9 Disassembly

Warning

Risk of injury from combustion and chemical burns.

The media in the piping system and the valve can be hot and under pressure.

Medium residues can be in the product and escape when open or dismantled.

Allow the valve and piping to cool and depressurize them.

Wear specified protective equipment.

Note

Disassembly only by qualified specialized personnel.

Do not reach into the opening of the valve.

1. De-pressurise the piping and the operating medium line.

2. Allow the valve and pipeline to cool.

3. Empty the piping and valve completely.

– Make sure no one is located in front of the outlet opening.

– Catch discharging media in a suitable container.

4. Disconnect the operating medium line from the valve.

5. Disconnect the piping connections and remove the valve.

10 Disposal

Observe the local specifications for environmentally friendly disposal.

Dispose of the product in an environmentally friendly manner. When doing this,

also take residual media into account (potential recycling of hazardous waste).

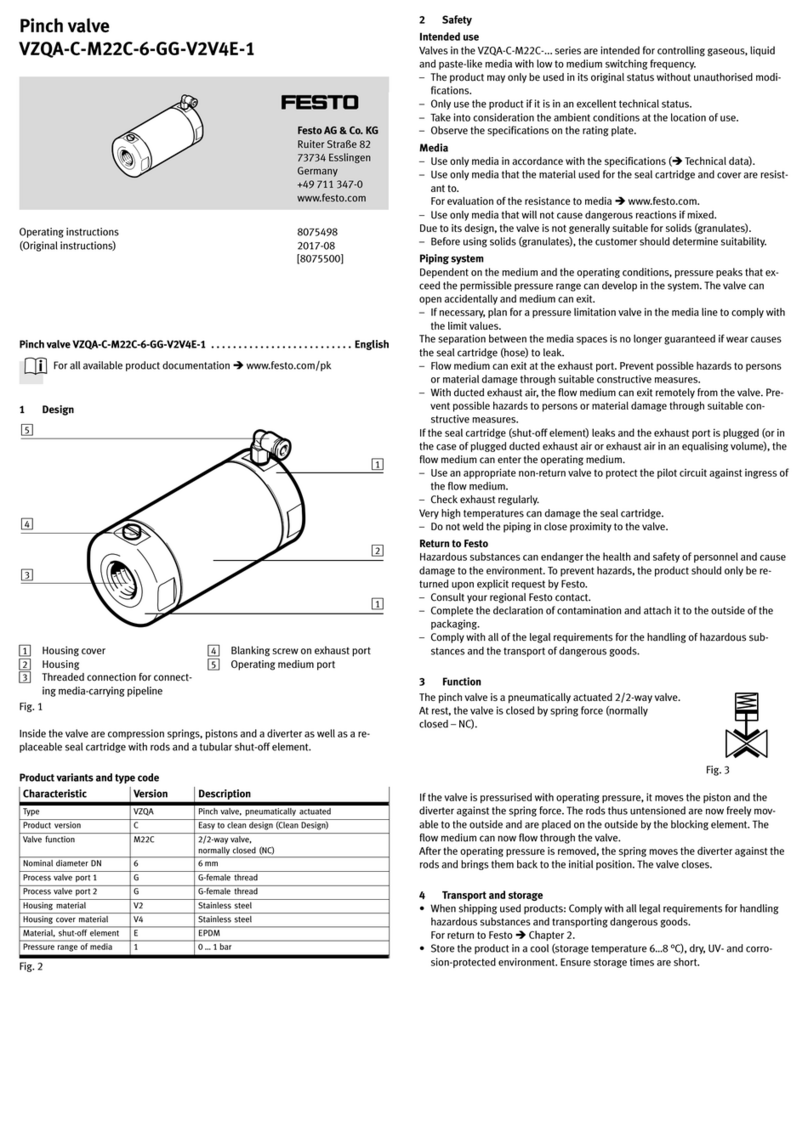

11 Fault clearance

Malfunction Possible cause Remedy

Valve does not close or

closes too slowly

Medium pressure is too high

or operating pressure too

low

Establish a differential pressure of

at least 2.5 bar (increase operating

pressure and/or lower medium

pressure)

