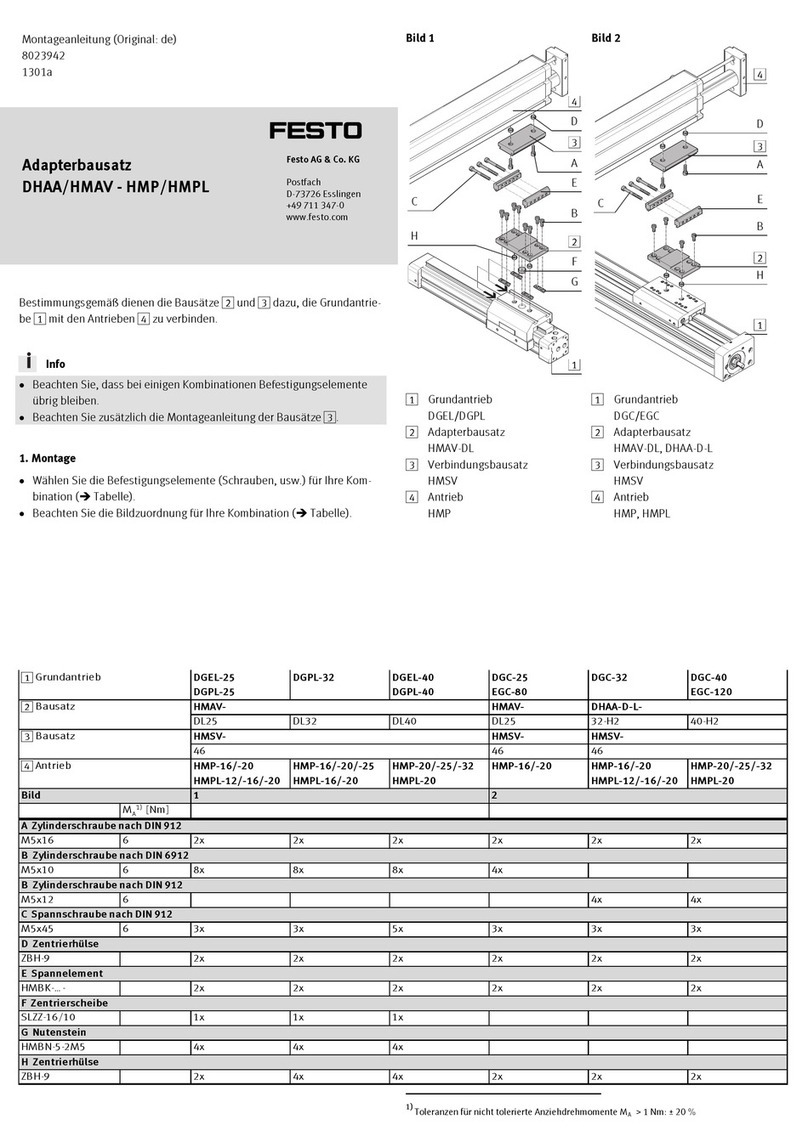

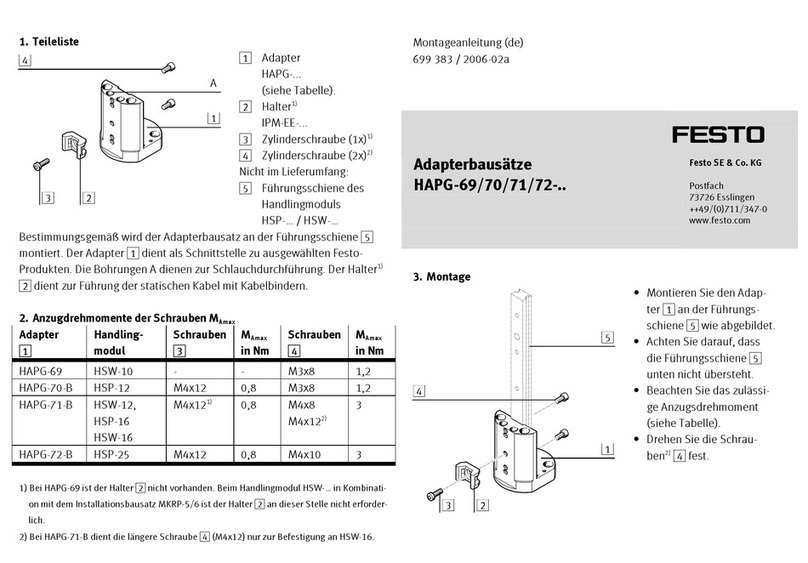

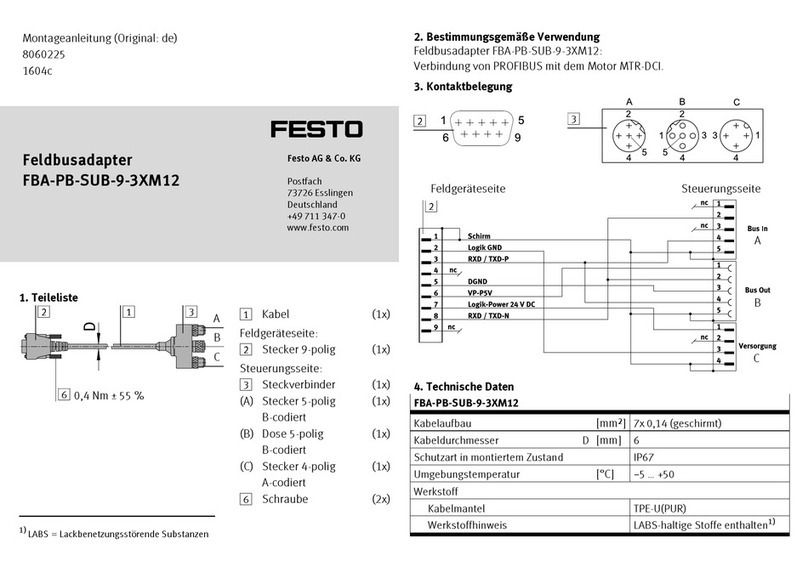

Product design of the central lubrication system EGC-HD-TB-C

1Lubrication adapter

2Lubrication port on rear guide,

rear

3Lubrication port on front guide,

front

Fig. 6 Product design of the central lubrication system EGCHDTBC

6 Assembly

6.1 Safety

WARNING!

Risk of Injury due to Unexpected Movement of Components

For vertical or slanted mounting position: when power is off, moving parts can

travel or fall uncontrolled into the lower end position.

• Bring moving parts of the product into a safe end position or secure them

against falling.

6.2 Fasten the central lubrication system supply line

Reducing load on the supply line

Attach the supply line to the lubrication adapter only in combination with a strain

