VYKB

Media separated solenoid valve

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Deutschland

+49 711 347-0

www.festo.com

Operating instructions

8146559

2021-02

[8146561]

Translation of the original instructions

© 2021 all rights reserved to Festo SE & Co. KG

1Applicable documents

Document Product Table of contents

Application note – Constraints for liquid handling, including media

resistance

Tab. 1

All available documents for the product è www.festo.com/sp.

2 Safety

2.1 Safety instructions

2.1.1 General safety instructions

–Only use the product in original status without unauthorised modifications.

–Only use the product if it is in perfect technical condition.

–Do not subject the product to mechanical stress.

–Before working on the product: switch off the power supply and medium supply

and secure it against being switched on again.

–Always grasp the plug by the housing. Do not pull on the cable.

–Comply with the handling specifications for electrostatically sensitive devices.

–The product can become hot during continuous operation, during operation

in block assembly and in the event of individual faults. Provide protective

measures for use and handling of the product.

–Do not operate the product in the vicinity of highly flammable media and

substances.

–Use the product indoors only.

–Use the product only in a dry environment.

–This product can generate high frequency interference, which may make it nec-

essary to implement interference suppression measures in residential areas.

–Do not exceed the maximum permissible pressure of the medium. In doing so,

take potential pressure peaks in the system into account.

2.1.2 Media

–Media may escape in the event of leakage. Take suitable protective measures

for use and handling of the product.

–When using crystallising media, plan appropriate rinsing routines for the

product.

–Use only media that will not cause dangerous reactions if mixed.

–Use only media to which the materials used for the product are resistant.

Materials in contact with the medium è 12 Technical data.

–For evaluation of the media resistance è 1 Applicable documents.

2.1.3 Return to Festo

Hazardous substances can endanger the health and safety of personnel and

cause damage to the environment. To prevent hazards, the product should only be

returned if explicitly requested by Festo.

–Consult your regional Festo contact.

–Complete the declaration of contamination and attach it to the outside of the

packaging.

–Comply with all legal requirements for the handling of hazardous substances

and the transport of dangerous goods.