Medium is too heavily con

taminated

Valve clogged Clean valve or replace seal cartridge

Pilot line clogged Clean or replace pilot line

Seal cartridge defective Replace seal cartridge

Valve does not open or

opens too slowly

Medium pressure too low Increase medium pressure

Medium causes gluing of the

shut-off element, because

the material of the shut-off

element is not suited for the

medium

Replace product with a product

variant made of appropriate

materials

Operating pressure is still

present

Switch off the operating pressure

Medium is getting into

the operating medium

or vice versa

Seal cartridge defective Replace seal cartridge

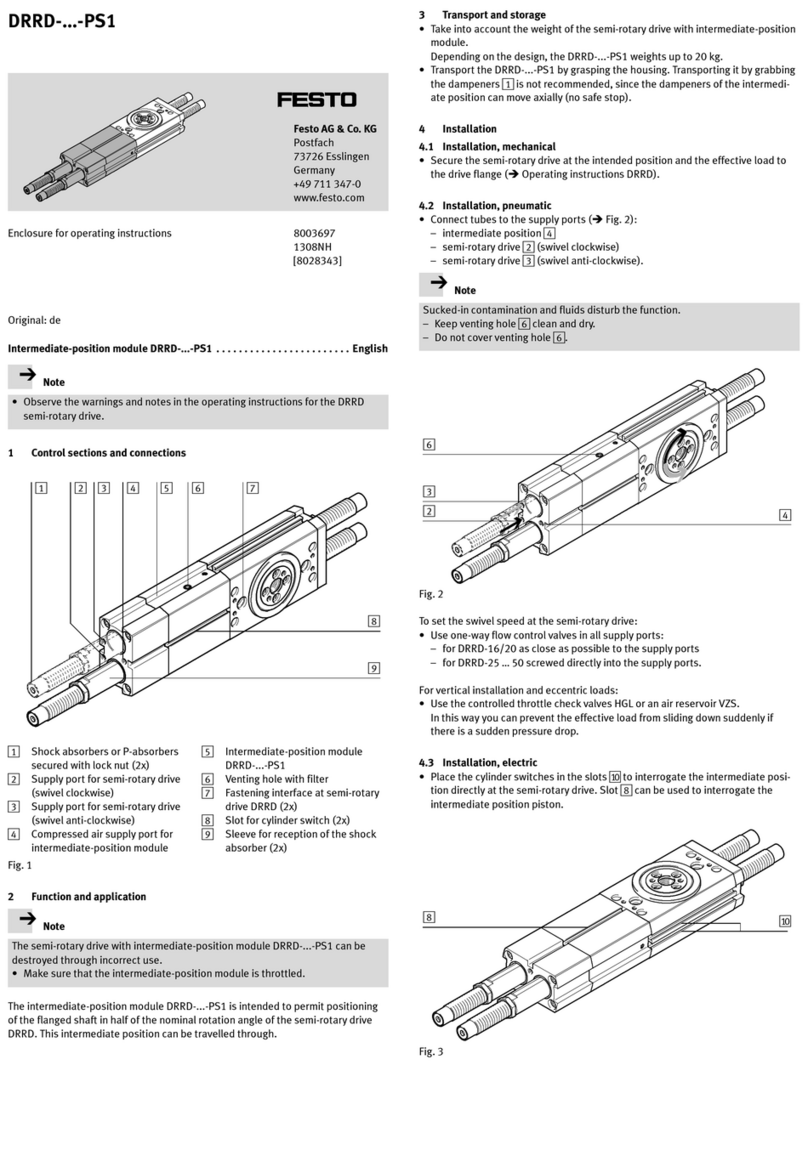

Fig. 6

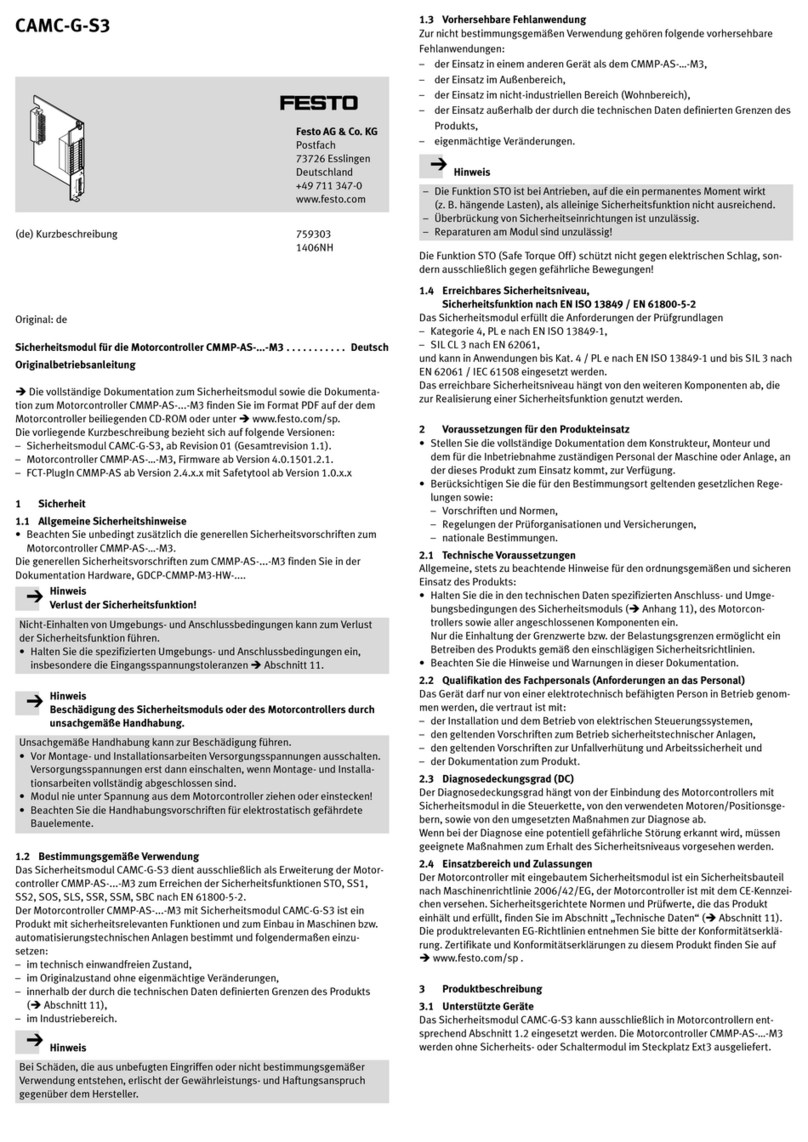

12 Technical data

General

VZQA-C-M22U-... -6 -15 -25

Design Pinch valve, pneumatically actuated

Nominal size DN 6 15 25

Actuation type Pneumatic

Sealing principle Soft

Mounting position any

Type of mounting In-line installation

Valve function 2/2-way, monostable, open

Direction of flow Reversible

Reset method Rebound resilience

Type of pilot control Externally actuated

Switching time on [ms] 125 250 250

Switching time off [ms] 125 250 250

Flow rate Kv 1) [m3/h] 0.7 5.0 18

Medium pressure [bar] 0 … 4

Nominal pressure of process valve PN 10

Differential pressure

– VZQA-...-N, VZQA-...-E [bar] 2.5

– VZQA-...-S1 [bar] 2.5 3.0

Burst pressure [bar] 16

Operating pressure [bar] 1.0 … 6.5

Operating medium

– VZQA-...-N Compressed air in accordance with ISO8573-1:2010 [7:4:4]

– VZQA-...-E Compressed air in accordance with ISO8573-1:2010 [7:4:1]

– VZQA-...-S1 Compressed air in accordance with ISO8573-1:2010 [7:4:4]

Medium