relief

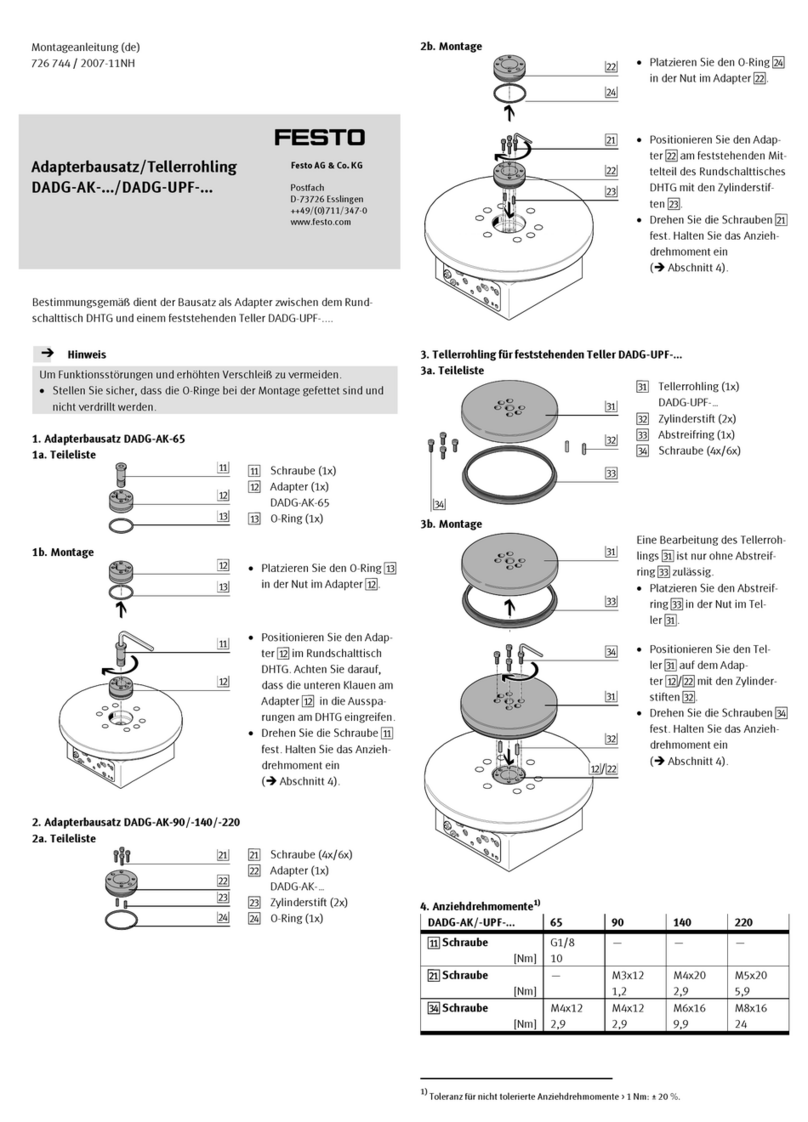

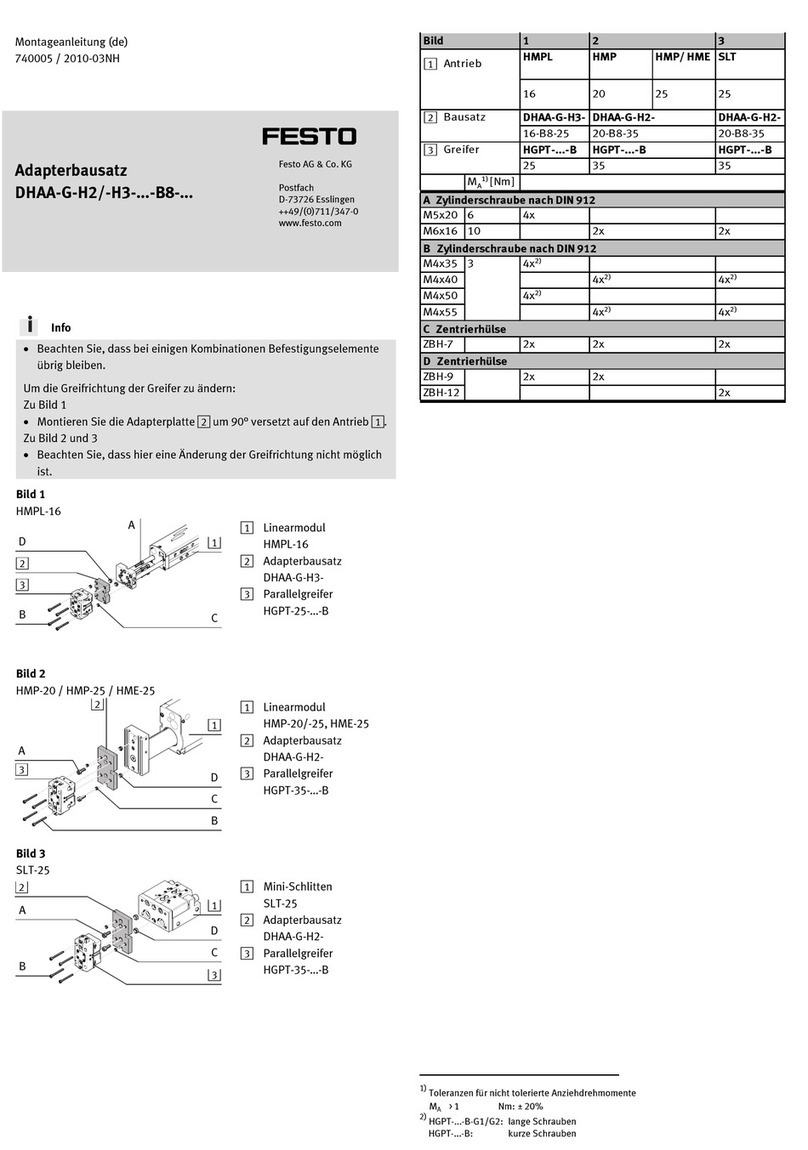

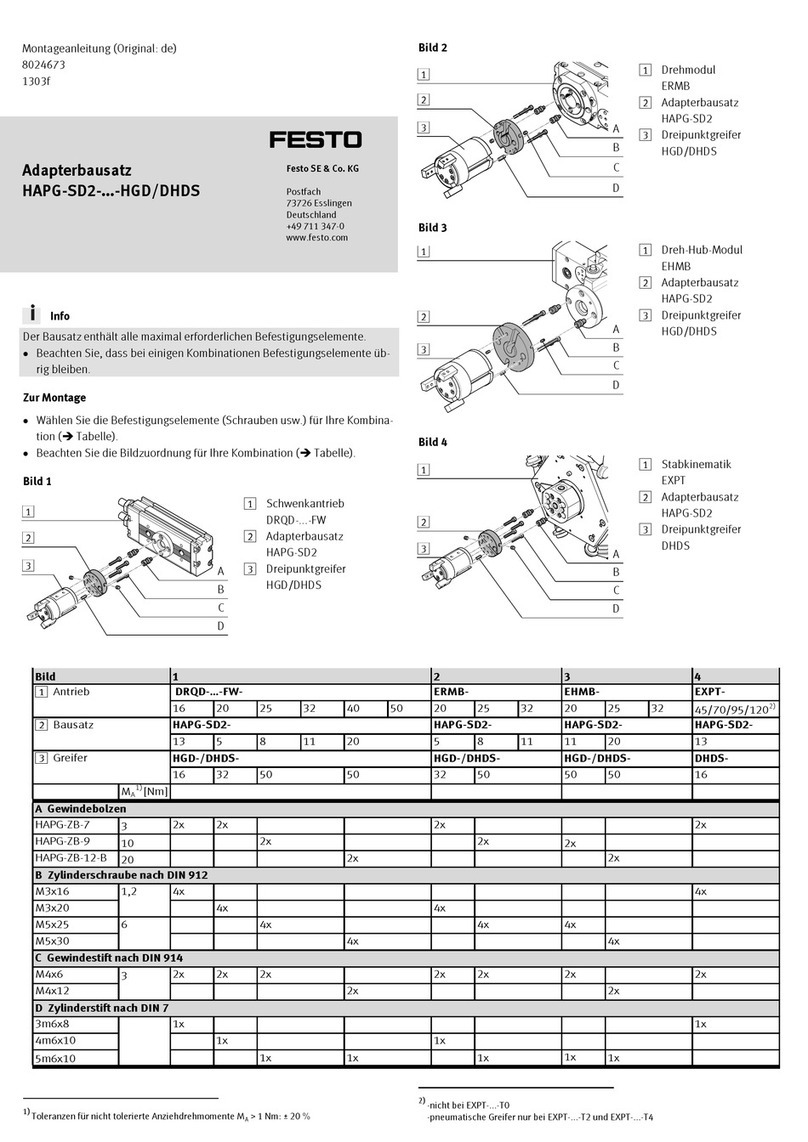

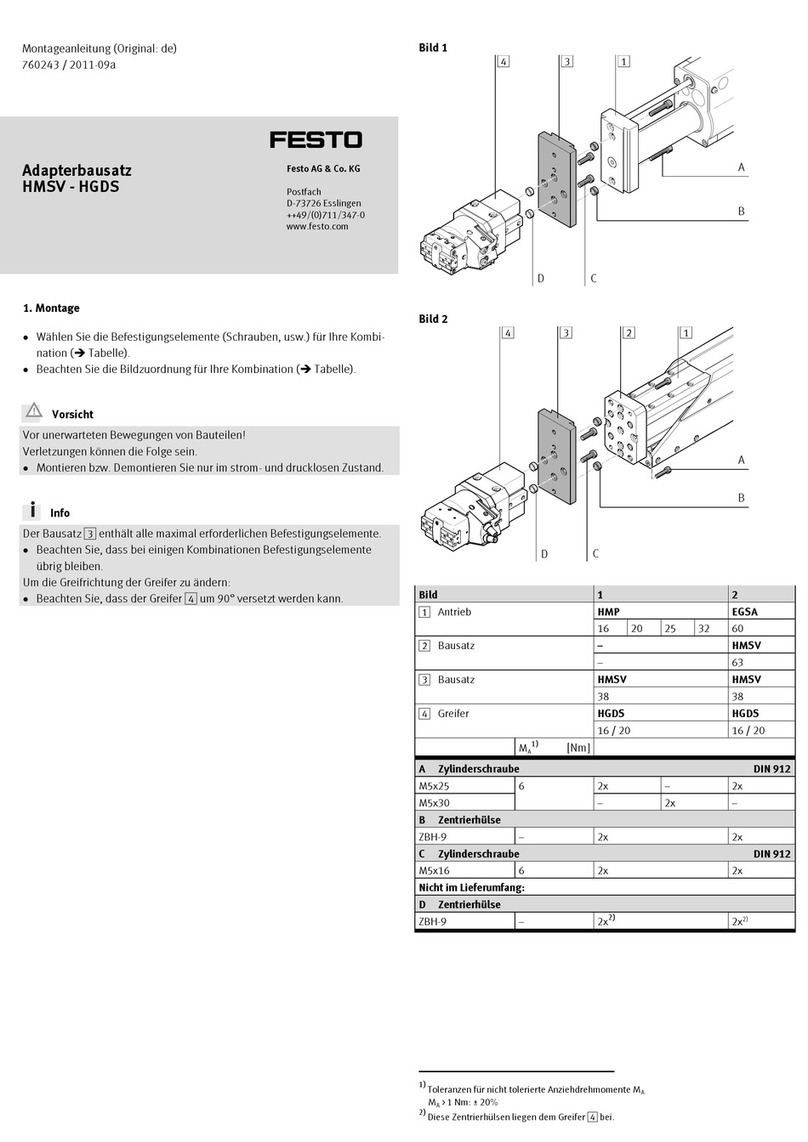

Connect central lubrication system DGC-C, DGC-FA-C, DGCI-C

Restriction of the central lubrication system connections

