6.

8.

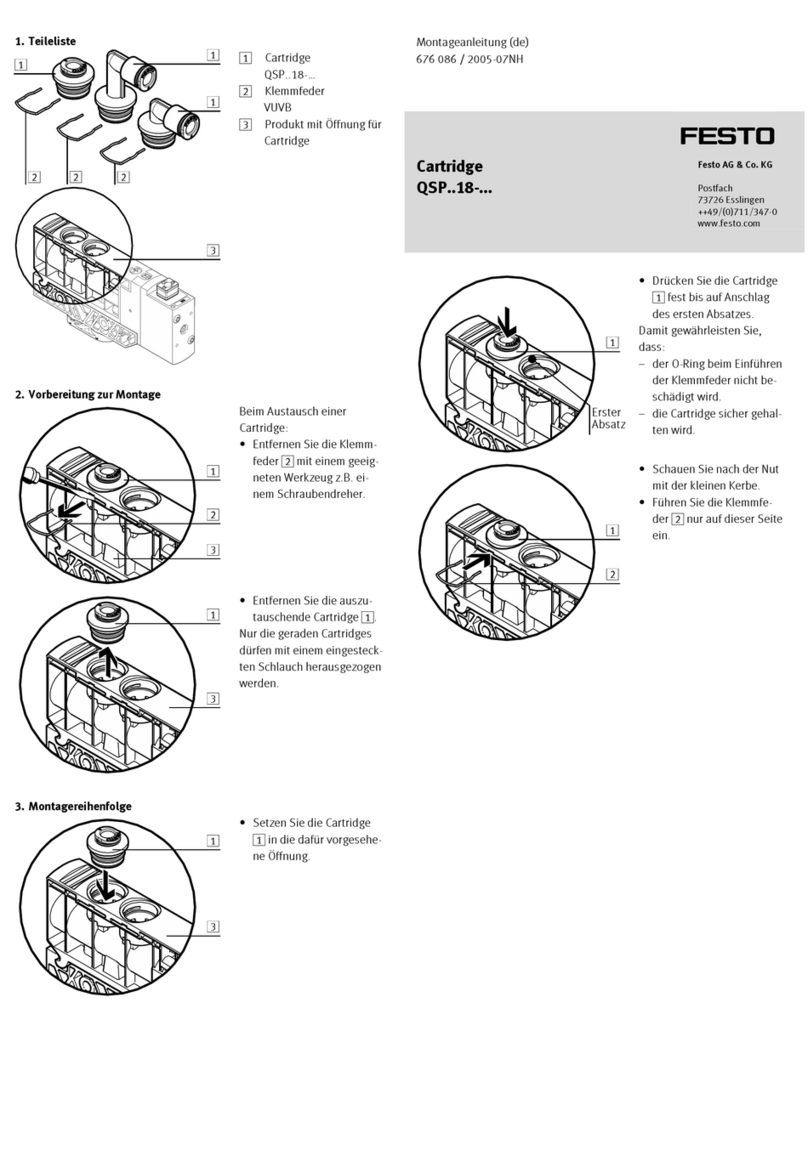

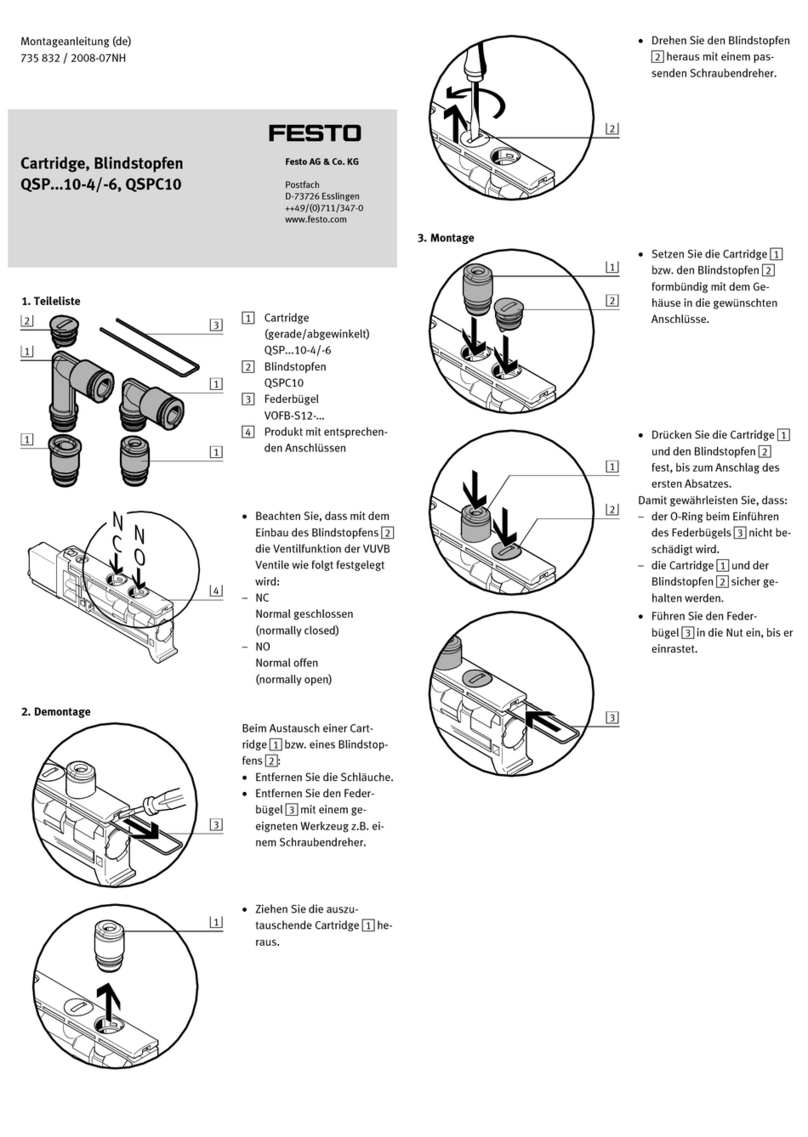

Fig. 6: Fastening strain relief

1. Check that the brass rings [K] of the cables [G] and [H] are correctly seated at

the position of the strain relief [E].

2. Fasten the strain relief [E] with the screw [F] to the brass rings [K]. Tightening

torque: 0.7 Nm ± 30%

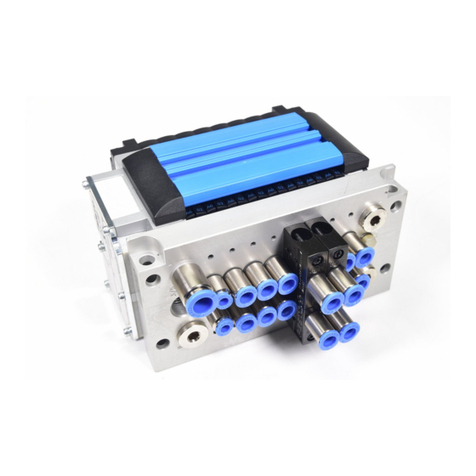

Fig. 7: Fasten the cover of the terminal box

1. Carefully position the cover [A] on the terminal box [B].

ÄThere are no wires pinched between the cover [A] and the terminal

box [B].