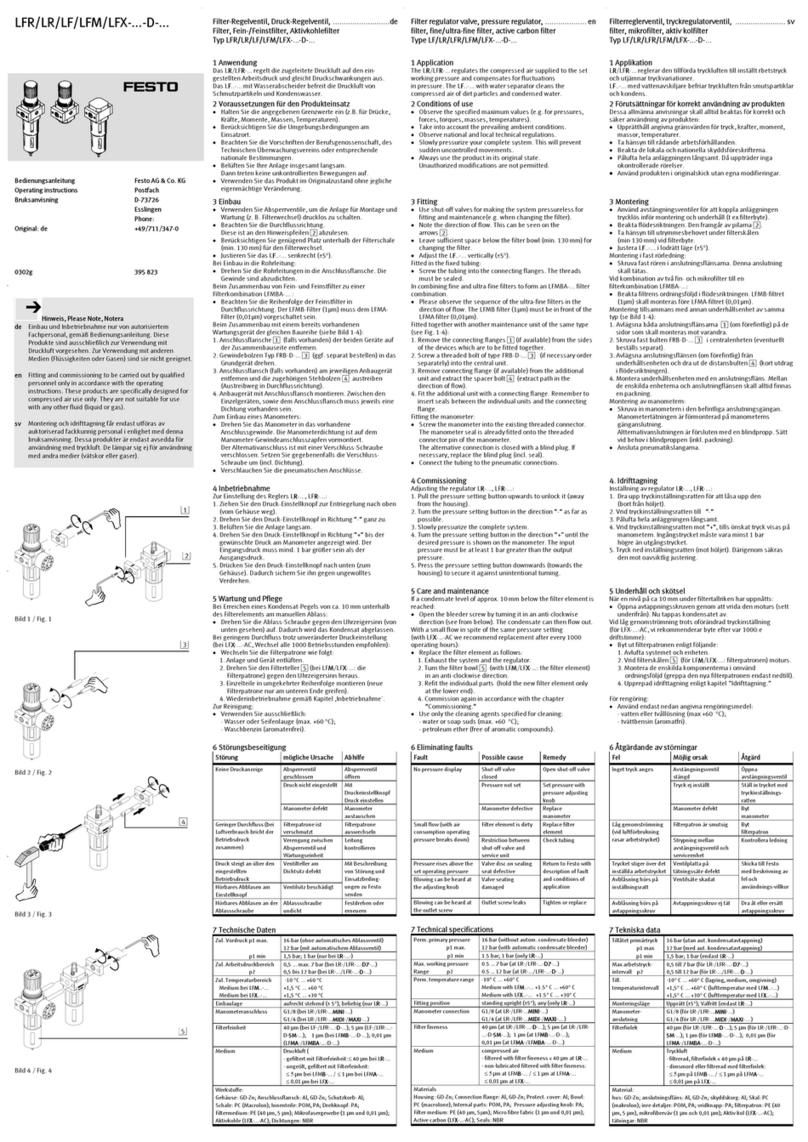

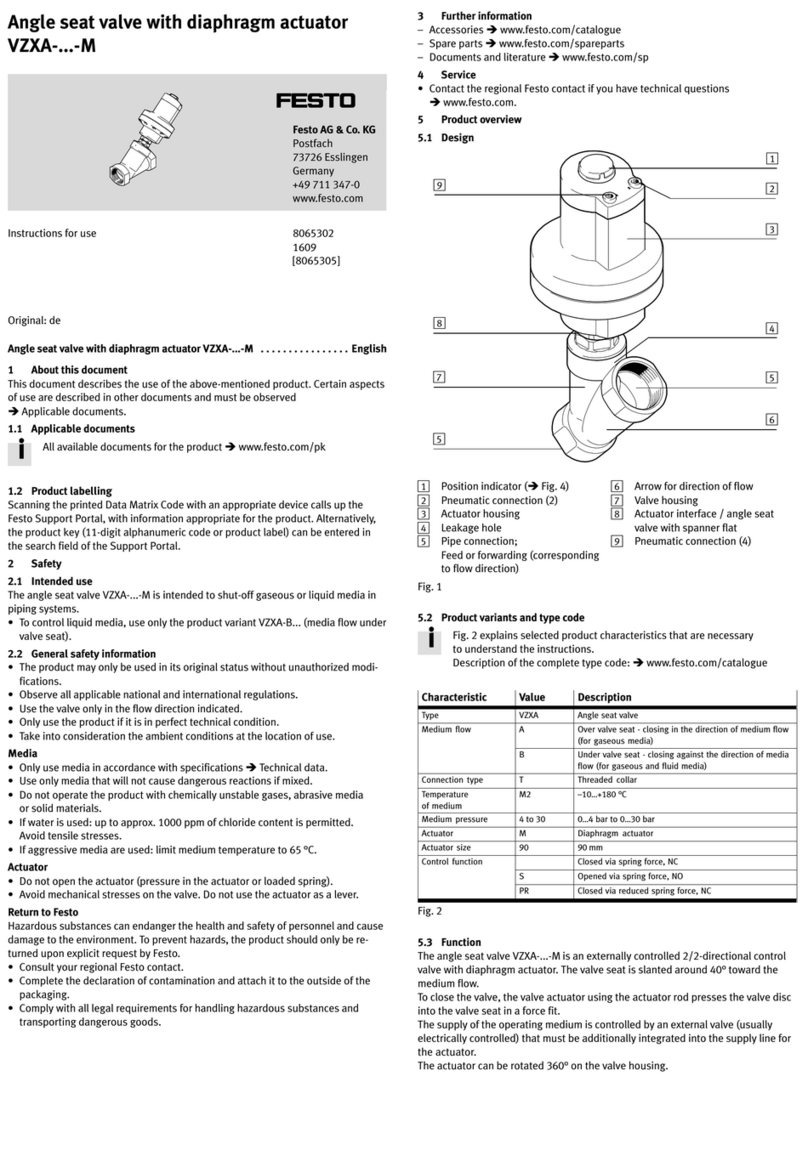

2.2 Intended use

The solenoid valve VYKB is intended for installation in laboratory devices. The

product is used to control gaseous and liquid media within the limits of the

technical data. The chemical resistance of the materials of the product in contact

with the media must be tested for every application. The user is responsible for

validating the application.