– VZQA-...-N Compressed air in accordance with ISO8573-1:2010 [-:-:-]

– VZQA-...-E Compressed air in accordance with ISO8573-1:2010 [-:-:1],

water

– VZQA-...-S1 Compressed air in accordance with ISO8573-1:2010 [-:-:-]

Foodsafe

– VZQA-...-E Supplementary material information èwww.festo.com

– VZQA-...-S1 Yes, declaration of conformityèwww.festo.com

Max. viscosity [mm²/s] 4000

Temperature of medium

– VZQA-...-N [°C] –5 … +60

– VZQA-...-V4E [°C] –5 … +100

– VZQA-...-ALE [°C] –5 … +100

– VZQA-...-POME [°C] –5 … +80

– VZQA-...-V4S1 [°C] –5 … +150

– VZQA-...-ALS1 [°C] –5 … +150

– VZQA-...-POMS1 [°C] –5 … +80

Ambient temperature [°C] –5 … +60

Storage temperature [°C] 8

Product weight èwww.festo.com/catalogue

Process valve port

– VZQA-C-M22U-...-G G¼ G½G1

– VZQA-C-M22U-...-T NPT¼ NPT½NPT1

– VZQA-C-M22U-...-S1 Clamp in accordance with ASME BPE, type A

– VZQA-C-M22U-...-S5 Clamp in accordance with DIN 32676-A

– VZQA-C-M22U-...-S12 Clamp in accordance with ASME BPE, type B

Operating medium port 12 M5 GÁGÁ

Housing material

– VZQA-C-M22U-...-V4 High-alloy stainless steel (1.4435)

– VZQA-C-M22U-...-AL Wrought aluminium alloy

Housing cover material

– VZQA-C-M22U-...-V4 High-alloy stainless steel (1.4435)

– VZQA-C-M22U-...-AL Wrought aluminium alloy

– VZQA-C-M22U-...-POM POM

Material of seals FPM

Material, shut-off element

– VZQA-...-N NBR

– VZQA-...-E EPDM

– VZQA-...-S1 Silicone

1) At +20 °C, medium pressure 1 bar at the valve input, free outlet

Fig. 7

Tightening torque

VZQA-C-M22U-... -6 -15 -25

Housing cover material V4/AL V4/AL POM V4/AL POM

Housing cover, customer interface,

connection type G/T

[Nm] 15 35 8 40 10

Housing cover with housing èMounting instructions for seal cartridge VAVC

Fig. 8