2. Tighten the screws [C]. Tightening torque: 1.2 Nm ± 20%

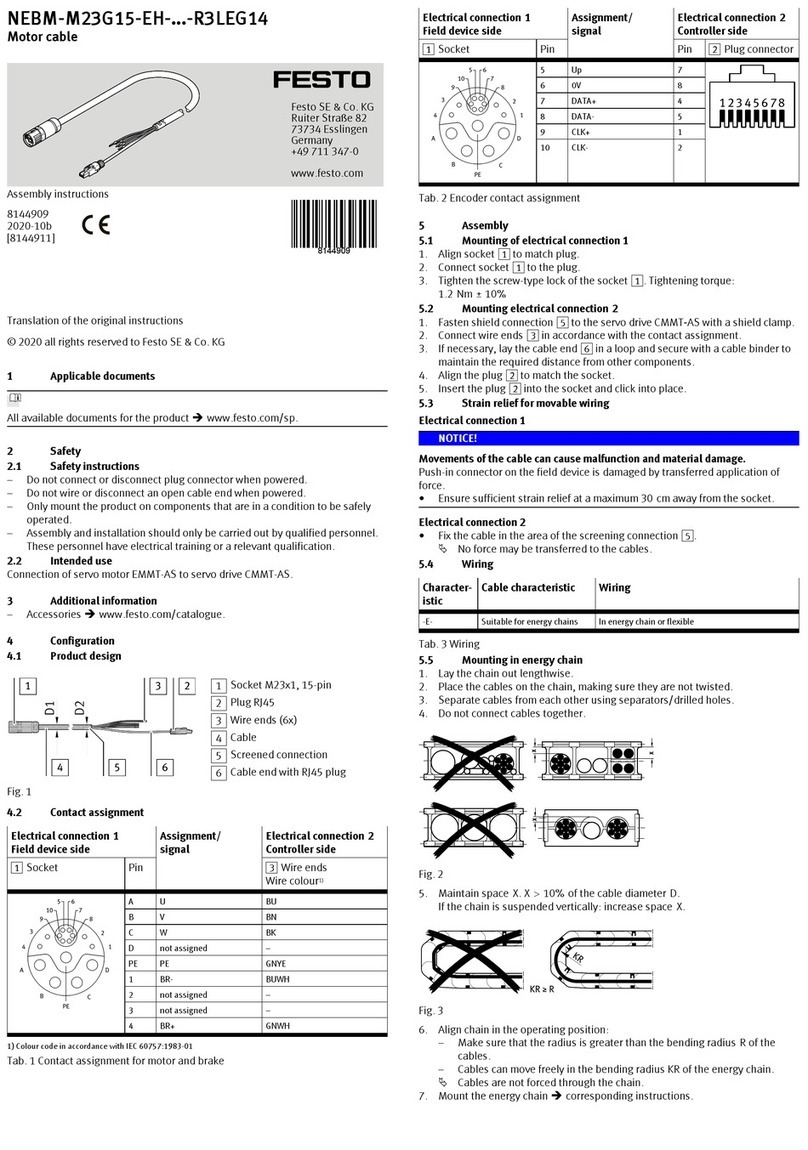

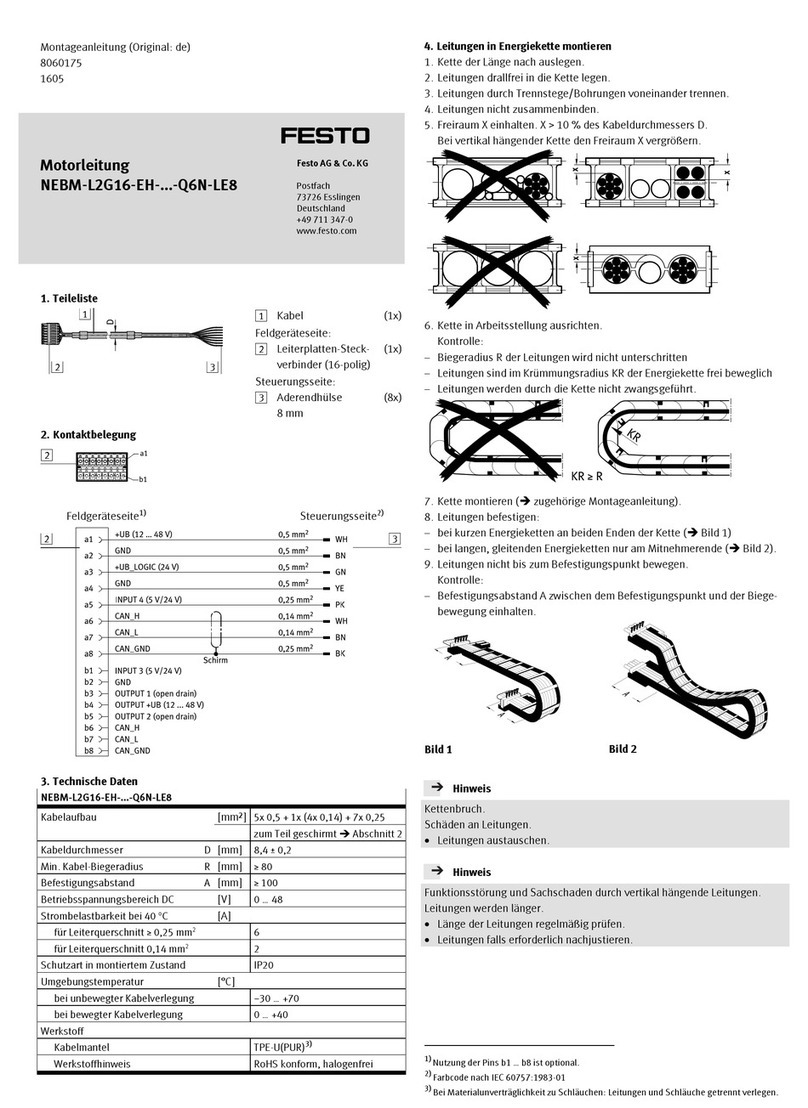

5.2 Mounting electrical connection 2

1. Align the plug 3 to match the socket.

2. Insert the plug 3 into the socket.

3. Tighten the screws 5. Tightening torque: 0.1 Nm ± 20%

5.3 Wiring

Feature Cable characteristic Wiring

-E Suitable for energy chains in energy chain or flexible

Tab. 3: Wiring

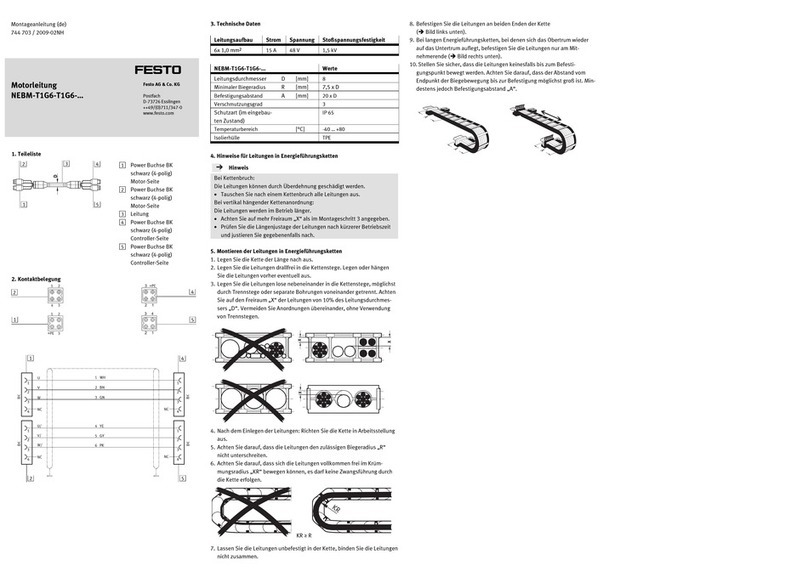

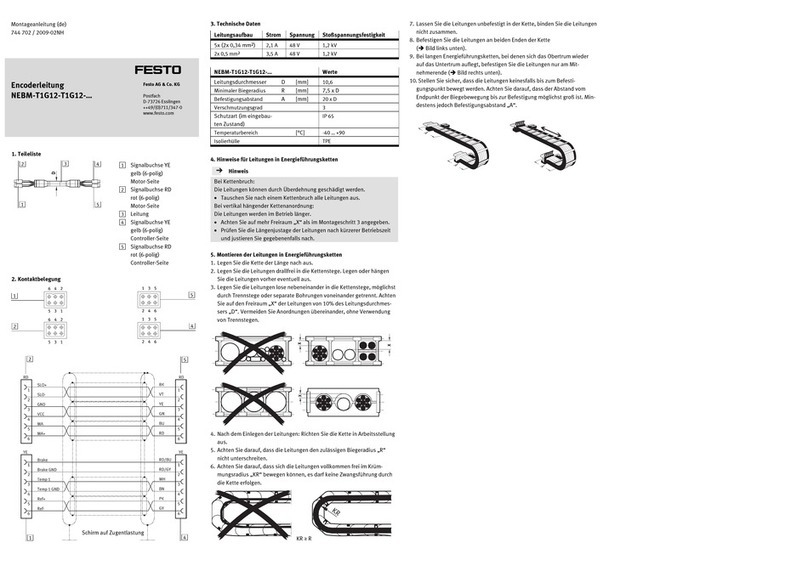

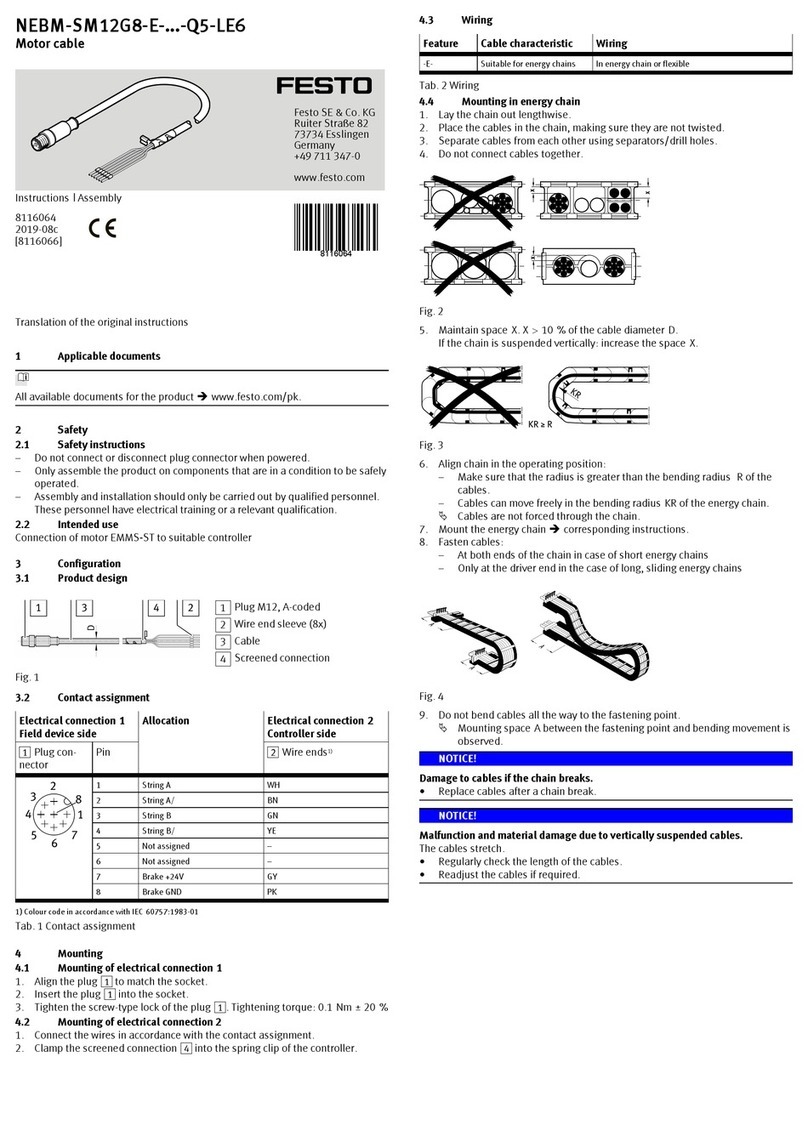

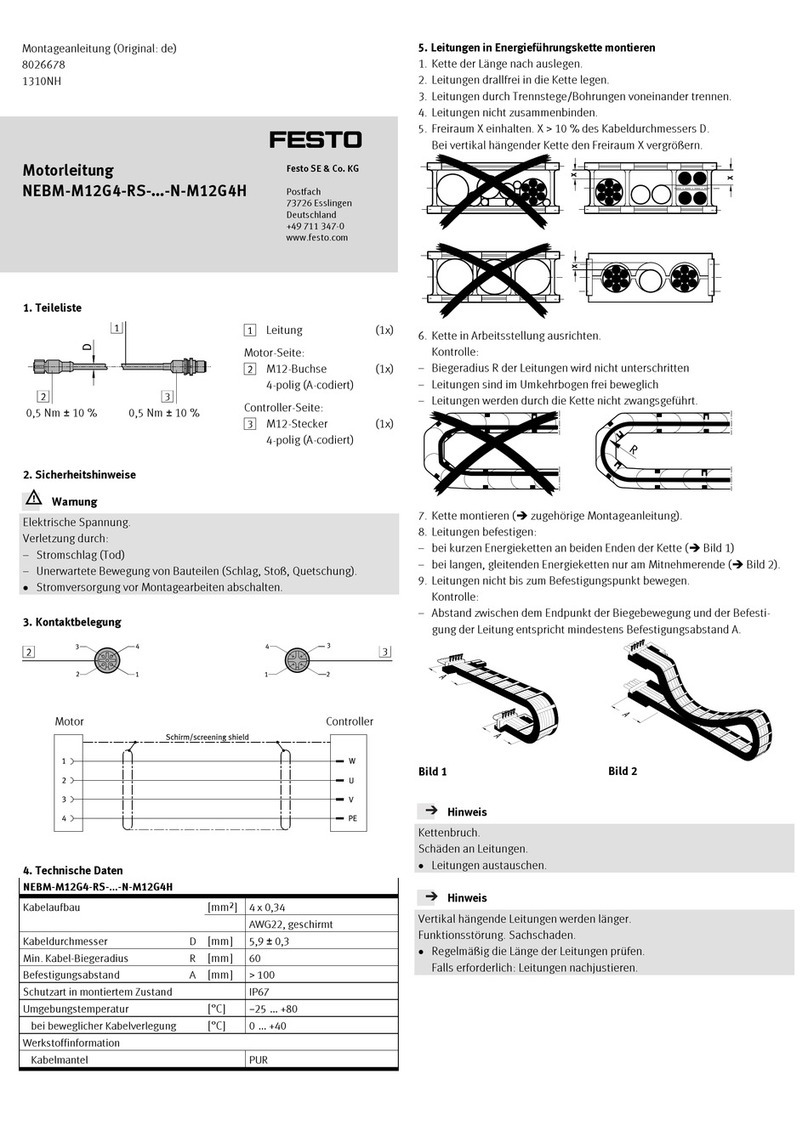