–Operate the product only with a suitable sub-base. Observe the product label-

ling on the sub-base.

2.3 Foreseeable misuse

–Do not bring the product into direct contact with foods or their ingredients.

–Do not use the product for installation in medical devices.

–Do not use the product bidirectionally.

2.4 Training of qualified personnel

Work on the product may only be carried out by qualified personnel who can

evaluate the work and detect dangers. The qualified personnel have skills and

experience in dealing with electrical (open-loop) control technology.

3 Additional information

–Accessories è www.festo.com/catalogue.

4Service

Contact your regional Festo contact person if you have technical questions

è www.festo.com.

5Product overview

5.1 Function

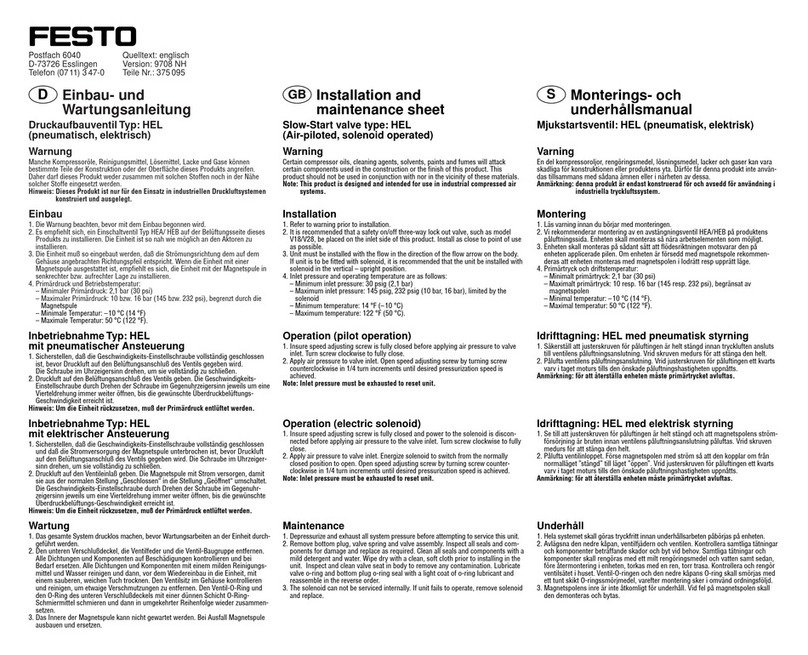

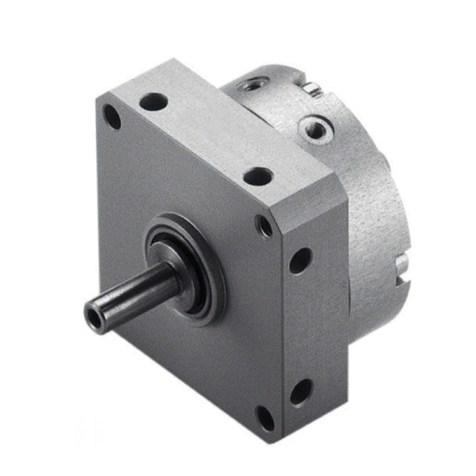

The product is a directly actuated directional control valve with solenoid coil. If

the solenoid coil is supplied with power, the LED on the electrical sub-base lights.

