Plug Pin Cable colours Function

Plug sensor M8 - only MS6-LRE-...-PI/PU1)

1 Brown Not assigned

3 Blue GND/0V

4 Black Analogue output

1) Tightening torque: £ 0.3Nm

Tab. 4 Pin Allocation of Plug Sensor M8

8 Commissioning

The output pressure can be set via the digital inputs on plug M12 or via the oper-

ator unit (MSE6-LRE-...-OP) è 9 Operation.

With simultaneous control, the operator unit has higher priority than the signal

lines at plug M12.

1. Switch on the operating voltage.

2. Close product. Control the drive unit in the direction DOWN.

3. Pressurise the system slowly.

4. Control the product in the direction UP up to the desired output pressure. The

pressure regulation range must not be exceeded

è 13.2 Technical Data, Pneumatic.

Correctly pressurised, the input pressure is 0.5bar higher than the output

pressure.

9 Operation

A new output pressure must always be set in a pressure rising direction. During

control, observe the ratio between the control duration and pause.

The desired output pressure is lower than the current output pressure:

1. Control the product in the direction DOWN until a value of at least 0.3bar

lower than the desired output pressure is reached.

During the control in the direction DOWN, take into account that the product

has a lower exhausting capacity

– The product adjusts faster than the output pressure is reduced.

This may result in the output pressure not corresponding to the desired

control pressure when electrically querying and evaluating the output

pressure. This must be taken into account when exhausting larger initial

volumes.

2. Control the product in the direction UP up to the desired output pressure.

In the event of a power failure, the last setting of the output pressure remains

stored èFail-safe mode.

The pneumatic pressure control is guaranteed.