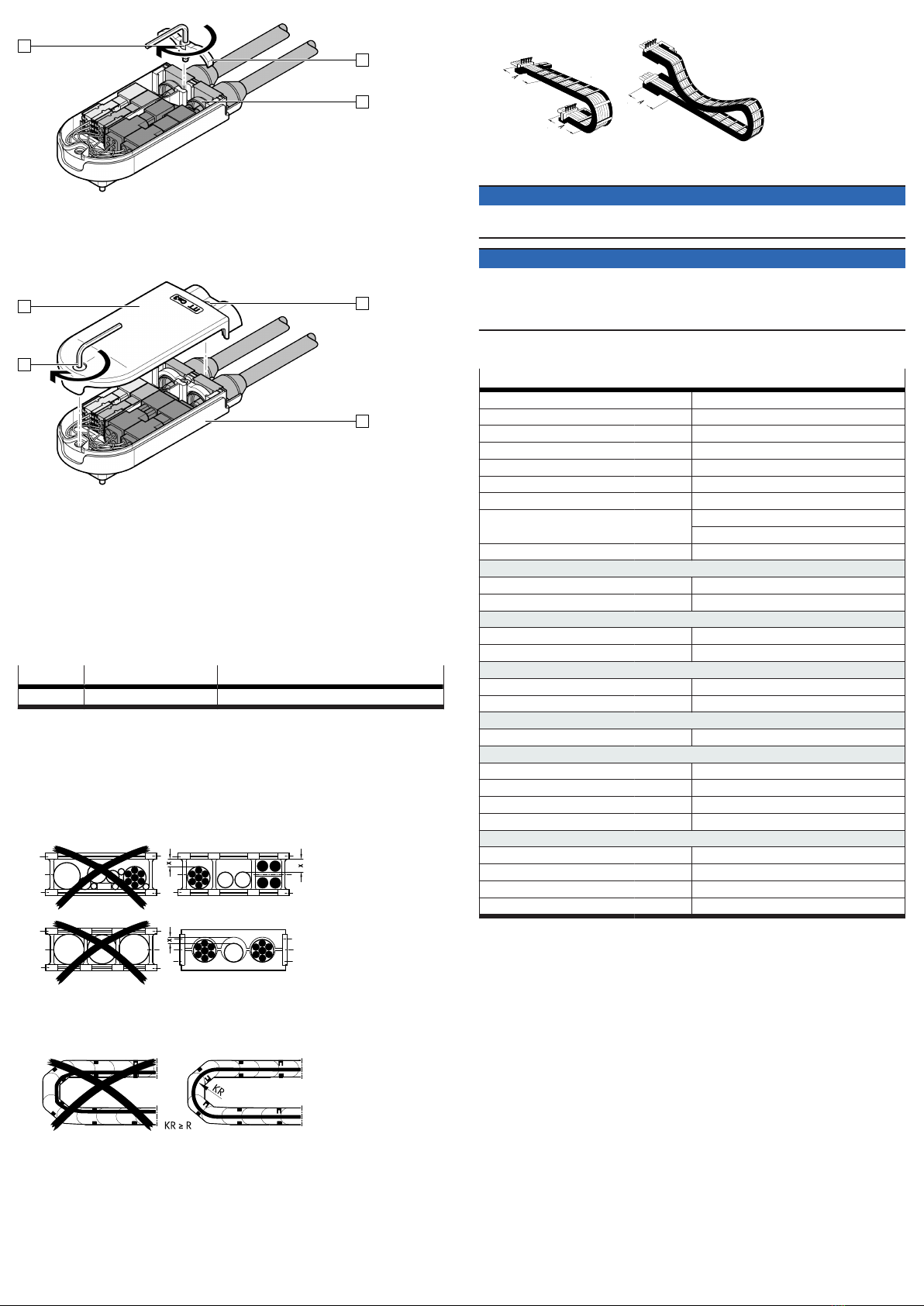

5.4 Mounting in energy chain

1. Lay out the energy chain lengthways.

2. Place the cables in the energy chain without twisting them.

3. Separate cables from each other using separators/drilled holes.

4. Do not bind cables in bundles.

5. Maintain space X. X > 10% of the cable diameter D.

With the energy chain hanging vertically: increase the space X.

Align the energy chain in the working position:

–Make sure that the radius is greater than the bending radius R of the

cables.

–The cables can move freely in the bending radius KR of the energy chain.