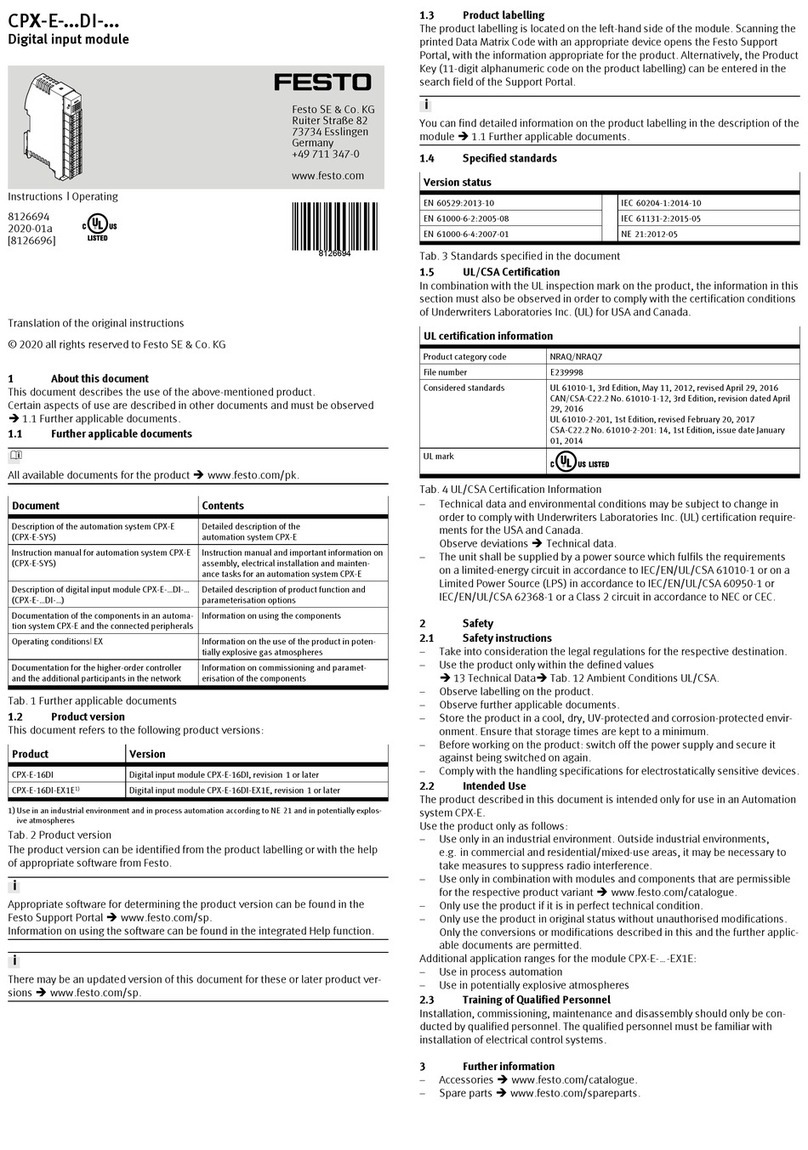

Product Circuit symbol Function

VYKB-...-M22C-... 2/2-way valve, normally closed (2) è (1)

VYKB-...-M32-... 3/2-way valve, normally closed (2) è (1) and opened

(2) è (3)

