Translation of the original instructions

1 Identification EX

Identification

Standard variant

II 2G Ex h IIC T4 Gb X

II 2D Ex h IIIC T105°C Db X

–20°C£Ta£+80°C

Variant T4

II 2G Ex h IIC T3 Gb X

II 2D Ex h IIIC T175°C Db X

0°C£Ta£+150°C

Variant T6

II 2G Ex h IIC T6 Gb X

II 2D Ex h IIIC T85°C Db X

–50°C£Ta£+60°C

Tab. 1

2 Further applicable documents

NOTICE!

Technical data for the product can have different values in other documents. For

operation in an explosive atmosphere, the technical data in this document always

have priority.

All available documents for the product èwww.festo.com/pk.

3 Certified products

Type Type

DFPD-10 DFPD-300

DFPD-20 DFPD-480

DFPD-40 DFPD-700

DFPD-80 DFPD-900

DFPD-120 DFPD-1200

DFPD-160 DFPD-2300

DFPD-240 –

Tab. 2

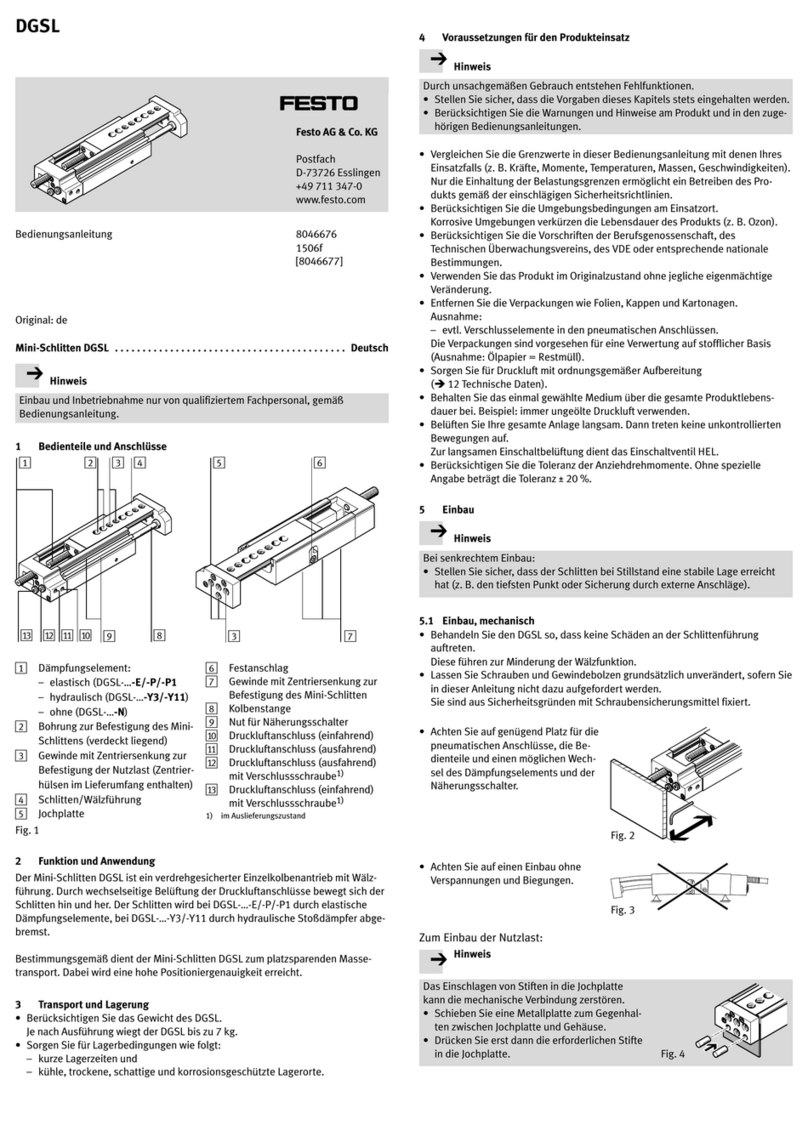

4 Function

Pressurising the cylinder chambers causes the piston in the pipe to move back

and forth. The conversion of the linear movement into turning movement is car-

ried out by a gear rack and pinion gear unit.

5 Safety

5.1 Safety instructions

– The device can be used under the stated operating conditions in zones 1 and

2, explosive gas atmospheres, and in zones 21 and 22, explosive dust atmo-

spheres.

– All work must be carried out outside of potentially explosive areas.

– The device is not intended for use with other fluids.

– It is not intended to be used as a spring and damping element. Impermissible

loads may occur.

5.2 Intended use

The actuator is intended for use for fittings with a movement range limited to 90°,

e.g. ball valves and butterfly valves:

5.3 Identification X: special conditions

– Danger of electrostatic discharge.