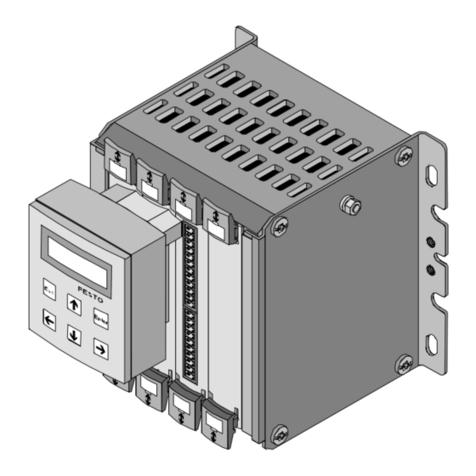

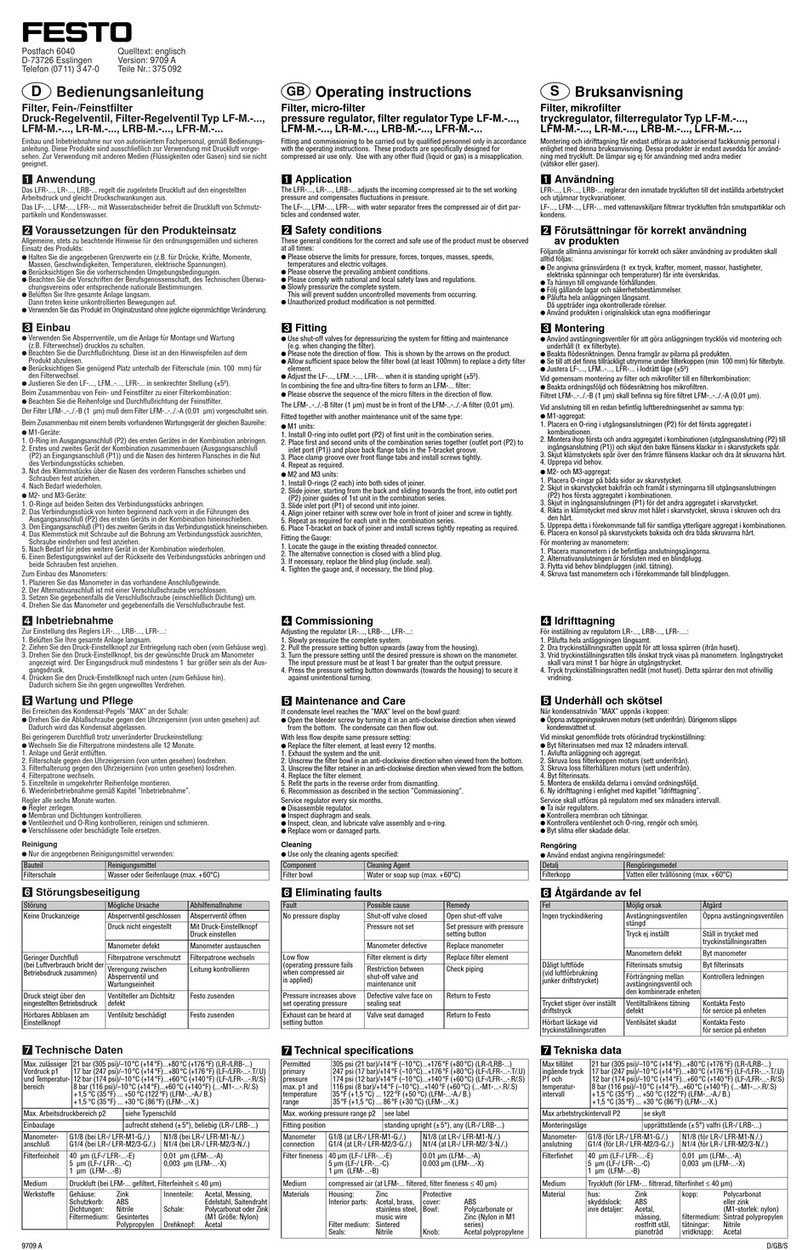

9.1 With Operator Unit for MSE6-LRE-...-OP

1Display

2Pushbutton [DOWN]

3Edit button

4Pushbutton [UP]

Fig. 2 Operator unit MS6-LRE-...-OP

5Adjustment bar

6Digits

7[kPa], [psi], [bar]

8Segments

9[lock]

Fig. 3 Display MS6-LRE-...-OP

Elements dis-

play

Function Description

Not illu-

minated

Electric drive unit cannot be controlled with pushbutton [DOWN]

2or pushbutton [UP] 4.

Adjustment bar 5

Flashing Electric drive unit can be controlled with pushbutton [DOWN]

2or pushbutton [UP]4.

Elements dis-

play

Function Description

Illuminated Current output pressure is displayed.Digits 6

Flashing Current output pressure has exceeded the pressure regulation

range.

Illuminated Active pressure unit. The output pressure is displayed in these

units.

Not illu-

minated

Pressure unit is inactive.

[kPa]

[psi]

[bar] 7

Flashing Pressure unit can be set.

Segments 8Illuminated Graphical display of the current output pressure, related to the

current value of the pressure regulation range.

Illuminated Active safety lock. For blocking against unauthorised changes to

the output pressure.

Not illu-

minated

Security lock is inactive. Value 0 is set.

[lock] 9

Flashing The security code can be set.

Tab. 5 Elements Display MS6-LRE-...-OP

Overview of Menu Structure

Fig. 4 Overview of Menu Structure

RUN Mode

The default state of the product is called RUN mode. It indicates the current out-

put pressure.

Change from EDIT mode to RUN mode:

– Press EDIT button for 3s or

– Expiration of monitoring time/timeout of 75 s

EDIT Mode

Adjust output pressure and pressure unit:

1. Press the EDIT button 3.

Only when the safety lock is activated:

– The display element [lock] 9flashes

– Press the [DOWN] 2 pushbutton or the [UP] 4 pushbutton until the

selected security code is set.

– To confirm, press the Edit button 3. If the correct entry is made, the

safety lock is released. If an incorrect entry is made, the safety lock

remains in effect. The unit returns to RUN mode. The procedure must be

repeated.

2. The adjustment bars 5 flash. Press the [DOWN] pushbutton or the [UP] push-

button until the desired output pressure is set. Exceeding the pressure regu-

lation range is possible and is indicated by a flashing value in the display.

3. Confirm with Edit button

4. The display elements [kPa], [psi] or [bar] 7 flash. Set the desired pressure

unit with the [DOWN] and [UP] pushbuttons.

5. Confirm with Edit button

6. The display element [lock] flashes. Use the [DOWN] pushbutton or the [UP]

pushbutton to set the desired security code (0…1999). The value 0 deactiv-

ates the safety lock.

7. Confirm with Edit button. The product is back in RUN mode.

9.2 Resetting MS6-LRE-...-OP to Factory Settings

This procedure can also be performed if the security code does not exist.

By resetting to the factory settings, the current settings are lost.

1. Switch off operating voltage.

2. Press the [DOWN] pushbutton, [UP] pushbutton and Edit button simultan-

eously. Switch on the operating voltage again.