Tab. 2: Circuit symbols

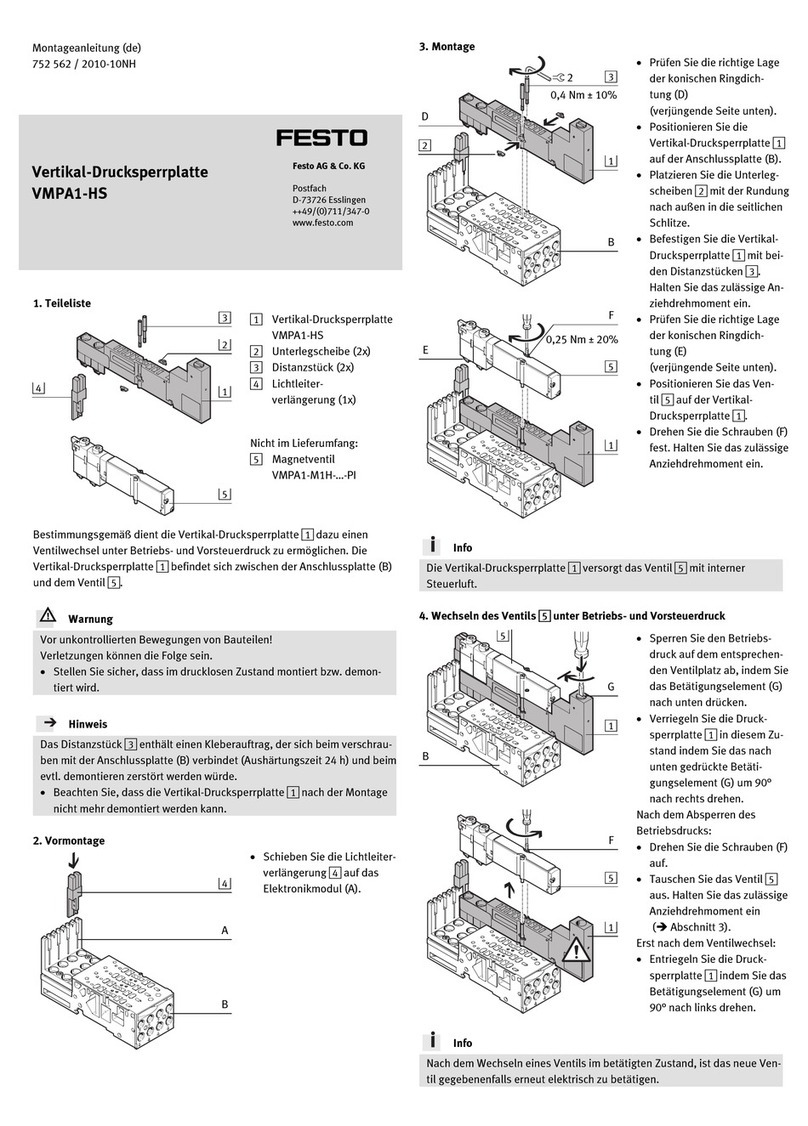

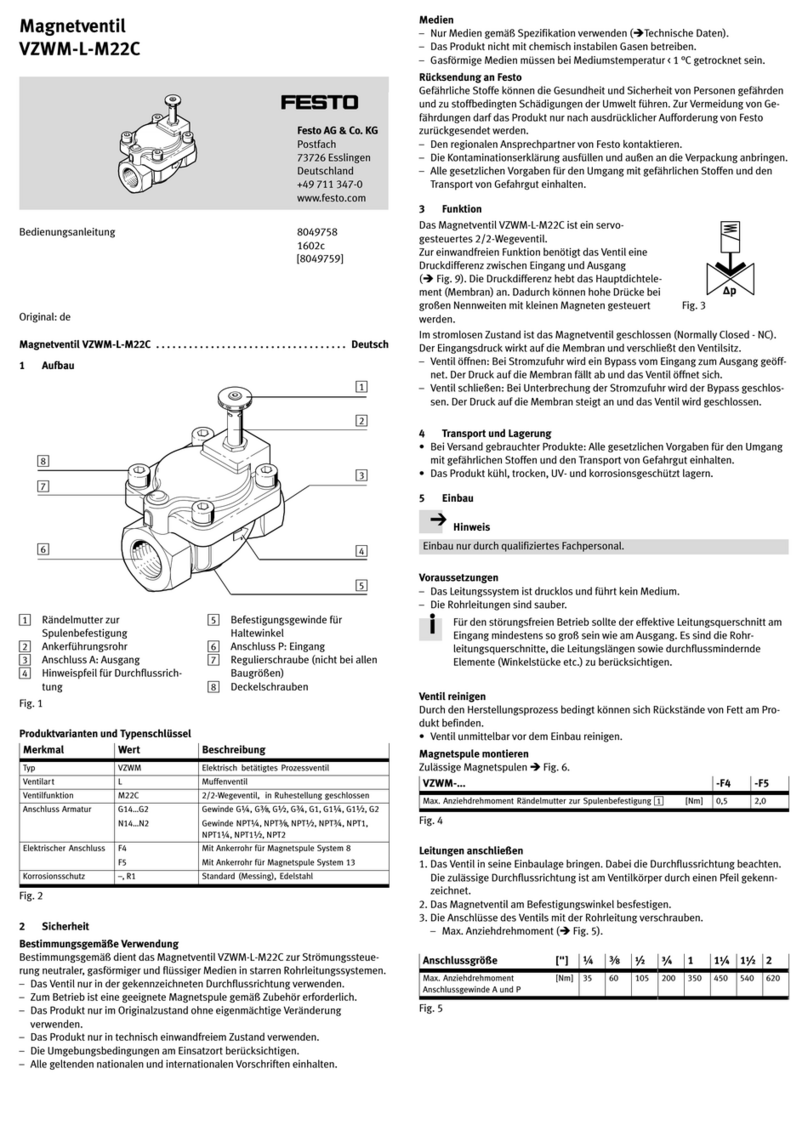

5.2 Structure

The product is a modular design. The connecting cable, the seal and the sub-base

are available as accessories. The connecting cable and the seal are included in the

scope of delivery.