ÄThe cable movement is not forced by the energy chain.

7. Mount the energy chain è corresponding instruction manual.

Fasten the cables:

–for short energy chains with a length < 1 m at both ends of the energy chain

–for long sliding energy chains with a length > 1 m at the driver end only

9. Do not move cables all the way to the fastening point.

ÄThe mounting space A between the fastening point and bending move-

ment is maintained.

NOTICE

Damage to cables if the chain breaks.

• Replace cables after a chain break.

NOTICE

Malfunction and material damage due to vertically suspended cables.

The cables stretch.

• Regularly check the length of the cables.

•Readjust the cables if required.

6Technical data

NEBM-T1G8-E-...-S1G15

Certificates, declaration of conformity è www.festo.com/sp

Cable characteristic Suitable for energy chains

Cable function Encoder cable

Cable composition [mm²] 1x4x0.15 + 4x1x0.34

Shielding Shielded

Cable diameter D [mm] 6

Mounting space A [mm] ³ 120

Current rating at 40 °C [A] 3 for conductor cross-section 0.34 mm2

2 for conductor cross-section 0.15 mm2

Surge resistance [kV] 0.5

Operating voltage range

AC UB[V] 0 … 30

DC UB[V] 0 … 30

Bending radius

Fixed cable installation R [mm] ³ 20

Flexible cable installation R [mm] ³ 48

Ambient temperature

Fixed cable installation [°C] –40 … +80

Flexible cable installation [°C] –10 … +80

Material

Cable sheath TPE-U(PUR)

Electrical connection 1

Function Field device side

Connection type Socket

Connection technology ITT M3

Degree of protection IP65 In assembled state

Electrical connection 2

Function Controller side

Connection type Plug connector

Connection technology Sub-D

Degree of protection IP30 In assembled state

Tab. 4: Technical data