When using shock absorbers, shock absorber retainers with stops or lateral pro

file mounting the number of permissible connection variants for the central lubric

ation system is reduced.

Profile mounting MUC

underneath at the side, rear

DGC8/.../63C

DGC8 /.../ 63FAC

DGCI18 /.../ 63C

DGC18/.../63C

DGC18 /.../ 63FAC

DGCI18 /.../ 63C

without cushioning

with elastic cushioning P

with pneumatic cushioning PPV

with shock absorber YSR / YSRW

Profile mounting MUC

underneath at the side, rear

with shock absorber retainer DADP and stop KYC

–

Tab. 1 Overview DGC... C, permissible connections for central lubrication system

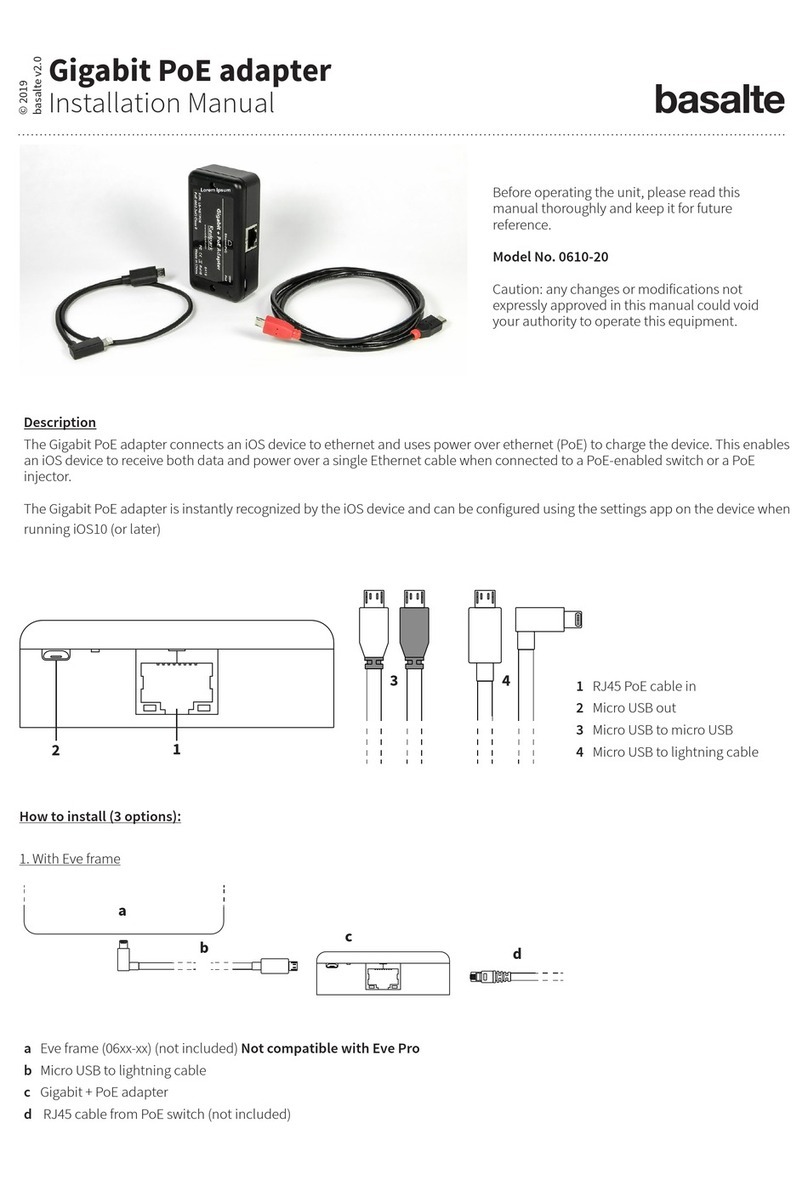

1Lubrication adapter

2Fitting or threaded pin

3Supply lines for central lubrication

system, guide

Fig. 7 Connect central lubrication system DGCC, DGCFAC, DGCIC (example: sup

ply cable at top)