Fig. 1: Structure of the product

1Solenoid valve VYKB

2Connecting cable NEBV-HPG2-...

3Seal VAVC-K2-...

4Sub-base VABS-K2-...

6 Transport and Storage

–Store the product in a cool, dry, UV-protected and corrosion-protected environ-

ment. Ensure that storage times are kept to a minimum.

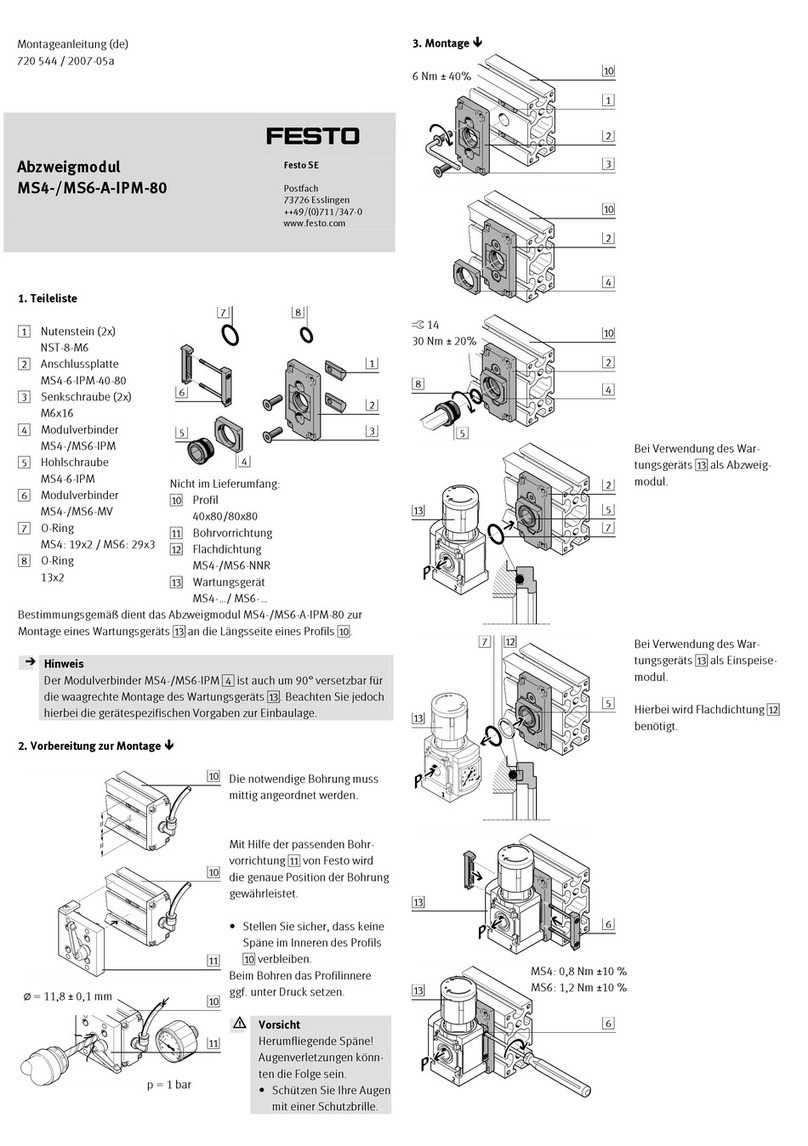

7Assembly

7.1 Valve mounting

Requirements

–The medium lines are unpressurised and do not carry any medium.

–The medium lines are free of particles and fibres.

–The medium line ends are mounted.

–Dirt filters are installed in the medium line upstream from the product. Max.

particle size: 5 µm.

–The power supply is switched off.

Mechanical

• Mount the product with the accompanying screws. Observe the following

tightening torque: