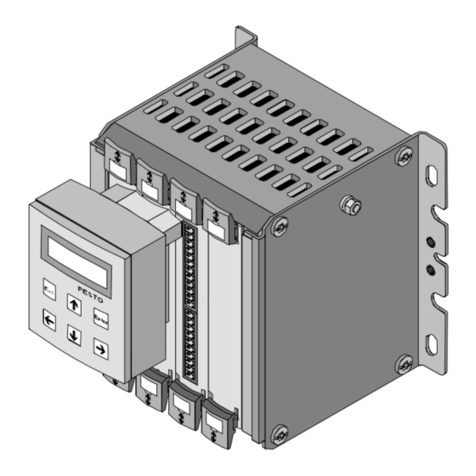

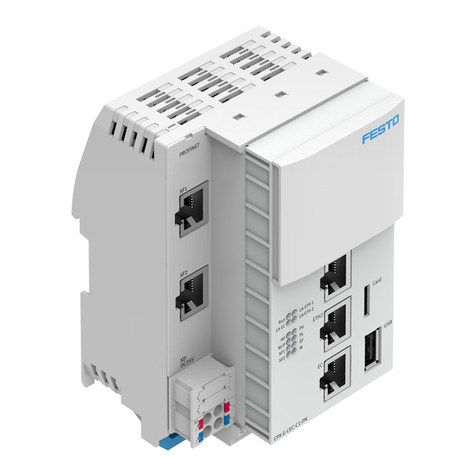

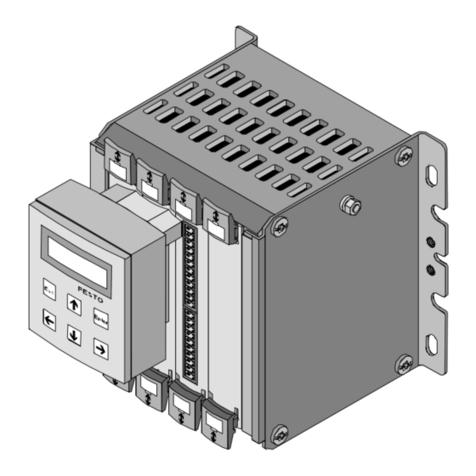

CMMO-ST-C5-1-DIOP/DION

Motor controller

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Deutschland

+49 711 347-0

www.festo.com

Brief instruction

8178188

2022-05b

[8178190]

Translation of the original instructions

© 2022 all rights reserved to Festo SE & Co. KG

1About this document

1.1 Applicable documents

All available documents for the product è www.festo.com/sp.

These brief instructions are for initial information only. The full description of the

motor controller CMMO-ST-C5-1-DIOP/DION includes the following documents:

Name, type Contents

Brief instructions CMMO-ST-...1) Brief product and functional description of the motor controller

for initial information

Manual

GDCP-CMMO-ST-EA-SY-...

Equipment and functional description of the motor controller for

all product variants

–Mounting

–Commissioning via web server/Festo Configuration Tool (FCT)

–Communication via I/O interface

–Technical data

Help system for the FCT soft-

ware

Descriptions of the Festo Configuration Tool (FCT) for commis-

sioning and parameterisation of:

–configurable axis/motor combinations

–positioning systems in the Festo Optimised Motion Series

(OMS)

Manual

GDCP-CMMO-ST-EA-S1-...

Use of the STO safety function (“Safe Torque Off”)

Parameter lists List with standard settings of the parameter files for positioning

systems in Festo's Optimised Motion Series (OMS)

Special documentation

CMMO-ST_SPUL1)

Requirements for operating the product in the USA and Canada

in accordance with certification by Underwriters Laboratories Inc.

(UL)

1) The documentation is enclosed in printed format

Tab. 1: Documentation on the CMMO-ST

1.2 Specified standards

Specified standards

Version

EN ISO 13849-1:2015-12 EN 62061:2005-04 + AC:2010-02 +

A1:2013-02+A2:2015-08

EN 61800-5-2:2017-04

Tab. 2: Standards specified in the document

2 Safety

–Observe the safety instructions and warnings in the documentation of the

motor controller and the documentation of the other components used.