– Lubrication port: guide at both ends; front, top or rear

1. Remove threaded pins2.

2. Mount fittings2. (tightening torque è Tab. 2 Information for fitting)

3. Connect guide for central lubrication system supply lines3. (2x)

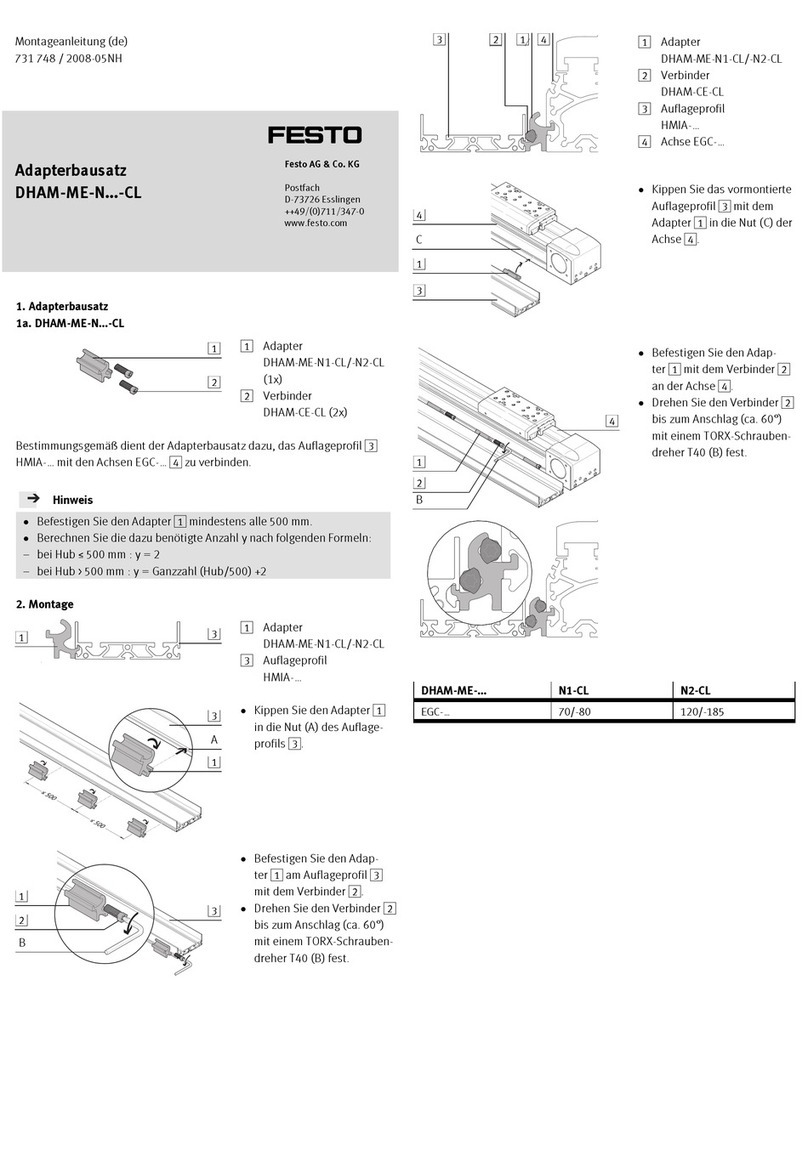

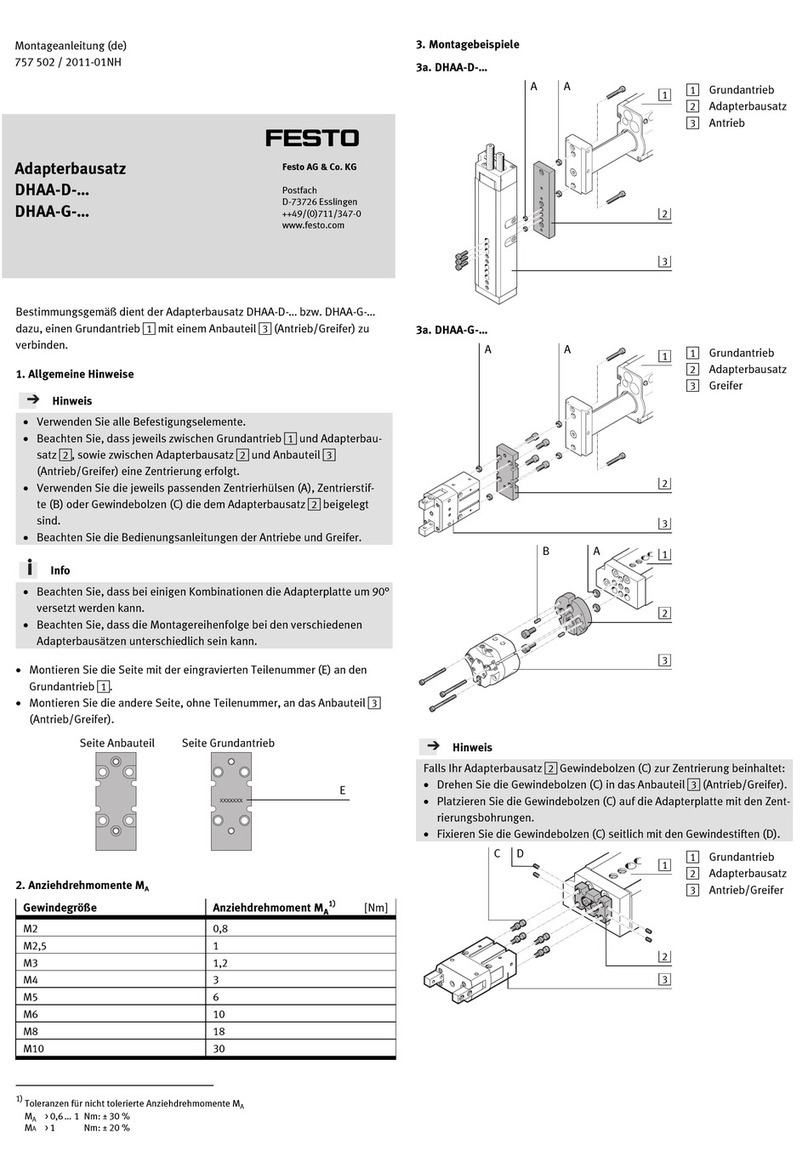

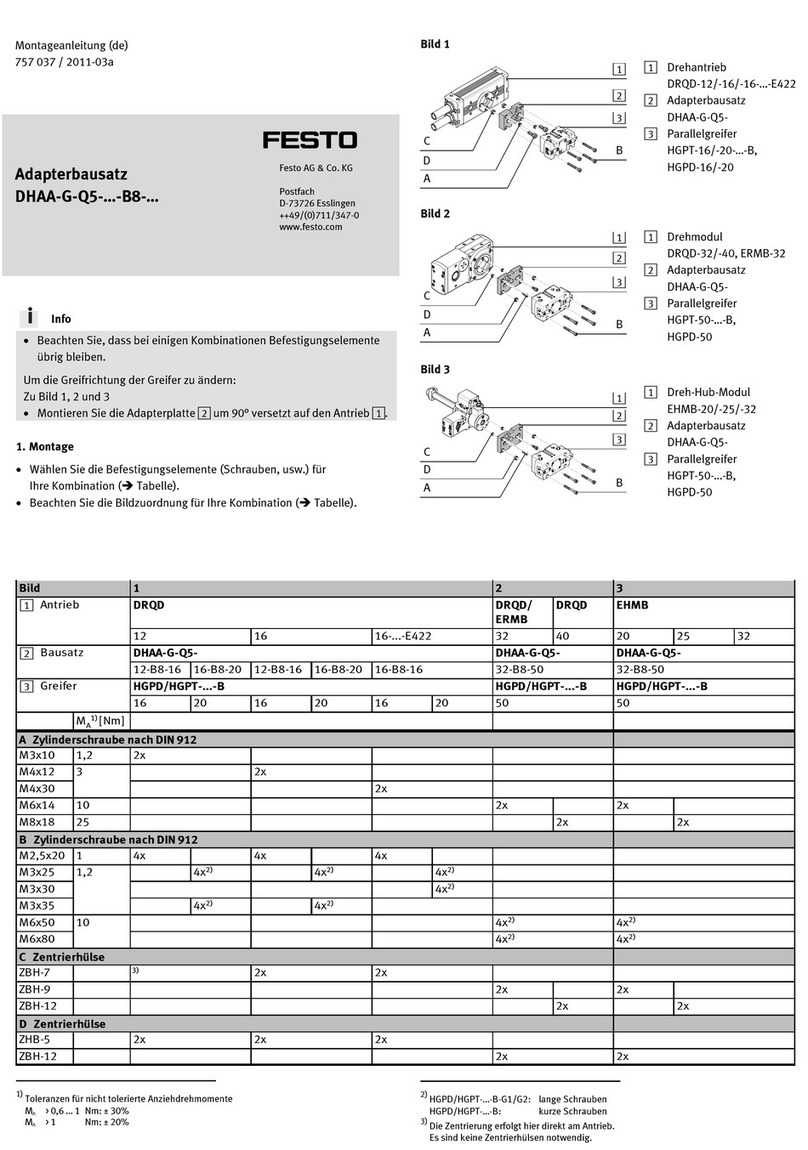

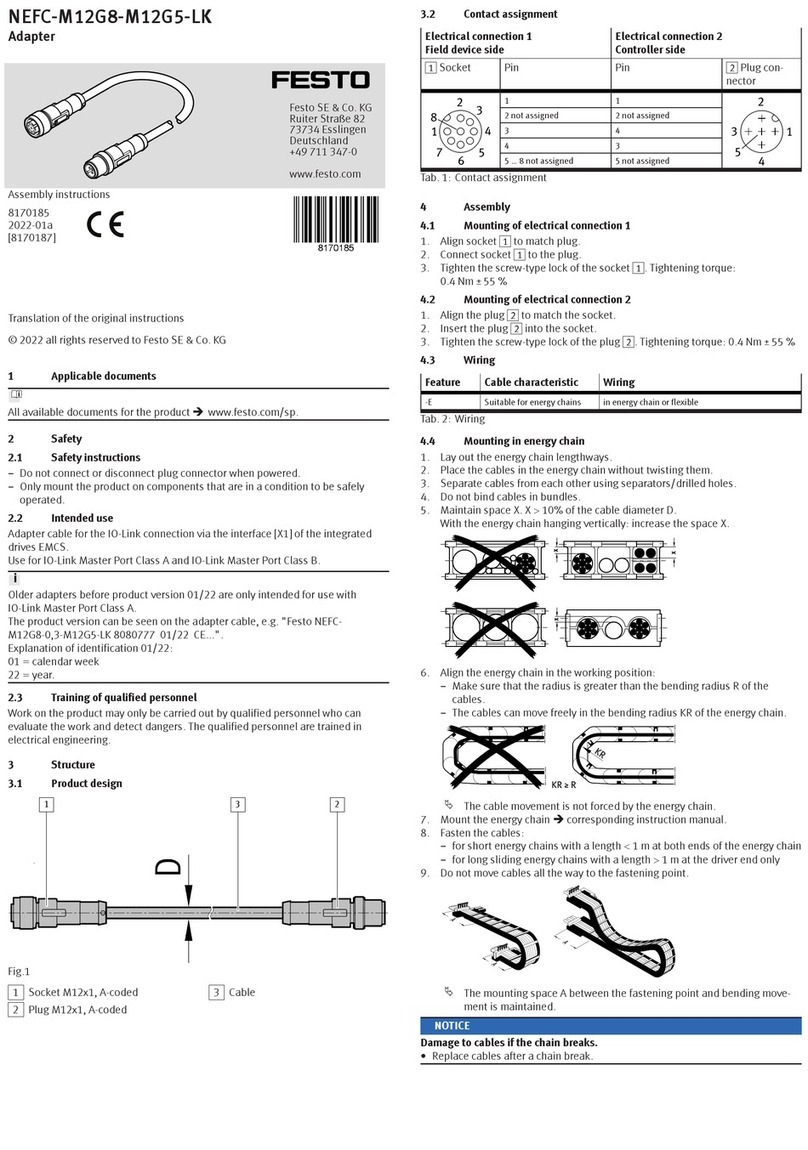

Connect central lubrication system EGC-C

1Lubrication adapter

2Fitting or threaded pin

3Supply lines for central lubrication

system, guide

4Supply line for central lubrication

system, ball screw drive

Fig. 8 Connect central lubrication system EGCBSC (example: supply line at top)

1Lubrication adapter

2Fitting or threaded pin

3Supply lines for central lubrication

system, guide

Fig. 9 Connect central lubrication system EGCTBC / EGCFAC (example: supply

line at top)

– Lubrication connection for guide (KF): at both ends; front, top or rear

– Lubrication port with ball screw drive (BS): one end; at the front

1. Remove threaded pins2.

2. Mount fittings2. (tightening torque è Tab. 2 Information for fitting)

3. Connect guide for central lubrication system supply lines3. (2x)

4. Connect supply line to ball screw drive central lubrication system4. (only

BS: 1x)