– Ambient temperature

Standard: –20°C£Ta£+80°C

Variant T4: 0°C£Ta£+150°C

Variant T6: –50°C£Ta£+60°C

6 Commissioning

– Seal unused openings with blanking plugs or slot covers.

WARNING!

The discharge of electrostatically charged parts can lead to ignitable sparks.

• Prevent electrostatic charging by taking appropriate installation and cleaning

measures.

• For equipotential bonding, connect all the conducting metal parts with one

another.

• Include the shaft in the system’s equipotential bonding.

• Include the housing in the equipotential bonding of the system.

• Earth the entire system.

WARNING!

Corrosive gases and dust particles inside components can result in changes to

material and material damage. Explosive gas atmospheres or dust should not

penetrate into the spring area of single-acting drives.

• Install an exhaust return using a 3/2-way valve that is suitable for zones 1, 2,

21 and 22 or

• extract the air in the spring area via tubing lines at connection 4 outside

potentially explosive areas.

NOTICE!

Installation and commissioning may only be performed in accordance with the

operating instructions and by qualified personnel.

NOTICE!

Escaping exhaust air can swirl up dust and create an explosive dust atmosphere.

NOTICE!

Strong charge-generating processes can charge non-conductive layers and coat-

ings on metal surfaces.

NOTICE!

Related type of ignition protection: c (constructional safety)

NOTICE!

Particulate matter in the compressed air can cause electrostatic charges.

In the following NAMUR valves from Festo, the exhaust air return is included in the

design:

• VSNC-…

• VOFC/VOFD-…

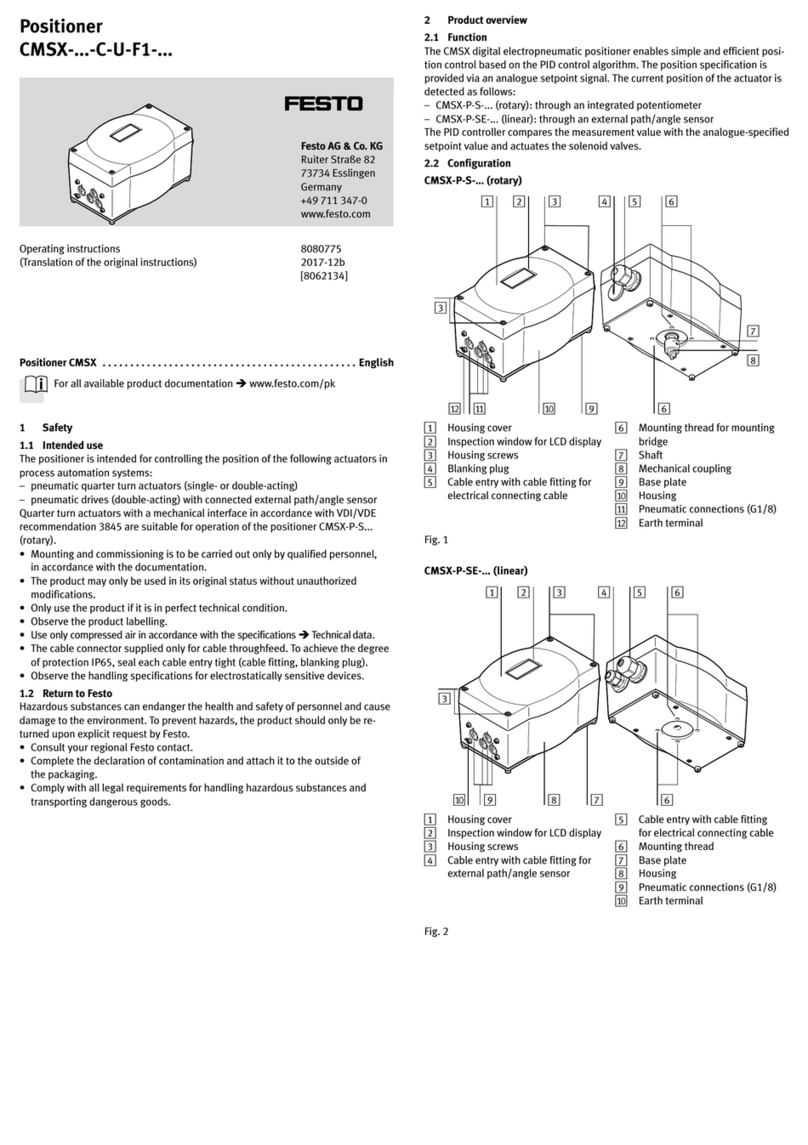

Fig. 1 Exhaust return

7 Maintenance and care

– Service the device after 6 months at the latest and ensure smooth function-

ing.

8099381

DFPD

Quater turn actuator

8099381

2018-10a

[8099383]

Operating conditions| EX

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com