–Before mounting and installation work: switch off the supply voltage. Lock to

prevent accidental reactivation. Only switch on the supply voltages again when

mounting and installation work is complete.

–Never remove or insert a plug when the power is switched on.

–Observe the handling specifications for electrostatically sensitive devices.

–Do not enable the closed-loop controller until the drive has been professionally

installed and fully parameterised.

–Do not perform any repairs on the motor controller. In the event of a defect:

replace the complete motor controller.

WARNING

Serious injury or damage to components as a result of collisions.

• Make sure that there are no objects in the motion path while the system is

connected to a source of electric power.

• Make sure that nobody is in or able to reach into the operating area of the

connected actuators.

• Secure the danger zone with suitable protective measures, e.g. guards and

warnings.

CAUTION

Personal injury and material damage

Falling loads in the event of a power failure or when the power supply is switched

off when the drive is installed in an inclined or vertical position.

• Secure loads by external safety measures (e.g. toothed latches or moveable

bolts).

CAUTION

High temperatures on the housing surfaces.

Touching the surface may cause a person to be startled and to react in an uncon-

trolled manner, causing subsequent secondary damage.

• Protect the product to prevent accidental touching.

• Before touching the product, e.g. for mounting or installation: allow the motor

controller to cool down to room temperature.

2.1 Intended use of the CMMO-ST

The motor controller CMMO-ST is intended for controlling the following drives

with Festo 2-phase stepper motors:

–Positioning systems in the Optimised Motion Series (OMS) with Festo axis/

motor units.

–Configured drives (rotary/linear):

–Festo axes, e.g. EGC, DNCE, DGE

–User-defined axes

•Observe the specified standards as well as the regulations of the trade asso-

ciations, the German Technical Control Board (TÜV), the VDE regulations or

the relevant national regulations.

•Observe the limit values for all additional components (e.g. sensors, actua-

tors).

Use the CMMO-ST only as follows

–in perfect technical condition

–in its original condition, without unauthorised modifications

–within the limits of the product defined by the technical data

–within the specified service life of the switching elements for the safety func-

tion

–as an installed device in a control cabinet

Use outside the control cabinet is possible if all of the plugs are connected and all

unused interfaces are sealed with protective caps.

2.2 Intended use of the STO function

The STO function ("Safe Torque Off") in accordance with EN 61800-5-2 is intended

to shut off the torque of a motor connected to the CMMO-ST. The STO function

prevents an unexpected start-up of the connected motor. The STO function should

only be used for applications for which the stated safety characteristics are suffi-

cient.

Safety characteristics

The STO function of the CMMO-ST satisfies the requirements for the following

safety characteristics:

–PL e/Cat. 3 in accordance with EN ISO 13849-1

–SIL 3 in accordance with EN 61800-5-2

–SIL CL 3 in accordance with EN 62061

The achievable safety level depends on the other components used to implement

a safety function.

To protect against unintended motor start-up, the motor controller must be acti-

vated via the connection [X3] with the category required for the application in

accordance with EN ISO 13849-1, e.g. via an external safety relay unit.

Qualification of the specialist technicians (requirements for staff)

The product may be placed in operation only by a qualified electrotechnician, who

is familiar with:

–The installation and operation of electrical control systems.

–The applicable instructions for operating safety engineering systems.

–The applicable regulations for accident prevention and occupational safety.

–The documentation for the product.

Diagnostic coverage (DC) for the safety function

The diagnostic coverage depends on the integration of the motor controller in the

control chain as well as the implemented diagnostics measures. If a potentially

dangerous malfunction is recognised during diagnostics, appropriate measures

must be taken to maintain the safety level.

NOTICE

The motor controller cannot detect a cross circuit in the input circuit by itself.

• If required, use a safety relay unit with detection of shorts across contacts.